Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Micro-10-QA-002 (1) (1)

Caricato da

Tahir IbrahimTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Micro-10-QA-002 (1) (1)

Caricato da

Tahir IbrahimCopyright:

Formati disponibili

Surge Laboratories (Pvt.) Ltd.

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Quality Assurance Department

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 1 of 13

There are 12 numbers of pages in this Protocol.

Controlled when in Red

Do Not Duplicate

Surge Laboratories (Pvt.) Ltd.

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Quality Assurance Department

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 2 of 13

We have reviewed the Aseptic Process Validation Protocol Micro-10-QA-002 for the Dry

Powder Injectable and found it acceptable.

Prepared By: ____________________________

Date: _______________

Umair Zubair (Microbiologist)

Reviewed By: ____________________________

Date: _______________

Kamran Atif (Manager QA)

Approved By: ____________________________

Date: _______________

Asad-Uz-Zaman (GM P & P)

Approved By: ____________________________

Date: _______________

Mutasma Yasmeen (Head of Technical Operations)

Controlled when in Red

Do Not Duplicate

Surge Laboratories (Pvt.) Ltd.

Quality Assurance Department

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 3 of 13

TABLE OF CONTENTS

S. No.

TITLE

01

Objective

02

Unit Operation

03

Acceptance Criteria

04

Reference

05

Process Flow

06

Equipment

07

Material

08

Procedure

09

Incubation & Inspection

10

Deviation & Change control

11

Analysis of Data

12

Re-Validation

13

Conclusion & Issuance of Certificate

Controlled when in Red

PAGE NO.

Do Not Duplicate

Surge Laboratories (Pvt.) Ltd.

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Quality Assurance Department

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 4 of 13

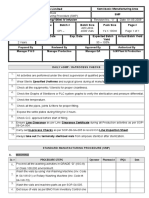

HISTORY SUMMARY SHEET

S. No

Nature of Change

Controlled when in Red

Page/Line

Sign.

Do Not Duplicate

Surge Laboratories (Pvt.) Ltd.

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Quality Assurance Department

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 5 of 13

1.0 OBJECTIVE:

1.1 To validate that Aseptic Filling of Dry Powder Injectable meet all pre-established

cGMP requirements to conform as Sterile Product and to demonstrate that online filling

operations of sterile Polyethylene Glycol 8000 (PEG 8000) Powder & Tryptic Soya Broth

Media conform to the actual filling process.

2.0 UNIT OF OPERATION:

2.1 Online Simulated media fill trial with Sterile Polyethylene Glycol 8000 (PEG) and

Tryptic Soya Broth (TSB) in Vial Filling Area.

3.0 ACCEPTANCE CRITERIA:

3.1 Minimum three thousand vials or units of 250mg will be filled with sterile

Polyethylene Glycol 8000 (PEG 8000) powder & Tryptic Soya Broth Media

3.2 Minimum three thousand vials or units of 1000mg will be filled with sterile

Polyethylene Glycol 8000 (PEG 8000) powder & Tryptic Soya Broth Media

3.3 Less than or equal to 0.1% contamination rate is acceptable . Not more than six vials

should be observed positive from the both filling processes out of 6000 or Not more than

three vials from each three thousands (3000) vials of 250mg & 1000mg.

4.0 REFERENCE:

Validation of Aseptic Processes (PI 007-5 1 July 2009), Section 4.3.1.

Controlled when in Red

Do Not Duplicate

Surge Laboratories (Pvt.) Ltd.

Quality Assurance Department

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 6 of 13

5.0 PROCESS FLOW:

Issuance of TSB Media

(0.954 Kg)

Preparation of media.

(31.8L) in WFI & Media in Vessel

(Capacity 50L)

Issuance of 6100 Vials of

both 250mg and 1000mg

capacity

2000 vials

for 500mg

Washing & Sterilization of

Vials.

o

Autoclavation at 250 C for 2

hrs

Sterilization of media at

121oC for 15 min

1950

Sterilization of Filling Accessories

e.g Machine Parts, Uniforms,

Rubber Stopper S.Gloves &

Dusters at 121oC for 1hr

vials for 1000mg

Issuance of PEG 8000 Powder

sterilized by gamma radiation

( Approximately 4.4Kg)

Assembling of Machine Parts

Sterile Process Simulation

Filling of Powder PEG 8000 as fill weight with TSB media (5.3ml per vial)

Sealing of vials

Expose the Settle plates during filling

IPQA check weight & Process after every 45min

Quantity: 3000 vials for 250mg & 3000 vials for 1000mg

Fill Weight: 250mg (225 - 288mg) & 1000mg (900 1150mg)

Transfer of Filled Vials to QC for

Incubation and Visual check for

any turbidity

Controlled when in Red

Do Not Duplicate

Surge Laboratories (Pvt.) Ltd.

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Quality Assurance Department

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 7 of 13

6.0 EQUIPMENT:

List of Major Equipment is as below.

Equipment

Name

Vial Washing

Machine

04-VW-073

Dry Oven

04-OV-04

P.V. Sterilizer

04-PVS-51

Vial Area

PQ-04-034

04-VF-55

Vial Filling

Area

PQ-04-028

04-VS-58

Vial Sealing

Area

PQ-04-005

4

5

Equipment

Code

Automatic

Microdoze Vial

Filling Machine

Vial Sealing

Machine

Equipment

Location

Equipment

Operated

Qualification

By

Document #

S. #.

Vial

Washing

Area

Vial

Washing

Area

Checked

By

Verified

By

PQ-04-007

PQ-04-030

7.0 MATERIAL:

Media: Tryptic Soya Broth ~ 0.954 Kg (30g per Liter)

PEG 8000 ~ 4.4Kg

Glass Vials:

3050 Glass Vial 8 ml for 250mg filling operation.

3050 Glass Vial 15ml for 1000mg filling operation.

8.0 PROCEDURE:

Reference: BMO-04-006 & SMP-04-006

8.1 ISSUANCE OF BULK:

Get issue of sealed sterile PEG 8000 powder (Sterilized by Gamma Radiation) from

Material Management & non-sterile TSB media from QC a day in advance as per SOP-

Controlled when in Red

Do Not Duplicate

Surge Laboratories (Pvt.) Ltd.

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Quality Assurance Department

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 8 of 13

08-QC-002 and then sterilize it at 121oC for 15 minutes in Steam Sterilizer (Autoclave)

of Dry Powder Injectable Area.

Separately perform sterility test of sterile PEG 8000 powder as per membrane filtration

method as per SOP-08-QC-014. Bioburden of Non sterilized Broth is to be evaluated

beside ve and Positive (+ve) test of Broth for growth formation.

8.2 WASHING & STERILIZATION OF VIALS:

Wash glass vials, with Deionized Water, Filtered Distilled Water, Compressed Air (0.45 &

0.2 Microns) as per SOP-04-005 & SOP-04-008 & sterilize the glass vials as per SOP-04009. Determine the bioburden of washed vials before sterilization as per SOP-08-QC106. Check the sterility of vials after sterilization as per SOP-08-QC-100. Monitor hot air

oven by using Spore Strip bioindicator as per SOP-08-QC-102.

8.3 WASHING & STERILIZATION OF MACHINE PARTS:

Wash & Sterilize the Machine Parts as per SOP-04-009. Monitor autoclave by using

Ampoule bioindicator as per SOP-08-QC-101.

8.4 STERILIZATION OF FILLING ACCESSORIES:

Sterilize the rubber plugs, uniforms, gloves & dusters as per SOP-04-009. Check the

sterility of rubber plugs after sterilization as per SOP-08-QC-100.

8.5 STERILIZATION OF MEDIA:

Prepare the Broth as per SOP-08-QC-002, i.e; 31.8L for 6000 units/vials (5.3 ml in each

vial) in SS container & sterilize it at 121oC for 15 min in Steam Sterilizer (Autoclave) of

Dry Powder Injectable Area. Perform Growth Promotion test of TSB medium as per

SOP-08-QC-027.

8.6 STERILE PROCESS SIMULATION:

8.6.1

All activities are performed under the direct supervision of Qualified Person from

QA, Production & Microbiology Section.

8.6.2

Perform all the activities in the specific classified areas.

8.6.3

Prepare the aseptic area as per SOP-04-001.

Controlled when in Red

Do Not Duplicate

Surge Laboratories (Pvt.) Ltd.

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Quality Assurance Department

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 9 of 13

8.6.4

Perform monitoring of Air Changes, Air Velocity of Laminar Flow Hood (LFH) &

Pressure Differential as per SOP-08-QC-058 and air flow pattern as per SOP-08QC-104.

8.6.5

First adjust Powder Filling machine for 250 mg (225 - 288mg) weight & fill

3000vials with(PEG 8000) powder and then immediately fill TSB Broth 5.3 ml in

each vial through Automatic Media Filling Nozzle fitted with compounding vessel

as per SOP-04-012. After Both filling, plug & seal the container.

8.6.6

Perform the filling of 1g on the same day after cleaning & mopping of area with

stay of 30 minutes in the presence of Microbiologist & QA. Now adjust the

machine for 1g (900 1150mg) weight to fill powder & then immediately fill

TSB Broth 5.3 ml in each vial through Automatic Media Filling Nozzle fitted with

compounding vessel as per SOP-04-012. After Both filling, plug & seal the

container.

8.6.7

After sealing of vials, the vials should be inverted and shake gently to ensure that

all internal surfaces of the vials are thoroughly wetted with the broth and PEG is

dissolved in Broth solution.

8.6.8

Perform sterility testing of filtered nitrogen and compressed air as per SOP-08QC-032.

8.6.9

Check the weight of vials for 250mg and 1g vial after every 45minutes as SOP04-025.

8.6.10 Expose the settle plates at specified location during filling as per SOP-08-QC-09.

8.6.11 Perform swab test at rest (before filling) & at operational (during filling) as per

SOP-08-QC-08.

8.6.12 Perform non-viable particle count at rest (before filling) & at operational (during

filling) as per SOP-08-QC-103.

8.6.13 Perform viable particle count by using centrifugal air sampler at rest (before

filling) & at operational (during filling) as per SOP-08-QC-07.

Controlled when in Red

Do Not Duplicate

Surge Laboratories (Pvt.) Ltd.

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Quality Assurance Department

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 10 of 13

8.6.14 Check the microbial status of finger of operators after filling as per SOP-08-QC026 then disinfect immediately (70% IPA) inside SS-bowl. This activity should be

performed outside the filling room.

8.6.15 Check the microbial status of clothing of operator after filling as per SOP-08-QC094. This activity should be performed outside the filling room.

8.6.16 Transfer all filled vials to QC for incubation and inspection. Incubate all vials as

in section 9.1.

8.6.17 After Broth Fill Trial, thoroughly wash/ clean, disinfect & fumigate for two

consecutive days as per SOP-04-001 & SOP-04-045

8.6.18 Now perform swab test as per SOP-08-QC-08 & expose settle plates as per SOP08-QC-09.

9.0 INCUBATION & INSPECTION:

After Filling & Sealing of Vials for 250mg & 1g, transfer all units to

Microbiology Section for Incubation & Inspection.

First invert the vials then incubate in straight position.

Incubation Conditions (First incubate at 30-35 oC for 7 days and then incubate at

20-25 oC for next 07 days)

Frequency of checking (0, 7 & 14th Day -100% while daily visual check on

random basis) in Light NLT 2000 Lux.

The Broth should be Clear in Vials-No Turbidity should be observed.

The Vials for +ve and ve test should also be checked

Record all observation on Material / Product Sterility Test Report (F-08-008), if

turbidity is observed in more than acceptable limits then Broth Fill is considered

as Failure of Aseptic Process.

Controlled when in Red

Do Not Duplicate

Surge Laboratories (Pvt.) Ltd.

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Quality Assurance Department

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 11 of 13

Perform Identification test for contamination observed & thorough investigation

for the failure of run as per SOP for Handling of Out of Specification (OOS)

{SOP-08-QA-027}.

Controlled when in Red

Do Not Duplicate

Surge Laboratories (Pvt.) Ltd.

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Quality Assurance Department

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 12 of 13

10.0 Deviation & Change Control:

Any Deviation (s) & Change Control from the pre approved Protocol must be recorded

investigated & justified as per SOP-08-QA-022.

11.0 Data Analysis:

Collect the data during execution of Protocol for all listed critical parameters & then

evaluate the data in the light of acceptable criteria to conclude whether the process is

validated or not, related formats for data collection as under:Sr. no.

Form Title

Form No.

Aseptic Validation Report

F-08-028

Material / Product Sterility Test Report

F-08-008

Microbial Bioburden Report

F-08-026

Sterility Testing of Nitrogen / Compressed air

F-08-021

Efficacy Testing of Disinfectants

F-08-019

Operators Breathing Test

F-08-022

Pressure Differential Monitoring

F-05-08

CFM Monitoring

F-08-001

10

Vial Washing Record

F-04-11

11

Sterilization Cycle Log

F-04-23

12

InProcess Control Record

F-04-17

13

InProcess Control Record (Vial Washing)

F-08-QA-22

14

Check List for Dry Powder Injectable Filling Area

15

InProcess Control Record (Optical checking)

F-08-QA-054

F-08-QA-23

16

InProcess Control Record (Weight )

F-08-QA-10

17

Surface Swab test report

F-08-037

18

Surface area monitoring of vial filling area

F-08-36

19

Air flow pattern report

F-08-030

20

Air particle count

F-08-002

Controlled when in Red

Do Not Duplicate

Surge Laboratories (Pvt.) Ltd.

ASEPTIC PROCESS VALIDATION

PROTOCOL (Dry Powder

Injectable Area)

Quality Assurance Department

Micro-10-QA-002

Revision No.: - 0

Issue Date: 25-09-2009

Page 13 of 13

21

Ampoule monitoring using ampoule indicator

F-08-027

22

Temp & Humidity Record

23

Bioburden Check for Ampoules and Vials after Washing

RG-QC-26

24

Sterility testing of empty vials/ampoules/rubber stoppers after Sterilization

RG-QC-28

25

Monitoring of Dry Heat Oven using Spore Strip Bioindicator

RG-QC-20

26

Growth Promotion Test

RG-QC-19

27

Sterility Testing of Nitrogen and Compressed Air

RG-QC-29

F-08-QA-031

12.0 RE-VALIADTION

12.1 Re-validation includes:

On Going Simulation will be performed after each six (06) months.

After Major Changes in manufacturing procedure

After Major Changes in the Area/HVAC System.

13. CONCLUSION & ISSUANCE OF CERTIFICATE

In the light of above acceptance criteria, conclude that whether Aseptic Filling Process is

Satisfactory or need some amendments . QA will issue Certificate of Successful Aseptic

Process Validation for Dry Powder Injectables.

Controlled when in Red

Do Not Duplicate

Potrebbero piacerti anche

- Production of Plasma Proteins for Therapeutic UseDa EverandProduction of Plasma Proteins for Therapeutic UseValutazione: 3 su 5 stelle3/5 (5)

- SOP Aseptic Filling PDFDocumento6 pagineSOP Aseptic Filling PDFSandraNessuna valutazione finora

- Process Validation For Atorvastatin Tablet - ArticleDocumento13 pagineProcess Validation For Atorvastatin Tablet - ArticleAnalyst NerdNessuna valutazione finora

- What Are The Key Benefits of Validation?Documento6 pagineWhat Are The Key Benefits of Validation?siva sankarNessuna valutazione finora

- Sop For High Performance Liquid ChromatographyDocumento3 pagineSop For High Performance Liquid ChromatographyRainMan75100% (1)

- Ophthalmic Dosage Forms Types and Characteristics 1) Liquid ...Documento6 pagineOphthalmic Dosage Forms Types and Characteristics 1) Liquid ...Kiran VemaNessuna valutazione finora

- Tier 1 CVSDocumento23 pagineTier 1 CVSCHETHAN K SNessuna valutazione finora

- Rideal Walker CoefficientDocumento3 pagineRideal Walker CoefficientManjusha KondepudiNessuna valutazione finora

- 2.Pv Semisolid FDADocumento37 pagine2.Pv Semisolid FDARahayu Maulida RNessuna valutazione finora

- Animal Ethical Committe Form B FinalDocumento9 pagineAnimal Ethical Committe Form B FinalChaitrashree GururajNessuna valutazione finora

- CV ProtocolDocumento4 pagineCV ProtocolIcee SinlapasertNessuna valutazione finora

- 2.PV Semisolid Fda PDFDocumento37 pagine2.PV Semisolid Fda PDFYuli SukmawatiNessuna valutazione finora

- (Shin Etsu) HPMCP (Eng)Documento12 pagine(Shin Etsu) HPMCP (Eng)vinay100% (2)

- Water Treatment System (Sistem Pengolahan Air Spa)Documento38 pagineWater Treatment System (Sistem Pengolahan Air Spa)Tjen MolynaNessuna valutazione finora

- FAQ of Blister Packaging Machine-Jornen Machinery - Blister Machine, Blister Packaging Machine, Blister Packing Machine, Cartoner, Cartoning Machine For Pharmaceutical PackagingDocumento3 pagineFAQ of Blister Packaging Machine-Jornen Machinery - Blister Machine, Blister Packaging Machine, Blister Packing Machine, Cartoner, Cartoning Machine For Pharmaceutical PackagingAshish MittalNessuna valutazione finora

- CIQA PQ Template Protocol Lyophilization Process Sample VersionDocumento3 pagineCIQA PQ Template Protocol Lyophilization Process Sample VersionAbdul KalimNessuna valutazione finora

- Media Fill Indicador de ColorDocumento6 pagineMedia Fill Indicador de Colorsteven correaNessuna valutazione finora

- Empagliflozin TabletDocumento3 pagineEmpagliflozin TabletAmik TuladharNessuna valutazione finora

- Operation and Calibration of HPLC SystemDocumento12 pagineOperation and Calibration of HPLC SystemMubarak PatelNessuna valutazione finora

- Yves MayeresseDocumento66 pagineYves MayeressesumankatteboinaNessuna valutazione finora

- Dossier Common Technical Document CTD Index: (Sample Document Will Provide On Request)Documento6 pagineDossier Common Technical Document CTD Index: (Sample Document Will Provide On Request)Karem EladweyNessuna valutazione finora

- Amlodipine and Celecoxib Tablets PDFDocumento38 pagineAmlodipine and Celecoxib Tablets PDFNarongchai PongpanNessuna valutazione finora

- ANDADocumento12 pagineANDAManish NangaliaNessuna valutazione finora

- Cleaning Validation NsDocumento83 pagineCleaning Validation Ns董彬彬Nessuna valutazione finora

- Compressed Air Testing ProcedureDocumento5 pagineCompressed Air Testing ProcedureroopadharNessuna valutazione finora

- Sterlization ProtocolsDocumento10 pagineSterlization ProtocolsSarathchandran BalachandranNessuna valutazione finora

- Pharmaceutical Preformulation and FormulationDocumento10 paginePharmaceutical Preformulation and FormulationPrashansa ShresthaNessuna valutazione finora

- Hold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104Documento8 pagineHold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104iloveit52252Nessuna valutazione finora

- In Process Process Quality Control in PharmaceuticalsDocumento28 pagineIn Process Process Quality Control in Pharmaceuticalssaininavdeep077Nessuna valutazione finora

- A Product Which Has Completed All Stages of Manufacture, Including Final PackagingDocumento4 pagineA Product Which Has Completed All Stages of Manufacture, Including Final Packagingom shankar JhaNessuna valutazione finora

- Terminal Sterilization V AsepticDocumento24 pagineTerminal Sterilization V AsepticvpnarashimmanNessuna valutazione finora

- Autoclave ValidationDocumento7 pagineAutoclave ValidationMohanad Alashkar100% (1)

- Procedure For Media-Fill Simulation of Aseptic TechniqueDocumento5 pagineProcedure For Media-Fill Simulation of Aseptic Techniquelimiyanto100% (1)

- Hold Time Study of Cleaned Equipment (CEHT) - Pharma BeginnersDocumento17 pagineHold Time Study of Cleaned Equipment (CEHT) - Pharma Beginnersdrs_mdu48Nessuna valutazione finora

- Semi Solid Dosage Forms Manufacturing Tools Critical Process Parameters Strategies Optimization and ValidationDocumento9 pagineSemi Solid Dosage Forms Manufacturing Tools Critical Process Parameters Strategies Optimization and ValidationGeotamNessuna valutazione finora

- Performance Qualification FOR Blister Packing Machine ( .BLOCK) EQUIPMENT ID: .Documento14 paginePerformance Qualification FOR Blister Packing Machine ( .BLOCK) EQUIPMENT ID: .mehrdarou.qaNessuna valutazione finora

- Microbiological Media Preparation SOPDocumento4 pagineMicrobiological Media Preparation SOPAzura Salsabila100% (1)

- Schedule M: Jijo Thomas M.Pharm Pharmaceutics College of Pharmaceutical Sciences TrivandrumDocumento77 pagineSchedule M: Jijo Thomas M.Pharm Pharmaceutics College of Pharmaceutical Sciences TrivandrumVivek PanchabhaiNessuna valutazione finora

- IPQC Tests For TabletsDocumento56 pagineIPQC Tests For TabletsTony Fares FathiNessuna valutazione finora

- Tablets Quality ControlDocumento18 pagineTablets Quality ControlThangabalan Than100% (2)

- Process Validation Protocol XXX 60 MG TabletsDocumento33 pagineProcess Validation Protocol XXX 60 MG TabletsfarNessuna valutazione finora

- Hold Time Protocol FinalDocumento20 pagineHold Time Protocol FinalSolomon0% (1)

- Headspace Oxygen Measurement in Vials and AmpoulesDocumento4 pagineHeadspace Oxygen Measurement in Vials and AmpoulesGhanta Ranjith KumarNessuna valutazione finora

- Coating Equipment Performance QualificationDocumento11 pagineCoating Equipment Performance QualificationOsama MahmoudNessuna valutazione finora

- Brexpiprazole - Chem RevDocumento112 pagineBrexpiprazole - Chem RevSam SonNessuna valutazione finora

- Cleaning Validation Report Dec2018 PDFDocumento21 pagineCleaning Validation Report Dec2018 PDFPrashansa ShresthaNessuna valutazione finora

- Cleaning Validation ProcessDocumento11 pagineCleaning Validation Processsamia khanNessuna valutazione finora

- MAPP 5200 14 Filing Checklist 9 1 17Documento43 pagineMAPP 5200 14 Filing Checklist 9 1 17Krazyboy KhmNessuna valutazione finora

- Checklist of Validation of Dy Heat SterilizerDocumento8 pagineChecklist of Validation of Dy Heat Sterilizersami2210Nessuna valutazione finora

- Operation, Cleaning and Monitoring of Dynamic Pass Box.Documento2 pagineOperation, Cleaning and Monitoring of Dynamic Pass Box.RainMan75Nessuna valutazione finora

- Jabed Process ValidationDocumento8 pagineJabed Process Validationjabed sarkarNessuna valutazione finora

- IQ Paste CattleDocumento24 pagineIQ Paste CattleDhaval ChaplaNessuna valutazione finora

- Gmail - Offer Letter of ManpowerGroupDocumento3 pagineGmail - Offer Letter of ManpowerGroupankitkelkar2Nessuna valutazione finora

- 2 CVPDocumento5 pagine2 CVPQANessuna valutazione finora

- Annual Product Quality Review (APQR) SOP - PharmaBDocumento14 pagineAnnual Product Quality Review (APQR) SOP - PharmaBrehmat ali100% (1)

- Hold Time Study GuidelineDocumento4 pagineHold Time Study GuidelineYousifNessuna valutazione finora

- US Environmental Protection Agency Office of Pesticide ProgramsDocumento20 pagineUS Environmental Protection Agency Office of Pesticide Programsanandhra2010Nessuna valutazione finora

- Standard Operating ProcedureDocumento13 pagineStandard Operating ProcedureNasir KhanNessuna valutazione finora

- Amendment 1: Replacement of 3Kl Uf Storage Tank & Installation of New 500 Ltr. Brine TankDocumento8 pagineAmendment 1: Replacement of 3Kl Uf Storage Tank & Installation of New 500 Ltr. Brine TankprakashNessuna valutazione finora

- Testing Procedure of Caps: Ferozsons Laboratories Limited Work InstructionsDocumento8 pagineTesting Procedure of Caps: Ferozsons Laboratories Limited Work InstructionsaKureishiNessuna valutazione finora

- Alternative Second-Order N-Point Spherical Response Surface Methodology Designs and Their EfficienciesDocumento9 pagineAlternative Second-Order N-Point Spherical Response Surface Methodology Designs and Their EfficienciesTahir IbrahimNessuna valutazione finora

- NeuralDocumento8 pagineNeuralTahir IbrahimNessuna valutazione finora

- Research Article: An Alternative Approach of Dual Response Surface Optimization Based On Penalty Function MethodDocumento7 pagineResearch Article: An Alternative Approach of Dual Response Surface Optimization Based On Penalty Function MethodTahir IbrahimNessuna valutazione finora

- DAS ADV 003, Undertaking For Mixing CoursesDocumento1 paginaDAS ADV 003, Undertaking For Mixing CoursesTahir IbrahimNessuna valutazione finora

- Purospher STAR LP - Application GuideDocumento22 paginePurospher STAR LP - Application GuideTahir IbrahimNessuna valutazione finora

- SMP 200mgDocumento7 pagineSMP 200mgTahir IbrahimNessuna valutazione finora

- Check List For Technical Audit: Surge Lab. (PVT) LTDDocumento20 pagineCheck List For Technical Audit: Surge Lab. (PVT) LTDTahir IbrahimNessuna valutazione finora

- SOP ADM 07 (New)Documento17 pagineSOP ADM 07 (New)Tahir IbrahimNessuna valutazione finora

- Monthly Data Analysis of Ampoules Manufacturing and Packaging Jun-2009Documento6 pagineMonthly Data Analysis of Ampoules Manufacturing and Packaging Jun-2009Tahir IbrahimNessuna valutazione finora

- Hemostatic AgentsDocumento18 pagineHemostatic AgentshariNessuna valutazione finora

- Manual Copolimeros de Bloque Series L y R-StepanDocumento8 pagineManual Copolimeros de Bloque Series L y R-StepanHebert FerneynesNessuna valutazione finora

- A Comprehensive Study of Interactions Occurring Between Superplasticizers and Clays, andDocumento245 pagineA Comprehensive Study of Interactions Occurring Between Superplasticizers and Clays, and胡家兵Nessuna valutazione finora

- Gastroretentive Drug Delivery System Stomach SpeciDocumento7 pagineGastroretentive Drug Delivery System Stomach SpeciDeslina Setria MitaNessuna valutazione finora

- Study Lipid NanoparticlesDocumento8 pagineStudy Lipid NanoparticlesÓscar SánchezNessuna valutazione finora

- Rayon Tre Cord Finish OilDocumento4 pagineRayon Tre Cord Finish OilLoganathan MurugadassNessuna valutazione finora

- Introduction To Protein Crystallization: Alexander McphersonDocumento12 pagineIntroduction To Protein Crystallization: Alexander McphersonJohnNessuna valutazione finora

- Olive Oil PEG-7 EstersDocumento29 pagineOlive Oil PEG-7 EstersNurulNessuna valutazione finora

- Eo Po Block Co PolymersDocumento29 pagineEo Po Block Co PolymersUtpalNessuna valutazione finora

- Formulation and Evaluation of Fast Dissolving Tablet Containing Domperidone Ternary Solid DispersionDocumento9 pagineFormulation and Evaluation of Fast Dissolving Tablet Containing Domperidone Ternary Solid DispersionKimia farma AntangNessuna valutazione finora

- Properties of Four Deep Eutectic Solvents: Density, Electrical Conductivity, Dynamic Viscosity and Refractive IndexDocumento12 pagineProperties of Four Deep Eutectic Solvents: Density, Electrical Conductivity, Dynamic Viscosity and Refractive IndexMaryNessuna valutazione finora

- Solubility Enhancement of Poorly Water Soluble Drugs by Solid DispersionDocumento10 pagineSolubility Enhancement of Poorly Water Soluble Drugs by Solid Dispersiondini hanifaNessuna valutazione finora

- Novolyte High Performance SolventsDocumento11 pagineNovolyte High Performance SolventsborgiamatriceNessuna valutazione finora

- Surfactants Classified by HLB NumbersDocumento5 pagineSurfactants Classified by HLB NumbersNatalia Moral FlorNessuna valutazione finora

- Natural DyesDocumento23 pagineNatural DyesSenelisile MoyoNessuna valutazione finora

- Macrogols BPDocumento4 pagineMacrogols BPASHOK KUMAR LENKANessuna valutazione finora

- ALKOXYLATESDocumento9 pagineALKOXYLATESDharmendra B MistryNessuna valutazione finora

- Research ProjectDocumento38 pagineResearch ProjectKarena NguyenNessuna valutazione finora

- Zwitterionic Polymers and Hydrogels ForDocumento15 pagineZwitterionic Polymers and Hydrogels ForIoana-Alexandra TrofinNessuna valutazione finora

- Preparation Methods and Properties of HydrogelDocumento6 paginePreparation Methods and Properties of HydrogelSorin LazarNessuna valutazione finora

- Nifedepine CR UKPARDocumento19 pagineNifedepine CR UKPARBIGALFA 001Nessuna valutazione finora

- Finishing-Spin FinishDocumento7 pagineFinishing-Spin FinishSethupathi K PNessuna valutazione finora

- Strategies For Working With Poorly Water Soluble APIs PDFDocumento29 pagineStrategies For Working With Poorly Water Soluble APIs PDFHendryck Joseth Reguillo GonzalezNessuna valutazione finora

- Buildings 12 00152 v3 SelfcuringDocumento27 pagineBuildings 12 00152 v3 Selfcuringraja sekharNessuna valutazione finora

- Parentral ProductsDocumento28 pagineParentral ProductsMD ABID ALAM100% (1)

- High Purity Excipients GuideDocumento8 pagineHigh Purity Excipients GuideSA100% (1)

- TritonDocumento2 pagineTritonVi Vian HiuNessuna valutazione finora

- UntitledDocumento32 pagineUntitledCheikh DjoudiNessuna valutazione finora

- AKZO Nobel Surf Act Ants - Non Ionic ProductsDocumento6 pagineAKZO Nobel Surf Act Ants - Non Ionic ProductsJosep BriantNessuna valutazione finora

- Advances in Solid Dispersion Techniques For Enhancing Drug Solubility, Bioavailability and Controlled ReleaseDocumento5 pagineAdvances in Solid Dispersion Techniques For Enhancing Drug Solubility, Bioavailability and Controlled ReleaseInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora