Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Analysis of Fatigue Properties of Unmodified and Polyethylene Terephthalate Modified Asphalt Mixtures Using Response Surface Methodology

Caricato da

mehrdad_so1981Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Analysis of Fatigue Properties of Unmodified and Polyethylene Terephthalate Modified Asphalt Mixtures Using Response Surface Methodology

Caricato da

mehrdad_so1981Copyright:

Formati disponibili

Engineering Failure Analysis 58 (2015) 238248

Contents lists available at ScienceDirect

Engineering Failure Analysis

journal homepage: www.elsevier.com/locate/efa

Analysis of fatigue properties of unmodied and polyethylene

terephthalate modied asphalt mixtures using response surface

methodology

Mehrtash Soltani a,, Taher Baghaee Moghaddam a,b, Mohamed Rehan Karim a, Hassan Baaj b

a

Center for Transportation Research, Department of Civil Engineering, Faculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia

Centre for Pavement and Transportation Technology, Department of Civil and Environmental Engineering, Faculty of Engineering, University of Waterloo, Waterloo N2L 3G1,

Canada

b

a r t i c l e

i n f o

Article history:

Received 18 May 2015

Received in revised form 10 August 2015

Accepted 10 September 2015

Available online 12 September 2015

Keywords:

Asphalt mixture

Waste PET

Environmental temperature

Response surface methodology

a b s t r a c t

Fatigue is a major distress mode of exible pavements that generally occurs in the form of irregular (alligator) cracking in the wheel paths. This paper evaluates the effects of applied stress and

temperature on the fatigue lives of polyethylene terephthalate (PET) modied asphalt mixtures

using response surface methodology (RSM). As it is shown in this study a quadratic model is

successfully tted to the experimental data. Fatigue lives of mixtures are inuenced by changes

in selected parameters. In addition, the effect of temperature variation is more drastic on the

fatigue lives than the effects of stress level and modier content.

2015 Elsevier Ltd. All rights reserved.

1. Introduction

Road pavement is subjected to external loads including mechanical loading induced by heavy trafc and thermal loading induced

by thermal changes. The applied loads, along with environmental conditions result in pavement deterioration which, in some cases,

happens even before its expected service life. Pavement damage is usually occurred in the form of permanent deformation (surface

rutting), fatigue failure and low temperature cracking. Fatigue failure is a common mode of distress of pavement structures which

is caused by successive tensile strain induced by repeated trafc loadings [1]. This form of distress mostly appears as cracking damage

which initially occurs at the bottom of asphalt layer where the tensile stresses are maximum. Then these cracks spread to the surface

of asphalt mixture. Previous studies showed the fatigue life of asphalt mixture has correlation with the mode and amount of applied

loads as well as environmental temperature [2,3].

Stone mastic asphalt (SMA) is gap-graded asphalt mixture which has been developed in Germany in 1960s [4]. It has a high

percentage (60 to 80%) of coarse aggregate, greater than 5 mm in size, high binder content (5.5 to 7% by weight), high percentage

of mineral ller (7 to 11%), and added bers (1%) [5]. Due to inherited structure of SMA, it can provide better permanent deformation

(rutting) performance and durability compared to conventional dense-graded mixture [6,7] but it becomes controversial in case of

fatigue property. However some studies showed that SMA mixture had lower fatigue life [8,9], others concluded that it had better fatigue properties compared to the conventional mixture [10,11]. In SMA mixture in order to prevent draindown (due to high asphalt

content) and improve mixture performance stabilizer additives, bers and polymers are used. In this case, using polymer in asphalt

Corresponding author.

E-mail address: mehrtashsoltani@gmail.com (M. Soltani).

http://dx.doi.org/10.1016/j.engfailanal.2015.09.005

1350-6307/ 2015 Elsevier Ltd. All rights reserved.

M. Soltani et al. / Engineering Failure Analysis 58 (2015) 238248

239

mixture is very common [1215]. Tapkn has utilized polypropylene bers as reinforcement in asphalt mixture and it was realized that

the mixture fabricated by polypropylene bers had better performance in comparison with control mixture [16].

In many cases, using polymers causes higher construction cost due to high polymer cost. In order to overcome this problem, many

studies have used waste polymers in asphalt mixtures [13,1720]. One of the important industrial plastic materials is polyethylene

terephthalate (PET). PET is a semi-crystalline thermoplastic polymer material which has been used in beverage and food industries

for years. Currently, a large amount of waste PET is being produced worldwide and it is going to cause a serious environmental

challenge due to its non-biodegradability [21]. Hence, some studies have been previously performed to evaluate the effects of using

post-consumer PET as secondary materials in road pavement in order to tackle this potential environmental hazard and, moreover,

to decrease construction cost imposed by application of polymers in asphalt mixture [2,13,22,23].

Mathematical modeling is useful for real-world application as it is robust in terms of its ability to deal with many constraints and

objectives [24,25]. In addition, using statistical analysis in pavement engineering is increasing among engineers and designers because

it helps to have better perspective about the pavement performance parameters. In this case, factorial design of experiments (DOE)

which through the use of techniques such as response surface methodology (RSM) simultaneously consider several factors at different

levels, and give a suitable model for the relationship between the various factors [2630].

The aim of this study is examining the fatigue property of SMA mixtures at elevated temperatures and stress levels for the

unmodied and PET modied mixtures followed by nding interactions between these fundamental factors using RSM based

on central composite design (CCD).

2. Materials and methods

SMA mixtures were fabricated using 80/100 penetration grade asphalt cement. Granite-rich aggregate particles were used for this

investigation. Nine percent of ller was utilized. The aggregate particle size distribution is shown in Fig. 1. As it is shown in this gure,

the SMA mixture contains coarser aggregate particle (68.5% of particles are greater than 4.75 mm) which provides better stone on

stone contact. In order to have better understanding of the materials' characteristics several tests were performed on asphalt cement

and aggregate particles and the results are listed in Table 1. As can be seen in Table 1, materials' properties are satisfactorily passed the

requirements.

PET akes which have been used for this study were obtained from waste PET bottles. For using PET akes in asphalt mixture, the

PET bottles were cut to small parts and crushed using a crushing machine. Thereafter, the crushed PET particles were sieved and

particles smaller than 2.36 mm in size were used for this research. Table 2 depicts physical and mechanical properties of PET.

2.1. Mixture fabrication

In order to fabricate SMA mixtures, 1100 g of mixed aggregate and ller were heated inside oven at temperature of 160 C for 3 h.

Asphalt cement was also heated at 130 C to be suitable for mixing with aggregate particles. Mixing temperature of 160 C was determined using plot of binder viscosity against temperature (viscosity at mixing temperature must be 0.17 0.02 Pa s). PET particles

with different percentages (0%, 0.5% and 1% by weight of aggregate particles) were added directly to the mixture as the method of

dry process. It is worth mentioning that in previous research it was believed that due to the high melting point of PET wet process

(adding modier to the asphalt cement) cannot be appropriate because it might hinder the mixing [17]. The loose mixture was

compacted using Marshall compactor and 50 blows of compaction effort were applied on each side of the mixture. It should be mentioned that all the mixtures were fabricated at their optimum asphalt contents using Marshall mix design method [22,31,32] and the

results are presented in Table 3.

Fig. 1. Aggregate particle size distribution for stone mastic asphalt.

240

M. Soltani et al. / Engineering Failure Analysis 58 (2015) 238248

Table 1

Properties of materials.

Property

Unit

Used specication

Value

Requirements

Asphalt

Penetration at 25 C

Softening point

Flash point

Fire point

Specic gravity

0.1 mm

C

C

C

(g/cm3)

ASTM D 5

ASTM D 36

ASTM D 92

ASTM D 92

ASTM D 70

87.5

46.6

300

320

1.03

Coarse aggregate

L.A. abrasion

Flakiness index

Elongation index

Aggregate crushing value

Bulk specic gravity

Absorption

%

%

%

%

(g/cm3)

%

ASTM C 131

BS 812 Part 105.1

BS 812 Part 105.2

BS 812 part 3

ASTM C 127

ASTM C 127

19.45

2.72

11.26

19.10

2.60

0.72

b30

b20

b20

b30

b2

Fine aggregate

Bulk specic gravity

Absorption

Soundness loss

(g/cm3)

%

%

ASTM C 128

ASTM C 128

ASTM C 88

2.63

0.4

4.1

b2

b15

2.2. Indirect tensile fatigue test

Indirect Tensile Fatigue Test (ITFT) was carried out in the controlled stress mode according to BS EN 12697-24. Universal Testing

Machine (UTM) which is a computer controlled system was used for running ITFT. Compressive cyclic load was applied along with

diametrical section of specimen in the form of haversine waveform with 500 ms repetition time and 100 ms pulse width

(see Fig. 2). ITFT was conducted at stress levels of 200 kPa, 300 kPa, and 400 kPa which are the stress values mostly used in pavement

laboratories. In addition, temperatures of 10 C, 25 C and 40 C are designated in this study to simulate the pavement temperature

ranges that fatigue damage usually occurs. Prior to the test, all the specimens were conditioned at the controlled temperature chamber

for about 2 h to reach the desired test temperature. Fatigue life was dened as the number of load repetitions reached when the

specimen splits [2,3335].

2.3. Method of analysis

One-factor-at-a-time (OFAT) methodology is a conventional approach for optimizing multifactor experiments. OFAT is a changeable single factor method for a specic experiment design while other factors are kept constant. OFAT is unable to generate appropriate output because the effects of interaction among all factors in the design are not examined truly, and so it is not capable of reaching

the true optimum value [36,37]. Hence, response surface methodology (RSM) has been introduced for parameter optimization in a

way that number of experiments and interaction among the parameters are reduced to minimal value [3840]. Consequently, Design

Expert 9.0.5.1 was designated for this purpose to generate statistical analysis and experimental designs and to calculate the sorbent

adaption conditions.

For this study, a developed quadratic model using RSM was suggested by the software for design and data analysis. In this investigation, the effects of three independent numerical variables including PET modier (A) from zero to 1%, stress levels (B) from

200 kPa to 400 kPa and temperatures between 10 C and 40 C, all at three levels, were studied through the central composite design

(CCD). Related literature and preliminary studies were used to choose these variables and the respective regions of interest [2,3,33].

Table 2

Physical and mechanical properties of PET.

Property

Unit

Method

Value

Water absorption

Tensile strength

Tensile modulus

Elongation at break

Flexural strength

Flexural modulus

Approx glass transition temperature

Approx melting temperature

Specic gravity

%

psi

psi

%

psi

psi

C

C

g/cm3

ASTM D570

ASTM D638

ASTM D638

ASTM D638

ASTM D790

ASTM D790

ASTM D792

0.11

11,500

4 105

70

15,000

4 105

75

250

1.35

M. Soltani et al. / Engineering Failure Analysis 58 (2015) 238248

241

Table 3

Summary of mix design.

PET(%)

BSGa

VMAb (%)

VFAc (%)

OACd (%)

0 (unmodied)

0.5

1

2.294

2.296

2.283

18.12

17.34

17.55

77.92

76.90

77.20

6.77

6.36

6.51

a

b

c

d

Bulk specic gravity of compacted mixture.

Void in mineral aggregate.

Void lled with asphalt.

Optimum asphalt content.

Table 4 shows the levels and range of the actual values of independent numerical variables. By using Eq. (1) all dened numerical

variables transformed to the coded form.

xi

X i X 0

X

where xi describes the coded value of the ith independent factor which is dimensionless. Actual value is dened as Xi, X0 is the

center point actual value and X refers to the step change of the ith variable.

A total of 34 experiments in random order were performed, together with ve replications at the center points to provide accurate

assessment of errors (Table 4). The fatigue life was dened as the response to develop design of experiment modeling.

(Eq. (2)) was developed to calculate the dependent variables [41,42]:

Xn

Xn

Xn Xn

2

Y0 i1 i xi i1 ii xi i1

x x

j1 ij i j

In Eq. (2), Y is the calculated response, 0 is constant value. Independent variables in coded form are described as xi, and xj. The

coefcients of i and ii are the linear and quadratic terms. ij is the interaction term coefcient, is the random error, and the studied

number of factors is dened as n.

In addition, in order to assess the appropriateness of proposed model, analysis of variance (ANOVA) was performed. The coefcients

of determination (R2 and R2adj) express the wellness of the t to the suggested model. These values can be determined using the

following equations [43]:

2

R 1

SSresidual

SSmodel SSresidual

SSresidual

Radj 1SS

model SSresidual

. D F residual

D F model D F residual

Fig. 2. Indirect Tensile Test loading set-up.

242

M. Soltani et al. / Engineering Failure Analysis 58 (2015) 238248

Table 4

Experimental design layout and experimental results of the responses.

Run

Factor 1: PET (%)

Factor 2: Stress level (kPa)

Factor 3: Temperature (C)

Fatigue cycles

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

0

1

0.5

0

1

0.5

0.5

0.5

0

0.5

1

0

1

0

0

0.5

0.5

1

0.5

0

1

1

0.5

0.5

0

0.5

1

0.5

1

0

0.5

1

0.5

0

200

400

300

200

300

300

200

400

300

300

400

300

200

400

200

300

300

400

300

400

200

300

300

300

400

300

400

400

200

400

200

200

300

200

10

40

10

40

25

25

25

25

25

25

10

25

10

10

40

25

25

40

25

40

10

25

40

40

40

10

10

25

40

10

25

40

25

10

196,720

1541

184,521

4341

7752

6072

51,421

1243

3019

6063

167,281

3033

385,866

91,291

4329

6061

6059

1544

6088

866

379,731

7739

3133

3141

878

179,491

167,312

1239

7829

91,302

53,320

7931

6077

188,821

In this equation, SS is the sum of squares and DF is degrees of freedom.

Eq. (5), Eq. (6) and an F-test in the program were used to check the model's adequate precision ratio (AP) to determine the

statistical importance of the model [44]:

Adequate Precision

V Y

maxY minY

p

V Y

1 Xn

p 2

V

i1

n

n

where Y is the predicted response, P represents the number of model parameters, residual mean square is described as 2, and n

is the number of experiments.

After the F-test had been performed, the insignicant terms were found and eliminated from the model. Thereafter, the nalized

model was introduced based on the signicant variables.

Fig. 3. Fracture patterns (left: ideal fracture, right: single cleft fracture).

M. Soltani et al. / Engineering Failure Analysis 58 (2015) 238248

243

3. Results and discussion

As it was mentioned by Allen at al., three different modes of failure have been observed for the ITFT. In the rst mode which has

been observed in most cases the specimen fractured completely; however, in the second mode specimen did not fail due to the fracture and no visible crack was observed. In such case, the failure was attributed to accumulation of permanent vertical deformation.

Additionally, the third mode of failure was dened by indentation of the loading strip into the specimen [34]. In this study, ITFT

was carried out in the controlled stress mode. The ITFT test was conducted on the mixtures at elevated temperatures and stress levels,

and the fracture patterns are shown in Fig. 3. As it can be seen in this gure two types of fracture are observed known as ideal fracture

and single cleft fracture [35]. Table 4 represents the layout for experimental design and the fatigue lives responses. According to this

table the fatigue lives vary between 866 and 385,866 cycles. Having these values, RSM was utilized to nd interactions between the

outputs and variables which are independent. Eventually, after a regression analysis had been applied to all responses described in the

design matrix, a tted quadratic polynomial equation was produced. The highest order polynomials in which the additional terms

were signicant and the models were not aliased were suggested by software. The numerical parameters (A, B and C) were used to

generate the predictive model according to Eq. (7):

2

Final Log10 fatigue equation 3:8 0:15A0:37B0:92C 0:57C :

Checking the adequacy of the model is an important part of the data analysis, as the model functions would give improper responses in case the t is not adequate [39,45]. Hence, in this study, in order to assess the signicance and adequacy of the model,

ANOVA analysis was performed and the results are reported in Table 5. In addition, this table shows the quadratic models for

coded factors, and represents other statistical parameters in logarithmic scale for the fatigue life. In this table, p-values which are

less than 0.0001 imply that the model and parameter are signicant (model and term with p-value b0.05 indicate the model and

the term are signicant for 95% condence intervals) for assessing the value of responses [46].

As the results show, PET (A), stress level (B), temperature (C), C2 are signicant terms with p-values less than 0.05. However, A2,

B2, AB, AC and BC were insignicant (p-value N 0.100). Therefore, in order to improve the model and optimize the results, the insignicant term can be removed from the model [47].

In order to check the tness of model regression coefcients, R2 and R2adj were calculated. Values of 0.9579 and 0.9422 were obtained for R2 and R2adj, respectively. This shows that 94.22% of the total variation in the fatigue life response could be explained by the

quadratic model. The high R2 and adjusted R2 values indicate that there is a good agreement between predicted and actual values

[40,41,48]. Ratio of signal-to-noise is measured by adequate precision to compare the variety of the estimated amounts at the design

points with the average prediction error. Adequate model discrimination was found in this study when the adequate precision ratio of

25.936 was calculated which is much higher than the value of 4 [49]. The lack of t (LOF) F-test was also used to evaluate the adequacy

of the model. LOF depicts the variation of the data around the tted model, and the amount of LOF would be signicant if the model

does not t the data well. It is worth noting that despite the LOF being signicant, a reasonable agreement between the predicted and

adjusted R2 were found for all responses and it can be concluded that the models suggested for all responses can be used to navigate

into design space to nd an optimum condition [50,51].

3.1. Statistical analysis

In order to have better understating about model satisfactoriness, diagnostic plots such as the predicted versus actual values are

worthwhile. Fig. 4 shows the actual versus predicted values of parameters for fatigue modeling. As shown in this gure there is an

adequate agreement between the actual data which were obtained through experiment and the predicted ones. This agreement

Table 5

ANOVA analysis for fatigue life.

Source

Sum of squares

df

Mean Square

Model

A PET

B Stress level

C Temperature

AB

AC

BC

A2

B2

C2

Residual

Lack of t

Pure error

Cor total

Adequate precision (AP)

22.74

0.44

2.76

16.76

5.472E004

7.234E004

0.13

0.082

0.051

1.74

1.00

1.00

4.205E004

23.73

25.936

9

1

1

1

1

1

1

1

1

1

24

5

19

33

2.53

0.44

2.76

16.76

5.472E004

7.234E004

0.13

0.082

0.051

1.74

0.042

0.20

2.213E005

F value

60.73

10.48

66.32

402.84

0.013

0.017

3.12

1.96

1.24

41.83

9017.24

p-value

Prob N F

Model performance

b0.0001

0.0035

b0.0001

b0.0001

0.9096

0.8962

0.0899

0.1739

0.2772

b0.0001

Signicant

Signicant

Signicant

Signicant

Insignicant

Insignicant

Insignicant

Insignicant

Insignicant

Signicant

b0.0001

Signicant

244

M. Soltani et al. / Engineering Failure Analysis 58 (2015) 238248

Fig. 4. Design-expert plot; predicted vs. actual values plot for fatigue life (logarithmic scale).

can also be understood by AP value (AP N 4) for the fatigue responses (see Table 5). This veries that the predicted model can be used

to navigate the design space dened by the CCD.

3.2. One factor analysis

One factor analysis is changing one factor at a time method. That is to say, in this method a single factor varies while all other

factors are kept constant for a particular set of experiments. This process exists for optimizing other variables which would be time

consuming. In this method, trial and error commonly exist for the optimization of variables, and, moreover, there is always a lack

of reaching a true optimum amount which is obtained by seeing the interaction among different variables [50,52]. Furthermore, in

one factor analysis when the software evaluates one parameter, other parameters are kept constant at their middle ranges. For instance, in case of PET content evaluation, temperature and stress level are kept constant at 25 C and 300 kPa respectively.

Figs. 5, 6 and 7 show the one factor analysis of PET percentage, stress level and temperature on logarithmic scale of fatigue life respectively. The logarithmic scale of fatigue life is shown for better underrating of difference between values. Fig. 5 indicates that by

increasing the PET the fatigue life is also increased. A possible reason for this result might be the mechanical properties of PET particles

in the mix. In fact, because the melting point of PET is high (over 250 C) and is higher than the mixture's fabrication temperature, the

PET particles do not melt during mixing. The solid PET particles can make mixture more elastic and cause higher fatigue life under

loading application. For another factor (Fig. 6) it can be observed that by increasing stress level the fatigue life is decreased. Same pattern is found for temperature when by increasing the temperature the fatigue life is decreased (Fig. 7). Fig. 7 also depicts that

Fig. 5. Effect of PET percentage on the fatigue life (logarithmic scale).

M. Soltani et al. / Engineering Failure Analysis 58 (2015) 238248

245

Fig. 6. Effect of different stress levels on the fatigue life (logarithmic scale).

increasing the temperature has negative effect on the fatigue life and that at higher temperatures (over 30 C) the fatigue life is

shifting to a constant value. This represents the importance of ambient temperature on the fatigue life of asphalt mixture. The ndings

of this study are based on controlled-stress test mode which are in support of previous studies [8,5356] that found the fatigue life of

asphalt mixtures increased at lower temperatures.

3.3. Effects of temperature, stress level and PET variables on the fatigue life using response surfaces

Three-dimensional response surface plots of the predictive quadratic model for the effect of stress level and temperature on

logarithmic scale is presented in Fig. 8. The response surfaces were generated based on Eq. (7).

Fig. 8 indicates at higher temperature and stress level the fatigue life is decreased. The variation of temperature for all stress level

seems to be signicant. In physical denition, when the ambient temperature increases, the asphalt binder becomes less stiff which

may weaken the fatigue resistance of asphalt mixtures and results in lower fatigue life. On the other hand the variation of stress levels

at higher temperatures is less effective on the fatigue life compared to lower temperature. That is to say, the changes in fatigue lives

are more tangible at lower stress levels and temperatures.

Fig. 9 indicates the effect of temperature and PET percentage on the SMA mixtures. Overall, increasing temperature had a negative

effect on the fatigue life. However, the effect of adding PET for improving the fatigue life is highlighted. Changes in fatigue life cannot

be attributed to the mixture air void content because all the mixtures were fabricated at their optimum asphalt contents with 4% air

Fig. 7. Effect of different temperature on the fatigue life (logarithmic scale).

246

M. Soltani et al. / Engineering Failure Analysis 58 (2015) 238248

Fig. 8. Effects of stress level and temperature on the fatigue life (logarithmic scale), 0.5% PET.

voids. In addition, improvement of fatigue life cannot be due to the higher asphalt content in the mixture because as it is shown in

Table 3 all the modied mixtures have lower asphalt contents than the unmodied mixture.

The correlation between stress level and PET content on the fatigue life of SMA mixture is shown in Fig. 10. Higher fatigue life is

found for the modied asphalt mixture associated with lower stress levels. By reducing the amount of PET in asphalt mixture the

fatigue life is decreased at all stress levels. In contrast, by increasing the stress level asphalt mixture experienced lower fatigue life

at all PET content. It can also be concluded that both PET increment and decrease in the stress level have roughly the same effect

on the fatigue life of asphalt mixture.

4. Conclusions

This paper aimed to evaluate the effect of applied load and temperature on the fatigue lives of unmodied and PET modied

asphalt mixture. Statistical analysis was used in this investigation to nd the interaction between selected variables. A good

agreement was found between predicted and actual values which indicated second-order response surface models provide a suitable

model to predict the fatigue life values within the range of dened factors. Based on the results achieved in this study the following

conclusions can be derived:

(1) The results showed that the changes in the fatigue lives are more tangible at lower stress levels and temperatures.

(2) Both PET increment and decrease in the stress level have roughly the same effect on the fatigue life of asphalt mixture.

(3) The effect of temperature on the fatigue lives is more drastic compared to stress level and PET content.

Fig. 9. Effects of PET percentage and temperature on the fatigue life (logarithmic scale), 300 kPa stress level.

M. Soltani et al. / Engineering Failure Analysis 58 (2015) 238248

247

Fig. 10. Effects of PET percentage and stress level on the fatigue life (logarithmic scale), 25 C.

Acknowledgements

The authors would like to thank to the University of Malaya Research Fund (Project No. RP010A-13SUS) for providing the

opportunity to make this research project.

References

[1] H. Di Benedetto, C. De La Roche, H. Baaj, A. Pronk, R. Lundstrm, Fatigue of bituminous mixtures, Mater. Struct. 37 (2003) 202216.

[2] T. Baghaee Moghaddam, M.R. Karim, T. Syammaun, Dynamic properties of stone mastic asphalt mixtures containing waste plastic bottles, Constr. Build. Mater. 34

(2012) 236242.

[3] G.G. Al-Khateeb, K.A. Ghuzlan, The combined effect of loading frequency, temperature, and stress level on the fatigue life of asphalt paving mixtures using the IDT

test configuration, Int. J. Fatigue 59 (2014) 254261.

[4] H. Baaj, D. Perraton, H. Di Benedetto, M. Paradis, Contribution l'etude de la relation entre le module complexe et la rsistance la fatigue et l'ornirage d'un

enrob SMA, Proceedings of the 48th Annual Conference of the CTAA, Halifax NS, November 1719, 2003.

[5] H. Baaj, M. Paradis, Use of post-fabrication asphalt shingles in stone matrix asphalt mix (SMA-10): laboratory characterization and field experiment on autoroute

20 (Quebec), Proceedings of the 53rd Annual Conference of the Canadian Technical Asphalt Association, Saskatoon SK, November 1619, 2008.

[6] R.B. Schmiedlin, Stone matrix asphalt: the Wisconsin experience, Trans. Res. Rec. 1616 (1988) 3441.

[7] I.M. Asi, Laboratory comparison study for the use of stone matrix asphalt in hot weather climates, J. Constr. Build Mater. 20 (2006) 982989.

[8] F.M. Nejad, E. Aflaki, M.A. Mohammadi, Fatigue behavior of SMA and HMA mixtures, J. Constr. Build Mater. 24 (2010) 11581165.

[9] T.B. Moghaddam, M.R. Karim, A. Mahrez, A review on fatigue and rutting performance of asphalt mixes, J. Sci. Res. Essays 6 (4) (2011) 670682.

[10] D. Perraton, H. Baaj, H. Di Benedetto, M. Paradis, Evaluation de la rsistance la fatigue des enrobs bitumineux fonde sur l'evolution de l'endommagement du

matriau en cours de l'essai : aspects fondamentaux et application l'enrob SMA, Can. J. Civ. Eng. 30 (2003) 902913.

[11] D. Perraton, H. Baaj, A. Carter, Comparison of some pavement design methods from a fatigue point of view. Effect of fatigue properties of asphalt materials, Road

Mater/ Pavement 11 (2010) 833861.

[12] A.I. Al-Hadidy, T. Yi-qiu, Mechanistic approach for polypropylene-modified flexible pavements, J. Mater. Des. 30 (2009) 11331140.

[13] E. Ahmadinia, M. Zargar, M.R. Karim, M. Abdelaziz, P. Shafigh, Using waste plastic bottles as additive for stone mastic asphalt, J. Mater. Des. 32 (2011) 48444849.

[14] C. Brovelli, M. Crispino, J. Pais, P. Pereira, Assessment of fatigue resistance of additivated asphalt concrete incorporating fibers and polymers, J. Mater. Civ. Eng. 2

(6) (2014) 554558.

[15] C. Brovelli, M. Crispino, J. Pais, P. Pereira, Using polymers to improve the rutting resistance of asphalt concrete, J. Constr. Build Mater. 77 (2015) 117123.

[16] S. Tapkin, The effect of polypropylene fibers on asphalt performance, Build. Environ. 43 (2008) 10651071.

[17] D. Casey, C. McNally, A. Gibney, M.D. Gilchrist, Development of a recycled polymer modified binder for use in stone mastic asphalt, J. Resour. Conserv. Recycl. 52

(2008) 11671174.

[18] S. Hnslolu, E. Aar, Use of waste high density polyethylene as bitumen modifier in asphalt concrete mix, J. Mater. Lett. 58 (2004) 267271.

[19] P.T.L. Liseane, Fontes, G. Trichs, J.C. Pais, A. Paulo, A. Pereira, Evaluating permanent deformation in asphalt rubber mixtures, J. Constr. Build Mater. 24 (2010)

11931200.

[20] M. Yu, G. Wu, Jinchuan Zhou and said easa, proposed compaction procedure for dry process crumb rubber modified asphalt mixtures using air void content and

expansion ratio, J. Test. Eval. 42 (2014) 111.

[21] M.N. Siddiqui, Conversion of hazardous plastic wastes into useful chemical products, J. Hazard. Mater. 167 (2009) 728735.

[22] T. Baghaee Moghaddam, M. Soltani, M.R. Karim, Evaluation of permanent deformation characteristics of unmodified and polyethylene terephthalate modified

asphalt mixtures using dynamic creep test, J. Mater. Des. 53 (2014) 317324.

[23] T. Baghaee Moghaddam, M. Soltani, M.R. Karim, Experimental characterization of rutting performance of polyethylene terephthalate modified asphalt mixtures

under static and dynamic loads, Constr. Build. Mater. 65 (2014) 487494.

[24] S. Kikuchi, N. Kronprasert, S. Easa, Aggregate blending using fuzzy optimization, J. Constr. Eng. Manage. ASCE 138 (2012) 14111420.

[25] M. Soltani, T.B. Moghaddam, M.R. Karim, S. Shamshirband, C. Sudheer, Stiffness performance of polyethylene terephthalate modified asphalt mixtures estimation

using support vector machine-firefly algorithm, Measurement 63 (2015) 232239.

[26] A. Khodaii, H.F. Haghshenas, H. Kazemi Tehrani, M. Khedmati, Application of response surface methodology to evaluate stone matrix asphalt stripping potential,

KSCE J. Civ. Eng. 17 (2013) 117121.

[27] A. Kavussi, M. Qorbani, A. Khodaii, H.F. Haghshenas, Moisture susceptibility of warm mix asphalt: a statistical analysis of the laboratory testing results, Constr.

Build. Mater. 52 (2014) 511517.

[28] A. Khodaii, H.F. Haghshenas, T.H. Kazemi, Effect of grading and lime content on HMA stripping using statistical methodology, Constr. Build. Mater. 34 (2012)

131135.

248

M. Soltani et al. / Engineering Failure Analysis 58 (2015) 238248

[29] T. Baghaee Moghaddam, M. Soltani, M.R. Karim, Stiffness modulus of polyethylene terephthalate modified asphalt mixture: a statistical analysis of the laboratory

testing results, J. Mater. Des. 68 (2015) 8896.

[30] T. Baghaee Moghaddam, M. Soltani, M.R. Karim, H. Baaj, Optimization of asphalt and modifier contents for polyethylene terephthalate modified asphalt mixtures

using response surface methodology, Measurement 74 (2015) 159169.

[31] A. Khodaii, A. Mehrara, Evaluation of permanent deformation of unmodified and SBS modified asphalt mixtures using dynamic creep test, Constr. Build. Mater. 23

(2009) 25862592.

[32] S.F. Kalyoncuoglu, M. Tigdemir, A model for dynamic creep evaluation of SBS modified HMA mixtures, Constr. Build. Mater. 25 (2011) 859866.

[33] J. Yan, F. Ni, M. Yang, J. Li, An experimental study on fatigue properties of emulsion and foam cold recycled mixes, Constr. Build. Mater. 24 (2010) 21512156.

[34] B. Allen, I. Artamendi, P. Phillips, Influence of temperature and aging on laboratory fatigue performance of asphalt mixtures, Advanced Testing and Characterization

of Bituminous Materials, Two Volume Set, Taylor & Francis group, London, 2009, ISBN 978-0-415-55854-9.

[35] A.M. Hartman, M.D. Gilchrist, G. Walsh, Effect of mixture compaction on indirect tensile stiffness and fatigue, J. Transp. Eng. 127 (2001) 370378.

[36] N.L. Frigon, D. Mathews, Practical Guide to Experimental Design, John Wiley and Sons, New York, 1997.

[37] D.C. Montogomery, Design and Analysis of Experiments, John Wiley and Sons, New York, 2005.

[38] A.I. Khuri, J.A. Cornell, Response Surfaces, Design and Analyses, 2nd ed. Marcel Dekker Inc., New York, 1996.

[39] R.H. Myer, D.C. Montogomery, Response Surface Methodology. Process and Product Optimization Using Designed Experiment. 2nd ed, John Wiley and Sons, New

York, 2002.

[40] R. Azargohar, A.K. Dalai, Production of activated carbon from Luscar char: experimental and modeling studies, Microporous Mesoporous Mater. 85 (2005)

219225.

[41] M.Y. Can, Y. Kaya, O.F. Algur, Response surface optimization of the removal of nickel from aqueous solution by cone biomass of Pinus sylvestris, Bioresour. Technol.

97 (2006) 17611765.

[42] Z. Aksu, F. Gnen, Binary biosorption of phenol and chromium (VI) onto immobilized activated sludge in a packed bed: prediction of kinetic parameters and

breakthrough curves, Sep. Purif. Technol. 49 (2006) 205216.

[43] B.K. Krbahti, M.A. Rauf, Response surface methodology (RSM) analysis of photoinduceddecoloration of toludine blue, Chem. Eng. J. 136 (2008) 2530.

[44] B.K. Krbahti, M.A. Rauf, Determination of optimum operating conditions of carmine decoloration by UV/H2O2 using response surface methodology, J. Hazard.

Mater. 161 (2009) 281286.

[45] B.K. Krbahti, M.A. Rauf, Application of response surface analysis to the photolytic degradation of basic red 2 dye, Chem. Eng. J. 138 (2008) 166171.

[46] M. Zabeti, W.M.A.W. Daud, M.K. Aroua, Optimization of the activity of CaO/Al2O3 catalyst for biodiesel production using response surface methodology, Appl.

Catal. A Gen. 366 (2009) 154159.

[47] V. Hosseinpour, M. Kazemeini, A. Mohammadrezaee, Optimisation of ru-promoted Ir catalysed methanol carbonylation utilising response surface methodology,

Appl. Catal. A Gen. 394 (2011) 166175.

[48] U.K. Garg, M.P. Kaur, V.K. Garg, D. Sud, Removal of nickel (II) from aqueous solution by adsorption on agricultural waste biomass using a response surface

methodological approach, Bioresour. Technol. 99 (2008) 13251331.

[49] T. lmez, The optimization of Cr (VI) reduction and removal by electrocoagulation using response surface methodology, J. Hazard. Mater. 162 (2009) 13711378.

[50] S.M.S. Wan, W.M.A. Daud, A. Houshmand, A. Arami-Niya, The application of response surface methodology to optimize the amination of activated carbon for the

preparation of carbon dioxide adsorbents, Fuel 94 (2012) 465472.

[51] J. Snchez-Romeu, J.M. Pas-Chanfrau, Y. Pestana-Vila, I. Lpez-Larraburo, Y. Masso-Rodrguez, M. Linares-Domnguez, et al., Statistical optimization of immunoaffinity purification of hepatitis B surface antigen using response surface methodology, Biochem. Eng. J. 38 (2008) 18.

[52] R.L. Mason, R.F. Gunst, J.L. Hess, Statistical Design and Analysis of Experiments, Eighth Applications to Engineering and Science, 2nd ed. Wiley, New York, 2003.

[53] J.A. Epps, C.L. Monismith, Fatigue of asphalt concrete mixtures-summary of existing information. Fatigue of compacted bituminous aggregate mixtures, ASTM

STP508, Am. Soc. Test. Mater. (1971) 1945.

[54] P.S. Pell, I.F. Taylor, Asphaltic road materials in fatigue, Proceedings of the association of the asphalt pavement technologists (AAPT), vol. 38 1969, pp. 577593

(Los Angeles, California, USA).

[55] G.G. Al-Khateeb, K.A. Ghuzlan, The combined effect of loading frequency, temperature, and stress level on the fatigue life of asphalt paving mixtures using the IDT

test configuration, Int. J. Fatigue 59 (2014) 254261.

[56] S. Bhattacharjee, R.B. Mallick, Effect of temperature on fatigue performance of hot mix asphalt tested under model mobile load simulator, Int. J. Pavement Eng. 13

(2012) 166180.

Potrebbero piacerti anche

- Guide To PG Binder Selection in MNDocumento19 pagineGuide To PG Binder Selection in MNbleh869968Nessuna valutazione finora

- Laboratory Performance Characteristics of High Modulus Asphalt Mixture With High-Content RAPDocumento8 pagineLaboratory Performance Characteristics of High Modulus Asphalt Mixture With High-Content RAPOscar Javier Lozano PinedaNessuna valutazione finora

- Intelligent Compaction For Asphalt MaterialsDocumento6 pagineIntelligent Compaction For Asphalt MaterialsHussain ElarabiNessuna valutazione finora

- Aci 330r 92Documento1 paginaAci 330r 92Sue JinsueNessuna valutazione finora

- Asphalt Concrete With Encapsulated CbsDocumento13 pagineAsphalt Concrete With Encapsulated CbsMariaNilaZaragozaPalacioNessuna valutazione finora

- Asphalt Concrete Report Final VersionDocumento11 pagineAsphalt Concrete Report Final VersionLorraine Custodio100% (1)

- ACPA City Street Pavement DesignDocumento8 pagineACPA City Street Pavement DesignFelipe Fernández100% (1)

- 1 What Is LevelingDocumento19 pagine1 What Is LevelingAbduraman Isa100% (1)

- Irc 115 2014 FWD FLEXIBLEDocumento4 pagineIrc 115 2014 FWD FLEXIBLESuyog GoreNessuna valutazione finora

- Bituminous Mixtures in Road ConstructionDocumento42 pagineBituminous Mixtures in Road ConstructionThamiresGuerraNessuna valutazione finora

- Design of Concrete Mixes .Hw3Documento12 pagineDesign of Concrete Mixes .Hw3RawandAlbarodyNessuna valutazione finora

- 21 Shamim ZafarDocumento30 pagine21 Shamim ZafarUsman RafiqNessuna valutazione finora

- Claycrete English v3Documento22 pagineClaycrete English v3supernaenergy100% (1)

- Fly Ash Fly Ash: Utility Bonanza From DustDocumento8 pagineFly Ash Fly Ash: Utility Bonanza From DustRajanmyth Mala100% (1)

- Layered Elastic Pavement Design Recent Developments. Wardle L.J. and Rodway B. 1998Documento10 pagineLayered Elastic Pavement Design Recent Developments. Wardle L.J. and Rodway B. 1998ChristineNyambeNessuna valutazione finora

- Development of in Situ Mass Stabilization Technique in FinlandDocumento6 pagineDevelopment of in Situ Mass Stabilization Technique in Finlandvickneshj9406Nessuna valutazione finora

- Asphalt Concrete (Commonly Called Asphalt, Blacktop, Macadam in Great Britain and Ireland) Is A CompositeDocumento7 pagineAsphalt Concrete (Commonly Called Asphalt, Blacktop, Macadam in Great Britain and Ireland) Is A CompositeZerotheoryNessuna valutazione finora

- Effect of Aggregate Inhomogeneity On Mechanical Properties of Asphalt MixturesDocumento460 pagineEffect of Aggregate Inhomogeneity On Mechanical Properties of Asphalt Mixturesalfredo torresNessuna valutazione finora

- Utilization of Fly Ash in Rural Road Construction in India and Its Cost EffectivenessDocumento6 pagineUtilization of Fly Ash in Rural Road Construction in India and Its Cost Effectivenessceanil100% (1)

- Beam Block BrochureDocumento7 pagineBeam Block BrochurehemendraengNessuna valutazione finora

- Resilient Modulus and Dynamic Modulus of Warm Mix AsphaltDocumento8 pagineResilient Modulus and Dynamic Modulus of Warm Mix AsphaltJorge LuisNessuna valutazione finora

- TR 331 - HIGHWAY MATERIALS @udsm by BUJULU in Share With Christian Nicolaus MbiseDocumento183 pagineTR 331 - HIGHWAY MATERIALS @udsm by BUJULU in Share With Christian Nicolaus MbiseChristian Nicolaus MbiseNessuna valutazione finora

- Performance Evaluation of Stone Matrix Asphalt Using Indonesian Natural Rock Asphalt As StabilizerDocumento6 paginePerformance Evaluation of Stone Matrix Asphalt Using Indonesian Natural Rock Asphalt As StabilizerAhmad FauziNessuna valutazione finora

- Assignment-2 Shear StrengthDocumento3 pagineAssignment-2 Shear StrengthRabindraSubediNessuna valutazione finora

- Exercises 5.5 and 5.6Documento7 pagineExercises 5.5 and 5.63cesNessuna valutazione finora

- Mix Design by Marshall MethodDocumento27 pagineMix Design by Marshall MethodS K SinghNessuna valutazione finora

- Asphaltic MixturesDocumento30 pagineAsphaltic MixturesFlorin MatisNessuna valutazione finora

- Flaky Elongated AggregatesDocumento7 pagineFlaky Elongated AggregatesAnkur GoyalNessuna valutazione finora

- Lec 4 - Road MaterialsDocumento51 pagineLec 4 - Road MaterialsRuel B. Ramos Jr.Nessuna valutazione finora

- SBS BinderDocumento11 pagineSBS Binderprabin kumar ashishNessuna valutazione finora

- Study On The Effect of Coir Fibre in The Bituminous Concrete MixDocumento5 pagineStudy On The Effect of Coir Fibre in The Bituminous Concrete MixIJSTENessuna valutazione finora

- Geosythetic Reinforced Unpaved RoadDocumento10 pagineGeosythetic Reinforced Unpaved RoadPalak ShivhareNessuna valutazione finora

- LWD Simulation in MnPAVE FlexibleDocumento6 pagineLWD Simulation in MnPAVE FlexibleLuis MogrovejoNessuna valutazione finora

- PPTDocumento53 paginePPTSampat KumarNessuna valutazione finora

- A Study of Cement Modified Bitumen Emulsion MixturesDocumento22 pagineA Study of Cement Modified Bitumen Emulsion MixturesVladimirPinzonNessuna valutazione finora

- Equivalent Single Wheel LoadDocumento12 pagineEquivalent Single Wheel LoadRajesh Khadka100% (1)

- Foamed Asphalt MixDocumento32 pagineFoamed Asphalt Mixentree4527Nessuna valutazione finora

- Chap 8Documento61 pagineChap 8Mekdelawit TewodrosNessuna valutazione finora

- Aashto T307Documento27 pagineAashto T307Viviana CruzNessuna valutazione finora

- M30 For Concrete PavementDocumento1 paginaM30 For Concrete PavementR ARUNPANDIANNessuna valutazione finora

- Introduction To Pavement DesignDocumento12 pagineIntroduction To Pavement DesignVijay KumarNessuna valutazione finora

- Study of Rheological and Creep Recovery Properties of AsphaltDocumento8 pagineStudy of Rheological and Creep Recovery Properties of AsphalttannuNessuna valutazione finora

- Development of A Mix Design Methodology For Concrete Paving Blocks. Part I: Mix Design ProcedureDocumento9 pagineDevelopment of A Mix Design Methodology For Concrete Paving Blocks. Part I: Mix Design ProcedureJosephNessuna valutazione finora

- BS For Highways TestsDocumento12 pagineBS For Highways Testsdbg2012Nessuna valutazione finora

- Concrete Flow TestDocumento7 pagineConcrete Flow TestDarrenTofuNessuna valutazione finora

- Stone Mastic AsphaltDocumento3 pagineStone Mastic AsphaltAshok SwamiNessuna valutazione finora

- Factors Affecting Pavement Design PDFDocumento2 pagineFactors Affecting Pavement Design PDFKris33% (3)

- Evaluating The Effect of Asphalt Binder Modification 2019 Case Studies in CDocumento13 pagineEvaluating The Effect of Asphalt Binder Modification 2019 Case Studies in CAmin ZuraiqiNessuna valutazione finora

- Aggregate Mix DesignDocumento5 pagineAggregate Mix DesignFatma MerxhaniNessuna valutazione finora

- Effect of Aggregate Size and Gradation On PerviousDocumento7 pagineEffect of Aggregate Size and Gradation On PerviousTianSing NgNessuna valutazione finora

- Los Angeles Abrasion TestDocumento2 pagineLos Angeles Abrasion TestyattapuNessuna valutazione finora

- Geosynthetics Types and FunctionsDocumento15 pagineGeosynthetics Types and Functionsjans_13Nessuna valutazione finora

- Manual of Pavement Design Atj 5-85Documento30 pagineManual of Pavement Design Atj 5-85Abdul Rahman HilmiNessuna valutazione finora

- Use of Waste High Density Polyethylene As Bitumen Modifier in Asphalt Concrete MixDocumento5 pagineUse of Waste High Density Polyethylene As Bitumen Modifier in Asphalt Concrete MixMehul BarotNessuna valutazione finora

- National Institute of Construction Management and Research, Pune-45Documento25 pagineNational Institute of Construction Management and Research, Pune-45Arnav GargNessuna valutazione finora

- Use of Waste High Density Polyethylene As Bitumen Modifier in Asphalt Concrete MixDocumento5 pagineUse of Waste High Density Polyethylene As Bitumen Modifier in Asphalt Concrete MixAnonymous VyjY4iNessuna valutazione finora

- Disposal of Large Consumed Plastics Cause An Environmental Pollution As They Are Considered Non-Biodegradable MaterialsDocumento18 pagineDisposal of Large Consumed Plastics Cause An Environmental Pollution As They Are Considered Non-Biodegradable MaterialsKanimozhi SNessuna valutazione finora

- 1 s2.0 S095006182202308X MainDocumento11 pagine1 s2.0 S095006182202308X MainKarolinaNessuna valutazione finora

- 2016-Chemical Recycling of Polyethylene Terephthalate (PET) As Additive For Asphalt.Documento6 pagine2016-Chemical Recycling of Polyethylene Terephthalate (PET) As Additive For Asphalt.Amanda Camejo CoronaNessuna valutazione finora

- Characteristics of Permanent DeformationDocumento9 pagineCharacteristics of Permanent Deformationali.engi1992Nessuna valutazione finora

- Section 05 Concrete Part 01 General - QCDocumento5 pagineSection 05 Concrete Part 01 General - QCmehrdad_so1981Nessuna valutazione finora

- LS-261 R27Documento12 pagineLS-261 R27mehrdad_so1981Nessuna valutazione finora

- Putman 2012Documento9 paginePutman 2012mehrdad_so1981Nessuna valutazione finora

- LS-261 R27Documento12 pagineLS-261 R27mehrdad_so1981Nessuna valutazione finora

- Section 05 Concrete Part 01 General - QC PDFDocumento205 pagineSection 05 Concrete Part 01 General - QC PDFJayakumar AnanthaNessuna valutazione finora

- 07.technical SpecificationDocumento122 pagine07.technical Specificationmehrdad_so1981Nessuna valutazione finora

- Method of Test For Preparation of Marshall SpecimensDocumento14 pagineMethod of Test For Preparation of Marshall SpecimensKiplagat ChelelgoNessuna valutazione finora

- 75 81 EngDocumento84 pagine75 81 Engmehrdad_so1981Nessuna valutazione finora

- Masterset Ac 100: Non-Chloride Hardening Accelerator For ConcreteDocumento2 pagineMasterset Ac 100: Non-Chloride Hardening Accelerator For Concretemehrdad_so1981100% (1)

- Mechanical Properties and ImpactDocumento10 pagineMechanical Properties and Impactmehrdad_so1981Nessuna valutazione finora

- MasterSet AC 100 v1Documento7 pagineMasterSet AC 100 v1mehrdad_so1981Nessuna valutazione finora

- Zhang 2018Documento7 pagineZhang 2018mehrdad_so1981Nessuna valutazione finora

- Masterset Ac 100: Non-Chloride Hardening Accelerator For ConcreteDocumento2 pagineMasterset Ac 100: Non-Chloride Hardening Accelerator For Concretemehrdad_so1981100% (1)

- Resources, Conservation and RecyclingDocumento9 pagineResources, Conservation and Recyclingmehrdad_so1981Nessuna valutazione finora

- 50 58 Eng Concrete TestingDocumento92 pagine50 58 Eng Concrete TestingJimmy LopezNessuna valutazione finora

- 77346Documento16 pagine77346mehrdad_so1981Nessuna valutazione finora

- 10 1016@j Asej 2013 02 005 PDFDocumento13 pagine10 1016@j Asej 2013 02 005 PDFmehrdad_so1981Nessuna valutazione finora

- Leaching From Solid Waste Incineration Ashes Used in Cement-Treated Base Layers For PavementsDocumento10 pagineLeaching From Solid Waste Incineration Ashes Used in Cement-Treated Base Layers For Pavementsmehrdad_so1981Nessuna valutazione finora

- Sika PDFDocumento2 pagineSika PDFmehrdad_so1981Nessuna valutazione finora

- Construction and Building Materials: Ningyi Su, Feipeng Xiao, Jingang Wang, Serji AmirkhanianDocumento15 pagineConstruction and Building Materials: Ningyi Su, Feipeng Xiao, Jingang Wang, Serji Amirkhanianmehrdad_so1981Nessuna valutazione finora

- Resources, Conservation and RecyclingDocumento9 pagineResources, Conservation and Recyclingmehrdad_so1981Nessuna valutazione finora

- Admixture Technical Sheet - ATS 4 Accelerating AdmixturesDocumento4 pagineAdmixture Technical Sheet - ATS 4 Accelerating Admixturesmehrdad_so1981Nessuna valutazione finora

- Construction and Building Materials: Gang Wang, Duan Yi Wang, Dan Ning LiDocumento10 pagineConstruction and Building Materials: Gang Wang, Duan Yi Wang, Dan Ning Limehrdad_so1981Nessuna valutazione finora

- EB236Documento26 pagineEB236mehrdad_so1981Nessuna valutazione finora

- SikaRapid-2 2011-10 - 1Documento2 pagineSikaRapid-2 2011-10 - 1mehrdad_so1981Nessuna valutazione finora

- 10 1080@13588265 2017 1301081Documento14 pagine10 1080@13588265 2017 1301081mehrdad_so1981Nessuna valutazione finora

- SikaRapid-2 2011-10 - 1 PDFDocumento2 pagineSikaRapid-2 2011-10 - 1 PDFmehrdad_so1981Nessuna valutazione finora

- SikaRapid-1 MY 2011-10 - 1Documento2 pagineSikaRapid-1 MY 2011-10 - 1mehrdad_so1981Nessuna valutazione finora

- ST 36Documento4 pagineST 36ray72roNessuna valutazione finora

- Prawn ProcessingDocumento21 paginePrawn ProcessingKrishnaNessuna valutazione finora

- Stanley B. Alpern - Amazons of Black Sparta - The Women Warriors of Dahomey-New York University Press (2011)Documento308 pagineStanley B. Alpern - Amazons of Black Sparta - The Women Warriors of Dahomey-New York University Press (2011)georgemultiplusNessuna valutazione finora

- Differential Geometry of Curves and Surfaces 3. Regular SurfacesDocumento16 pagineDifferential Geometry of Curves and Surfaces 3. Regular SurfacesyrodroNessuna valutazione finora

- SP 73Documento105 pagineSP 73Rodrigo Vilanova100% (3)

- The Variable Resistor Has Been AdjustedDocumento3 pagineThe Variable Resistor Has Been AdjustedPank O RamaNessuna valutazione finora

- Ni Elvis ManualDocumento98 pagineNi Elvis ManualZhi YiNessuna valutazione finora

- Latihan To: Nilai: 7.4 Benar: 37 Salah: 13Documento17 pagineLatihan To: Nilai: 7.4 Benar: 37 Salah: 13glensNessuna valutazione finora

- 1ST SUMMATIVE TEST FOR G10finalDocumento2 pagine1ST SUMMATIVE TEST FOR G10finalcherish austriaNessuna valutazione finora

- Rido, Rudini - Paediatric ECGDocumento51 pagineRido, Rudini - Paediatric ECGFikriYTNessuna valutazione finora

- Shell Gadus: Designed To Do More. Just Like Our Greases - Shell GadusDocumento2 pagineShell Gadus: Designed To Do More. Just Like Our Greases - Shell Gadusperi irawanNessuna valutazione finora

- Module in Pe 103Documento79 pagineModule in Pe 103Kym Dacudao100% (1)

- 4 5803133100506483687Documento245 pagine4 5803133100506483687Malik HamidNessuna valutazione finora

- Banachek UnlimitedDocumento34 pagineBanachek UnlimitedserenaNessuna valutazione finora

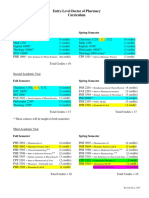

- Pharmd CurriculumDocumento18 paginePharmd Curriculum5377773Nessuna valutazione finora

- Full Download Short Term Financial Management 3rd Edition Maness Test BankDocumento35 pagineFull Download Short Term Financial Management 3rd Edition Maness Test Bankcimanfavoriw100% (31)

- Astm 2017-F2059Documento5 pagineAstm 2017-F2059laythNessuna valutazione finora

- Hurricanes Grade5Documento3 pagineHurricanes Grade5Anonymous m3yrUPNessuna valutazione finora

- A Presentation On-: Dr. Nikhil Oza Intern BvdumcDocumento43 pagineA Presentation On-: Dr. Nikhil Oza Intern BvdumcMaheboob GanjalNessuna valutazione finora

- Clinical Case StudyDocumento20 pagineClinical Case Studyapi-252004748Nessuna valutazione finora

- Pineapple in JohorDocumento6 paginePineapple in JohorHaiqal AzizNessuna valutazione finora

- Yadea User Manual For e Scooter 1546004910Documento44 pagineYadea User Manual For e Scooter 1546004910Danthe ThenadNessuna valutazione finora

- Earth Sciences Notes Csir-Ugc Net JRFDocumento57 pagineEarth Sciences Notes Csir-Ugc Net JRFmanas773Nessuna valutazione finora

- iPQ-Center Webvideo Star TTB MA R1 42 en PDFDocumento32 pagineiPQ-Center Webvideo Star TTB MA R1 42 en PDFHamid KharazmiNessuna valutazione finora

- Smoldering Combustion: Guillermo ReinDocumento20 pagineSmoldering Combustion: Guillermo ReinAhmed HussainNessuna valutazione finora

- Properties of Matter ReviewDocumento8 pagineProperties of Matter Reviewapi-290100812Nessuna valutazione finora

- DCS YokogawaDocumento17 pagineDCS Yokogawasswahyudi100% (1)

- Easergy PS100 48VDC Power SupplyDocumento2 pagineEasergy PS100 48VDC Power SupplyRichard SyNessuna valutazione finora

- SPM 1449 2006 Mathematics p2 BerjawapanDocumento18 pagineSPM 1449 2006 Mathematics p2 Berjawapanpss smk selandar71% (7)

- Orofacial Complex: Form and FunctionDocumento34 pagineOrofacial Complex: Form and FunctionAyushi Goel100% (1)