Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

The Use of Quar

Caricato da

George OparTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

The Use of Quar

Caricato da

George OparCopyright:

Formati disponibili

IRACST Engineering Science and Technology: An International Journal (ESTIJ),ISSN: 2250-3498

Vol. 3, No. 6, December 2013

BEHAVIOUR OF CONCRETE ON THE USE OF

QUARRY DUST TO REPLACE SAND AN

EXPERIMENTAL STUDY

G.Balamurugan

Associate Professor and Head

Department of Civil Engineering

Jayamatha Engineering College

Aralvoimozhi,Tamilnadu,India

Abstract This experimental study presents the variation in the

strength of concrete when replacing sand by quarry dust from

0% to 100% in steps of 10%. M20 and M25 grades of concrete

are taken for the study keeping a constant slump of 60mm. The

compressive strength of concrete cubes at age of 7 and 28 days is

obtained at room temperature. Split tensile strength and flexural

strength of concrete are found at the age of 28 days. From the test

results it is found that the maximum compressive strength, tensile

strength and flexural strength are obtained only at 50%

replacement. This result gives clear picture that quarry dust can

be utilized in concrete mixtures as a good substitute for natural

river sand at 50% replacement with additional strength than

control concrete.

Keywords- Concrete, quarry dust, river sand, compressive

strength.

I.

INTRODUCTION

Concrete is the most widely used construction material

today. The constituents of concrete are coarse aggregate, fine

aggregate binding material and water. Rapid increase in

construction activities leads to acute shortage of conventional

construction materials. It is conventional that sand is being

used as fine aggregate in concrete. For the past some years, the

escalation in cost of sand due to administrative restrictions in

India, demands comparatively greater cost at around two to

three times the cost of quarry dust even in places where river

sand is available nearby.

To achieve economy, it is proposed to study with the use of

crusher powder, a quarry waste as an alternative material to

replace sand by crusher powder. There was a remarkable

increase in compressive strength of concrete with 20%

replacement of sand with manufactured sand[1], 40%

replacement is possible[2] and 50% replacement gave higher

strength[3]. Quarry dust fine aggregate decreased the

compressive strength due to deficient grading and excessive

flakiness [4]. The w/c ratio and slump value increased with the

replacement of sand [5]. Voids present in quarry dust mortar

were lesser as compared to that of sand hence higher

compressive strength [6]. A comparatively good strength is

expected when sand is replaced partially or fully with or

without concrete admixtures.

Dr.P.Perumal

Principal

Mahendra Institute of Engineering and Technololgy

Mallasamudram

Namakkal, Tamilnadu, India

It is proposed to study the possibility of replacing sand with

locally available quarry dust without sacrificing the strength

and workability of concrete.

Coarse aggregate is an important material used in R.C.C

work of all types of structures. This is obtained by crushing the

stone boulders of size 100 to 150mm in the stone crushers. The

aggregate is sieved and the sieved aggregates which is less than

4.75mm in size, used in building construction works is called

quarry dust. This dust is heaped like a mountain near the stone

crushers. The volume of the waste dust produced is increased

day by day. The owners of the crushers find it difficult to clear

the dust from the crusher units.

In highways department the quarry dust is used to sprinkle

over the newly laid bituminous road as a binding material

between the bitumen and coarse aggregate. The fine powder

from quarry dust is mixed with cement and used in grouting

works. The quarry dust is used in the manufacturing of hollow

blocks. Some mosaic companies use quarry dust partly for

sand. In telecommunication department the quarry dust is used

to refill the excavated pits after laying the telephone cables.

II.

PROPERTIES OF MATERIALS

A. Cement

The cement used for this project work is Birla Super 43grade Portland pozzolana cement. The various properties of

cement are tabulated in Table I.

TABLE I.

S.No

PROPERTIES OF CEMENT

Description

Value

Normal Consistency

29.5%

Initial setting time

30 min

Final setting time

230 min

Specific Gravity

3.05

Fineness

6%

776

IRACST Engineering Science and Technology: An International Journal (ESTIJ),ISSN: 2250-3498

Vol. 3, No. 6, December 2013

B. Aggregates

1) Coarse Aggregate: The crushed granite aggregate of

size passing through 20mm and retaining on 12.5mm standard

sieve is used as coarse aggregate. The various properties of

coarse aggregate are presented in Table II.

TABLE II.

PROPERTIES OF COARSE AGGREGATE

S.No

Description

Value

Specific Gravity

2.98

Fineness Modulus

6.36

Density

1.58 gm/cc

2) Fine Aggregate:

a) Sand: Sand collected from nearby river Thamirabarani

is used for this project. The various properties of sand are

tabulated in Table III.

TABLE III.

PROPERTIES OF FINE AGGREGATE

S.No

Properties

Sand

Quarry dust

1.

Specific Gravity

2.53

2.57

2.

Fineness Modulus

3.08

2.41

3.

Void ratio

0.55

0.42

4.

Density

1.63

1.85

b) Quarry dust: Quarry dust an alternative for sand is

collected from nearby quarry. The properties of quarry dust are

tabulated in Table III.

C. Water

Potable water with pH value 7 is used for mixing and

curing throughout the experiment.

III.

EXPERIMENTAL INVESTIGATIONS

A. Mix proportioning

Two grades M20 and M25 having proportion 1:1.5:3 and

1:1:2 respectively are used by weight and w/c ratio is fixed

according to the slump of 60mm. For this concrete mix, quarry

dust is added for replacement of sand at 0% to 100% in step of

10%.

B. Casting of specimen

As the aggregate of size less than 20 mm and greater than

12.5 mm are used, cubes mould of 150x150x150 mm are used.

Cylindrical moulds of size 150 mm diameter and 300 mm

height are used for casting specimen for split tensile test. For

flexural strength, beam moulds of size 500x100x100 mm of

internal dimension are used. Moulds are removed after 24hours

of casting and cured in water up to the date of testing.

IV.

TESTING PROCEDURE

A. Fresh concrete workability

To determine consistency of concrete, Slump test was

conducted with varying water content and a particular w/c is

fixed according to the slump of 60mm from graph plotted. The

various w/c for different proportions of sand with quarry dust is

tabulated in Table IV

TABLE IV.

WORKABILITY OF CONCRETE ( SLUMP 60MM)

water cement ratio ( w/c )

Fine aggregate

Sand: Quarry dust

M20

M25

100:0

0.489

0.475

90:10

0.495

0.480

80:20

0.500

0.490

70:30

0.512

0.503

60:40

0.520

0.509

50:50

0.525

0.512

40:60

0.535

0.521

30:70

0.542

0.532

20:80

0.550

0.535

10:90

0.560

0.540

0:100

0.568

0.556

B. Compression test

The cube specimen was tested for compressive strength at

the end of 7 days and 28 days. The specimen was tested after

the surface gets dried. The load was applied on the smooth

sides without shock and increased continuously till the

specimen failed. The mean compressive strength is calculated

and tabulated in Table V.

TABLE V.

MEAN COMPRESSIVE STRENGTH OF CONCRETE ( MPA)

Fine aggregate

Sand: Quarry

dust

7 days

28 days

7 days

28 days

100:0

18.37

22.00

21.33

28.58

90:10

18.45

22.22

22.22

29.18

80:20

19.25

22.52

22.76

29.33

70:30

19.67

24.30

23.25

29.48

M20

M25

Identify applicable sponsor/s here. (sponsors)

777

IRACST Engineering Science and Technology: An International Journal (ESTIJ),ISSN: 2250-3498

Vol. 3, No. 6, December 2013

60:40

20.44

24.89

23.56

29.62

50:50

21.18

26.22

24.43

30.07

40:60

19.67

24.43

22.76

28.58

30:70

18.15

22.22

20.44

26.22

20:80

17.55

20.89

19.25

24.29

10:90

15.85

19.67

18.66

23.25

0:100

14.86

18.66

17.78

22.66

From the Figures 1 and 2, it is observed that the 7 days and

28 days compressive strength of concrete reached maximum

value at 50% replacement.

Figure 1. Compressive strength of concrete in 7 days.

C. Split tensile test

Split tensile test is also referred as Brazilian Test.

Placing a cylindrical specimen horizontally between the

loading surfaces of a compression-testing machine and the

load is applied till the cylinder failed along the vertical

diameter.

Tensile strength = 2W /( DL )

The mean tensile strength is calculated and tabulated in

Table VI.

TABLE VI.

TENSILE STRENGTH OF CONCRETE ( MPA)

28 days

Fine aggregate

Sand: Quarry dust

M20

M25

100:0

2.80

3.17

90:10

2.90

3.29

80:20

3.10

3.35

70:30

3.25

3.44

60:40

3.30

3.58

50:50

3.40

3.63

40:60

3.15

3.56

30:70

3.00

3.40

20:80

2.85

3.36

10:90

2.70

3.20

0:100

2.60

3.03

From the Figure 3, it is observed that the increase in the 28

days tensile strength of concrete reached the maximum value

Figure 2. Compressive strength of concrete in 28 days.

at 50% replacement of sand by quarry dust.

Figure 3. Mean Tensile strength of concrete ( MPa).

778

IRACST Engineering Science and Technology: An International Journal (ESTIJ),ISSN: 2250-3498

Vol. 3, No. 6, December 2013

D. Flexure test

The flexural strength of the concrete was determined by

using loading frame. The loading is done using hydraulic jack

on the beam and the load applied is measured using the

proving ring. The span of the beam adopted is 450 mm and

central concentrated load was applied.

Flexural strength = 1.5Wl / bd2

The mean flexural strength is calculated and tabulated in

Table VII.

TABLE VII.

FLEXURAL STRENGTH OF CONCRETE ( MPA)

28 days

Fine aggregate

Sand: Quarry dust

M20

M25

100:0

3.30

3.66

90:10

3.40

3.78

80:20

3.60

3.84

70:30

3.72

3.92

60:40

3.78

4.05

50:50

3.88

4.10

40:60

3.65

4.03

30:70

3.50

3.88

20:80

3.36

3.85

10:90

3.22

3.70

0:100

3.10

3.54

E. Flexure test on RCC beam

Concrete is weak in tension. To increase the tensile

strength, steel was introduced in concrete members. In the

reinforced concrete members, the reinforcement resists the

tension produced in the concrete and hence they play a vital

role in maintaining the tensile stress. Apart from loading some

of the reasons for tensile stresses development in concrete are

drying shrinkage, rusting of steel reinforcement and

temperature variation.

To cast the specimen for RCC beam, moulds of 100mm

breadth 150mm thick and length 1000mm were used. Two

numbers of 10 mm diameter bars were used as main bars and

two numbers of 10 mm diameter bars were used as hanger

bars. Two legged 8mm diameter vertical stirrups @ 150 mm

spacing were provided as shear reinforcement.

W

300

300

L =900

Figure 5. Loading for flexure test on RCC beam

Fresh concrete was prepared with replacement of sand by

quarry dust from 0% to 100% at increments of 10%. Water

was added as per the w/c ratio mentioned in the Table IV. The

specimens were cast after placing the reinforcement properly

inside the mould and the concrete filled in the mould in layers

with proper compaction to each layer. After 24 hours the

specimens were demoulded and immersed in water for curing.

The specimens were cured for 28 days and placed horizontally

between two roller supports of the bending table in the

Universal testing machine with unsupported length 900mm as

in Fig. 6. Concentrated loads were applied at one third points

until failure has occurred. Flexural strength of reinforced

Concrete beam was calculated and the values are presented in

Table VIII.

Flexural strength = WL/bd2

where

Figure 4. Flexural strength of concrete ( MPa).

W - Ultimate load

L - Unsupported length of the beam

b - Breadth of the beam

d - Depth of the beam\

From the Figure 4, it is observed that the 28 days flexural

strength of concrete reached maximum value at 50%

replacement.

779

IRACST Engineering Science and Technology: An International Journal (ESTIJ),ISSN: 2250-3498

Vol. 3, No. 6, December 2013

Figure 7. Flexural strength of RCC beam

Figure 6. Flexure test on RCC beam- Experimental setup

TABLE VIII.

Fine aggregate

Sand: Quarry

dust

FLEXUREL STRENGTH OF RCC BEAM ( MPA)

Flexural strength

(MPa)

% of variation with

respect to control

concrete

M20

M25

M20

M25

100:0

17.20

19.0

90:10

17.40

19.2

1.17

1.06

80:20

17.60

19.4

2.33

2.11

70:30

17.80

19.6

3.49

3.16

60:40

18.20

20.2

5.82

6.32

50:50

18.80

20.6

9.31

8.43

40:60

18.00

19.4

4.66

2.11

30:70

17.80

19.2

3.49

1.06

20:80

17.60

19.0

2.33

10:90

17.50

18.8

1.75

-1.06

From the above discussion it is concluded that:

0:100

17.00

18.6

-1.17

-2.11

Concrete acquires maximum increase in compressive

strength at 50 % sand replacement. When compared

with concrete with only river sand, the amount of

increase in strength is 19.18% and 5.21% for M20 and

M25 respectively.

Split tensile strength is maximum at 50 % replacement

of natural sand by quarry dust. The percentage of

increase with control concrete is 21.43 and 14.51 for

M20 and M25 respectively.

Maximum flexural strength is also at 50 %

replacement. The percentage of increase compared

with control concrete is 17.58 and 12.02 for M20 and

M25 respectively.

Maximum flexural strength of RCC beam is obtained

at 50% sand replacement by quarry dust. The

percentage of increase in strength compared with

control concrete is 9.31 and 8.43 for M20 and M25

concrete respectively.

From Figure 7, it is observed that the flexural strength of

RCC beam is maximum at 50% sand replacement by quarry

dust. From Table VIII, the value of this maximum flexural

strength is found to be 18.8 MPa and 20.6 MPa with the

percentage of increase in strength compared with control

concrete of 9.31 and 8.43 for M20 and M25 concrete

respectively. Figures 8 represents the variation in flexural

strength compared with control concrete of M20 and M25

concrete RCC beams with sand replacement. From that it is

observed that quarry dust can be comfortably used for

replacing sand upto 80% without any reduction in strength

compared to control concrete.

Figure 8. Variation in flexural strength (%) of RCC beam

Flat and elongated aggregate particles should be avoided

(or) limited to 15% by mass of total aggregates. Quarry dust

often contains flat and elongated particles require an increase

in mixing water and thus it affect the flexural strength of

concrete if the water cement ratio is not adjusted.

V.

CONCLUSION

780

IRACST Engineering Science and Technology: An International Journal (ESTIJ),ISSN: 2250-3498

Vol. 3, No. 6, December 2013

The derivation gives clear picture that quarry dust can

be utilized in concrete mixture as a quality substitute

instead of river sand to a high strength at 50% replacement.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

B.P.Hudson, Manufactured sand for concrete, The Indian Concrete

Journal, May 1997 , pp237-240.

A.K.Sahu, Sunil kumar and A.K.Sachan, Crushed stone waste as fine

aggregate for concrete, The Indian Concrete Journal, January 2003

pp845-847.

Selvakoodalingam, B. and Palanikumar, M. Partial Replacement of

Sand in Concrete with Quarry dust, Proceedings of National

Symposium, Karunya Institute of Technology, Coimbatore, pp. 41-43,

2002.

Md.Safiuddin, S.N.Raman and M.F.M. Zain, Utilization of Quarry

waste

fine Aggregate inconcrete mixures, 2007 Journal of Applied

sciences research 3(3) : 202-208.

Manasseh Joel, Use of Crushed Granite Fine as Replacement of River

Sand in Concrete Production, Leonardo Electronic Journal of Practices

and Technologies, Issue 17, pp. 85-96, 2010.

I.R.Mithanthaya, Jayaprakash Narayan, Replacement of Sand by Quarry

Dust for Plastering and in the Pavement Design, Proceedings of national

Symposium at Karunya Institute of Technology on 20-21,December

2002, pp 9-15.

AUTHORS PROFILE

First Author G.Balamurugan, B.E., M.E.(Struct.),

Associate Professor and Head, Department of Civil

Engineering, Jayamatha Engineering College, Aralvoimozhi.

Email: gbalamuruganjec@gmail.com

Second Author Dr.P.Perumal, B.E., M.E.(Struct.), Ph.D,

F.I.E.,M.I.S.T.E, Principal, Mahendra Institute of Engineering

and Technololgy, Mallasamudram, Namakkal,

Correspondence Author G.Balamurugan,

Email: gbalamuruganjec@gmail.com,

Phone : 09943025303

781

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Fluid Mechanics Tutorial No.5 Potential FlowDocumento26 pagineFluid Mechanics Tutorial No.5 Potential FlowGeorge OparNessuna valutazione finora

- Cim CatDocumento1 paginaCim CatGeorge OparNessuna valutazione finora

- Fluid ForcesDocumento16 pagineFluid ForcesGeorge OparNessuna valutazione finora

- Fluid Mechanics Tutorial No.8A Water Turbines: Dr. Owino George. PH.DDocumento19 pagineFluid Mechanics Tutorial No.8A Water Turbines: Dr. Owino George. PH.DGeorge OparNessuna valutazione finora

- Centrifugal Pumps 8 B PDFDocumento14 pagineCentrifugal Pumps 8 B PDFGeorge OparNessuna valutazione finora

- Faculty of Smart Vehicle EngineeringDocumento6 pagineFaculty of Smart Vehicle EngineeringGeorge OparNessuna valutazione finora

- Notes of F.MDocumento159 pagineNotes of F.Mnidhalsaada100% (1)

- Fluid Flow TheoryDocumento257 pagineFluid Flow TheoryGeorge OparNessuna valutazione finora

- Fluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of PumpsDocumento17 pagineFluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of Pumps12Nessuna valutazione finora

- Fluid Mechanics Tutorial No.4 Flow Through Porous PassagesDocumento8 pagineFluid Mechanics Tutorial No.4 Flow Through Porous PassagesGeorge OparNessuna valutazione finora

- Fluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of PumpsDocumento17 pagineFluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of Pumps12Nessuna valutazione finora

- Engineering: Dept. of Aerospace EngineeringDocumento2 pagineEngineering: Dept. of Aerospace EngineeringGeorge OparNessuna valutazione finora

- Centrifugal Pumps 8 B PDFDocumento14 pagineCentrifugal Pumps 8 B PDFGeorge OparNessuna valutazione finora

- Fluid Mechanics 203 Tutorial No.2 Applications of BernoulliDocumento37 pagineFluid Mechanics 203 Tutorial No.2 Applications of BernoulliGeorge Opar100% (1)

- Grain Drying: Turbulence in A Rectangular Shaped DryerDocumento10 pagineGrain Drying: Turbulence in A Rectangular Shaped DryerGeorge OparNessuna valutazione finora

- Main Campus Recertification Audit PlanDocumento4 pagineMain Campus Recertification Audit PlanGeorge OparNessuna valutazione finora

- Capitulo 1 PDFDocumento24 pagineCapitulo 1 PDFJ Alexander A CabreraNessuna valutazione finora

- Maggot ProductionDocumento3 pagineMaggot ProductionGeorge Opar100% (1)

- Schemes of Service FinalDocumento217 pagineSchemes of Service FinalGeorge OparNessuna valutazione finora

- Fluid Mechanic AnswerDocumento32 pagineFluid Mechanic AnswerIser88% (40)

- Data PDFDocumento10 pagineData PDFGeorge OparNessuna valutazione finora

- Schemes of Service FinalDocumento217 pagineSchemes of Service FinalGeorge OparNessuna valutazione finora

- Engineering: Dept. of Mechanical EngineeringDocumento3 pagineEngineering: Dept. of Mechanical EngineeringGeorge OparNessuna valutazione finora

- Thermo ExamDocumento7 pagineThermo ExamGeorge OparNessuna valutazione finora

- Air Cargo Operations Lecture Notes 1Documento31 pagineAir Cargo Operations Lecture Notes 1George OparNessuna valutazione finora

- Data PDFDocumento4 pagineData PDFGeorge OparNessuna valutazione finora

- Paper 1 OptimizationDocumento6 paginePaper 1 OptimizationGeorge OparNessuna valutazione finora

- Mechanical Guide PDFDocumento4 pagineMechanical Guide PDFGeorge OparNessuna valutazione finora

- Research Proposal FormatDocumento7 pagineResearch Proposal FormatMubeen ShaikhNessuna valutazione finora

- ReviewDocumento20 pagineReviewGeorge OparNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 3 WO Copper NickelDocumento78 pagine3 WO Copper NickelAnonymous Kr13NEBNessuna valutazione finora

- Eutectic Cell and Nodule Count in Cast Irons: International Journal of Cast Metals ResearchDocumento8 pagineEutectic Cell and Nodule Count in Cast Irons: International Journal of Cast Metals ResearchKhairul MuzafarNessuna valutazione finora

- The Impact of Using Specialist Geotechnical Software in Modeling of Pile Raft Foundation (PRF)Documento94 pagineThe Impact of Using Specialist Geotechnical Software in Modeling of Pile Raft Foundation (PRF)Haytham AlmaghariNessuna valutazione finora

- CT2 AssignmentDocumento16 pagineCT2 AssignmentCHI YAN KONGNessuna valutazione finora

- SSE QC CIV 402 Rev0 PDFDocumento2 pagineSSE QC CIV 402 Rev0 PDFBhalsingh JangraNessuna valutazione finora

- Dunham-Bush AFHX-6SR-77-191TRDocumento28 pagineDunham-Bush AFHX-6SR-77-191TRBaltik2672Nessuna valutazione finora

- Waste Heat Recovery in Cement Plant IJERTV3IS051014 PDFDocumento5 pagineWaste Heat Recovery in Cement Plant IJERTV3IS051014 PDFDurjoy ChakrabortyNessuna valutazione finora

- Actionair Iris DamperDocumento12 pagineActionair Iris DamperPeterOLearyNessuna valutazione finora

- Asme Sa-562-Sa-562M Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Titanium Forglass or Diffused Metallic Coatings PDFDocumento4 pagineAsme Sa-562-Sa-562M Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Titanium Forglass or Diffused Metallic Coatings PDFElkin Dario Aguirre MesaNessuna valutazione finora

- Proplast RC50 - TDSDocumento2 pagineProplast RC50 - TDSAhmed AbuoelnagaNessuna valutazione finora

- Serie KGDocumento10 pagineSerie KGDanner Rodolfo Santisteban CheroNessuna valutazione finora

- Product Information F737 OberonDocumento2 pagineProduct Information F737 OberonCosmic TitusNessuna valutazione finora

- Soil Structure Berbagai Macam Struktur TanahDocumento17 pagineSoil Structure Berbagai Macam Struktur TanahFauziah AlmunawarohNessuna valutazione finora

- Template - USJ DME Front Page For Practical ReportsDocumento11 pagineTemplate - USJ DME Front Page For Practical ReportsUshmikaNessuna valutazione finora

- Chap. 3 - Split Air Conditioning SystemDocumento17 pagineChap. 3 - Split Air Conditioning SystemSparsh ShukalNessuna valutazione finora

- Ubstructure Esign: Bridge Design Manual - 2002 Substructure DesignDocumento14 pagineUbstructure Esign: Bridge Design Manual - 2002 Substructure DesignHundeejireenyaNessuna valutazione finora

- 100 Questions For IEEDocumento18 pagine100 Questions For IEEmusleh19Nessuna valutazione finora

- Monitoring Pekerjaan Dan MaterialDocumento3 pagineMonitoring Pekerjaan Dan MaterialHarits Angga KusumaNessuna valutazione finora

- Experiment On Flow Through PipesDocumento2 pagineExperiment On Flow Through PipesAyon Sengupta100% (1)

- Daya Dukung - Pondasi DangkalDocumento34 pagineDaya Dukung - Pondasi DangkalRaditya PurnamahadiNessuna valutazione finora

- 50ucupv PSD enDocumento58 pagine50ucupv PSD enMohd AzharNessuna valutazione finora

- Chapter 30 - : Punch ListDocumento8 pagineChapter 30 - : Punch ListAkunda AmaniNessuna valutazione finora

- 2017 Fdot July Ebook PDFDocumento1.226 pagine2017 Fdot July Ebook PDFDamen JohnsonNessuna valutazione finora

- Lysaght Trimdek-Optima 2021Documento12 pagineLysaght Trimdek-Optima 2021Fahmi YusoffNessuna valutazione finora

- C Staehle Kalt Datenblatt EN 1511Documento7 pagineC Staehle Kalt Datenblatt EN 1511pierocarnelociNessuna valutazione finora

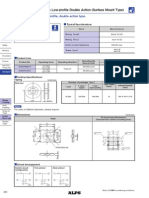

- 0.6mm Low-Profile, Double Action TypeDocumento3 pagine0.6mm Low-Profile, Double Action TypeshyhuNessuna valutazione finora

- Pe Ball Valves: CertusDocumento4 paginePe Ball Valves: CertusheviNessuna valutazione finora

- CITATION Jen15 /L 13321Documento2 pagineCITATION Jen15 /L 13321Kent Aldwin MangalinoNessuna valutazione finora

- Duracrete FichaDocumento2 pagineDuracrete FichavankarpNessuna valutazione finora

- Astm D2447 (2001)Documento8 pagineAstm D2447 (2001)moustafaNessuna valutazione finora