Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

EDS 06-0016 LV Network Earthing Design PDF

Caricato da

Rajendra Prasad ShuklaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

EDS 06-0016 LV Network Earthing Design PDF

Caricato da

Rajendra Prasad ShuklaCopyright:

Formati disponibili

Document Number: EDS 06-0016

Date: 31/12/2013

ENGINEERING DESIGN STANDARD

EDS 06-0016

LV NETWORK EARTHING DESIGN

Network(s):

EPN, LPN, SPN

Summary:

This standard details the design requirements for earthing of low voltage (LV)

networks.

Owner:

Allan Boardman

Date:

31/12/2013

Approved By:

Steve Mockford

Approved Date:

17/01/2014

Review Date:

17/01/2017

This document forms part of the Companys Integrated Business System and its requirements are mandatory throughout UK

Power Networks. Departure from these requirements may only be taken with the written approval of the Director of Asset

Management. If you have any queries about this document please contact the author or owner of the current issue.

Document History

(The document history notes below are intended as a guide only and may not cover all of the changes. If you wish to make use

of this document it should be read in full.)

Version

Date

Details

Author

5.0

31/12/2013

Further clarity around the use of additional PME

electrodes on underground networks added

(Sections 6.2, 6.3.2 and 6.3.3). Earth resistance

value for introducing CNE into SNE networks

changed back to 10 in line with revised

ENA ER G12/4 requirements (Sections 6.3.2)

Stephen Tucker

4.0

12/04/2013

Earthing of service joints for PME conversion

removed (section 6.3.3) and section 6.3.4

removed

Stephen Tucker

3.1

06/07/2012

Minor updates to ensure consistency with other

standards and greater use of aluminium

conductors. Document reviewed for publishing on

G81 website

Stephen Tucker

THIS IS AN UNCONTROLLED DOCUMENT, THE READER MUST CONFIRM ITS VALIDITY BEFORE USE

Version: 5.0

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Version

Date

Details

Author

3.0

17/11/2011

Underground cable sections revised. PNB section

added

Stephen Tucker

2.2

29/09/2011

Reclassification of document from Earthing Design

Manual Section 6

Stephen Tucker

2.0

01/06/2010

Completely rewritten to provide a more consistent

and practical approach. Customer installation

earthing moved to Section 7 of the Earthing

Design Manual

Stephen Tucker

1.0

31/03/2008

Original

Stephen Tucker/

Rob Weller

UK Power Networks 2014 All rights reserved

2 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Contents

1

Introduction ............................................................................................................. 5

Scope ....................................................................................................................... 5

Glossary and Abbreviations ................................................................................... 6

Definitions ................................................................................................................ 6

LV Earthing Standard .............................................................................................. 8

Design Criteria ......................................................................................................... 9

6.1

General Requirements .............................................................................................. 9

6.2

Supply Neutral Conductor Earthing Requirements .................................................... 9

6.3

Underground Cable Networks ................................................................................. 10

6.3.1

New Underground Cable Networks ......................................................................... 10

6.3.2

Converting Existing Underground Cable Networks to PME ...................................... 10

6.3.3

Converting Existing Customers to PME ................................................................... 12

6.3.4

Looped Services ...................................................................................................... 12

6.4

Overhead Line Networks ......................................................................................... 13

6.5

Protective Neutral Bonding (PNB) ........................................................................... 14

6.6

Load Balance .......................................................................................................... 15

6.7

Earth Fault Loop Impedance ................................................................................... 15

LV Earthing Requirements.................................................................................... 16

7.1

Earth Electrodes ...................................................................................................... 16

7.2

Bonding Connections .............................................................................................. 16

7.3

Earth Resistance Values ......................................................................................... 17

References ............................................................................................................. 18

Appendix A ESQC Regulations ..................................................................................... 19

Appendix B Earthing Systems ...................................................................................... 21

B.1

IEC Standard for the Naming of Earthing Systems .................................................. 21

B.2

BS 7671 Definitions ................................................................................................. 21

B.3

TN-S (Terra-Neutral Separated) .............................................................................. 22

B.4

TN-C-S (Terra-Neutral-Combined-Separated) ......................................................... 22

B.5

TT (Terra-Terra) ...................................................................................................... 24

Appendix C Typical Electrode Systems ....................................................................... 25

UK Power Networks 2014 All rights reserved

3 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Figures

Figure 6-1 Supply Neutral Conductor Earthing Requirements for PME ............................ 10

Figure 6-2 Typical Application of CNE Cables in Existing Networks ................................. 11

Figure 6-3 PNB Options using CNE and SNE Cut-outs .................................................... 14

Figure 6-4 PNB for up to Four Customers ........................................................................ 15

Figure B-1 TN-S Earthing System .................................................................................... 22

Figure B-2 PME Earthing System..................................................................................... 23

Figure B-3 PNB Earthing System ..................................................................................... 23

Figure B-4 TT Earthing System ........................................................................................ 24

UK Power Networks 2014 All rights reserved

4 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Introduction

This standard (previously Section 6 of the Earthing Design Manual) details the earthing

design requirements for low voltage (LV) networks. It supersedes all previous EPN, LPN and

SPN specific guidance on PME network design, and brings together a common approach to

system design and operation.

The standard is based on the best practice from the latest draft of ENA ER G12/4 and has

also been updated to reflect the requirements of BS 7671:2008 (2011) IEE Wiring

Regulations Seventeenth Edition.

Although this standard covers most aspects of LV network earthing there will be some

situations where advice from an earthing specialist is required, refer to EDS 06-0001 for

further details.

The earthing design for secondary distribution substation (including the substation LV earth)

and pole-mounted equipment are covered respectively in EDS 06-0014 and EDS 06-0015.

Earthing associated with customer installations, including the provision of an earth terminal,

is detailed in EDS 06-0017.

This standard is divided into the following sub-sections:

Definitions (Section 4).

LV Earthing Standard (Section 5).

PME Network Design (Section 6).

LV Earthing Requirements (Section 7).

References (Section 8).

Regulations (Appendix A).

LV Earthing Systems (Appendix B).

Significant changes from existing practice or previous versions:

The statutory requirements from the Electricity, Supply Quality and Continuity (ESQC)

regulations 2002 are included in the text.

The guidance from the latest draft of ENA G12/4 is included.

The requirements from BS 7671:2008 (2011) are included.

The additional PME earth electrode requirements, at each branch and service joint,

introduced in version 1 of this standard have been removed as they are deemed

unnecessary for modern cables and current network construction.

The electrodes, bonding conductors and labels have all been reviewed.

All earthing requirements for LV customer installations including the provision of PME

terminals and special situations have been removed and are now included in

EDS 06-0017.

The use of protective neutral bonding (PNB) is reinstated.

Scope

This standard applies to the earthing design for all new LV networks and existing LV

networks where a material alteration is to take place.

This document is intended for internal and external use.

UK Power Networks 2014 All rights reserved

5 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Glossary and Abbreviations

Term

Definition

EPR

Earth potential rise

ROEP

Rise of earth potential

NetMap

UK Power Networks graphical information system (GIS).

Definitions1

Combined Neutral and Earth (CNE)

Typically used to describe a cable with a combined neutral and earth metallic outer sheath

with a PVC covering, or overhead line with a combined neutral and earth conductor.

Customer

Any person who has responsibility for premises connected by agreement to distribution

networks owned by UK Power Networks.

Customer's Installation

The electrical apparatus under the control of the customer on the customers premises

together with the wiring connecting this apparatus to the supply terminals. A cut-out and

meter shall not form part of the customers installation (unless additional metering is supplied

by the customer e.g. landlords supplies).

Customer's Premises

Any area or building in the sole occupation of the customer.

Distributing Main (or Main)

A low voltage electric line which connects a source of voltage to one or more service lines,

or directly to a single customers installation.

Distributor*

A person who owns or operates a network, except for a network situated entirely offshore or

where that person is an operator of a network within the meaning of Part I of the Railways

Act 1993.

Earth Electrode

A metal rod, plate, stranded or strip conductor buried in the earth for the purpose of

providing a connection with the general mass of earth.

Earth Loop Impedance (ELI) or Earth Fault Loop Impedance (EFLI)

The impedance of the earth fault current loop starting and ending at the point of earth fault.

This impedance is denoted by the symbol Zs. The part of the earth fault loop impedance

which is external to the customer installation is denoted by the symbol Ze.

*Definitions taken from the Electricity Safety, Quality and Continuity Regulations 2002.

UK Power Networks 2014 All rights reserved

6 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Earthing Systems (refer to Appendix B for further details)

Protective Multiple Earthing (PME)

PME is the most common form of earthing provided at new installations. A single conductor

for neutral and earthing functions is utilised and an earth terminal is provided at the

customers installation. The customers earthing may be connected to this terminal providing

the relevant requirements in BS 7671 are satisfied. In some cases it is not appropriate to

provide a PME earth terminal, either due to the nature of the distribution system or due to

the type of installation itself.

Cable Sheath Earth/Separate Continuous Earth Wire

Cable sheath earth and separate continuous earth wire arrangements are often found on

supplies to older properties, or occasionally where PME facilities are unavailable. Separate

conductors for neutral and earthing functions are utilised and an earth terminal is provided at

the customers installation. The customers earthing may be connected to this terminal

providing the relevant requirements in BS 7671 are satisfied.

Independent Local Earthing (TT)

Independent local or TT earthing is common in older installations and is also used where

PME cannot be provided. An earth terminal is not provided and the customer is responsible

for providing the earth electrode system (buried earth rods and conductor). Where local

earthing is employed, the installation normally has to be protected by a residual current

device (RCD) in order to comply with BS 7671.

Earthing Terminal

The main earth terminal for an installation, usually sited close to the incoming service. If an

earth terminal is provided by UK Power Networks as part of a PME supply (TN-C-S), the

main earth terminal will usually be directly connected to the supply neutral conductor at the

cut-out position.

Electric Line*

Any line which is used or intended to be used for carrying electricity for any purpose and

includes, unless the context otherwise requires:

a) Any equipment connected to any such line for the purpose of carrying electricity.

b) Any wire, cable, tube, pipe, insulator or other similar thing (including its casing or

coating) which surrounds or supports, or is associated with, any such line.

Multi-service

Any electric line through which energy may be supplied to two, three or four adjacent

customers from any distributing main or substation.

Residual Current Device (RCD)

An RCD is a current operated device which measures the imbalance between phase and

neutral currents. If this unbalance or leakage current exceeds a preset level it will operate to

interrupt current flow. Typical domestic RCDs will have a 30mA operating threshold.

Secondary Substation

An HV/LV substation typically transforming 11(6.6)kV to 400V.

Separate Neutral and Earth (SNE)

Typically used to describe a cable or overhead line with an earthed sheath or additional

earth wire in addition to a neutral conductor.

UK Power Networks 2014 All rights reserved

7 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Service Line* (or Service)

Any electric line which either connects a street electrical fixture, or no more than four

customers installations in adjacent buildings, to a distributing main.

Service Termination

The cut-out where the service cable terminates.

Street Electrical Fixture*

A permanent fixture which is, or is intended to be, connected to a supply of electricity and

which is in, on, or is associated with a highway.

Supplier*

A person who contracts to supply electricity to consumers.

LV Earthing Standard

The Electricity Safety, Quality and Continuity Regulations 2002 (24(4)) (refer to Appendix A)

state that a distributor shall make an earthing terminal available when installing a new low

voltage connection or replacing an existing connection, unless it is inappropriate for reasons

of safety.

UK Power Networks' standard is to provide an earth terminal from a PME system wherever it

is appropriate to do so. EDS 06-0017 (Customer Installation Earthing Design) details the

situations where it may be inappropriate to provide an earth terminal from a PME system.

Therefore all new low voltage mains and services shall be constructed to PME standards

described in Section 6 using combined neutral earth (CNE) cables and overhead lines to

enable an earth terminal to be provided.

Whenever major work (e.g. refurbishment, diversion etc.) is carried out on the low voltage

distribution network, it shall be brought up to PME standards where appropriate, as

described in Section 6.

Generally only one service and earth terminal shall be provided to a customer or a building.

Multiple services to a single customer or building are not recommended practice since this

causes problems due to neutral current diversion2 and uncertainty when isolating the

supplies. Refer EDS 06-0017 for further information on multiple supplies.

Out of balance three-phase loads and single-phase loads cause current to flow in the neutral conductor. Neutral

current diversion occurs when multiple PME supplies are provided to the same building and an alternative path

exists, for example through the structural steelwork of a building and an earth bond, to the other neutral/earth

terminal. The natural passage of neutral current through the structural steelwork can give rise to magnetic field

problems both close to the steelwork and at the source which may cause interference to VDUs etc. Furthermore,

equipotential bonding conductors may carry neutral current resulting in overheating and consequential fire risk.

Refer to EDS 06-0017 for further information.

UK Power Networks 2014 All rights reserved

8 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Design Criteria

This section describes the requirements for PME networks and is split into the following

sub-sections:

6.1

General requirements.

Supply neutral conductor earthing.

Underground cable networks.

Overhead line networks.

Load balance.

Protective neutral bonding (PNB).

Earth fault loop impedance.

General Requirements

The following general requirements apply to all new and existing low voltage networks to

enable PME to be used:

6.2

For combined HV and LV earthing systems, the earth potential rise (EPR) or rise of earth

potential (ROEP) at the secondary substation supplying the PME network shall not

exceed 430V during a HV earth fault. If the EPR exceeds 430V the HV and LV earthing

systems shall be segregated. Refer EDS 06-0014 for further details on secondary

substation design.

Protective devices shall not be included in the supply neutral conductor or any earthing

connection.

The integrity of the supply neutral conductor shall be maintained throughout the network

and should be considered during the design, construction, maintenance and operation of

the distribution system.

The supply neutral conductor shall be connected to earth (or the supply neutral

conductor of another main) at other points throughout the network in addition to the LV

earth at or near to the secondary substation (refer to Section 6.2).

The resistance of the supply neutral conductor to the earth shall not exceed 20 at any

point (refer to Section 7.3).

Loads shall be shown uniformly distributed across the phases along a main at the design

stage (refer to Section 6.5).

Supply Neutral Conductor Earthing Requirements

In addition to the main LV neutral earth at or near the substation, the supply neutral

conductor shall be connected at other points to earth electrodes, or to the supply neutral

conductor of another main to ensure that the resistance of the supply neutral conductor does

not exceed 20 at any point on the network.

The additional earth connections will also ensure that the potential of the supply neutral

conductor is as close to that of true earth as possible, and provide resilience against opencircuit neutral conditions, therefore reducing the likelihood of the neutral rising to undesirable

voltage levels. This means that the combined neutral/earth conductor will be earthed at

multiple locations.

UK Power Networks 2014 All rights reserved

9 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Additional neutral earth electrodes, as specified in Section 7.1, shall be installed as follows:

In the pot-end at the end of each main. Alternatively, connecting the supply neutral

conductor to that of another main with a separate path back to the substation will serve

the same purpose.

In the pot-end at the end of any branch or service supplying more than four customers.

In the pot-end at the end of any branch or service supplying more than one customer

and longer than 40 metres.

In the pot-end at the end of any branch or service supplying street furniture with a PME

earth terminal.

At additional locations on overhead line systems to ensure the distance between

electrodes are not more than six spans.

These arrangements are illustrated in Figure 6-1.

4 customers

< 40 metres

No additional

earth required

Single customer

No additional earth

required

4 customers

> 40 metres

Additional

earth required

> 4 customers

Additional

earth required

100

Secondary

Substation

No

maximum

length

40m

100

> 40m

20

100

100

100

End of main

electrode or

link to next

PME main

Additional earth required every

6 poles on overhead lines

For street furniture requirements

refer to EDS 06-0017

100

Key:

Main or branch cable or overhead line

Main 20W Earth Electrode

20

Service

Single Customer

Multi-occupancy

Biulding

Additional 100W PME Earth Electrode (at pot-end, cut-out or pole)

100

Figure 6-1 Supply Neutral Conductor Earthing Requirements for PME

6.3

Underground Cable Networks

6.3.1

New Underground Cable Networks

New underground networks shall use CNE cable and an earth terminal shall be provided

from the PME system wherever possible.

6.3.2

Converting Existing Underground Cable Networks to PME

The opportunity shall be taken wherever possible to upgrade existing networks to PME. Any

extension or modification shall use CNE cables. Figure 6-2 shows the typical application of

UK Power Networks 2014 All rights reserved

10 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

CNE cables in existing networks. The following requirements shall be applied when CNE

cables are introduced into SNE networks:

The neutral conductor of the CNE cable shall be connected to the neutral conductor and

sheath earth conductor of the SNE cable at the transition joint.

An earth electrode is required at the transition joint furthest from the secondary

substation. However a length of SNE cable in direct contact with the ground will normally

provide a suitable connection with earth and satisfy this requirement.

Further electrodes shall be installed on the CNE cable in accordance with the

requirements for new PME networks in accordance with Section 6.2 above.

S/S

SNE

CNE

Key:

SNE

S/S

Secondary substation

S/S

LB

CNE

Link box

SNE

See note 2

SNE Separate neutral and earth cable

CNE Combined neutral and earth cable

See note 1

Transition joint CNE neutral

connected to SNE neutral and shealth

S/S

SNE

CNE

SNE

PME earth electrode

See note 2

Meets PME requirements

See note 1

S/S

CNE

SNE

S/S

LB

SNE

New CNE Service

S/S

SNE

Notes:

1. 15m of non-insulated SNE cable in direct contact

with the ground will usually provide an adequate

earth electrode, otherwise an earth electrode is

required.

2. These sections of SNE cable will meet the PME

requirements if the sheath and neutral are bonded

at the end of main and an end of main electrode

added.

SNE

See note 2

Figure 6-2 Typical Application of CNE Cables in Existing Networks

All reasonable precautions shall be taken to ensure that customers supplied via SNE cables

are not adversely affected by repairs, modifications or additions to existing networks. When

a CNE cable is introduced into a SNE network, existing customers may retain a SNE service

provided:

A continuous metallic earth return path exists to the source substation, and;

They are connected to a continuous length of non-insulated metallic sheathed cable in

direct contact with the ground, sufficient to limit the rise of potential under open-circuit

neutral conditions. These criteria will be satisfied if the length of metallic cable sheath in

contact with the ground is sufficient to give a resistance to earth of 10 or less. Table 6-1

specifies the length required to achieve this in different soil conditions.

UK Power Networks 2014 All rights reserved

11 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

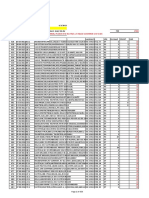

Table 6-1 Non-insulated Sheathed Cable Lengths Required to Achieve 10

Typical Soil Type

Resistivity (m)

Length (m)

Loams, garden soils etc.

25 or less

Chalk

50 or less

15

Clay

100 or less

29

Marsh/Peat

200 or less

58

Sand/Gravel/Clay mix

300 or less

87

Slate/Shale/Rock

500 or less

115

If these conditions cannot be satisfied the service shall be converted to PME (provided the

installation complies with the BS 7671 bonding requirements), or a TT earthing system shall

be used.

6.3.3

Converting Existing Customers to PME

Customers with an existing separate neutral and earth, connected to an SNE cable network

can be converted to a combined neutral and earth (PME) provided the following

requirements are satisfied:

The customer's installation complies with BS 7671.

A new PME cut-out is installed.

There are no shared metallic services (water, gas etc) with other properties (e.g. flats). If

there are shared metallic services all properties shall be converted to PME and the

neutrals bonded together in accordance with the rules for multi-occupancy buildings

detailed in EDS 06-0017.

The SNE cable is replaced with a CNE cable (or the neutral and earth are combined at

the service joint and at the cut-out).

An earth electrode is required at the service joint. However a length of SNE cable in

direct contact with the ground will normally provide a suitable connection with earth and

satisfy this requirement.

Note: It is not permitted to simply bond the neutral and earth at the cut-out.

6.3.4

Looped Services

When alterations are made to any cable associated with a SNE cable looped3 service

arrangement, with cable sheath earth terminals provided by UK Power Networks, the

earthing systems at the looped property and the house connected to the primary4 service

shall remain the same as each other. If one property is converted to PME, with the other

retaining a SNE cable sheath earth, there would be a risk of differences in potential between

un-bonded metalwork within the SNE earthed property in the event of an open circuit neutral

fault on the primary service. Refer to EDS 08-0129 for further information.

A looped service is a service that is derived from a connection to another service cable, either by an

underground cable joint on or from the live-side cut-out terminals of the primary service.

4

The primary service is the service that connects directly to the mains cable and to which the loop service

connects.

UK Power Networks 2014 All rights reserved

12 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

6.4

Overhead Line Networks

New overhead line networks are constructed using aerial bundled conductors (ABC) and will

be suitable for PME.

Existing open-wire low voltage overhead line networks are also suitable for PME. If an

overhead line network is encountered that is not PME, it shall be converted to PME before

any other work proceeds.

Low voltage overhead line PME networks shall satisfy the following requirements:

The HV and LV earths on pole-mounted transformers shall be segregated as specified in

EDS 06-0015.

The supply neutral conductor shall be connected in such a way to minimise corrosion or

breakage risks. (Single line tap type connections for neutral line conductors, tier type

cable box neutrals or transformer neutral connections are not acceptable).

The supply neutral conductor shall be connected to an earth electrode or the supply

neutral conductor of another main at the final support of every main.

Additional earth electrodes shall be installed every six spans along the overhead line and

at the end of each section of overhead line.

The cable sheaths and metallic cable boxes on poles supporting cable terminations shall

be connected to the supply neutral conductor.

Any multi-service, group service position or under-eaves wiring supplying more than four

customers shall be fitted with an earth electrode.

The following additional requirements shall be applied when open-wire overhead line

networks with continuous earth wires are replaced with ABC:

All sections of associated main and any other main likely to be used as an alternative

supply between the secondary substation and the customer shall be constructed to the

PME requirements outlined above.

Any service aerial earth wires shall be removed.

Customers utilising a SNE service shall be converted to PME (provided the installation

complies with the BS 7671 bonding requirements) or a TT earthing system shall be used.

However, existing customers beyond the ABC may retain a SNE service provided they

are connected to a continuous length of non-insulated metallic sheathed cable in direct

contact with the ground sufficient to limit the rise of potential under open-circuit neutral

conditions. These criteria will be satisfied if the length of metallic cable sheath in contact

with the ground is sufficient to give a resistance to earth of 20 or less. Table 6-1

specifies the length required to achieve this in different soil conditions.

UK Power Networks 2014 All rights reserved

13 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

6.5

Protective Neutral Bonding (PNB)

Although PME is the preferred option protective neutral bonding (PNB) may provide a better

solution in circumstances where it is not practical to install the LV earth at the transformer. In

a PNB earthing system the LV neutral conductor is connected to an earth electrode at a

point remote from the transformer at or near the customer's supply terminals (refer to

Appendix B for further details).

PNB may only be used if the following criteria are satisfied:

A maximum of four customers.

The connection to earth shall be made as close as possible to customer's supply

terminals and no more than 40m from the furthest customer.

The earth electrode shall have a maximum resistance of 20.

The earth electrode shall be a minimum of 8m from any HV earth or HV metallic sheath

cable.

The metallic sheaths of any LV cables shall also be connected to the earth electrode.

The transformer tank and associated HV metalwork shall be connected to the HV earth

electrode.

A PNB earth terminal shall be treated as a PME earth terminal and the appropriate

labelling applied (Refer to EDS 06-0017).

Various PNB arrangements are illustrated in Figure 6-3 and Figure 6-4.

HV : LV

HV : LV

CNE Cut-out

HV : LV

SNE Cut-out

HV : LV

CNE Cut-out

SNE Cut-out

HV : LV

SNE Cut-out

Figure 6-3 PNB Options using CNE and SNE Cut-outs

UK Power Networks 2014 All rights reserved

14 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

CNE Cut-out

CNE Cut-out

HV : LV

CNE Cut-out

CNE Cut-out

<40m

Figure 6-4 PNB for up to Four Customers

6.6

Load Balance

The voltage which appears on the supply neutral conductor (and consequently on

customers exposed metalwork) beyond a broken neutral position is influenced by the load

balance on the main. If the load is uniformly distributed across the phases along the main,

the neutral voltage rise is theoretically zero beyond a neutral break and will be low in

practice. Maintaining good load balance will therefore minimise neutral voltage rise and

consequent risk of shock under broken neutral conditions. Good load balance will also

minimise neutral voltage rise under normal operating conditions, reduce losses, and

maximise the load capacity available from the assets concerned. It is the best way to reduce

risks associated with broken neutrals and is an extremely important factor in network

operation and design.

Therefore designs for new networks and alterations to existing networks shall clearly indicate

the phase to which customers shall be connected. Furthermore this shall be clearly

communicated to those making the service connections.

When legacy single-phase or two-phase SNE cable networks are replaced with modern

three-phase CNE cable, particular care should be taken to balance load. Wherever possible,

cable sheaths and neutrals at the ends of SNE cables should be bonded and

interconnected.

6.7

Earth Fault Loop Impedance

For guidance on earth fault loop impedance refer to EDS 08-0136 (new network design) or

EDS 06-0004 (existing networks).

UK Power Networks 2014 All rights reserved

15 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

LV Earthing Requirements

7.1

Earth Electrodes

The permitted earth electrodes are given in Table 7-1. Refer to Appendix C for a complete

range of electrode sizes for different values of soil resistivity.

Note: The use of rod electrodes is preferred but due to practical difficulties, particularly in

urban areas where damage can be caused to other services, cable electrodes are

acceptable.

Table 7-1 Earth Electrodes

Electrode Type

Location

Cable Size

Rod

Cable Joints

Up to 35mm

> 35mm

Cable Joints

New

Cable

Cable Joints

Existing

7.2

2.4m earth rod connected via 35mm PVC

covered copper cable

2

2.4m earth rod connected via 70mm PVC

covered copper cable

2

2 x 2m of 35mm bare copper cable

loosely wrapped around the joint

2

Up to 35mm

> 35mm

Up to 35mm

> 35mm

Electrode

2 x 2m of 70mm bare copper cable

loosely wrapped around the joint

2

2m of 35mm bare copper cable laid

directly in the trench

2

2m of 70mm bare copper cable laid

directly in the trench

Bonding Connections

The minimum size of earthing and bonding connections are given in Table 7-2. Below

ground, i.e. buried, earthing and bonding conductors shall be copper. Above ground bonding

conductors may be copper, aluminium or corrosion protected steel of the appropriate cross

sectional area.

Table 7-2 Bonding Connections

Connection Type

Copper or Copper Equivalent

Main LV earth at secondary substation i.e.

connection between transformer neutral (starpoint) and earth

Refer to EDS 06-0014 for the requirements

Between neutral busbar and earth busbar at

secondary substation

LV earth at pole-mounted sites

UK Power Networks 2014 All rights reserved

Refer to EDS 06-0015 for the requirements

16 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Connection Type

Copper or Copper Equivalent

Between supply neutral conductor and PME

earth electrode

For cable sizes up to 35mm : 50mm PVC

2

covered aluminium cable or 35mm PVC

covered copper cable

Between supply neutral conductor and link box

or feeder pillar steelwork

Between sheath of SNE cable and neutral of

CNE cable

At customers premises between service neutral

and main earthing terminal

For cable sizes greater than 35mm : 95mm

2

PVC covered aluminium cable or 50mm PVC

covered copper cable

2

16mm or half the size of the neutral meter tail,

whichever is the larger.

Note: This is usually built into the cut-out

At customers premises between the main

earthing terminal and the earth bar of the

consumer unit

16mm or half the size of the neutral meter tail,

whichever is the larger

Note: The bonding between the main earthing

terminal and the consumer unit is the

responsibility of the consumer. It is given here

for information only.

7.3

Earth Resistance Values

The resistance of the supply neutral conductor to the general mass of earth shall not at any

point exceed 20. To achieve this value the earth electrode resistance values given in Table

7-3 shall be used.

Table 7-3 Earth Electrode Resistance Values.

Electrode

Resistance Value

Electrode Systems

Main LV Earth

20

Refer to Appendix C

Additional PME Earth

100

UK Power Networks 2014 All rights reserved

17 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

References

EDS 06-0001

Earthing Standard

EDS 06-0004

Earth Fault Loop Impedance Requirements (internal document only)

EDS 08-0129

Underground Services up to 100A

EDS 08-0133

Underground Services to Unmetered Street Furniture

EDS 08-0136

LV Network Design

EDS 06-0014

Secondary Substation Earthing Design

EDS 06-0015

Pole-mounted Equipment Earthing Design

EDS 06-0017

Customer Installation Earthing Design

EDS 06-0018

NetMap Earthing Information System (internal document only)

EDS 08-0136

LV Network Design

ENA ER G12/4

Requirements for the Application of Protective Multiple Earthing to Low

Voltage Networks

IEC 60364

Electrical Installations for Buildings

The Electricity Safety, Quality and Continuity Regulations (ESQC) 2002 as amended (2006)

BS 7671:2008 incorporating Amendment No 1: 2011 Requirements for Electrical

Installations (IEE Wiring Regulations Seventeenth Edition)

UK Power Networks 2014 All rights reserved

18 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Appendix A ESQC Regulations

The Electricity Safety, Quality and Continuity Regulations 2002 contain a number of clauses

covering earthing. A summary of these is given below:

Continuity of the Supply Neutral Conductor and Earthing Connections

Regulation 7(1) A generator or distributor shall, in the design, construction, maintenance or

operation of his network, take all reasonable precautions to ensure continuity of the supply

neutral conductor.

Regulation 7(2) No generator or distributor shall introduce or retain any protective device in

any supply neutral conductor or any earthing connection of a low voltage network which he

owns or operates.

General Requirements for Connection with Earth

Regulation 8(1) A generator or distributor shall ensure that, so far as is reasonably

practicable, his network does not become disconnected from earth in the event of any

foreseeable current due to a fault.

Regulation 8(3) A generator or distributor shall, in respect of any low voltage network which

he owns or operates ensure that:

a) the outer conductor of any electric line consisting of concentric conductors shall be

connected with earth.

b) every supply neutral conductor is connected with earth at, or as near as is practical, to

the source of voltage, except that where there is only one point in a network at which

consumers installations are connected to a single source of voltage, that connection

may be made at that point, or at another point nearer to the source of voltage.

c) no impedance shall be inserted in any connection with earth of a low voltage network

other than that required for the operation of switching devices or instruments, or

equipment for control, telemetry or metering.

Regulation 8(5) A consumer shall not combine the neutral and protective functions in a

single conductor in his installation.

Regulation 8(5) Paragraphs (1) to (4) shall not apply to a generators network which is

situated within a generating station if, and only if, adequate alternative arrangements are in

place to prevent danger.

Protective Multiple Earthing

Regulation 9(1) This regulation applies to distributors low voltage networks in which the

neutral and protective functions are combined.

Regulation 9(2) In addition to the neutral with earth connection required under regulation

8(4)(b), a distributor shall ensure that the supply neutral conductor is connected with earth

at:

a) a point no closer to the source of voltage (as measured along the distributing main) than

the junction between the distributing main and the service line (the supply neutral

conductor of the latter being connected to the protective conductor of a consumers

installation) which is most remote from the source.

b) such other points as may be necessary to prevent, so far as is reasonably practicable,

the risk of danger arising from an accidental disconnection of any such connection with

earth.

UK Power Networks 2014 All rights reserved

19 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Regulation 9(3) Paragraph (2)(a) shall only apply where the supply neutral conductor of the

service line referred to in paragraph (2)(a) is connected to the protective conductor of a

consumer's installation.

Regulation 9(4) The distributor shall not connect his combined neutral and protective

conductor to any metalwork in a caravan or boat.

Equipment on a Consumer's Premises

Regulation 24 (1) A distributor or meter operator shall ensure that each item of his

equipment which is on a consumer's premises, but which is not under the control of the

consumer (whether forming part of the consumer's installation or not), is:

a) suitable for its purpose.

b) installed and, so far as is reasonably practicable, maintained so as to prevent danger.

c) protected by a suitable fusible cut-out or circuit-breaker which is situated as close as is

reasonably practicable to the supply terminals.

Regulation 24(2) Every circuit breaker or cut-out fuse forming part of the fusible cut-out

mentioned in paragraph (1)(c) shall be enclosed in a locked or sealed container as

appropriate.

Regulation 24(3) Where they form part of his equipment, which is on a consumer's premises

but which is not under the control of the consumer, a distributor or meter operator (as

appropriate) shall mark permanently, so as clearly to identify the polarity of each of them, the

separate conductors of low voltage electric lines which are connected to supply terminals,

and such markings shall be made at a point which is as close as is practicable to the supply

terminals in question.

Regulation 24(4) Unless he can reasonably conclude that it is inappropriate for reasons of

safety, a distributor shall, when providing a new connection at low voltage, make available

his supply neutral conductor or, if appropriate, the protective conductor of his network for

connection to the protective conductor of the consumer's installation.

Regulation 24(5) In this regulation the expression "new connection" means the first electric

line, or the replacement of an existing electric line, to one or more consumer's installations.

Earthing of Metalwork

Regulation 10(1) Subject to paragraph (2), and without prejudice to any other requirement as

to earthing, a generator, distributor or meter operator, as the case may be, shall ensure that

any metalwork enclosing, supporting or otherwise associated with his equipment in a

network and which is not intended to serve as a phase conductor is, where necessary to

prevent danger, connected with earth.

Regulation 10(2) Paragraph (1) shall not apply:

a) to any metalwork attached to, or forming part of, a wooden pole support, the design and

construction of which is such as to prevent, so far as is reasonably practicable, danger

within 3m of the ground from any failure of insulation or failure of insulators.

b) to any wall-mounted metal bracket carrying an overhead line not connected with earth,

where the line is both supported by an insulator and the part of the line in contact with

the insulator is itself surrounded by insulation.

UK Power Networks 2014 All rights reserved

20 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Appendix B Earthing Systems

B.1

IEC Standard for the Naming of Earthing Systems

Mains electricity systems are categorised in IEC 60364 according to how the earthing is

implemented. The common ones are TN-C-S, TN-S and TT. In these descriptions, system

refers to both the supply and the installation, and live parts includes the neutral conductor.

These conventions are used in BS 7671.

First letter (refers to supply networks):

T The live parts in the system have one or more direct connects to earth (i.e. via the

neutral).

I The live parts in the system have no connection to earth or are connected only

through a high impedance.

Second Letter (refers to the customer's installation):

T All exposed conductive parts are connected via earth conductors to a local earth

connection.

N All exposed conductive parts are connected to the earth provided by the supply

network.

Remaining Letters:

C Combined neutral and earth functions (same conductor).

S Separate neutral and protective earth functions (separate conductors).

Note: The letters are derived from the French language: T Terre (earth), N Neutre

(neutral), S Spar (separate), C Combin (combined) and I Isol (isolated).

B.2

BS 7671 Definitions

TN (Terra-Neutral)

A system having one or more points of the source of energy directly earthed, the exposed

conductive-parts of the installation being connected to that point by protective conductors.

TN systems may be subdivided as described below.

TN-C (Terra-Neutral-Combined)

A system in which neutral and protective functions are combined in a single conductor

throughout the system.

TN-S (Terra-Neutral Separated)

A system having separate neutral and protective conductors throughout the system.

TN-C-S (Terra-Neutral-Combined-Separated)

A system in which neutral and protective functions are combined in a single conductor in part

of the system.

TT (Terra-Terra)

A system having one point of the source of energy directly earthed, the exposed-conductive

parts of the installation being connected to earth electrodes electrically independent of the

earth electrodes of the source.

UK Power Networks 2014 All rights reserved

21 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

B.3

TN-S (Terra-Neutral Separated)

In a TN-S earthing system (refer to Figure B-1), the incoming supply has a single point of

connection between the supply neutral and earth at the supply transformer. The supply

cables have separate neutral and protective earth conductors (SNE) for the complete

system, and there is no bonding between the neutral and earth conductors, except at the

supply transformer. The neutral conductor may be a fourth core, or a split concentric cable

may be used with part of the concentric conductor insulated and used as the neutral. The

sheath or a separate conductor is used to provide the protective earth. The customer is

provided with an earth terminal connected to the sheath of the service cable or to the

separate earth conductor.

Note:

TN-S was the default earthing system pre-1978 before PME became commonplace.

Since all extensions and repairs use CNE cable it shall be assumed that all networks will

have the neutral and protective earth conductors combined for at least part of the

system; they will therefore be TN-C-S. The only exceptions will be dedicated supplies to

single customers using a separate earth conductor.

Figure B-1 TN-S Earthing System

B.4

TN-C-S (Terra-Neutral-Combined-Separated)

The TN-C-S earthing system is a combination of TN-C and TN-S earthing systems. The

supply cables have a combined neutral and earth (CNE) metallic outer sheath with a PVC

covering (TN-C). The supply neutral conductor also serves as the protective earth and an

earth terminal is provided from it. The supply on the customers side is TN-S, i.e. the neutral

and earth are separate and only linked at the service termination. Both PME and PNB are

examples of the TN-C-S earthing system.

Note: If any part of a network has CNE cable, or has SNE cable with the sheath and neutral

bonded at any point other than at the transformer neutral terminal, the complete system is

classified as TN-C-S.

PME is a variant of the TN-C-S earthing system but additional earth electrodes are

connected to the neutral (Figure B-2).

UK Power Networks 2014 All rights reserved

22 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

(PME)

Figure B-2 PME Earthing System

PNB is another variant of the TN-C-S earthing system and is similar to PME. PNB is

generally only used for supplies to a single customer or a small group of customers, e.g. a

customer supplied from a pole-mounted transformer. The neutral conductor is only earthed

at one point and therefore the transformer and the customer share a common neutral earth.

The earth is located closer to the customer than the transformer and often connected at cutout. The customers electrical installation requirements are exactly the same as for PME.

Refer to Figure B-3.

Figure B-3 PNB Earthing System

UK Power Networks 2014 All rights reserved

23 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

B.5

TT (Terra-Terra)

In a TT earthing system (Figure B-4), the supply is earthed at one or more points and the

supply cable sheaths are connected to it. The customer has an independent earth electrode

to which any exposed metalwork of the customers installation is connected. The earth loop

impedance is relatively high for this arrangement and therefore a residual current device

(RCD) is usually required to protect the customer's installation.

RA

Customer's Earth

Figure B-4 TT Earthing System

Note:

The resistance of this electrode shall be low enough to ensure that under fault conditions

the voltage on exposed metalwork will not exceed 50V.

BS 7671:2008 411.5.3 (ii) states that R A I n 50 V where R A is the customers electrode

resistance and I n is the rated residual operating current of the residual current device

(RCD). BS 7671:2008 also suggests that R A should not exceed 200 otherwise it may

not be stable.

BS 7671:2008 generally requires the use of an RCD for domestic properties, including

installations which utilise a distributors earth terminal; these systems are not TT

systems.

UK Power Networks 2014 All rights reserved

24 of 25

LV Network Earthing Design

Document Number: EDS 06-0016

Version: 5.0

Date: 31/12/2013

Appendix C Typical Electrode Systems

Table C-1 shows various options for achieving earth resistance values.

Note: NetMap also contains earthing maps showing the earthing requirements to achieve

10 and 20 earths (refer to EDS 06-0018).

Table C-1 Earth Electrode Values

Typical Soil

Type/Soil

Resistivity

10 Earth Resistance

(a)

20 Earth Resistance

(b)

(a)

100 Earth Resistance

(b)

(c)

Loam

25m

1 x 2.4m

1 x 2.4m

1 x 1.2m

1 x 2.4m

1 x 1.2m

Chalk

50m

1 x 6.0m

2 x 2.4m

1 x 2.4m

1 x 2.4m

1 x 1.2m

Clay

100m

3 x 4.8m

4 x 2.4m

2 x 4.8m

2 x 2.4m

1 x 1.2m

<150m

4 x 4.8m

7 x 2.4m

2 x 4.8m

3 x 2.4m

1 x 2.4m

<200m

5 x 4.8m

9 x 2.4m

3 x 4.8m

4 x 2.4m

1 x 2.4m

>200m

Site specific design required

500m

Site specific design required

Sand,

Gravel,

Clay

mix

Slate,

Shale,

Rock

1 x 6m or

2 x 2.4m + 1 x 1.2m

Column (a)

denotes

Deep-driven Vertical and Horizontal Electrodes

Column (b)

denotes

Short Vertical and Horizontal Electrodes

Column (c)

denotes

It is assumed that LV PME system additional earths will be installed

horizontally although they can be installed vertically if appropriate.

UK Power Networks 2014 All rights reserved

3m

2.4m

Each short-vertical electrode comprises of 1.2m rods

coupled together to form the final vertical length e.g.

2.4m = 2 x 1.2m. Where there is more than one rod

required, the spacing between them is 3m. The top of

each electrode should be at a minimum depth of 0.6m

below ground level.

1.2 - 6m

5m

Each deep-driven vertical electrode comprises of 1.2m

rods coupled together to form the final vertical length

e.g. 4.8m = 4 x 1.2m. Where there is more than one

rod required, the spacing between them is 5m. The top

of each electrode should be at a minimum depth of

0.6m below ground level.

25 of 25

Potrebbero piacerti anche

- UKPN G81 Design Planning Appendix v1.0 KK 040711Documento20 pagineUKPN G81 Design Planning Appendix v1.0 KK 040711Sandeep LallNessuna valutazione finora

- EPC Services for Power ProjectsDocumento6 pagineEPC Services for Power ProjectsEdzwan RedzaNessuna valutazione finora

- E1 Earthing Manual ScopeDocumento27 pagineE1 Earthing Manual ScopeAndrew1221568Nessuna valutazione finora

- Electrical MetodologyDocumento40 pagineElectrical MetodologyrasoolNessuna valutazione finora

- Relevant Electrical Standards: Issue 2 October 2014Documento8 pagineRelevant Electrical Standards: Issue 2 October 2014zabiruddin786Nessuna valutazione finora

- SubstationsDocumento2 pagineSubstationsmilind199Nessuna valutazione finora

- Instruction Manual: Directional Power Relays BE1-32R and BE1-32O/UDocumento79 pagineInstruction Manual: Directional Power Relays BE1-32R and BE1-32O/UpwmvsiNessuna valutazione finora

- EDS 05-2010 Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFDocumento14 pagineEDS 05-2010 Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFLimuel EspirituNessuna valutazione finora

- General Method For Cable SizingDocumento13 pagineGeneral Method For Cable SizingMuhammad Mahmud100% (1)

- GCS Presentation 24-12-09Documento20 pagineGCS Presentation 24-12-09Rahul Srivastava100% (1)

- ELT - 281 - 3 HVDC Connection of Offshore WindPower Plants (2015)Documento3 pagineELT - 281 - 3 HVDC Connection of Offshore WindPower Plants (2015)Nam Hoai LeNessuna valutazione finora

- Jakson Eminence Private Limited - V5Documento18 pagineJakson Eminence Private Limited - V5Abhinav ChoudharyNessuna valutazione finora

- Conceptual Design and Costing PDFDocumento20 pagineConceptual Design and Costing PDFkrit_kasemNessuna valutazione finora

- PDS BentleyRacewayCableMgmt LTR en HRDocumento2 paginePDS BentleyRacewayCableMgmt LTR en HRbibiana8593Nessuna valutazione finora

- Cable sizing tables for PVC and XLPE insulated conductorsDocumento3 pagineCable sizing tables for PVC and XLPE insulated conductorsLucky MalihanNessuna valutazione finora

- Paddington Zone Substation FireDocumento20 paginePaddington Zone Substation FireAmany HamdyNessuna valutazione finora

- C338_TOBOH PALAPAH Power Survey FormDocumento5 pagineC338_TOBOH PALAPAH Power Survey FormAnton RNessuna valutazione finora

- Part G.9 Appendix I - ADEC ICT GuidelinesDocumento245 paginePart G.9 Appendix I - ADEC ICT GuidelineskRiSHNagiLLoNessuna valutazione finora

- UGC05 - BOQ - STATIONS - MEP Elect - ICTDocumento83 pagineUGC05 - BOQ - STATIONS - MEP Elect - ICTManglesh SinghNessuna valutazione finora

- S-AAA-CAB-ACC-LV-S&I (Rev.0-2019)Documento10 pagineS-AAA-CAB-ACC-LV-S&I (Rev.0-2019)Wael AlmassriNessuna valutazione finora

- IP Telephony Design GuideDocumento12 pagineIP Telephony Design Guideptaka123100% (1)

- iBusway DC Solution Provides 1.6x Power AvailabilityDocumento25 pagineiBusway DC Solution Provides 1.6x Power AvailabilitySargurusivaNessuna valutazione finora

- ZYn 30 TransformerDocumento77 pagineZYn 30 TransformerPhani KumarNessuna valutazione finora

- TG Net Cab 001Documento102 pagineTG Net Cab 001crazy devil100% (1)

- NGR Technical InformationDocumento6 pagineNGR Technical InformationPrabakar PNessuna valutazione finora

- MCCB Selection: SL No. Load in KW Load in KW With 25% Standard MCCBDocumento2 pagineMCCB Selection: SL No. Load in KW Load in KW With 25% Standard MCCBshaikhsajid242Nessuna valutazione finora

- Loading TestDocumento1 paginaLoading TestHtet Mrak AungNessuna valutazione finora

- Substation Tender DocumentDocumento97 pagineSubstation Tender DocumentthibinNessuna valutazione finora

- Siemens Power Engineering Guide 7E 138Documento1 paginaSiemens Power Engineering Guide 7E 138mydearteacherNessuna valutazione finora

- CR4 - Thread - Power Generator SizingDocumento6 pagineCR4 - Thread - Power Generator Sizingjhakg_169712275Nessuna valutazione finora

- Electrical Design Narrative Template PDFDocumento16 pagineElectrical Design Narrative Template PDFdyıldırım_4Nessuna valutazione finora

- Hong Kong EEGS - 2012 Edition - 20110526Documento414 pagineHong Kong EEGS - 2012 Edition - 20110526reilaudio1Nessuna valutazione finora

- DEI - Complete DPR - 50 KWP X 2 - Rooftop Solar PlantDocumento63 pagineDEI - Complete DPR - 50 KWP X 2 - Rooftop Solar PlantPrem Prakash100% (1)

- Tolland Solar Farm AppealDocumento6 pagineTolland Solar Farm AppealMike Rigby100% (1)

- Annexure E - Division of ResponisbilityDocumento4 pagineAnnexure E - Division of Responisbilityshaikhsajid242Nessuna valutazione finora

- Model SS ChecklistDocumento30 pagineModel SS ChecklistAnonymous PeuxGWWy8tNessuna valutazione finora

- Selection Table Type 2 CoordinationDocumento7 pagineSelection Table Type 2 CoordinationVishal Patel100% (1)

- Design Document v2Documento17 pagineDesign Document v2api-533235687Nessuna valutazione finora

- Electromech BOQDocumento3 pagineElectromech BOQCoreg ToNessuna valutazione finora

- ICC Yard - Rathmalana-Model PDFDocumento1 paginaICC Yard - Rathmalana-Model PDFsajeevi piumikaNessuna valutazione finora

- Detailed Syllabu Ssubstaiion DesignDocumento10 pagineDetailed Syllabu Ssubstaiion Designwaqqar shaikhNessuna valutazione finora

- Medium Voltage Switchgear Construction Checklist (Over 500 kVA)Documento6 pagineMedium Voltage Switchgear Construction Checklist (Over 500 kVA)dony ramdhaniNessuna valutazione finora

- Satto Sinha Subject Matter ExpertDocumento3 pagineSatto Sinha Subject Matter ExpertSatto SinhaNessuna valutazione finora

- Aalon Mahmood Sheikh: (Msc. Electrical Engineering)Documento4 pagineAalon Mahmood Sheikh: (Msc. Electrical Engineering)Aalon SheikhNessuna valutazione finora

- Ecs 03 0054 Connection of LV Large Services To Secondary Distribution SubstationsDocumento23 pagineEcs 03 0054 Connection of LV Large Services To Secondary Distribution SubstationsRadulescu AndreiNessuna valutazione finora

- Energy Consumption Calculator Project ReportDocumento70 pagineEnergy Consumption Calculator Project ReportMuhammad Bilal DhudiNessuna valutazione finora

- Electrical Specs KsaDocumento75 pagineElectrical Specs KsaMEP299 MAPUANessuna valutazione finora

- 1 11 FR 11 Substation Lightning ProtectionDocumento12 pagine1 11 FR 11 Substation Lightning Protectionkhaldoun sami100% (1)

- Erection BOQ - SaranDocumento339 pagineErection BOQ - SaranPrasanna kumar subudhiNessuna valutazione finora

- D-AAA-TRAFO-ATR-EXP-11 - 200 (Rev.0-2011)Documento7 pagineD-AAA-TRAFO-ATR-EXP-11 - 200 (Rev.0-2011)virasamirNessuna valutazione finora

- 000 SP EL56 0001 Electrical Design CriteriaDocumento58 pagine000 SP EL56 0001 Electrical Design CriteriaMahmoud ElboraeNessuna valutazione finora

- Senior Electrical Design Engineer CVDocumento3 pagineSenior Electrical Design Engineer CVMohamedNessuna valutazione finora

- Shaft BBT Installation: Method Statement - 002Documento39 pagineShaft BBT Installation: Method Statement - 002Sufiyan KhedekarNessuna valutazione finora

- Technical Spec - Station Lighting-BanharpallifinalDocumento166 pagineTechnical Spec - Station Lighting-BanharpallifinalSreenubabu KandruNessuna valutazione finora

- ENA ER G81 Part 1 Issue 2 Amendment 1 080109Documento19 pagineENA ER G81 Part 1 Issue 2 Amendment 1 080109Tony AppsNessuna valutazione finora

- EDS 06-0017 Customer Installation Earthing DesignDocumento48 pagineEDS 06-0017 Customer Installation Earthing DesignelectworldNessuna valutazione finora

- SD5A - 5 (Draft)Documento23 pagineSD5A - 5 (Draft)jaramib776Nessuna valutazione finora

- Quectel BG96 Hardware Design V1.6Documento73 pagineQuectel BG96 Hardware Design V1.6diemariasNessuna valutazione finora

- Sizing Conductors and Selecting Protection Devices: Power Guide 2009 / Book 04Documento71 pagineSizing Conductors and Selecting Protection Devices: Power Guide 2009 / Book 04zbyszko201234Nessuna valutazione finora

- La Tabella Delle Cadute Di Tensione Unitarie Sui Cavi ElettriciDocumento1 paginaLa Tabella Delle Cadute Di Tensione Unitarie Sui Cavi ElettriciRajendra Prasad ShuklaNessuna valutazione finora

- TN System - Protection Against Indirect Contact - Electrical Installation GuideDocumento4 pagineTN System - Protection Against Indirect Contact - Electrical Installation GuideRajendra Prasad ShuklaNessuna valutazione finora

- MU040 - KRT EngHandbook Lowres PDFDocumento24 pagineMU040 - KRT EngHandbook Lowres PDFRajendra Prasad ShuklaNessuna valutazione finora

- La Tabella Delle Cadute Di Tensione Unitarie Sui Cavi ElettriciDocumento1 paginaLa Tabella Delle Cadute Di Tensione Unitarie Sui Cavi ElettriciRajendra Prasad ShuklaNessuna valutazione finora

- 21 PDFDocumento6 pagine21 PDFRajendra Prasad ShuklaNessuna valutazione finora

- TN System - Protection Against Indirect Contact - Electrical Installation GuideDocumento4 pagineTN System - Protection Against Indirect Contact - Electrical Installation GuideRajendra Prasad ShuklaNessuna valutazione finora

- TN System - Protection Against Indirect Contact - Electrical Installation GuideDocumento4 pagineTN System - Protection Against Indirect Contact - Electrical Installation GuideRajendra Prasad ShuklaNessuna valutazione finora

- Worked Example of Cable Calculation - Electrical Installation GuideDocumento5 pagineWorked Example of Cable Calculation - Electrical Installation GuideRajendra Prasad ShuklaNessuna valutazione finora

- Worked Example of Cable Calculation - Electrical Installation GuideDocumento5 pagineWorked Example of Cable Calculation - Electrical Installation GuideRajendra Prasad ShuklaNessuna valutazione finora

- T: Direct Connection of A With Earth Point (French: Terre)Documento5 pagineT: Direct Connection of A With Earth Point (French: Terre)Rajendra Prasad ShuklaNessuna valutazione finora

- Worked Example of Cable Calculation - Electrical Installation GuideDocumento5 pagineWorked Example of Cable Calculation - Electrical Installation GuideRajendra Prasad ShuklaNessuna valutazione finora

- Short Circuit Current CalculationDocumento7 pagineShort Circuit Current CalculationKalyan RanjanNessuna valutazione finora

- 05 LV CV Iec Single PDFDocumento2 pagine05 LV CV Iec Single PDFRajendra Prasad ShuklaNessuna valutazione finora

- Cable 2011 PDFDocumento32 pagineCable 2011 PDFRajendra Prasad ShuklaNessuna valutazione finora

- Earth Loop Impedance Tests PDFDocumento20 pagineEarth Loop Impedance Tests PDFRajendra Prasad Shukla100% (1)

- ZS Chart - 090315 - Final PDFDocumento2 pagineZS Chart - 090315 - Final PDFRajendra Prasad ShuklaNessuna valutazione finora

- Short Circuit CalculationsDocumento10 pagineShort Circuit CalculationsBalan DanielNessuna valutazione finora

- Polycab HT Cable SpecificationDocumento36 paginePolycab HT Cable Specificationranjish_007100% (2)

- App3 PDFDocumento2 pagineApp3 PDFRajendra Prasad ShuklaNessuna valutazione finora

- Earth Fault Loop Impedance TableDocumento2 pagineEarth Fault Loop Impedance TableRajendra Prasad Shukla50% (2)

- Ze pdf4 PDFDocumento2 pagineZe pdf4 PDFRajendra Prasad ShuklaNessuna valutazione finora

- Code of Practice For Earthing LV Networks and HV Distribution Substations IMP010011Documento89 pagineCode of Practice For Earthing LV Networks and HV Distribution Substations IMP010011SatyaNessuna valutazione finora

- 46 Cable Volatge Drop For Different Size of Cables 1.9.15Documento33 pagine46 Cable Volatge Drop For Different Size of Cables 1.9.15Rajendra Prasad ShuklaNessuna valutazione finora

- Max Earth Fault Loop Impedance Values For Overcurrent ProtectiveDocumento1 paginaMax Earth Fault Loop Impedance Values For Overcurrent ProtectiveRa ArNessuna valutazione finora

- Electrical Cable SizingDocumento21 pagineElectrical Cable SizingKuwat Riyanto100% (7)

- 33 Short Circuit Current at Various Point of Distribution System 1.9.15Documento8 pagine33 Short Circuit Current at Various Point of Distribution System 1.9.15Rajendra Prasad ShuklaNessuna valutazione finora

- EDS 01-0045 Overhead Line Ratings PDFDocumento10 pagineEDS 01-0045 Overhead Line Ratings PDFRajendra Prasad ShuklaNessuna valutazione finora

- Broken Earth Neutral Faults in Distribution Systems With Traffic Signal LoadsDocumento13 pagineBroken Earth Neutral Faults in Distribution Systems With Traffic Signal LoadsRajendra Prasad ShuklaNessuna valutazione finora

- Importance of Proper Grounding in Power SystemsDocumento24 pagineImportance of Proper Grounding in Power SystemsRajendra Prasad ShuklaNessuna valutazione finora

- Unit 2: Installation Inspection, Testing and Commissioning: Sample Questions/model AnswersDocumento10 pagineUnit 2: Installation Inspection, Testing and Commissioning: Sample Questions/model Answersashraf.rahim139Nessuna valutazione finora

- AUH ElecWiringRegs2007Rev01Documento240 pagineAUH ElecWiringRegs2007Rev01Muhammad RazaNessuna valutazione finora

- 2 Pole: 1 Phase IP21 or IP23Documento2 pagine2 Pole: 1 Phase IP21 or IP23Brendan StackNessuna valutazione finora

- CI Contractor Series 16-2Documento1 paginaCI Contractor Series 16-2Jun SilabanNessuna valutazione finora

- Cable Tray MTO - WBS-1-0001Documento2 pagineCable Tray MTO - WBS-1-0001aateka02Nessuna valutazione finora

- The MB PanelDocumento2 pagineThe MB PanelDevendra PhatakNessuna valutazione finora

- Preview Only: Malaysian StandardDocumento5 paginePreview Only: Malaysian StandardAndy ChoongNessuna valutazione finora

- Siemens Sirius MigrationDocumento6 pagineSiemens Sirius MigrationJsgNessuna valutazione finora

- PVC Insulation Copper Single-core Non-armoured Current CapacitiesDocumento1 paginaPVC Insulation Copper Single-core Non-armoured Current CapacitiesGoh Zai PengNessuna valutazione finora

- 2 in 1 Out Ablon SolarDocumento3 pagine2 in 1 Out Ablon SolarVirat PatelNessuna valutazione finora

- B15-ECU-70-SP-003-0 - Wiring MethodsDocumento13 pagineB15-ECU-70-SP-003-0 - Wiring Methodsfran.obando1332Nessuna valutazione finora

- Electrical Estimate TemplateDocumento5 pagineElectrical Estimate Templatedanny hugNessuna valutazione finora

- LK Distribution Board enDocumento1 paginaLK Distribution Board enjojokawayNessuna valutazione finora

- Camus 2Documento1 paginaCamus 2shuckss taloNessuna valutazione finora

- bs7671 Meiwcv2Documento3 paginebs7671 Meiwcv2James SmithNessuna valutazione finora

- Power Distribution StandardsV1Documento35 paginePower Distribution StandardsV1ajalbornozNessuna valutazione finora

- Updated Register of Licensed Electrical ContractorsDocumento63 pagineUpdated Register of Licensed Electrical ContractorsmachariakaruriNessuna valutazione finora

- ASCO Series 300 D-Design 30-230A, Oper Manual, 381333-228Documento20 pagineASCO Series 300 D-Design 30-230A, Oper Manual, 381333-228Kevin DampmanNessuna valutazione finora

- Electricity ReportDocumento42 pagineElectricity ReportNik TahNessuna valutazione finora

- 2023-Apr 10101NSWHDocumento659 pagine2023-Apr 10101NSWHArie amNessuna valutazione finora

- Siemens - LXD63B600 600a Lxd6-ADocumento1 paginaSiemens - LXD63B600 600a Lxd6-AJosé Antonio Mayol Del VecchioNessuna valutazione finora

- Insulation Test ReportDocumento28 pagineInsulation Test ReportMARE MARENessuna valutazione finora

- E6855 - Add Rev01Documento8 pagineE6855 - Add Rev01chris110Nessuna valutazione finora

- Kitchen Electrical Layout NotesDocumento1 paginaKitchen Electrical Layout NotesNORTSEN ALBERTNessuna valutazione finora

- 1PX - Installation Manual Single PhaseDocumento2 pagine1PX - Installation Manual Single PhaseKD7 ITSolutionNessuna valutazione finora

- Making Such A Change To Assure Type 2 Performance. Please Consult SiemensDocumento1 paginaMaking Such A Change To Assure Type 2 Performance. Please Consult SiemensPawan kumarNessuna valutazione finora

- Eim Diagnostic1Documento2 pagineEim Diagnostic1Michael Angelo ChuaNessuna valutazione finora

- GE 15312 Sun Smart ManualDocumento4 pagineGE 15312 Sun Smart ManualScottstpNessuna valutazione finora

- 7Documento8 pagine7Ibrar YousafNessuna valutazione finora

- Dry-Single Line Diagram-Ci-Sld-Lp-106Documento1 paginaDry-Single Line Diagram-Ci-Sld-Lp-106Ahmed BoraeyNessuna valutazione finora