Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CarTech® Ferrium® S53® Alloy

Caricato da

rohithvijayakumarrCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CarTech® Ferrium® S53® Alloy

Caricato da

rohithvijayakumarrCopyright:

Formati disponibili

6/3/2016

CarTechFerriumS53Alloy

UnitDisplay: English

PrintNow

CarTechFerriumS53Alloy

EmailDatasheet

AddtoMyMaterials

Identification

U.S.PatentNumber

7,967,927B2

UNSNumber

S10500

TypeAnalysis

Singlefiguresarenominalexceptwherenoted.

Carbon

Nickel

Cobalt

Tungsten

0.21 %

5.50 %

14.00 %

1.00 %

Chromium

Molybdenum

Vanadium

Iron

10.00 %

2.00 %

0.30 %

Balance

GeneralInformation

Description

Acorrosionresistant,ultrahighstrengthsteelthathasbeenusedinstructuralaerospaceapplications.Thealloy

hasprovidedmechanicalpropertiesequaltoorbetterthanconventionalultrahighstrengthsteelssuchas300M

andSAE4340withtheaddedbenefitofgeneralcorrosionresistance.Thiscaneliminatetheneedforcadmium

coatingandthesubsequentaccompanyingprocessing.FerriumS53alloypossessesgreatlyimprovedresistance

tostresscorrosioncracking(SCC)comparedwith300Mand4340alloys.

Applications

Typicalapplicationsincludeaircraftlandinggears,pins,flaptracks,actuators,fastenersandotherstructural

applications.FerriumS53hasbeenusedforseveralsafetylandinggearcomponentsonAirForceplatformsA10,

C5,KC135andT38withoutcadmiumplating.

CorrosionResistance

ImportantNote:Thefollowing4levelratingscaleisintendedforcomparativepurposesonly.Corrosiontestingis

recommendedfactorswhichaffectcorrosionresistanceincludetemperature,concentration,pH,impurities,

aeration,velocity,crevices,deposits,metallurgicalcondition,stress,surfacefinishanddissimilarmetalcontact.

NitricAcid

Excellent

SaltSpray(NaCl)

Good

Properties

PhysicalProperties

Density

0.2880 lb/in

MeanSpecificHeat

73F

0.1080 Btu/lb/F

392F

0.1200 Btu/lb/F

752F

0.1340 Btu/lb/F

1076F

0.2330 Btu/lb/F

MeanCTE

75to220F

5.86 x106in/in/F

75to400F

5.89 x106in/in/F

75to600F

6.00 x106in/in/F

75to800F

6.13 x106in/in/F

75to1000F

6.22 x106in/in/F

75to1100F

6.19 x106in/in/F

ThermalConductivity

73F

124.6 BTUin/hr/ft/F

http://cartech.ides.com/datasheet.aspx?I=102&TAB=DV_DS&E=335&SKEY=102.36.5056540:12aaf1b70a664af1a7df3ce2545ca7c1&CULTURE=enUS&&FM 1/5

6/3/2016

CarTechFerriumS53Alloy

212F

140.2 BTUin/hr/ft/F

392F

157.2 BTUin/hr/ft/F

572F

171.3 BTUin/hr/ft/F

752F

181.2 BTUin/hr/ft/F

932F

199.8 BTUin/hr/ft/F

1100F

243.9 BTUin/hr/ft/F

ModulusofElasticity(E)

29.6 x103ksi

CriticalTemperature(AC1)

1364 F

CriticalTemperature(AC3)

1436 F

MartensiteStart

212 F

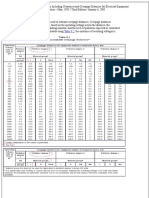

TypicalMechanicalProperties

http://cartech.ides.com/datasheet.aspx?I=102&TAB=DV_DS&E=335&SKEY=102.36.5056540:12aaf1b70a664af1a7df3ce2545ca7c1&CULTURE=enUS&&FM 2/5

6/3/2016

CarTechFerriumS53Alloy

HeatTreatment

FerriumS53canbesolutiontreatedandtemperedineithervacuum,airorothermediaasdescribedbelow,and

selectionoftheprocesscandependonfactorssuchas:industryapplicationabilityanddesiretofinalmachinea

partaftertemperingsizeorweightofpartachievablequenchratesetc.

Decarburization

FerriumS53issubjecttodecarburizationduringhardening.Tomitigatedecarburization,heattreatmentshould

takeplaceinaneutralatmospherefurnace,saltbathorvacuum.Theextentofdecarburizationcanbe

determinedbycomparingthesurfaceandinternalhardnessofasmalltestcoupon.

Normalizing

1975F(1080C)for1hourandaircool.

Annealing

1255F(680C)for8hoursandaircool.Anannealedhardnessof327HBorlowerisobtainedfollowing

annealing.

SolutionTreatment

1985F(1085C)1hourandoilquenchorequivalent.

http://cartech.ides.com/datasheet.aspx?I=102&TAB=DV_DS&E=335&SKEY=102.36.5056540:12aaf1b70a664af1a7df3ce2545ca7c1&CULTURE=enUS&&FM 3/5

6/3/2016

CarTechFerriumS53Alloy

Deformation(SizeChange)inHardening

HeattreatmentgrowthofFerriumS53isdependentuponthethermalhistoryandmachiningpath(e.g.

machiningstresses)ofthepartsbeingproduced.TypicalgrowthofS53isuniformandapproximately0.002

0.003inchesperinch.

Quenching

Gas,Oil,orEquivalent.

ColdTreatment

Followingnormalizationand/orsolutiontreatment,100F(73C)for1hourandairwarm.

Straightening

Operationssuchasshaftstraightening(ifrequired)shouldpreferablybedoneafterthesubzerotreatmentbut

priortothetemper.S53achievesfullmechanicalstrengthaftertempering,andthustryingtostraightenparts

aftertemperingwillbemoredifficult.

Forsomeparts,mechanicalstraighteningmaybedesiredtocompensateforpossibledistortionduringheat

treatment.Priortostraightening,alowtemperaturestressreliefat392F(200C)for1hourfollowingthefirst

refrigerationoperationshouldbeconducted.Hotstraighteningshouldbeconductedbelow700F(371C)toavoid

tempering,oxidationordecarburization.

StressRelieving

Ifitisdesiredtostressrelieveamachinedpartinthemillannealedconditionasameanstohelpprevent

distortionduringfurtherprocessing(e.g.ifsignificantforceswereimposedonthepartduringmachining),then

eitheroftwooptionsarerecommended:

i.Producethepartinaroughmachinedstatewithadequatestockmaterialonallsurfacessothatoxidescale

canberemoved,andthenstressrelievethepartat~1200F(649C)for2hours,followedbycoolinginair.

Thencompleteallfinalmachiningoperationspriortosolutiontreatment,quench,subzerotreatmentand

temper,inordertoremovetheoxidescaleformedat1200F(649C).

ii.Producethepartinafullyornearlyfullymachinedstatepriortosolutiontreatment,subzerotreatment

quenchandtemper,andthenstressrelievethepartat700F(371C)for2hoursor525F(274C)for4hours,

followedbycoolinginair.

Tempering

Doubletemperat934F(501C)for3hoursandoilquenchorequivalent,followedby100F(73C)for1hour

andairwarm,thenathirdandfinaltemperat900F(482C)for12hoursandaircool.

Preheating

Apreheattemperatureofnohigherthan600F(315C)isrecommended.

Workability

HotWorking

18002050F(9821121C).

Recommendedreductionratioof4:1.

Forging

Standardforgingofbilletandbarstockshouldbeconductedat18002050F(9821121C).Ifhigherforging

temperaturesarepreferred,hotfiretemperaturesof23002350F(12601288C)maybeused,provideda

minimumof4:1forgingreductionratioisachieved.Followingforgingthepartsshouldbeaircooledtoroom

temperature,followedbynormalization,coldtreatmentandannealingtoimprovemachinability.

Machinability

http://cartech.ides.com/datasheet.aspx?I=102&TAB=DV_DS&E=335&SKEY=102.36.5056540:12aaf1b70a664af1a7df3ce2545ca7c1&CULTURE=enUS&&FM 4/5

6/3/2016

CarTechFerriumS53Alloy

AnnealedFerriumS53hasmachinabilitysimilarto300Mat35HRC.Toolsusedforcuttinganddrillingaretypically

thoseusedforother400seriesstainlesssteels.Recommendedspeedsare225to260SFMformilling,250300

SFMfordrilling.

PreheatingofDies

None

Plating

FerriumS53canbeelectroplatedwithsurfaceprotectionoptionssuchas:CrNiduplexNi+CrZnNiCdAl,

includingAlumiplateandIonVaporDeposition(IVD)aluminumandWCCopowderbyHVOFthermalspray.

Passivation

Passivationina50%nitricacidsolutionisrecommendedformaximumcorrosionresistanceperAMS2700B,

Method1.

OtherInformation

Descaling(Cleaning)

BarPeeling

MetallurgicalRequirements

Perbelowmaterialspecifications.

ApplicableSpecifications

Note:Whilethismaterialmeetsthefollowingspecifications,itmaybecapableofmeetingorbeingmanufactured

tomeetothergeneralandcustomerspecificspecifications.

AMS5922

FormsManufactured

BarFlats

BarRounds

References

BarRectangles

Billet

CINDASASMD/ASMH

MMPDS09

AMS2759/3forthermalprocessing

AMS2759/9forhydrogenbakeoutparameters

AMS2759/11forstressrelievingparameters

Disclaimer:

Theinformationanddatapresentedhereinaretypicaloraveragevaluesandarenotaguaranteeofmaximumor

minimumvalues.Applicationsspecificallysuggestedformaterialdescribedhereinaremadesolelyforthepurposeof

illustrationtoenablethereadertomakehis/herownevaluationandarenotintendedaswarranties,eitherexpress

orimplied,offitnessfortheseorotherpurposes.Thereisnorepresentationthattherecipientofthisliteraturewill

receiveupdatededitionsastheybecomeavailable.

Unlessotherwisespecified,registeredtrademarksarepropertyof

CRSHoldingsInc.,asubsidiaryofCarpenterTechnologyCorporation.

Copyright2016CRSHoldingsInc.Allrightsreserved.

EditionDate:10/26/2015

ContactourU.S.SalesOfficeoroneofourInternationalSalesOfficesformoreinformation.

http://cartech.ides.com/datasheet.aspx?I=102&TAB=DV_DS&E=335&SKEY=102.36.5056540:12aaf1b70a664af1a7df3ce2545ca7c1&CULTURE=enUS&&FM 5/5

Potrebbero piacerti anche

- ASM Specialty Handbook: Carbon Alloy SteelsDocumento2 pagineASM Specialty Handbook: Carbon Alloy SteelsGaurav Tripathi25% (4)

- AMS-S-6758 4130 SteelDocumento14 pagineAMS-S-6758 4130 SteelJesse KrebsNessuna valutazione finora

- WX100 Fastener Finish Speecification PDFDocumento16 pagineWX100 Fastener Finish Speecification PDFJulion2009Nessuna valutazione finora

- Duplex Ss WPSDocumento8 pagineDuplex Ss WPSVinu Raveendran100% (1)

- 20 TMSS 02 R0Documento0 pagine20 TMSS 02 R0renjithas2005Nessuna valutazione finora

- Timber DesignDocumento10 pagineTimber DesignAprille Lyn Silla100% (1)

- Material Finish GuideDocumento7 pagineMaterial Finish GuideRomie CubalNessuna valutazione finora

- Engineering Material SpecificationDocumento10 pagineEngineering Material SpecificationMike FiorenNessuna valutazione finora

- Green Box PDFDocumento20 pagineGreen Box PDFRolando El BlancoNessuna valutazione finora

- Repair refractory lining incineratorDocumento5 pagineRepair refractory lining incineratorcengiz kutukcu50% (2)

- Build Up RateDocumento4 pagineBuild Up RateLai Chungyi100% (2)

- WX100 World Wide Fastener Standard PDFDocumento16 pagineWX100 World Wide Fastener Standard PDFRico Malibiran100% (1)

- Corrugated Aluminum Jacketing CladdingDocumento3 pagineCorrugated Aluminum Jacketing CladdingGia Minh Tieu TuNessuna valutazione finora

- Basic Nec Code Rules and Design PracticeDocumento13 pagineBasic Nec Code Rules and Design PracticeSiswoyo Suwidji100% (1)

- WSS-M1A346-A - Calidad de ChapaDocumento12 pagineWSS-M1A346-A - Calidad de ChapaDANIEL DIAZNessuna valutazione finora

- Ffs-su-5216-A - Structural Welding and Inspection For Offshore PlatformsDocumento28 pagineFfs-su-5216-A - Structural Welding and Inspection For Offshore PlatformsBolarinwaNessuna valutazione finora

- 01 07-2Documento954 pagine01 07-2bs2002Nessuna valutazione finora

- Design and Construction of Ornamental Steel Picket Fence Systems For Security PurposesDocumento4 pagineDesign and Construction of Ornamental Steel Picket Fence Systems For Security PurposesDarwin DarmawanNessuna valutazione finora

- Method Statement For Foundation Cm1b 0 SCL Civ Ms 0006 Rev.ADocumento127 pagineMethod Statement For Foundation Cm1b 0 SCL Civ Ms 0006 Rev.AMinh HảiNessuna valutazione finora

- Ferri Um S 53 Carpenter Data SheDocumento2 pagineFerri Um S 53 Carpenter Data SherohithvijayakumarrNessuna valutazione finora

- HW6Documento2 pagineHW6Miguel CRNessuna valutazione finora

- 20 SDMS 01Documento43 pagine20 SDMS 01tapas_jitu100% (1)

- CH 05 PDFDocumento11 pagineCH 05 PDF朱亦詳Nessuna valutazione finora

- 307691505-Duplex-Ss-WPS 3 PDFDocumento8 pagine307691505-Duplex-Ss-WPS 3 PDFsteve aNessuna valutazione finora

- Defect TypesDocumento58 pagineDefect TypesStefano GiardiniNessuna valutazione finora

- Engineering Material SpecificationDocumento10 pagineEngineering Material SpecificationaldairlopesNessuna valutazione finora

- CH 05Documento11 pagineCH 05chaitanyachegg100% (2)

- PassivationDocumento1 paginaPassivationSaketh VandeNessuna valutazione finora

- Carpenter Stainless Type 431Documento7 pagineCarpenter Stainless Type 431rezaeibehrouzNessuna valutazione finora

- Ic381 TM5043 SMTP PPT01Documento25 pagineIc381 TM5043 SMTP PPT01steveNessuna valutazione finora

- Wx100 PDF FreeDocumento17 pagineWx100 PDF Freechinkal miglaniNessuna valutazione finora

- WSS M1a347 (Hsla)Documento14 pagineWSS M1a347 (Hsla)Enrique Maya VisuetNessuna valutazione finora

- WX100Documento21 pagineWX100Emir AkçayNessuna valutazione finora

- JMR&T-2023 Final PaperDocumento20 pagineJMR&T-2023 Final PaperUroš TrdanNessuna valutazione finora

- Tab 5000 V 6000 White Paper Final 03.08.10Documento5 pagineTab 5000 V 6000 White Paper Final 03.08.10TaberExtrusionsNessuna valutazione finora

- Astm A0490Documento7 pagineAstm A0490ndt_inspectorNessuna valutazione finora

- 41xx Steel: 1 Properties 2 Other CharacteristicsDocumento2 pagine41xx Steel: 1 Properties 2 Other CharacteristicsFerdinand A AlbarNessuna valutazione finora

- Copper AlloysDocumento4 pagineCopper AlloysBookMaggotNessuna valutazione finora

- 6 - Specifications Ductile Cast UronDocumento3 pagine6 - Specifications Ductile Cast UronFabFabFabFabNessuna valutazione finora

- Fastener Corrosion Protection in Arabian GulfDocumento5 pagineFastener Corrosion Protection in Arabian GulfJeevan Prasad JalliNessuna valutazione finora

- Enclosure IVDocumento7 pagineEnclosure IVvinayakNessuna valutazione finora

- Platforms in Cargo Tanks: Standard Practice ForDocumento5 paginePlatforms in Cargo Tanks: Standard Practice ForDarwin DarmawanNessuna valutazione finora

- Mig/Tig Arc Welding For Stainless Steels & Carbon SteelsDocumento10 pagineMig/Tig Arc Welding For Stainless Steels & Carbon SteelsTrương Ngọc SơnNessuna valutazione finora

- Ferritic Stainless Stell 1.4003Documento4 pagineFerritic Stainless Stell 1.4003rusf123Nessuna valutazione finora

- Laby Seal-Abbradable TypeDocumento1 paginaLaby Seal-Abbradable Typefjafarvand100% (1)

- Composite Corrugated Steel Pipe For Sewers and DrainsDocumento8 pagineComposite Corrugated Steel Pipe For Sewers and DrainsfaroukNessuna valutazione finora

- Airworthiness Bulletin: AWB Issue: Date: 1. EffectivityDocumento3 pagineAirworthiness Bulletin: AWB Issue: Date: 1. EffectivitymazaherramazaniNessuna valutazione finora

- Properties FSW 5083Documento11 pagineProperties FSW 5083Daniel MarquesNessuna valutazione finora

- Relationships Between Aluminum Alloy Properties and FSW ParametersDocumento20 pagineRelationships Between Aluminum Alloy Properties and FSW ParametersrajesaravindNessuna valutazione finora

- Document For MetalDocumento14 pagineDocument For MetalSean ThomasNessuna valutazione finora

- Hardened Steel Washers (Metric) : Standard Specification ForDocumento5 pagineHardened Steel Washers (Metric) : Standard Specification ForPaulo GalvãoNessuna valutazione finora

- Mil DTL 5099CDocumento18 pagineMil DTL 5099CDavid ChNessuna valutazione finora

- Acetabular Prostheses: Standard Specification ForDocumento6 pagineAcetabular Prostheses: Standard Specification ForVijay KumarNessuna valutazione finora

- 4.3.10 - Astm F366-10 2011Documento4 pagine4.3.10 - Astm F366-10 2011Emílio DechenNessuna valutazione finora

- BT MarineDocumento2 pagineBT MarinestrtsNessuna valutazione finora

- High - Strength - Low - Alloy - Structural - Steel-2019 - 2Documento30 pagineHigh - Strength - Low - Alloy - Structural - Steel-2019 - 2Exp KNessuna valutazione finora

- Aalco Metals LTD Stainless Steel 1.4003 Nirosta 4003 3CR12 96Documento2 pagineAalco Metals LTD Stainless Steel 1.4003 Nirosta 4003 3CR12 96Xingfeng HanNessuna valutazione finora

- Amt 4201 Aircraft Structures Ii Compilation of Final Term DiscussionsDocumento95 pagineAmt 4201 Aircraft Structures Ii Compilation of Final Term DiscussionsangeloNessuna valutazione finora

- Alloy 4043 - Aluminium Welding Alloy 4043Documento2 pagineAlloy 4043 - Aluminium Welding Alloy 4043chandraNessuna valutazione finora

- Effect of Pin Length On Friction Stir Spot Welding (FSSW) of Dissimilar Aluminum-Steel JointsDocumento10 pagineEffect of Pin Length On Friction Stir Spot Welding (FSSW) of Dissimilar Aluminum-Steel JointsLinaceroNessuna valutazione finora

- ASTM-A490M: Licensed by Information Handling Services Licensed by Information Handling ServicesDocumento6 pagineASTM-A490M: Licensed by Information Handling Services Licensed by Information Handling ServicesRoland CepedaNessuna valutazione finora

- Superalloy BrochureDocumento16 pagineSuperalloy Brochurearien_merlianaNessuna valutazione finora

- Shipboard Oil Pollution Abatement System: Standard Specification ForDocumento27 pagineShipboard Oil Pollution Abatement System: Standard Specification ForfordNessuna valutazione finora

- Hardened Steel Washers (Metric) : Standard Specification ForDocumento5 pagineHardened Steel Washers (Metric) : Standard Specification ForAdán Cogley CantoNessuna valutazione finora

- F 2215 - 03 - RjiymtuDocumento33 pagineF 2215 - 03 - RjiymtuSTAFFORDNessuna valutazione finora

- Analysis of Distortion, Corrosion and Mechanical Properties of Welded ASTM A36 Steel U-Type ProfilesDocumento8 pagineAnalysis of Distortion, Corrosion and Mechanical Properties of Welded ASTM A36 Steel U-Type ProfilesIJAERS JOURNALNessuna valutazione finora

- Evaluation of Mechanical Properties of Medium Carbon Stell Qunched in Water and OilDocumento4 pagineEvaluation of Mechanical Properties of Medium Carbon Stell Qunched in Water and OilrohithvijayakumarrNessuna valutazione finora

- Ferri Umm 54 Machining StudyDocumento23 pagineFerri Umm 54 Machining StudyrohithvijayakumarrNessuna valutazione finora

- High-Strength Low-Alloy Steel - Wikipedia, The Free EncyclopediaDocumento5 pagineHigh-Strength Low-Alloy Steel - Wikipedia, The Free EncyclopediarohithvijayakumarrNessuna valutazione finora

- Mech 473 Lectures: Professor Rodney HerringDocumento25 pagineMech 473 Lectures: Professor Rodney HerringrohithvijayakumarrNessuna valutazione finora

- SUPERCITO MMA Electrodes for Structural and Heavy WorkDocumento1 paginaSUPERCITO MMA Electrodes for Structural and Heavy Workantonio111aNessuna valutazione finora

- UL 840 Third Edition January 2005 Section 9 Creepage DistancesDocumento4 pagineUL 840 Third Edition January 2005 Section 9 Creepage DistancesRobert LegaultNessuna valutazione finora

- Improvement of Mechanical Properties in Structural Steels by Development of Acicular Ferrite MicrostructuresDocumento2 pagineImprovement of Mechanical Properties in Structural Steels by Development of Acicular Ferrite MicrostructuresevfratNessuna valutazione finora

- Steam Jet Ejectors in Pilot and Production PlantsDocumento5 pagineSteam Jet Ejectors in Pilot and Production PlantsPrabhakar KattulaNessuna valutazione finora

- Kabale Culvert TypicalsDocumento15 pagineKabale Culvert TypicalsPhillip KakuruNessuna valutazione finora

- Wall Mounted PDFDocumento5 pagineWall Mounted PDFAhmed AzadNessuna valutazione finora

- Electrical Plan ComputationDocumento1 paginaElectrical Plan ComputationMarc Adrienne MarquezNessuna valutazione finora

- Deisgn Mix9.5.xls (M'LANG)Documento6 pagineDeisgn Mix9.5.xls (M'LANG)Kathy MigzNessuna valutazione finora

- Center of Mass N Rigidity Lecture-Sample Problem1Documento5 pagineCenter of Mass N Rigidity Lecture-Sample Problem1Francis CabinganNessuna valutazione finora

- Assistant Bar Bender Theory Set 1 MergedDocumento252 pagineAssistant Bar Bender Theory Set 1 Mergedmaneesh kumar shuklaNessuna valutazione finora

- GRANOR AC-AR Expansion JointDocumento5 pagineGRANOR AC-AR Expansion JointscribdarellNessuna valutazione finora

- RedBuilt Open-Web DesignDocumento40 pagineRedBuilt Open-Web Designmeetvinayak2007Nessuna valutazione finora

- A Numerical and Experimental Approach To Study The Parametric Effect of Ultrasonic WeldingDocumento80 pagineA Numerical and Experimental Approach To Study The Parametric Effect of Ultrasonic WeldingCostica PetreNessuna valutazione finora

- Behavior of Reinforced Concrete Wide Concealed-Beam PDFDocumento12 pagineBehavior of Reinforced Concrete Wide Concealed-Beam PDFMarimuthu KaliyamoorthyNessuna valutazione finora

- 23 05 29 - HVAC Hangers and SupportsDocumento9 pagine23 05 29 - HVAC Hangers and SupportsperezismaelNessuna valutazione finora

- Mantri Metro-Residential Commercial Station Projects AnalysisDocumento2 pagineMantri Metro-Residential Commercial Station Projects AnalysisraviNessuna valutazione finora

- (2017 Nilforoush Et Al.) - Influence of Surface Reinforcement, Member Thickness and Cracked Concrete On Tensile Capacity of Anchor BoltsDocumento14 pagine(2017 Nilforoush Et Al.) - Influence of Surface Reinforcement, Member Thickness and Cracked Concrete On Tensile Capacity of Anchor BoltsmanoelmangabeiraNessuna valutazione finora

- Flextures Hourglass PivotDocumento2 pagineFlextures Hourglass PivotReyginald MarronNessuna valutazione finora

- Description Specify MEP Engineering CD EngineersDocumento2 pagineDescription Specify MEP Engineering CD EngineersSameera LakmalNessuna valutazione finora

- PipeWrap BTDocumento2 paginePipeWrap BTPrashantBaruaNessuna valutazione finora

- Heavy-Duty Safety Rope Pull Switches for Long ConveyorsDocumento3 pagineHeavy-Duty Safety Rope Pull Switches for Long ConveyorsMasood NizamNessuna valutazione finora

- Suva R-507Documento2 pagineSuva R-507Eliott Noe Rumiche ChungaNessuna valutazione finora

- 4.1.5 Axis T92e20Documento2 pagine4.1.5 Axis T92e20nisarahmedgfecNessuna valutazione finora