Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Interpretation of An Indication

Caricato da

Ashfaq KhanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Interpretation of An Indication

Caricato da

Ashfaq KhanCopyright:

Formati disponibili

PT

LIQUID PENETRANT TESTING

IQIS

INTERPRETATION OF AN INDICATION

PT L II M05

Purpose: To locate and evaluate indications caused by surface discontinuities.

Interpretation of an indication is determining the cause of the indication.

After the proper development time is over, inspection is carried out to look for indications formed due

to presence of surface discontinuities. The terms interpretation and evaluation are often confused.

Actually, the terms refer to two entirely different steps in the testing process. The success and

reliability of the interpretation and evaluation of liquid penetrant test indications is dependent on the

thoroughness, training and dedication of the technician. The liquid penetrant test is not a method by

which a test object is processed through a machine that separates the good test object from the bad.

Testing personnel are required to carefully process each test object, interpret indications and then

evaluate the indication to the acceptance standard referenced or given in the procedure they are

performing.

Interpretation: To interpret an indication is to decide what condition caused it. The word indication

refers to the presence of any penetrant visible in the developer layer on the test surface. These

indications are typically classified into three categories:

1. FALSE INDICATIONS

2. NON RELEVANT INDICATIONS

3. RELEVANT INDICATIONS

False Indications: These indications are typically caused by entrapment of penetrant in some

foreign matter on the job surface such as rust, paint boundary, lint, etc., which remains on the job

surface due to improper pre-cleaning. False indications could also be caused by the inadvertent

presence of some penetrant on the job surface caused by transfer of some penetrant from the hand

or cloth of an operator.

If any indication is suspected to be a false indication, the part/area should be thoroughly cleaned and

the part/area reprocessed (i.e. retested) to confirm whether it is a False indication or a True

indication.

Non-Relevant Indications: These indications are a type of true indication caused by physical

entrapment of penetrant in a geometrical feature of the job such as hole, sharp corner, surface

Prepared by: ASHFAQ A. KHAN

ASNT Level III, CSWIP 3.1, BARC RT level II

khanashfaq@consultant.com Revision #: 00

Page #: 1

ashfaqkhannde@gmail.com

Mobile#: +91-8108576465

PT

LIQUID PENETRANT TESTING

IQIS

INTERPRETATION OF AN INDICATION

PT L II M05

roughness, press fit joint, thread bottom, etc. Some codes also refer to very small indications, smaller

than a specified size, as non-relevant indication.

If any indication is suspected to be a non-relevant indication, the design of the job should be reviewed

and the job reprocessed and retested for confirmation, when required.

Relevant Indications: These indications are a type of true indication caused by physical

entrapment of penetrant inside a surface discontinuity. One method of determining if an indication is

relevant is to dampen a cotton swab with solvent and gently wipe the indication off. If the indication

reappears, it is a relevant indication. This technique is known as the bleed back evaluation technique.

The inspector uses his judgment to classify the indication and assess it's relevance. The

interpretation should be made according to the characteristics of the indication.

A. Location

E. Brightness

B. Shape

F. Sharpness

C. Size

G. Persistence

D. Color

H. The amount of time the indication takes to form.

Watching the indication form immediately after developer application and awareness of the type of

discontinuities that may be encountered beforehand is extremely helpful. Remember, the indication is

not the same size as the discontinuity. The developer will magnify the discontinuity size to make it

more visible to the naked eye for easier detection. The penetrant bleeds out into the developer

throughout the development time. Therefore, the longer the development time used to make an

evaluation, the larger the indication will be. Timing of when to make an evaluation of an indication

becomes very important when the indication is on the borderline of acceptance or rejection.

NOTE: Acceptance criteria will specify the maximum allowable indication size and not the

discontinuity size.

When the technician determines that the indication is relevant, it must then be evaluated to the

acceptance criteria. The relevant indications are further analyzed to determine their significance with

respect to the use of the job in service. The size of indication is measured and the indication is

classified as Linear or Rounded - based to their length to width (L/ W) ratio.

Usually the indication is classified as linear when the L 3W.

Prepared by: ASHFAQ A. KHAN

ASNT Level III, CSWIP 3.1, BARC RT level II

khanashfaq@consultant.com Revision #: 00

Page #: 2

ashfaqkhannde@gmail.com

Mobile#: +91-8108576465

Potrebbero piacerti anche

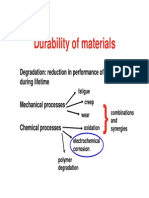

- ME2101E - Design Against Fatigue - BWDocumento26 pagineME2101E - Design Against Fatigue - BWZhang DunJieNessuna valutazione finora

- Modern Methods of Industrial Radiology - A Rev1ewDocumento19 pagineModern Methods of Industrial Radiology - A Rev1ewphanthanhhungNessuna valutazione finora

- Corrosion Cotrol ManualDocumento36 pagineCorrosion Cotrol ManualNwosu AugustineNessuna valutazione finora

- High Entropy Alloys A Critical Assessment of Their Founding Principles and Future ProspectsDocumento21 pagineHigh Entropy Alloys A Critical Assessment of Their Founding Principles and Future ProspectsFeng ZhuNessuna valutazione finora

- Tutorial Answers - Mechanical Behaviour of MaterialsDocumento2 pagineTutorial Answers - Mechanical Behaviour of MaterialsbananaNessuna valutazione finora

- MSE 280: Introduction To Engineering MaterialsDocumento44 pagineMSE 280: Introduction To Engineering Materialsjains.boyNessuna valutazione finora

- 4 Unit - Heat Treatment of SteelsDocumento72 pagine4 Unit - Heat Treatment of SteelsAnway WalkeNessuna valutazione finora

- 2 - Mechanical Properties-StudentDocumento119 pagine2 - Mechanical Properties-StudentNishant DeyNessuna valutazione finora

- TLL-Welding ImperfectionDocumento43 pagineTLL-Welding ImperfectionCanis Guk100% (1)

- Properties of Engineering Materials Lesson 3 (I)Documento11 pagineProperties of Engineering Materials Lesson 3 (I)Douglas Kufre-Abasi GilbertNessuna valutazione finora

- Elastic/Plastic Deformation (Chapter 6canggaan)Documento11 pagineElastic/Plastic Deformation (Chapter 6canggaan)qc12345Nessuna valutazione finora

- Foundations of Materials Science and Engineering 5th Edition Smith Solutions ManualDocumento79 pagineFoundations of Materials Science and Engineering 5th Edition Smith Solutions Manualdextrermachete4amgqgNessuna valutazione finora

- Physical Metallurgy-18 Heat Treatment of SteelDocumento7 paginePhysical Metallurgy-18 Heat Treatment of SteelDSGNessuna valutazione finora

- Chapter11 Mechanical BehaviorDocumento31 pagineChapter11 Mechanical BehaviorDheivendranRamiah100% (1)

- FM (MEE84) Module-1 PresentationDocumento29 pagineFM (MEE84) Module-1 Presentationsonic somannaNessuna valutazione finora

- Lecture Ccorrosionorrosion PDFDocumento28 pagineLecture Ccorrosionorrosion PDFJonathan DaviesNessuna valutazione finora

- How To Use Damage MechanicsDocumento13 pagineHow To Use Damage MechanicsAnthony GómezNessuna valutazione finora

- Usnrc Tech Guide On NdeDocumento355 pagineUsnrc Tech Guide On Ndeniraj_hwb100% (1)

- Deformation & StrengthDocumento35 pagineDeformation & StrengthcolorofstoneNessuna valutazione finora

- Dislocations and Strengthening Mechanisms: Module-6Documento29 pagineDislocations and Strengthening Mechanisms: Module-6Baskar ManiNessuna valutazione finora

- Introduction To Materials: Prof. H. K. KhairaDocumento75 pagineIntroduction To Materials: Prof. H. K. KhairaDhanush NairNessuna valutazione finora

- Welding Jurnal 1982 07 s212Documento10 pagineWelding Jurnal 1982 07 s212Ashley JacksonNessuna valutazione finora

- Plastic Deformation of MetalsDocumento42 paginePlastic Deformation of MetalsNaresh DeshpandeNessuna valutazione finora

- Module 6 CDocumento26 pagineModule 6 CAlejandro RodríguezNessuna valutazione finora

- Bulk Deformation ProcessesDocumento41 pagineBulk Deformation ProcessesAbdullahNessuna valutazione finora

- AE6007 Fatigue and Fracture PDFDocumento53 pagineAE6007 Fatigue and Fracture PDFJustin RajaNessuna valutazione finora

- Microstructure Properties: I Sensitivity of Properties To Thermal History?Documento35 pagineMicrostructure Properties: I Sensitivity of Properties To Thermal History?MadhusudanNessuna valutazione finora

- Crystal Imperfections - Point DefectsDocumento21 pagineCrystal Imperfections - Point DefectsAbhijeet Singh KatiyarNessuna valutazione finora

- Physical Metallurgy M1 PDFDocumento21 paginePhysical Metallurgy M1 PDFAnca ElenaNessuna valutazione finora

- COE10102, Forms of CorrosionDocumento60 pagineCOE10102, Forms of CorrosionامينNessuna valutazione finora

- L02 Introduction To Materials Science and EngineeringDocumento14 pagineL02 Introduction To Materials Science and EngineeringVivek vermaNessuna valutazione finora

- GE 201/203 Introduction To Materials Science and EngineeringDocumento21 pagineGE 201/203 Introduction To Materials Science and EngineeringVivek vermaNessuna valutazione finora

- Mechanical Behaviour of MaterialsDocumento10 pagineMechanical Behaviour of Materialsaditya2092Nessuna valutazione finora

- Chapter 8: Failure: Issues To Address..Documento27 pagineChapter 8: Failure: Issues To Address..Rowen PratherNessuna valutazione finora

- Creep & Superplasticity PDFDocumento54 pagineCreep & Superplasticity PDFWahab AhmedNessuna valutazione finora

- Karakteristik Material 1Documento37 pagineKarakteristik Material 1Rony AgistaNessuna valutazione finora

- TEM Lecture CrystallineDocumento30 pagineTEM Lecture CrystallineSyed Abdul AhadNessuna valutazione finora

- MT 03 - Mechanical Properties and Tests, A-Z Abbrev (Tinius Olsen - Kul 1)Documento25 pagineMT 03 - Mechanical Properties and Tests, A-Z Abbrev (Tinius Olsen - Kul 1)zingerNessuna valutazione finora

- Bonding and Properties 2018 PDFDocumento31 pagineBonding and Properties 2018 PDFJackNessuna valutazione finora

- 06-Fatigue and Creep of Materials - F17 PDFDocumento23 pagine06-Fatigue and Creep of Materials - F17 PDFsabavoonNessuna valutazione finora

- Understanding of TWI J-R CurvesDocumento21 pagineUnderstanding of TWI J-R CurvespcastlesmithNessuna valutazione finora

- 8403 PDF ch15Documento39 pagine8403 PDF ch15vyhtran4731Nessuna valutazione finora

- Chapter 17 - CorrosionDocumento11 pagineChapter 17 - CorrosionmuthuhcuNessuna valutazione finora

- Welding Troubleshooting & Remedies - pdf1 PDFDocumento2 pagineWelding Troubleshooting & Remedies - pdf1 PDFAAISATNessuna valutazione finora

- ENGR 313 - Chapter 4 - DislocationsDocumento48 pagineENGR 313 - Chapter 4 - DislocationsMelissa LaraNessuna valutazione finora

- SolidificationDocumento10 pagineSolidificationAnonymous RY3dAWN9o100% (1)

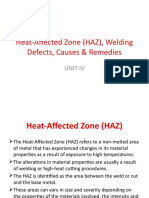

- 9-Haz, Welding Defecs, Causes and RemdiesDocumento24 pagine9-Haz, Welding Defecs, Causes and RemdiesRamu Amara100% (1)

- Introduction To Fracture MechanicsDocumento22 pagineIntroduction To Fracture Mechanicsrpadhra8803Nessuna valutazione finora

- Weld ImperfectionsDocumento11 pagineWeld Imperfections0502raviNessuna valutazione finora

- The National Shipbuilding Research Program: Carbon Equivalent (PCM) Limits For Thick Carbon and Low Alloy SteelsDocumento81 pagineThe National Shipbuilding Research Program: Carbon Equivalent (PCM) Limits For Thick Carbon and Low Alloy SteelsiulianticNessuna valutazione finora

- Recovery, Recrystallization, and Grain GrowthDocumento12 pagineRecovery, Recrystallization, and Grain GrowthstevenwhittlNessuna valutazione finora

- @standardsharin - ASME STP-NU-044-2011-12Documento62 pagine@standardsharin - ASME STP-NU-044-2011-12EricNessuna valutazione finora

- Chapter 9e FatigueDocumento20 pagineChapter 9e FatigueavenashaNessuna valutazione finora

- MODULE 4 - Introduction To EbsdDocumento8 pagineMODULE 4 - Introduction To EbsdOmar VillanuevaNessuna valutazione finora

- Lecture 1427492067Documento356 pagineLecture 1427492067Abhilash SahooNessuna valutazione finora

- Toughness TestDocumento25 pagineToughness TestNehaJainNessuna valutazione finora

- Procedure For Visual Examination Per Tech Pub T9074-AS-GIB-010/271Documento14 pagineProcedure For Visual Examination Per Tech Pub T9074-AS-GIB-010/271EdAlmNessuna valutazione finora

- BSBPMG505ADocumento9 pagineBSBPMG505ADavid Mark100% (2)

- QC Inspection and Test PlanDocumento9 pagineQC Inspection and Test PlanGK VISWANATH100% (3)

- QC Inspection and Test Plan ITPDocumento9 pagineQC Inspection and Test Plan ITPArfanAli100% (1)

- MPT Mandatory Appendix 6Documento2 pagineMPT Mandatory Appendix 6Ashfaq Khan100% (1)

- IQIS Provides Following Services NDT ServicesDocumento1 paginaIQIS Provides Following Services NDT ServicesAshfaq KhanNessuna valutazione finora

- LPT Article 6Documento5 pagineLPT Article 6Ashfaq KhanNessuna valutazione finora

- ASME SecDocumento5 pagineASME SecAshfaq KhanNessuna valutazione finora

- Introduction To Magnetic Particle Testing: Basic ConceptsDocumento3 pagineIntroduction To Magnetic Particle Testing: Basic ConceptsAshfaq KhanNessuna valutazione finora

- Specifi Cation FortheDocumento3 pagineSpecifi Cation FortheAshfaq KhanNessuna valutazione finora

- The Way To Improvise, Extemporize, Deliver Offhand (A Speech) To Become A Man, Reachthe Age ofDocumento3 pagineThe Way To Improvise, Extemporize, Deliver Offhand (A Speech) To Become A Man, Reachthe Age ofAshfaq KhanNessuna valutazione finora

- Ultrasonic Testing: by Geetanjali Sharma Devendra Singh Amit Kumar JhaDocumento55 pagineUltrasonic Testing: by Geetanjali Sharma Devendra Singh Amit Kumar Jhajhaamit4100% (2)

- Welder, Welding Operator, or Tack Welder Qualification Test RecordDocumento1 paginaWelder, Welding Operator, or Tack Welder Qualification Test RecordAshfaq KhanNessuna valutazione finora

- Welding OF Aluminiu MDocumento1 paginaWelding OF Aluminiu MAshfaq KhanNessuna valutazione finora

- Radiation Protection and Laboratory TechniquesDocumento30 pagineRadiation Protection and Laboratory TechniquesAshfaq KhanNessuna valutazione finora

- Piping Inspection SystemDocumento30 paginePiping Inspection SystemAshfaq KhanNessuna valutazione finora

- The Hazards of Dead LegsDocumento1 paginaThe Hazards of Dead LegsAshfaq KhanNessuna valutazione finora

- Basic Principles of Ultrasonic TestingDocumento42 pagineBasic Principles of Ultrasonic TestingyoungfpNessuna valutazione finora

- Ultrasonic Testing: by Geetanjali Sharma Devendra Singh Amit Kumar JhaDocumento55 pagineUltrasonic Testing: by Geetanjali Sharma Devendra Singh Amit Kumar Jhajhaamit4100% (2)

- Misconceptions About ISLAMDocumento2 pagineMisconceptions About ISLAMAshfaq KhanNessuna valutazione finora

- Industrial Quality and Inspection Services: About UsDocumento9 pagineIndustrial Quality and Inspection Services: About UsAshfaq KhanNessuna valutazione finora

- Vfd-E: Parameter ManualDocumento26 pagineVfd-E: Parameter ManualMohamed ElsayedNessuna valutazione finora

- Masters Thesis by Evan O'Brien Final Draft PDFDocumento184 pagineMasters Thesis by Evan O'Brien Final Draft PDFkatfy1Nessuna valutazione finora

- Chapter11 - SEISMICALLY ISOLATED STRUCTURESDocumento48 pagineChapter11 - SEISMICALLY ISOLATED STRUCTUREScfajardo16Nessuna valutazione finora

- AnswerDocumento2 pagineAnswerdahliaNessuna valutazione finora

- Flexiweigh Balance AccuracyDocumento6 pagineFlexiweigh Balance AccuracyArfan SubhaniNessuna valutazione finora

- Chapter 3 Haemoglobin Pattern Analysis: 3.1. Chromatographic Methods (For Hba Determination)Documento27 pagineChapter 3 Haemoglobin Pattern Analysis: 3.1. Chromatographic Methods (For Hba Determination)সোমনাথ মহাপাত্রNessuna valutazione finora

- By Dr. Gamal Helmy, PH.D., P.EDocumento43 pagineBy Dr. Gamal Helmy, PH.D., P.EAhmed ArafaNessuna valutazione finora

- Spe 84497 MS PDFDocumento11 pagineSpe 84497 MS PDFShiyeng CharmaineNessuna valutazione finora

- Well AbandonmentDocumento30 pagineWell Abandonmentsmithyry2014Nessuna valutazione finora

- Laminar Imperfections in Strip Area Adjacent To Welded JointDocumento1 paginaLaminar Imperfections in Strip Area Adjacent To Welded Jointqc_531040655Nessuna valutazione finora

- Large Hadron ColliderDocumento23 pagineLarge Hadron ColliderPrakhar AgrawalNessuna valutazione finora

- Celesta Ire 2012 CatalogDocumento96 pagineCelesta Ire 2012 Catalogjsom1021Nessuna valutazione finora

- Hydrology EvaporationDocumento21 pagineHydrology EvaporationMr. Mark B.Nessuna valutazione finora

- U0/U U Is The Power Frequency Voltage Between Phase and Earth (V RMS)Documento3 pagineU0/U U Is The Power Frequency Voltage Between Phase and Earth (V RMS)ShashidharNessuna valutazione finora

- K To 12 Grade 8 Math Module Part 2Documento90 pagineK To 12 Grade 8 Math Module Part 2Drei78% (9)

- Microbiological Precipitation of CaCO3 1999 PDFDocumento9 pagineMicrobiological Precipitation of CaCO3 1999 PDFmsohailashrafNessuna valutazione finora

- Interpolation and The Lagrange PolynomialDocumento9 pagineInterpolation and The Lagrange PolynomialEmmanuel Jerome TagaroNessuna valutazione finora

- 841 Atprime2Documento4 pagine841 Atprime2uzzy2Nessuna valutazione finora

- USGS Design Maps Summary Report Universal Hollywood Site Class CDocumento7 pagineUSGS Design Maps Summary Report Universal Hollywood Site Class CDan Dela Peña0% (1)

- 9701 s09 QP 32 PDFDocumento12 pagine9701 s09 QP 32 PDFtess_15Nessuna valutazione finora

- 1st Periodical Test in English 2019-2020Documento10 pagine1st Periodical Test in English 2019-2020ginadel timanNessuna valutazione finora

- For ECT & ECE Board ExamDocumento60 pagineFor ECT & ECE Board ExamRalph Alvin Quizon100% (2)

- OPSS 1202 Nov08Documento10 pagineOPSS 1202 Nov08Safa GhasemkhaniNessuna valutazione finora

- Matrix InverseDocumento2 pagineMatrix InverseComFnoNessuna valutazione finora

- MeasurementDocumento55 pagineMeasurementAna Mae AbiertasNessuna valutazione finora

- Lec5 PDFDocumento15 pagineLec5 PDFRaviNessuna valutazione finora

- T 7 OxDocumento2 pagineT 7 OxMiguel Dominguez de GarcíaNessuna valutazione finora

- A.C. Frequency Sonometer by MR - Charis Israel AnchaDocumento3 pagineA.C. Frequency Sonometer by MR - Charis Israel AnchaCharis Israel AnchaNessuna valutazione finora

- DQ1A SolutionDocumento2 pagineDQ1A SolutionmeepmeeNessuna valutazione finora

- Mental Math: How to Develop a Mind for Numbers, Rapid Calculations and Creative Math Tricks (Including Special Speed Math for SAT, GMAT and GRE Students)Da EverandMental Math: How to Develop a Mind for Numbers, Rapid Calculations and Creative Math Tricks (Including Special Speed Math for SAT, GMAT and GRE Students)Nessuna valutazione finora

- Quantum Physics: A Beginners Guide to How Quantum Physics Affects Everything around UsDa EverandQuantum Physics: A Beginners Guide to How Quantum Physics Affects Everything around UsValutazione: 4.5 su 5 stelle4.5/5 (3)

- Basic Math & Pre-Algebra Workbook For Dummies with Online PracticeDa EverandBasic Math & Pre-Algebra Workbook For Dummies with Online PracticeValutazione: 4 su 5 stelle4/5 (2)

- Build a Mathematical Mind - Even If You Think You Can't Have One: Become a Pattern Detective. Boost Your Critical and Logical Thinking Skills.Da EverandBuild a Mathematical Mind - Even If You Think You Can't Have One: Become a Pattern Detective. Boost Your Critical and Logical Thinking Skills.Valutazione: 5 su 5 stelle5/5 (1)

- Images of Mathematics Viewed Through Number, Algebra, and GeometryDa EverandImages of Mathematics Viewed Through Number, Algebra, and GeometryNessuna valutazione finora

- A Mathematician's Lament: How School Cheats Us Out of Our Most Fascinating and Imaginative Art FormDa EverandA Mathematician's Lament: How School Cheats Us Out of Our Most Fascinating and Imaginative Art FormValutazione: 5 su 5 stelle5/5 (5)

- Limitless Mind: Learn, Lead, and Live Without BarriersDa EverandLimitless Mind: Learn, Lead, and Live Without BarriersValutazione: 4 su 5 stelle4/5 (6)

- Math Workshop, Grade K: A Framework for Guided Math and Independent PracticeDa EverandMath Workshop, Grade K: A Framework for Guided Math and Independent PracticeValutazione: 5 su 5 stelle5/5 (1)

- ParaPro Assessment Preparation 2023-2024: Study Guide with 300 Practice Questions and Answers for the ETS Praxis Test (Paraprofessional Exam Prep)Da EverandParaPro Assessment Preparation 2023-2024: Study Guide with 300 Practice Questions and Answers for the ETS Praxis Test (Paraprofessional Exam Prep)Nessuna valutazione finora

- Mental Math Secrets - How To Be a Human CalculatorDa EverandMental Math Secrets - How To Be a Human CalculatorValutazione: 5 su 5 stelle5/5 (3)

- Fluent in 3 Months: How Anyone at Any Age Can Learn to Speak Any Language from Anywhere in the WorldDa EverandFluent in 3 Months: How Anyone at Any Age Can Learn to Speak Any Language from Anywhere in the WorldValutazione: 3 su 5 stelle3/5 (80)

- Interactive Math Notebook Resource Book, Grade 6Da EverandInteractive Math Notebook Resource Book, Grade 6Nessuna valutazione finora