Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Spilling Steam Engines

Caricato da

SimEnzCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Spilling Steam Engines

Caricato da

SimEnzCopyright:

Formati disponibili

Spilling Steam Power: Engines and Turbines

IEA Workshop Copenhagen

Small scale biomass co-generation

with modern steam engines

Dipl.-Ing. Till Augustin

October, 7th 2010

Spilling Steam Power: Engines and Turbines

Solid Biomass Cogeneration

with Spilling Steam Engines

Contents:

Who is Spilling

Heat and Power from Biomass Steam Power Plants

The Spilling Steam Engine

Examples

Spilling Steam Power: Engines and Turbines

Spilling: Company Information

Engine and Turbine Manufacturer

Location: Hamburg

Founded in 1889

Product Lines:

Steam Engines

Steam Turbines

Gas Expanders

Spilling Steam Power: Engines and Turbines

Spillings Program: Decentralized Co-Gen Equipment

Spilling Steam Power: Engines and Turbines

Biomass Steam Cogeneration

Spilling Steam Power: Engines and Turbines

Optimal Use of Energy with CHP

~10 - 25 % Boiler Losses

~ 5 19 % Power

100 %

~ 70 - 85 %

Fuel

Energy

Energy

Utilization

Other Losses

Sankey Diagram of Biomass Steam CHP-Plant

~ 60 - 80 % Heat

Utilization

Spilling Steam Power: Engines and Turbines

Optimal Use of Energy with CHP

Examples for Energy Balances: Biomass Steam Cogeneration Plants

Date / Name:

Case

04.10.2010 / Au

Primemover

Turbine

Engine

Engine

Design / Type

Multi Stage

Single Stage

Double Stage

[bar abs.]

42

62

26

[C]

425

dry sat.

265

Steam Pressure Boiler Outlet

Steam Temperature Boiler Outlet

Solid Biomass

Fuel

Steam Procution

[t/h]

30,0

24,0

4,0

[kWh/t]

782

649

685

[kW]

23.460

15.576

2.740

0,88

0,88

0,84

[kW]

26.659

17.700

3.262

Inlet Engine / Turbine

[bar abs.]

40,0

60,0

25,0

Inlet Engine / Turbine

[C]

420

dry sat.

260

[bar abs.]

0,8

11,0

1,5

Output at Generator Terminals

[kWel]

4.830

1.000

333

Exhaust Steam Heat

[kWth]

18.000

13.500

2.330

18,1%

5,6%

10,2%

93

185

111

District Heating

Process

Process and Heating

Stecific Heat Demand for Steam Prorduction

Steam Heat Capacity Boiler

Boiler Efficiency

Firing Capacity Boiler

Outlet Engine / Turbine

El. Efficiency (gross) related to fuel input

Exhaust Steam Temperature

Exhaust Steam Utilization

[C]

Electricity as valuable by-product

Spilling Steam Power: Engines and Turbines

Pure Electricity Production

~10 - 25 % Boiler Losses

100 %

Fuel

Energy

~ 70 - 80 %

Energy

into

Steam

15 25 (30) % Power

~ 55 - 65 % Heat Loss

Condenser

Other Losses

Sankey Diagram of Biomass Condensing Steam Power Plant

Spilling Steam Power: Engines and Turbines

Example for Vacuum Condensing Power Generation

Examples for Energy Balances: Biomass Steam Power Generation

Case

Primemover

Turbine

Design / Type

Multi Stage

Steam Pressure Boiler Outlet

Steam Temperature Boiler Outlet

[bar abs.]

42

[C]

425

Fuel

Steam Procution

Stecific Heat Demand for Steam Prorduction

Steam Heat Capacity Boiler

solid biomass

[t/h]

30,0

[kWh/t]

782

[kW]

23.460

Boiler Efficiency

Firing Capacity Boiler

0,88

[kW]

26.659

Inlet Engine / Turbine

[bar abs.]

40,0

Inlet Engine / Turbine

[C]

420

[bar abs.]

0,1

[kWel]

6.700

Outlet Engine / Turbine

Output at Generator Terminals

El. Efficiency (gross) related to fuel input

Exhaust Steam Temperature

Exhaust Steam Utilization

25,1%

[C]

46

none

Spilling Steam Power: Engines and Turbines

The Spilling Steam Engine: Modular Design

Spilling Steam Power: Engines and Turbines

The Spilling Steam Engine

Design Features:

modular design

(from 1 to 6 cylinders; 15 different piston diameters)

volumetric flow control: filling regulation

oil free steam

skid mounted engine set for flexible installation

Spilling Steam Power: Engines and Turbines

The Spilling Steam Engine

Key Figures and Facts

Power Output

up to ~ 1.200 kW

Steam Flow Rates

up to ~ 40 t/h

Live Steam Pressures

~ 6 to 60 bar

Back Pressures

up to ~ 15 bar

Spilling Steam Power: Engines and Turbines

Spilling Steam Engine

Animation Steam Engine

Spilling Steam Power: Engines and Turbines

Spilling Steam Engines: High Part Load Performance

75

160

140

50

120

25

100

80

0

0

25

50

Throughput

75

100

Spec. Steam consumption [%]

Capacity

[%]

100

Spilling Steam Power: Engines and Turbines

Engine Type:

Number of Expansion Stages:

Number of Cylinders:

Speed:

[rpm]

Generator Rating:

Voltage:

Frequency:

[kVA]

[V]

[Hz]

Boiler (Exit):

Inlet - Engine:

Outlet - Engine:

[barg] / [C]

[barg] / [C]

[barg]

1/ 1-H12 TS

2

2

1000

Spilling Steam Engines:

420

400

50

Example 4 t/h

25,0/ 265

24,0/ 260

0,5

400

350

Electrical Output [kW el]

300

250

200

150

100

50

0

0,0

1,0

2,0

3,0

4,0

Steam Flow Rate [t/h]

Project: Example IEA - Workshop

Steam Engine Set

Chart: DA 14056

Name: Au

Date: 4.10.10

5,0

Spilling Steam Power: Engines and Turbines

Spilling Engine: Characteristics / Advantages:

wide operation range

high (partload) efficiencies

good regulation behaviour at fluctuating live steam cond.

good capability for saturated steam

moderate requirements for boiler feed water treatment

maintenance by local staff / technicians possible

Spilling Steam Power: Engines and Turbines

Comparision of Output Regulation Principles

100

Filling Regulation (Engine)

Nozzle Group Valve Control (T.)

Power

[%]

75

Throttle Valve Control (Turbine)

50

25

0

0

25

50

75

Steam Flow [%]

100

Spilling Steam Power: Engines and Turbines

Example 1

Bio Sludge Incineration

Plant

(Netherlands)

Exhaust Steam

Utilization for Boiler

Feed Water Preheating

and Space Heating

El. Output:

514 kWel

Live Steam Data:

11 t/h / 8 bar / Saturated

Steam Outlet Pressure:

0,5 barg

Spilling Steam Power: Engines and Turbines

Example 2

Wood Industry

Wood Residues Fired

Boiler Plant

(Austria)

Exhaust Steam

Utilization for Process

and Drying Kilns

El. Output:

2 x 1.000 kWel

Live Steam Data:

2 x 24 t/h / 60 bar / Saturated

Steam Outlet Pressure:

11 barg

Spilling Steam Power: Engines and Turbines

Example 3

Remote Power

Generation for

Saw Mill

(Congo)

with Wood fired

Steam Boiler

El. Output:

700 kWel

Live Steam Data:

9 t/h / 25 bar / 250 C

Steam Outlet Pressure:

0,5 barg

Spilling Steam Power: Engines and Turbines

Example 4

Power Generation

in a

Saw Mill

(Australia)

with Wood Fired

Steam Boiler

El. Output:

425 kWel

Live Steam Data:

5,5 t/h / 34 bar / dry sat.

Steam Outlet Pressure:

1,0 barg

Spilling Steam Power: Engines and Turbines

Spilling Steam Engines suit perfect in small scale

co-generation applications with ...

typical output range from 100 to 1.000 kWel

fluctuating live steam conditions

variable steam flow rates

moderate live steam parameters

Spilling Steam Power: Engines and Turbines

Thank you very much for your attention!

Potrebbero piacerti anche

- LCR 200 Wiring Routing and Connector PDFDocumento397 pagineLCR 200 Wiring Routing and Connector PDFYannick de WalqueNessuna valutazione finora

- Defender 300 Tdi MY96 - Workshop Manual (LRL0097ENG 3rd Ed)Documento455 pagineDefender 300 Tdi MY96 - Workshop Manual (LRL0097ENG 3rd Ed)Riahi Rezeg100% (1)

- WD400U Service ManualDocumento180 pagineWD400U Service ManualJorjNessuna valutazione finora

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsDa EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNessuna valutazione finora

- PowerplantapplicationsDocumento90 paginePowerplantapplicationsRicky Lao100% (2)

- B15 18S-5 (Sb1086e09)Documento254 pagineB15 18S-5 (Sb1086e09)GORDNessuna valutazione finora

- ORC Working Fluids Comparison ECOS PresentationDocumento16 pagineORC Working Fluids Comparison ECOS Presentationoverlord5555Nessuna valutazione finora

- Gas Turbine Power PlantDocumento28 pagineGas Turbine Power PlantPao CastillonNessuna valutazione finora

- LOGAN UputstvoDocumento231 pagineLOGAN Uputstvosdunja100% (2)

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferDa EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferValutazione: 5 su 5 stelle5/5 (2)

- Boiler CombustionDocumento20 pagineBoiler CombustionAnand SwamiNessuna valutazione finora

- Turbine General Training ModuleDocumento23 pagineTurbine General Training Moduletaharazvi83% (6)

- MS3-ASME Gas Turbine Technologies PresentationDocumento54 pagineMS3-ASME Gas Turbine Technologies PresentationVeerabhadra Rao Korimilli100% (1)

- Cog en Era Ti OnDocumento12 pagineCog en Era Ti OnMayank DubeyNessuna valutazione finora

- Combined Cycle Gas TurbineDocumento188 pagineCombined Cycle Gas TurbineAbbas_Makki94% (16)

- Gas Turbine TechnologyDocumento39 pagineGas Turbine Technologysciencelov100% (2)

- Byc 8.5-17 TonDocumento28 pagineByc 8.5-17 TonMike Zeller100% (1)

- Combined Cycle Power PlantDocumento9 pagineCombined Cycle Power PlantAbinCBabuNessuna valutazione finora

- Report On Steam Power PlantDocumento5 pagineReport On Steam Power PlantBabbu Mehra100% (1)

- Gas TurbineDocumento26 pagineGas Turbineramamurthy123100% (4)

- Fundamentals of Power PlantsDocumento53 pagineFundamentals of Power PlantsRam KumarNessuna valutazione finora

- Ajuste de VálvulasDocumento3 pagineAjuste de VálvulasEmerson MercadoNessuna valutazione finora

- Gas Power Plants by Muhammad Arif: EE-415: Power Generation, Transmission and Distribution, Spring 2013Documento31 pagineGas Power Plants by Muhammad Arif: EE-415: Power Generation, Transmission and Distribution, Spring 2013Muhammad Farooq MalikNessuna valutazione finora

- CLG414 India 35F0022 41 51 52 Parts Manual 201507005-ENDocumento345 pagineCLG414 India 35F0022 41 51 52 Parts Manual 201507005-ENdeepakchandraadhikariNessuna valutazione finora

- Power Generation From Combustion NEWDocumento49 paginePower Generation From Combustion NEWhridita purbaNessuna valutazione finora

- Steam Turbine For IndustriesDocumento24 pagineSteam Turbine For Industriesashokparikh100% (2)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDa EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNessuna valutazione finora

- Energy Audit & Efficiency Improvement of Operating Power PlantsDocumento56 pagineEnergy Audit & Efficiency Improvement of Operating Power Plantsmhdsoleh100% (1)

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentDa EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNessuna valutazione finora

- Gas Turbine Technology: Ashish Kumar MDS12M002Documento40 pagineGas Turbine Technology: Ashish Kumar MDS12M002karthikeyan murugesan100% (2)

- Main Schematic 980KDocumento4 pagineMain Schematic 980KHENRYNessuna valutazione finora

- Cogeneration - Combined Heat and Power (CHP)Documento23 pagineCogeneration - Combined Heat and Power (CHP)Reyes SanchezNessuna valutazione finora

- 04 Gas Turbine TurbomachDocumento42 pagine04 Gas Turbine Turbomachlalit92112760Nessuna valutazione finora

- Gas Turbine Technologies For Electric GenerationDocumento54 pagineGas Turbine Technologies For Electric GenerationFabbrox100% (3)

- Cogeneration CycleDocumento30 pagineCogeneration Cyclekaladher5311937Nessuna valutazione finora

- Technology and Economics of Modern Biogas EnginesDocumento36 pagineTechnology and Economics of Modern Biogas EnginesnguyenbmtsvNessuna valutazione finora

- Purification KATALCO Mar 07Documento16 paginePurification KATALCO Mar 07SimEnzNessuna valutazione finora

- The Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattDa EverandThe Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattNessuna valutazione finora

- Steam Power Plant: Pros & Cons: What This Power Station Presents Advantages DisadvantagesDocumento4 pagineSteam Power Plant: Pros & Cons: What This Power Station Presents Advantages Disadvantagesyanblade100% (1)

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasDa EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNessuna valutazione finora

- ORC Technology For Waste Heat Recovery Power Generation: DR Vijayakumar Kunche, M.Tech., PH.DDocumento45 pagineORC Technology For Waste Heat Recovery Power Generation: DR Vijayakumar Kunche, M.Tech., PH.Dandri.motoGNessuna valutazione finora

- Brochure Gas Turbine SGT-800 For Power GenerationDocumento4 pagineBrochure Gas Turbine SGT-800 For Power GenerationJuan AraqueNessuna valutazione finora

- IEA Workshop Copenhagen Small Scale Biomass Co-Generation With Modern Steam EnginesDocumento23 pagineIEA Workshop Copenhagen Small Scale Biomass Co-Generation With Modern Steam EnginesPhong Hoang LeNessuna valutazione finora

- Thermea Flyer EnglDocumento6 pagineThermea Flyer EnglMark ChongNessuna valutazione finora

- Spilling PDFDocumento15 pagineSpilling PDFabetlejNessuna valutazione finora

- 7.8 Typical Cogeneration Performance ParametersDocumento5 pagine7.8 Typical Cogeneration Performance ParametersaizatmaricanNessuna valutazione finora

- Konservasi Enegri Pada Ketel Uap - CompressedDocumento66 pagineKonservasi Enegri Pada Ketel Uap - CompressedDedi HermansyahNessuna valutazione finora

- Co GenerationDocumento24 pagineCo GenerationNiki StevensNessuna valutazione finora

- Gas Turbine Power Plant PDFDocumento28 pagineGas Turbine Power Plant PDFPao CastillonNessuna valutazione finora

- 10 Electricity Generation and CogenerationDocumento34 pagine10 Electricity Generation and CogenerationCristhian Garcia VillarroelNessuna valutazione finora

- Cogeneration in IndiaDocumento22 pagineCogeneration in Indiaashwini_kumar19840% (1)

- Cogeneration by Naresh Meena 10EMBME036 Mechnical 8 SemDocumento20 pagineCogeneration by Naresh Meena 10EMBME036 Mechnical 8 SemMultiverseIitNessuna valutazione finora

- Thermal Efficiency of Stoves - Math Clarification Request - ACM0012 - SKonthamDocumento5 pagineThermal Efficiency of Stoves - Math Clarification Request - ACM0012 - SKonthamSamanway DasNessuna valutazione finora

- 4.3 Gas Turbines: 4.3.1 Technology DescriptionDocumento11 pagine4.3 Gas Turbines: 4.3.1 Technology DescriptionZahid HussainNessuna valutazione finora

- CogenerationDocumento53 pagineCogenerationSri Ch.V.Krishna Reddy Assistant Professor (Sr,)Nessuna valutazione finora

- Y.pabbI - 28 July 15 - EE ImpOperatg PlantsDocumento56 pagineY.pabbI - 28 July 15 - EE ImpOperatg Plantsamerie joy onateNessuna valutazione finora

- Biomass-Fired CHP Plant Based On A Screw-Type Engine Cycle"Documento4 pagineBiomass-Fired CHP Plant Based On A Screw-Type Engine Cycle"Lahiru BoralugodaNessuna valutazione finora

- C9 Part3 V2Documento33 pagineC9 Part3 V2Emin ÇelikNessuna valutazione finora

- 4 3 CogenerationDocumento10 pagine4 3 CogenerationJayvin RossNessuna valutazione finora

- Paper 4A SolutionDocumento10 paginePaper 4A SolutionSHAMSIK2002Nessuna valutazione finora

- 12 Chapter3 Section4 Oil Refining Industry Page193 220Documento26 pagine12 Chapter3 Section4 Oil Refining Industry Page193 220Muhammad FarooqNessuna valutazione finora

- CCTP AdstractDocumento10 pagineCCTP Adstractmkarthikeyan023Nessuna valutazione finora

- Integration of CCGT Plant and LNG TerminalDocumento28 pagineIntegration of CCGT Plant and LNG Terminalcicko45100% (1)

- Cogeneration Heat Power CHPDocumento10 pagineCogeneration Heat Power CHPMKOZERDEMNessuna valutazione finora

- Combined Cycle Power PlantDocumento2 pagineCombined Cycle Power Plantiman562Nessuna valutazione finora

- AlfaDisc ENGDocumento4 pagineAlfaDisc ENGSimEnzNessuna valutazione finora

- Synloop Waste Heat BoilerDocumento12 pagineSynloop Waste Heat BoilerSimEnzNessuna valutazione finora

- Alfa Laval Packinox For Methanol SynthesisDocumento2 pagineAlfa Laval Packinox For Methanol SynthesisSimEnzNessuna valutazione finora

- Nps 38 CFDocumento16 pagineNps 38 CFGauden Marie C. BangngayNessuna valutazione finora

- Explosion of Methanol DistillationDocumento12 pagineExplosion of Methanol DistillationSimEnzNessuna valutazione finora

- Penyetelan Clutch Pedal AvanzaDocumento3 paginePenyetelan Clutch Pedal Avanzareza takarai100% (1)

- Hyd Schematic 2658487205 - 005Documento3 pagineHyd Schematic 2658487205 - 005Angelo Solorzano100% (2)

- Pistons and Connecting Rods - InstallDocumento4 paginePistons and Connecting Rods - InstallYudi setiawanNessuna valutazione finora

- Repulsion MotorDocumento9 pagineRepulsion MotorSukanta Parida50% (2)

- 2750-2850 O&M EnglishDocumento34 pagine2750-2850 O&M EnglishshaikhbwcNessuna valutazione finora

- HATZ-IM - Unidad DieselDocumento33 pagineHATZ-IM - Unidad DieselAdrian MartinNessuna valutazione finora

- Penerapan Doubly-Fed Induction Generator Untuk Pembangkit Listrik Tenaga AnginDocumento5 paginePenerapan Doubly-Fed Induction Generator Untuk Pembangkit Listrik Tenaga AnginRizkyhaikalNessuna valutazione finora

- CarrilloDocumento48 pagineCarrilloTheoo RutterNessuna valutazione finora

- Topaire R32 Inverter Air Cooled Split UNIT 2023Documento6 pagineTopaire R32 Inverter Air Cooled Split UNIT 2023bitalohNessuna valutazione finora

- Alarm ListaDocumento4 pagineAlarm ListaNhím BiểnNessuna valutazione finora

- EE213 Applied Electrical Engineering: Fall 2020 Mazhar JavedDocumento18 pagineEE213 Applied Electrical Engineering: Fall 2020 Mazhar JavedElbert VonVerimNessuna valutazione finora

- Comparative Study of Four Stroke Diesel and Petrol EngineDocumento7 pagineComparative Study of Four Stroke Diesel and Petrol EnginepandiyaNessuna valutazione finora

- DK 1008-En 04.15 13 PDFDocumento1 paginaDK 1008-En 04.15 13 PDFIulia CostacheNessuna valutazione finora

- Service Manual: Carbureted Suzuki 970 CC EngineDocumento95 pagineService Manual: Carbureted Suzuki 970 CC EngineHallex OliveiraNessuna valutazione finora

- Ae Lab ManualDocumento48 pagineAe Lab Manualसंकेत कलगुटकर100% (1)

- Auxiliary System of Diesel Electric Power PlantDocumento12 pagineAuxiliary System of Diesel Electric Power PlantAllen EspeletaNessuna valutazione finora

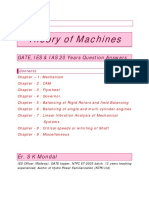

- TOM IES GATE IAS 20 Years Question and Answers by S K Mondal PDFDocumento137 pagineTOM IES GATE IAS 20 Years Question and Answers by S K Mondal PDFgaurav jha100% (3)

- Test SpecificationsDocumento2 pagineTest SpecificationsBest Auto Tech100% (1)

- UHP Triplex Pump: Ultrabar30Documento2 pagineUHP Triplex Pump: Ultrabar30Frederik CañabiNessuna valutazione finora