Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Exp 6

Caricato da

Aryan Kumar0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

7 visualizzazioni3 paginerwt5we

Titolo originale

exp6

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentorwt5we

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

7 visualizzazioni3 pagineExp 6

Caricato da

Aryan Kumarrwt5we

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

Aim: Dismantle solenoid and self starter.

Clean and inspect all

components. Reassemble,test and record preocedure.

Material required: - screw driver ,ring spanner ,soldering rod,

spanner, wire brush,multimeter.

Theory: What to Check:

1. Check if the battery has some charged. Measure the voltage

across the terminals, it should be approximately 12.5 volts. If not

charge it first with an external charger. If you have a hydrometer,

measure the specific gravity of each cells, it should be around

1.25 . If not charge it. After chargin,. installed it back. Ttest it

again but this time you should have a tester to measure the

voltage of the battery as you switch on the ignition key switch. If

the voltage that you read drops dramatically as you start the

engine, then we could say that we have a problem with the

battery or it did not charge at all for some reason.

2. Check the wiring for some loose connection. Check also the

battery terminals and the negative or ground terminals. You might

need to clean and tighten the connection of terminals or may be it

is better to replace some of the burnt wires.

3. Check if there is a positive voltage in the control wire terminal

of the solenoid, that is going to the key switch or relay when the

ignition switch is activated.( referring to starter parts figure ). If

no voltage then you have a problem in the electrical circuit of the

vehicle. May be busted fuse, key switch or some loose connection.

4. If there is voltage and still problem persist , may be its time to

remove the starter assembly and open it to see if there is a

problem inside. Most likely the problem is in the carbon brush, the

solenoid or the motor it self. So you have to open and see for your

self.

Steps to open the starter:

1. You have to remove the starter from the engine. Be sure to

remove one of the terminal of the battery to avoid getting

electrocuted or short circuit of the battery. Remove all the wires

connected to the starter assembly and remove it to its mounting.

2 . Make some markings on the motor. One at the upper cover

where the carbon brush holder is attached and one at the bottom

part. The purpose of our marking is to avoid confusion when it is

time to re- assemble the starter. Make sure that the marking will

not be erased by all means or we will be at lost.

3. Remove all the screw and bolts on the upper cover including

small screw for carbon holder. Slowly remove the upper cover.

Remove the two carbon brush attached to the stator assembly.

Make sure to put a marking on the carbon brush holder ( see

picture below ). You can now slowly remove the stator assembly.

After that you may end up like in the figure ( open starter ).

4. Now you can thoroughly inspect all the parts you see. In most

cases if there is a problem you can see it as soon as you open it.

Some problems that you may encounter are some burned part,

damage commutator, bearings or bushing worn out, sometimes it

only needs some cleaning due to carbon deposits that hinders the

performance of the starter, and already short carbon brushes.

Replace the carbon brush if necessary, you may need to solder

some of the connections.

Check the commutator for damage or worn out. If it is good then

just clean it. You can have a fine sand paper to help you remove

some stains in the commutator. It is best if you have compressed

air to blow away the carbon dust deposit in the stator and

armature assembly area or use some kind of soft brush to remove

those sticky sludge for all corners of the field coils.

5. If everything is clean and good assemble it back. Remember

there are marking so you wont get lost.

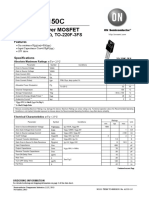

6. In our case we need to replace the solenoid assembly because

its been damage for some reason. Be very careful on choosing the

right solenoid for your starter. There are so many types or kinds

of solenoid out in the market. Sometimes you have to look out for

the model of the solenoid written on the body of the solenoid. In

some instances you need to bring the old one to compare it as

you try to select which one is the correct one. Here are some

samples of solenoid you can find in the market. Besides the

physical appearance you have to consider the voltage of the coil.

It is usually 12 volts or 24 volts.

In some cases you will find it hard to loosen the screws of the

mounting of the solenoid because of the rust and dirt in the

screw.All you have to do is spray a little bit of penetrating oil and

let it be for couple of minutes and try again. If still not successful

then you have to apply some force in it by using some kind of

chisel and try to hit the bolt or screw head counter clockwise with

the help of a small hammer. Not so hard you might end up

damaging the mounting. But still you can not remove it then you

will just have to try to grind the head of the bolt and pull the

solenoid assembly. This time you have to replace the bolt with

new one.

After you installed the solenoid assembly, we are now to test the

starter. Follow the wiring in the figure below. After connecting the

wiring of the two big terminals in the picture and control wire to

the coil on the left side. Connect also the negative terminal of the

battery to the body of the starter assembly. We can now finally

test it, just take the control wire and jog it to the positive side of

the battery. It should push the bendix gear and rotate the gear. Be

sure to hold it firmly when you try to start the starter. If every

thing is good then you can install it back to the engine.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Simplex Motion Servo Cncmillbf20Documento19 pagineSimplex Motion Servo Cncmillbf20Tomas LopezNessuna valutazione finora

- Testing & Commissioning Procedure For Earthing System - Method StatementDocumento3 pagineTesting & Commissioning Procedure For Earthing System - Method Statementvin ssNessuna valutazione finora

- IEEE STD 4-1995 Standard Techniques For High Voltage Testing PDFDocumento138 pagineIEEE STD 4-1995 Standard Techniques For High Voltage Testing PDFJohn PaulNessuna valutazione finora

- UPS Fundamentals DMRCDocumento34 pagineUPS Fundamentals DMRCash_jediNessuna valutazione finora

- Viking XL Service Manual Incl ACUDocumento94 pagineViking XL Service Manual Incl ACUMichal Szymanski100% (1)

- Baldor - Large Frame AC Induction MotorsDocumento55 pagineBaldor - Large Frame AC Induction MotorsscottNessuna valutazione finora

- Konica-Minolta Bizhub 364e Trouble Error CodesDocumento32 pagineKonica-Minolta Bizhub 364e Trouble Error CodesNafeesAhmad100% (1)

- Aim: Dismantle Fuel Injector of Adiesel Engine .Clean and Inspect All Component .Carry OutDocumento2 pagineAim: Dismantle Fuel Injector of Adiesel Engine .Clean and Inspect All Component .Carry OutAryan KumarNessuna valutazione finora

- Electrical Generator Direct Current CommutatorDocumento3 pagineElectrical Generator Direct Current CommutatorAryan KumarNessuna valutazione finora

- Exp 5Documento6 pagineExp 5Aryan KumarNessuna valutazione finora

- 19 Mar Atul Bhatnagar BioDocumento1 pagina19 Mar Atul Bhatnagar BioAryan KumarNessuna valutazione finora

- Basic Equipment: AgilentDocumento4 pagineBasic Equipment: AgilentAryan KumarNessuna valutazione finora

- Vishwanath ComputationDocumento14 pagineVishwanath ComputationAryan KumarNessuna valutazione finora

- Unified Communication Federation: by Name of Student: Roll NoDocumento4 pagineUnified Communication Federation: by Name of Student: Roll NoAryan KumarNessuna valutazione finora

- Lingaya'S University Faridabad Date Sheet B.Tech Year (Semester-) End Semester Examination, December, 2015Documento2 pagineLingaya'S University Faridabad Date Sheet B.Tech Year (Semester-) End Semester Examination, December, 2015Aryan KumarNessuna valutazione finora

- Punjab Technical University: Special Purpose VehiclesDocumento2 paginePunjab Technical University: Special Purpose VehiclesAryan KumarNessuna valutazione finora

- Registration Form For Compartment Exam 2015Documento1 paginaRegistration Form For Compartment Exam 2015Aryan KumarNessuna valutazione finora

- Lingaya'S University Date Sheet B.TECH 2nd, 3rd & 4th Year (Reappear) End Semester Examination - June, 2015Documento3 pagineLingaya'S University Date Sheet B.TECH 2nd, 3rd & 4th Year (Reappear) End Semester Examination - June, 2015Aryan KumarNessuna valutazione finora

- Lingaya'S University Faridabad Date Sheet B.Tech Year (Semester-) End Semester Examination, May-June 2015Documento1 paginaLingaya'S University Faridabad Date Sheet B.Tech Year (Semester-) End Semester Examination, May-June 2015Aryan KumarNessuna valutazione finora

- B.tech. Syllabus AE With Short NotesDocumento64 pagineB.tech. Syllabus AE With Short NotesAryan KumarNessuna valutazione finora

- Chapter 9:: Diodes and Diode CircuitsDocumento32 pagineChapter 9:: Diodes and Diode CircuitsAryan KumarNessuna valutazione finora

- Aim: Dismantle Fuel Injector of Adiesel Engine .Clean and Inspect All Component .Carry OutDocumento2 pagineAim: Dismantle Fuel Injector of Adiesel Engine .Clean and Inspect All Component .Carry OutAryan KumarNessuna valutazione finora

- Xlsemi: 80V 1A Switching Current Buck PFM LED Constant Current Driver XL8004Documento11 pagineXlsemi: 80V 1A Switching Current Buck PFM LED Constant Current Driver XL8004Brenno FigueiredoNessuna valutazione finora

- Microprocessor 8085 - Two Mark QuestionsDocumento23 pagineMicroprocessor 8085 - Two Mark Questionssaravanamoorthy81% (16)

- 2GCS301015A0050-RVC Pamphlet en Controller Automatic Power Factor ABB RVC-6Documento4 pagine2GCS301015A0050-RVC Pamphlet en Controller Automatic Power Factor ABB RVC-6Marcos Ivan Ramirez AvenaNessuna valutazione finora

- SBC Telecom Split enDocumento26 pagineSBC Telecom Split enChimban ChappuNessuna valutazione finora

- Ece V Digital Signal Processing (10ec52) NotesDocumento161 pagineEce V Digital Signal Processing (10ec52) NotesrafeshNessuna valutazione finora

- v3 iMediaTouchOnAirUsersManualDocumento19 paginev3 iMediaTouchOnAirUsersManualIgroufa NaguibNessuna valutazione finora

- Building A Serial Interface For JP1.2 and JP1.3Documento2 pagineBuilding A Serial Interface For JP1.2 and JP1.3Yo YoNessuna valutazione finora

- Julabo MP Controller 19Documento23 pagineJulabo MP Controller 19Migue ZabaletaNessuna valutazione finora

- Unit Ii Rectifiers & FiltersDocumento26 pagineUnit Ii Rectifiers & FiltersRegine LamayoNessuna valutazione finora

- Ena2232 D 1Documento5 pagineEna2232 D 1Abdul RahmanNessuna valutazione finora

- Res Dip 104 419Documento15 pagineRes Dip 104 419Akhil Nath P SNessuna valutazione finora

- DC To DC Converter WikipediaDocumento37 pagineDC To DC Converter WikipediaaronsanjayNessuna valutazione finora

- Premier 300: CT/VT-Operated Energy MeterDocumento6 paginePremier 300: CT/VT-Operated Energy Meterveera chaitanyaNessuna valutazione finora

- Weak Infeed Conditions PDFDocumento22 pagineWeak Infeed Conditions PDFMuhammad Fahad SheikhNessuna valutazione finora

- Transients and Electric MeteringDocumento54 pagineTransients and Electric MeteringManpreet SinghNessuna valutazione finora

- Standard and Technical Specifications of The Security Systems by SIRADocumento31 pagineStandard and Technical Specifications of The Security Systems by SIRASuhaib Al NajjarNessuna valutazione finora

- CMS1 Owner's ManualDocumento44 pagineCMS1 Owner's ManualTemplarios Puerto EscondidoNessuna valutazione finora

- Electronic Circuits Chapter 5: Frequency ResponseDocumento54 pagineElectronic Circuits Chapter 5: Frequency ResponseBùi Quốc AnNessuna valutazione finora

- Using Your PowerLogic System To Improve Your Facility - S PowDocumento4 pagineUsing Your PowerLogic System To Improve Your Facility - S PowEarl Jenn AbellaNessuna valutazione finora

- DALI ConverterDocumento1 paginaDALI Converteralexwongks6118Nessuna valutazione finora

- CNT-8050 Cable and Network Tester: DADI TelecomDocumento5 pagineCNT-8050 Cable and Network Tester: DADI TelecomDragomir BogdanNessuna valutazione finora

- CMOS (Complementary Metal Oxide Semiconductor)Documento5 pagineCMOS (Complementary Metal Oxide Semiconductor)Hirakjyoti GoswamiNessuna valutazione finora

- Mmse ProofDocumento2 pagineMmse ProofQaddafi KhanNessuna valutazione finora