Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MSDS for Chockfast Orange Hardener

Caricato da

anandakoeDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MSDS for Chockfast Orange Hardener

Caricato da

anandakoeCopyright:

Formati disponibili

Material Safety Data Sheet

ITW Philadelphia Resins

Part No.: 1010H

Page 1

CHOCKFAST ORANGE HARDENER

This product appears in the following stock number(s):

1010U 1020U

Last revised:

Printed:

03/20/03

03/20/2003

1. CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

Tradename:

CHOCKFAST ORANGE HARDENER

General use:

The following data pertain to the hardener only; properly mixed and cured epoxies are not

hazardous.

Chemical family:

Aliphatic amines

MANUFACTURER

EMERGENCY INFORMATION

ITW Philadelphia Resins

130 Commerce Dr.

Montgomeryville, PA 18936

Emergency telephone number

(800) 424-9300

(CHEMTREC):

Other Calls:

(215) 855-8450

2. COMPOSITION/INFORMATION ON INGREDIENTS

Exposure limits

HAZARDOUS CONSTITUENTS

Constituent

Triethylenetetramine

Abbr.

TETA

CAS No.

112243

Weight

percent

> 80

ACGIH

TLV

n/e

OSHA

PEL

Other

Limits

1 ppm (skin)

(AIHA-WEEL)

n/e

"TLV" means the Threshold Limit Value exposure (eight-hour, time-weighted average, unless otherwise noted) established by the American

Conference of Governmental Industrial Hygienists. "STEL" indicates a short-term exposure limit. "PEL" indicates the OSHA Permissible Exposure

Limit."n/e" indicates that no exposure limit has been established. An asterisk (*) indicates a substance whose identity is a trade secret of our supplier

and unknown to us.

3. HAZARDS IDENTIFICATION

Emergency Overview

Appearance, form, odor: amber liquid with fishy odor.

DANGER! Corrosive. Causes eye and skin burns. Eye, skin and respiratory irritant. Toxic by skin absorption. May

cause skin sensitization.

Potential health effects

Primary routes of exposure:

Skin contact

Skin absorption

Eye contact

Inhalation

Ingestion

Symptoms of acute overexposure:

Skin: Corrosive. Severe irritant. Can cause pain, burns, necrosis and permanent injury. Toxic by skin absorption

(malaise, discomfort, injury and death unless treated promptly). May cause skin sensitization.

Eyes: Corrosive. Severe irritant. Can cause pain, burns, necrosis and permanent injury (blindness). Vapors can cause

lacrimation, conjunctivitis and corneal edema when absorbed into the tissue of the eye.

MSDS0619

Material Safety Data Sheet

ITW Philadelphia Resins

Part No.: 1010H

Page 2

Inhalation:

Inhalation of vapors can cause irritation in the respiratory tract. Inhalation of mists and aerosols may severely damage

contacted tissue and produce scarring.

Ingestion:

May cause irritation of mouth and throat and gastrointestinal tract.

Effects of chronic overexposure:

Repeated skin contact can cause sensitization, with itching, rashes, or swelling of the skin. May cause respiratory

sensitization/asthmatic response. Repeated and /or prolonged exposures may result in: adverse skin effects (such as

defatting, rash, irritation or corrosion), adverse eye effects (such as conjunctivitis or corneal damage), and adverse

respiratory effects (cough, tightness of chest, shortness of breath).

Carcinogenicity -- OSHA regulated: No

ACGIH: No

National Toxicology Program: No

International Agency for Research on Cancer:No

Cancer-suspect constituent(s) : None

Medical conditions which may be aggravated by exposure:

Asthma. Chronic respiratory disease (e.g. Bronchitis, Emphysema). Eye disease. Skin disorders and allergies.

Other effects:

Repeated and/or prolonged exposure to low concentrations of vapor may cause: sore throat, eye irritation, nausea,

faintness, headache, which are transient. Exposure to vapor may also cause minor transient edema of the corneal

epithelium (blue-haze). This effect produces a blurring of vision against a general bluish haze and the appearance of

halos around bright objects. The effect disappears spontaneously within a few hours of the end of exposure and

leaves no sequelae.

4. FIRST AID MEASURES

First aid for eyes:

Immediately flush with clean water for at least 15 minutes while gently holding eyelids open. Get medical help as

soon as possible.

First aid for skin:

Immediately remove contaminated clothing and excess contaminant. Flush skin with water. Wash thoroughly with

soap and warm water. Consult a physician if irritation develops.

First aid for inhalation:

Remove patient to fresh air. Give oxygen or artificial respiration if needed. Prevent aspiration of vomit. Turn victims

head to side. Seek medical advice.

First aid for ingestion:

Do NOT induce vomiting. Dilute with lots of milk or water (3-4 glasses). Never give anything by mouth to an

unconscious person. Get immediate medical help.

5. FIRE FIGHTING MEASURES

General fire and explosion characteristics:

Ignition will give rise to a class B fire.

Extinguishing media:

Carbon dioxide

Water

Flash Point (F): >240

Dry chemical

Foam

Alcohol foam

Method: CC

Explosive limits in air (percent) -- Lower: n/d

Upper: n/d

Special firefighting procedures:

Firefighters should wear self-contained breathing apparatus and sufficient protective gear (butyl rubber) to prevent all

skin and eye contact with this material. Retain liquids from fire fighting for later disposal.

MSDS0619

ITW Philadelphia Resins

Material Safety Data Sheet

Part No.: 1010H

Page 3

Unusual fire and explosion hazards:

Sudden reaction and fire may result if product is mixed with an oxidizing agent. Personnel in vicinity and downwind

should be evacuated.

Hazardous products of combustion:

Acrid and toxic fumes with organic amines, ammonia, oxides of carbon and nitrogen.

6. ACCIDENTAL RELEASE MEASURES

Spill control:

Avoid personal contact. Eliminate ignition sources. Ventilate area. Reduce vapor spreading with a water spray.

Clean-up personnel should wear proper protective clothing and respirator.

Containment:

Dike, contain and absorb with clay, sand or other suitable (non-reactive) material.

Cleanup:

For large spills, pump to storage/salvage vessels. Soak up residue with an absorbent such as clay, sand, or other

suitable material and dispose of properly. Flush area with water to remove trace residue.

Special procedures:

Prevent spill from entering drainage/sewer systems, waterways, and surface waters.

7. HANDLING AND STORAGE

Handling precautions:

Avoid contact with skin, eyes, or clothing. Handle in well ventilated work space. Wash thoroughly with soap and water

after using and particularly before eating, drinking, smoking, applying cosmetics, or using toilet facilities.

Launder contaminated clothing and protective gear before reuse. Discard contaminated leather articles.

Handle mixed resin and hardener in accordance with the potential hazard of the curing agent used. Provide

appropriate ventilation/respiratory protection against decomposition products (see Section 10) during welding/flame

cutting operations and to protect against nuisance dust during sanding/grinding of cured product. Do not use sodium

nitrite or other nitrosating agents in formulations containing this product, cancer-causing nitrosamines could be

formed.

Storage:

Keep away from acids and oxidizers. Store in a cool, dry, ventilated area in closed containers. Keep away from high

temperatures and flames. Do not store in iron or other reactive metal containers.

8. EXPOSURE CONTROLS/PERSONAL PROTECTION

Engineering controls

Ventilation :

General mechanical ventilation is adequate for occasional use. For prolonged or repeated use, local exhaust is

recommended. Provide adequate ventilation to maintain air concentrations below established exposure levels.

Other engineering controls :

Have emergency shower and eye wash stations available.

Personal protective equipment

Eye and face protection:

Splash-proof eye goggles. In emergency situations, use eye goggles with full face shield.

Skin protection:

Chemical-resistant rubber (for example, neoprene, butyl rubber or nitrile) gloves and other protective gear as needed

MSDS0619

Material Safety Data Sheet

ITW Philadelphia Resins

Part No.: 1010H

Page 4

to prevent skin contact.

Respiratory protection:

None needed in normal use with proper ventilation. In poorly ventilated areas or when creating a dust or mist, use

NIOSH-approved ammonia vapor respirator as exposure levels dictate.

9. PHYSICAL AND CHEMICAL PROPERTIES

Specific gravity:

0.98

Boiling point (F):

530.6

Melting point (F):

n/d

Vapor density (air = 1):

5.03

Vapor pressure (mmHg):

.00752 mmHg at 70 F

Evaporation rate (butyl acetate = 1): <<1

VOC (grams/liter):

Solubility in water:

Percent volatile by volume: 0

Percent solids by weight:

Completely

pH (5% solution or slurry in water): alkaline

100

10. STABILITY AND REACTIVITY

This material is chemically stable. Hazardous polymerization will not occur.

Conditions to avoid :

Extreme heat or open flame. Product slowly corrodes copper, aluminum, zinc and galvanized surfaces.

Incompatible materials:

Oxidizers, acids, reactive metals. Sodium or calcium hypochlorite. Nitrous acid, nitrites, nitrous oxide atm. Peroxides.

Mat'ls reactive with hydroxyl compounds.

Hazardous products of decomposition:

Acrid and toxic fumes including organic amines, ammonia, oxides of nitrogen and carbon, nitric acid, nitrosamines.

Aldehydes.

Conditions under which hazardous polymerization may occur:

Heat is generated when this hardener reacts with acids and epoxy resins. Mix only as instructed.

11. TOXICOLOGICAL INFORMATION

Acute oral effects:

LD50 (rat): > 2000 mg/kg (estimate)

Acute dermal effects:

LD50 (rabbit): 805 mg/kg

TETA has been found to be toxic by skin absorption (ANSI Z129.1 1988). TETA is a severe irritant to the skin of a

rabbit.

Acute inhalation effects:

LC50 (rat): No data

Exposure:

hours.

Eye irritation:

TETA is a severe irritant to the eyes of a rabbit.

Subchronic effects:

MSDS0619

Material Safety Data Sheet

ITW Philadelphia Resins

Part No.: 1010H

Page 5

No data.

Carcinogenicity, teratogenicity, and mutagenicity:

TETA has tested positive in screening tests for mutagenicity. TETA was found fetotoxic and teratogenic when fed to

rats at 0.83% and 1.67% of diet. When applied dermally to the skin of pregnant guinea pigs, there was a 90%

abortion rate or death of fetus with developmental anomolies.

Other chronic effects:

It has been generally observed in animal studies that aliphatic amines can cause changes in the lungs and heart.

TETA has been found to produce liver and kidney damage and brain congestion in dermally exposed animals.

Sensitization has occurred in laboratory animals after repeated exposures.

Toxicological information on hazardous chemical constituents of this product:

Constituent

Triethylenetetramine

Oral LD50

(rat)

2500 mg/kg

Dermal LD50

(rabbit)

805 mg/kg

Inhalation LC50

4hr, (rat)

n/d

'n/d' = 'not determined'

12 ECOLOGICAL INFORMATION

Ecotoxicity:

No data.

Mobility and persistence:

No data.

Environmental fate:

No data.

13. DISPOSAL CONSIDERATIONS

Please see also Section 15, Regulatory Information.

Waste management recommendations:

If this material becomes a waste, it would not be a hazardous waste by RCRA criteria (40CFR 261). Dispose of

according to applicable federal, state, and local regulations.

MSDS0619

Material Safety Data Sheet

ITW Philadelphia Resins

Part No.: 1010H

Page 6

14. TRANSPORT INFORMATION

Proper shipping name:

Triethylenetetramine

Technical name :

N/A

Hazard class :

UN number:

2259

Packing group:

II

Emergency Response Guide no.:

IMDG page number:

N/A

Other:

N/A

ORM-D :

LtdQty :

153

15. REGULATORY INFORMATION

U.S. Federal Regulations

TSCA

: ingredients of this product are listed, or are exempt from listing, on the TSCA inventory.

All

The following RCRA code(s) applies to this material if it becomes waste:

None

Regulatory status of hazardous chemical constituents of this product:

Constituent

Triethylenetetramine

Extremely

Hazardous*

No

Toxic

Chemical**

CERCLA

RQ (lbs)

No

0.0

TSCA 12B Export

Notification

Not required

*Consult the appropriate regulations for emergency planning and release reporting requirements for substances on the SARA Section 301

Extremely Hazardous Substance list.

**Substances for which the "Toxic Chemical" column is marked "Yes" are on the SARA Section 313 list of

Toxic Chemicals, for which release reporting may be required. For specific requirements, consult the appropriate regulations.

For purposes of SARA Section 312 hazardous materials inventory reporting, the following hazard

classes apply to this material: - Immediate health hazard -- Delayed health hazard -

Canadian regulations

WHMIS hazard class(es) : D1B; E

All components of this product are on the Domestic Substances List.

MSDS0619

Material Safety Data Sheet

ITW Philadelphia Resins

Part No.: 1010H

Page 7

16. OTHER INFORMATION

Hazardous Materials

Identification System (HMIS)

ratings:

Health

3*

Flammability

1

Reactivity

1

The information and recommendations in this document are based on the best information available to us at the time of preparation, but we make no

other warranty, express or implied, as to its correctness or completeness, or as to the results of reliance on this document.

MSDS0619

Material Safety Data Sheet

ITW Philadelphia Resins

Part No.: 1010R

Page 1

CHOCKFAST ORANGE RESIN

This product appears in the following stock number(s):

1010U 1020U

Last revised:

Printed:

04/16/02

4/17/2002

1. CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

Tradename:

CHOCKFAST ORANGE RESIN

General use:

This information applies to the resin component of the two-part kit; handle freshly-mixed resin and

hardener as recommended for the hardener. After curing, the product is not hazardous.

Chemical family:

Epoxy resin

MANUFACTURER

EMERGENCY INFORMATION

ITW Philadelphia Resins

130 Commerce Dr.

Montgomeryville, PA 18936

Emergency telephone number

(800) 424-9300

(CHEMTREC):

Other Calls:

(215) 855-8450

2. COMPOSITION/INFORMATION ON INGREDIENTS

Exposure limits

HAZARDOUS CONSTITUENTS

Constituent

Abbr.

Crystalline silica

Bisphenol A diglycidyl ether resin

CAS No.

Weight

percent

ACGIH

TLV

OSHA

PEL

Other

Limits

14808607

30-60

0.05 mg/m3

DGEBPA 25068386

30-60

n/e

0.10 mg/m^3

10/(%Q+2) mg/m3

(Canada)

n/e

n/e

Epoxy phenol novalac resin

TRADE SECRET

1-5

n/e

n/e

n/e

Inert filler

TRADE SECRET

5-10

n/e

n/e

n/e

"TLV" means the Threshold Limit Value exposure (eight-hour, time-weighted average, unless otherwise noted) established by the American

Conference of Governmental Industrial Hygienists. "STEL" indicates a short-term exposure limit. "PEL" indicates the OSHA Permissible Exposure

Limit."n/e" indicates that no exposure limit has been established. An asterisk (*) indicates a substance whose identity is a trade secret of our supplier

and unknown to us.

3. HAZARDS IDENTIFICATION

Emergency Overview

Appearance, form, odor: Orange viscous liquid with little odor.

WARNING! Eye and skin irritant. Potential skin sensitizer.

Potential health effects

Primary routes of exposure:

Skin contact

Skin absorption

Eye contact

Inhalation

Ingestion

Symptoms of acute overexposure:

Skin: Moderate irritant. Contact at elevated temperatures can cause thermal burns which may result in permanent

damage. May cause skin sensitization (itching, redness, rashes, hives, burning, swelling).

MSDS0619

Material Safety Data Sheet

ITW Philadelphia Resins

Part No.: 1010R

Page 2

Eyes: Moderate irritant (stinging, burning sensation, tearing, redness, swelling). Contact at elevated temperatures can

cause thermal burns which may result in permanent damage or blindness.

Inhalation:

The low vapor pressure of the resin makes inhalation unlikely in normal use. In applications where vapors (caused by

high temperature) or mists (caused by mixing) are created, breathing may cause a mild burning sensation in the nose,

throat and lungs.

Ingestion:

Acute oral toxicity is low. May cause gastric distress. Large oral doses may produce moderate depression and slight

difficulty breathing.

Effects of chronic overexposure:

Prolonged or repeated skin contact may cause sensitization, with itching, swelling, or rashes on later exposure.

Studies have shown bisphenol A diglycidyl ether resin to to be a sensitizing agent causing allergic contact dermititis.

Carcinogenicity -- OSHA regulated: No

ACGIH: No

National Toxicology Program: Yes

International Agency for Research on Cancer:Yes

Cancer-suspect constituent(s) : Silica

Medical conditions which may be aggravated by exposure:

Preexisting eye and skin disorders. Development of preexisting skin or lung allergy symptoms may increase.

Other effects:

See section 11.

4. FIRST AID MEASURES

First aid for eyes:

Flush eye with clean water for at least 20 minutes while gently holding eyelids open, lifting upper and lower lids. Get

immediate medical attention.

First aid for skin:

Immediately remove contaminated clothing and excess contaminant. Flush skin with water for at least 15 minutes.

Wash thoroughly with soap and warm water. Consult a physician if irritation develops.

First aid for inhalation:

Remove patient to fresh air. Administer oxygen if breathing is difficult. Get medical attention if symptoms persist.

First aid for ingestion:

Do NOT induce vomiting. Rinse mouth out with water, then sip water to remove taste from mouth. Never give

anything by mouth to an unconscious person. If vomiting occurs spontaneously, keep head below hips (if sitting) or to

the side (if lying down) to prevent aspiration. Get medical attention.

5. FIRE FIGHTING MEASURES

Extinguishing media:

Water

Flash Point (F): >400

Carbon dioxide

Dry chemical

Foam

Alcohol foam

Method: PMCC

Explosive limits in air (percent) -- Lower: n/d

Upper: n/d

Special firefighting procedures:

Material will not burn unless preheated. Do not enter confined space without full bunker gear. Firefighters should

wear self-contained breathing apparatus and protective clothing. Cool fire exposed containers with water.

Unusual fire and explosion hazards:

Heating above 300 deg F in the presence of air may cause slow oxidative decomposition and above 500 deg F may

cause polymerization. Personnel in vicinity and downwind should be evacuated.

MSDS0619

ITW Philadelphia Resins

Material Safety Data Sheet

Part No.: 1010R

Page 3

Hazardous products of combustion:

When heated to decomposition it emits fumes of Cl- , carbon monoxide, other fumes and vapors varying in

composition and toxicity.

6. ACCIDENTAL RELEASE MEASURES

Spill control:

Avoid personal contact. Eliminate ignition sources. Ventilate area.

Containment:

Dike, contain and absorb with clay, sand or other suitable material.

Cleanup:

For large spills, pump to storage/salvage vessels. Soak up residue with an absorbent such as clay, sand, or other

suitable material and dispose of properly. Flush area with water to remove trace residue.

Special procedures:

Prevent spill from entering drainage/sewer systems, waterways, and surface waters.

7. HANDLING AND STORAGE

Handling precautions:

Avoid contact with skin, eyes, or clothing. Wash thoroughly with soap and water after using and particularly before

eating, drinking, smoking, applying cosmetics, or using toilet facilities.

Launder contaminated clothing and protective gear before reuse. Discard contaminated leather articles.

Handle mixed resin and hardener in accordance with the potential hazard of the curing agent used. Provide

appropriate ventilation/respiratory protection against decomposition products (see Section 10) during welding/flame

cutting operations and to protect against silica dust during sanding/grinding of cured product.

Storage:

Store in a cool, dry area away from high temperatures and flames. Keep containers closed when not in use.

8. EXPOSURE CONTROLS/PERSONAL PROTECTION

Engineering controls

Ventilation :

Use ventilation that is adequate to keep employee exposure to airborne concentrations below exposure limits (or to

the lowest feasible levels when limits have not been established). Although good general mechanical ventilation is

usually adequate for most industrial applications, local exhaust ventilation is preferred (see ACGIH - Industrial

Ventilation). Local exhaust may be required for confined areas (see OSHA 1910.146).

Other engineering controls :

Have emergency shower and eye wash available.

Personal protective equipment

Eye and face protection:

Chemical goggles if liquid contact is likely, or Safety glasses with side shields.

Skin protection:

Chemical-resistant gloves (i.e. butyl) and other gear as required to prevent skin contact.

Respiratory protection:

None needed in normal use with proper ventilation. In poorly ventilated areas use NIOSH approved organic vapor

cartidges respirator for uncured resin, dust/particle respirators during grinding/sanding operations for cured resin, or

MSDS0619

Material Safety Data Sheet

ITW Philadelphia Resins

Part No.: 1010R

Page 4

fresh airline respirator as exposure levels dictate (see OSHA 1910.134).

9. PHYSICAL AND CHEMICAL PROPERTIES

Specific gravity:

1.64

Boiling point (F):

>500

Melting point (F):

n/d

Vapor density (air = 1):

>1

Vapor pressure (mmHg):

0.03 mm Hg at 171 F

Evaporation rate (butyl acetate = 1): <<1

VOC (grams/liter):

<1

Solubility in water:

Percent volatile by volume: 0

Percent solids by weight:

Negligible

pH (5% solution or slurry in water): neutral

100

10. STABILITY AND REACTIVITY

This material is chemically stable. Hazardous polymerization will not occur.

Conditions to avoid :

Open flame and extreme heat

Incompatible materials:

Strong Lewis or mineral acids, strong oxidizing agents, strong mineral and organic bases (especially primary and

secondary aliphatic amines).

Hazardous products of decomposition:

Oxides of carbon; aldehydes, acids and other organic substances may be formed during combustion or elevated

temperature (>500 deg F) degradation.

Conditions under which hazardous polymerization may occur:

Heat is generated when resin is mixed with curing agents; Run-a-way cure reactions may char and decompose the

resin, generating unidentified fumes and vapors which may be toxic.

11. TOXICOLOGICAL INFORMATION

Acute oral effects:

LD50 (rat): Not available.

Acute dermal effects:

LD50 (rabbit): Not available.

Acute inhalation effects:

LC50 (rat): Not available.

Exposure:

hours.

Eye irritation:

Not available.

Subchronic effects:

No data available.

Carcinogenicity, teratogenicity, and mutagenicity:

MSDS0619

Material Safety Data Sheet

ITW Philadelphia Resins

Part No.: 1010R

Page 5

1) MUTAGENICITY: Liquid resins based on diglycidyl ether of Bisphenol A (DGEBPA), have proved to be inactive

when tested by in vivo mutagenicity assays. These resins have shown activity in in vitro microbial mutagenicity

screening and have produced chromosomal aberrations in cultured rat liver cells. The significance of these tests to

man is unknown. 2) CARCINOGENICITY: Recent 2-year bioassays in rats and mice exposed by the dermal route to

DGEBPA yielded no evidence of carcinogenicy to the skin or any other organs. This study clarifies prior equivocal

results from a 2-year mouse skin painting study, which were suggestive, but not conclusive, for weak carcinogenic

activity. 3) The International Agency for Research on Cancer (IARC) concluded that DGEBPA is not classifiable as a

carcinogen (IARC group 3), that is human and animal evidence of carcinogenicy is inadequate. Also, crystalline silica

has been shown to have in vitro mutagenic effects in mammalian cells. Trade secret diluent showed positive

mutagenicity in vitro in the Salmonella/mammalian microsome assay with and without metabolic activation, and in the

point mutation assay with mouse lymphoma cells.

Other chronic effects:

Prolonged or repeated skin contact may cause sensitization, with itching, swelling, or rashes on later exposure.

Studies have shown bisphenol A diglycidyl ether resin to cause allergic contact dermititis.

Toxicological information on hazardous chemical constituents of this product:

Oral LD50

(rat)

Constituent

Dermal LD50

(rabbit)

Inhalation LC50

4hr, (rat)

Crystalline silica

n/d

n/d

n/d

Bisphenol A diglycidyl ether resin

11.4 g/kg

>20 ml/kg

no deaths

Epoxy phenol novalac resin

> 5000 mg/kg

> 6000 mg/kg

> 1.7 mg/L

Inert filler

n/d

n/d

n/d

'n/d' = 'not determined'

12 ECOLOGICAL INFORMATION

Ecotoxicity:

No data available.

Mobility and persistence:

No data available.

Environmental fate:

No data available.

13. DISPOSAL CONSIDERATIONS

Please see also Section 15, Regulatory Information.

Waste management recommendations:

If this resin becomes a waste, it would not be a hazardous waste by RCRA criteria (40CFR 261). Dispose of

according to applicable federal, state, and local regulations. Incineration is the preferred method of disposal.

MSDS0619

Material Safety Data Sheet

ITW Philadelphia Resins

Part No.: 1010R

Page 6

14. TRANSPORT INFORMATION

Proper shipping name:

Non-regulated

Technical name :

N/A

Hazard class :

N/A

UN number:

N/A

Packing group:

N/A

Emergency Response Guide no.:

IMDG page number:

N/A

Other:

N/A

ORM-D : N/A

LtdQty : N/A

N/A

15. REGULATORY INFORMATION

U.S. Federal Regulations

TSCA

: ingredients of this product are listed, or are exempt from listing, on the TSCA inventory.

All

The following RCRA code(s) applies to this material if it becomes waste:

None

Regulatory status of hazardous chemical constituents of this product:

Constituent

Extremely

Hazardous*

Toxic

Chemical**

CERCLA

RQ (lbs)

TSCA 12B Export

Notification

Crystalline silica

No

No

0.0

Not required

Bisphenol A diglycidyl ether resin

No

No

0.0

Not required

Epoxy phenol novalac resin

No

No

0.0

Not required

Inert filler

No

No

0.0

Not required

*Consult the appropriate regulations for emergency planning and release reporting requirements for substances on the SARA Section 301

Extremely Hazardous Substance list.

**Substances for which the "Toxic Chemical" column is marked "Yes" are on the SARA Section 313 list of

Toxic Chemicals, for which release reporting may be required. For specific requirements, consult the appropriate regulations.

For purposes of SARA Section 312 hazardous materials inventory reporting, the following hazard

classes apply to this material: - Immediate health hazard -- Delayed health hazard -

Canadian regulations

WHMIS hazard class(es) : D2B; D2A

Regulatory notes:

HMIRC claim registry number 4078 granted 3/19/99.

MSDS0619

Material Safety Data Sheet

ITW Philadelphia Resins

Part No.: 1010R

Page 7

16. OTHER INFORMATION

Hazardous Materials

Identification System (HMIS)

ratings:

Health

2*

Flammability

1

Reactivity

1

The information and recommendations in this document are based on the best information available to us at the time of preparation, but we make no

other warranty, express or implied, as to its correctness or completeness, or as to the results of reliance on this document.

MSDS0619

Potrebbero piacerti anche

- Material Safety Data Sheet for Chockfast Black HardenerDocumento14 pagineMaterial Safety Data Sheet for Chockfast Black Hardenergustavofx21Nessuna valutazione finora

- Oatey PVC Regular Clear CementDocumento5 pagineOatey PVC Regular Clear CementPaul Christian Rojas FloresNessuna valutazione finora

- Sea Foam MSDS Provides Details on Motor TreatmentsDocumento4 pagineSea Foam MSDS Provides Details on Motor TreatmentsCrystal McCraineNessuna valutazione finora

- Material Safety Data Sheet: Section 1 Identification of The Substance/Preparation and of The Company/UndertakingDocumento5 pagineMaterial Safety Data Sheet: Section 1 Identification of The Substance/Preparation and of The Company/UndertakingAnonymous gUySMcpSqNessuna valutazione finora

- Tmah SDSDocumento6 pagineTmah SDSCheNessuna valutazione finora

- Material Safety Data Sheet: Development Associates, IncDocumento3 pagineMaterial Safety Data Sheet: Development Associates, IncDedi MulyadiNessuna valutazione finora

- Eletric-Weld PVC Regular Bodied Clear CementDocumento5 pagineEletric-Weld PVC Regular Bodied Clear CementMarcelo SimoesNessuna valutazione finora

- Sigma-Aldrich: Material Safety Data SheetDocumento8 pagineSigma-Aldrich: Material Safety Data SheetRebecaNascimentoNessuna valutazione finora

- Generic Msds Ammonium Persulphate1Documento7 pagineGeneric Msds Ammonium Persulphate1Maria RenataNessuna valutazione finora

- Gasoline 95 Ron 97 RonDocumento7 pagineGasoline 95 Ron 97 RonGeal Geol PentolNessuna valutazione finora

- Methylated SpiritDocumento7 pagineMethylated SpiritPiNessuna valutazione finora

- Weld-On 3 MsdsDocumento2 pagineWeld-On 3 MsdsSergio SanchezNessuna valutazione finora

- Material Safety Data Sheet: Ingredient Name Cas No. % WT Exposure LimitsDocumento8 pagineMaterial Safety Data Sheet: Ingredient Name Cas No. % WT Exposure LimitsaggibudimanNessuna valutazione finora

- Safety Data Sheet: SECTION 1. Identification of The Substance/mixture and of The Company/undertakingDocumento11 pagineSafety Data Sheet: SECTION 1. Identification of The Substance/mixture and of The Company/undertakingBalaji NamachivayamNessuna valutazione finora

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocumento5 pagineMaterial Safety Data Sheet: 1. Chemical Product and Company IdentificationEdgar Julio Sara TairoNessuna valutazione finora

- BrominDocumento7 pagineBrominIchwan Gates SevenfoldismNessuna valutazione finora

- Contact CleanerDocumento5 pagineContact CleanerlovefiezNessuna valutazione finora

- SEO Oil Safety Data SheetDocumento4 pagineSEO Oil Safety Data SheetbuddhansamratNessuna valutazione finora

- MSDS Potassium DichromateDocumento8 pagineMSDS Potassium DichromateAyu Lakshemini OkaNessuna valutazione finora

- Formaldehyde Solution, Reagnt, ACS MSDS: Section 1: Chemical Product and Company IdentificationDocumento7 pagineFormaldehyde Solution, Reagnt, ACS MSDS: Section 1: Chemical Product and Company IdentificationGilang RamadhanNessuna valutazione finora

- Safety Data Sheet IngredientsDocumento5 pagineSafety Data Sheet Ingredientsalinus4y100% (1)

- Material Safety Data Sheet: Classified As HAZARDOUS SUBSTANCE, DANGEROUS GOODS According To The Criteria of NOHSCDocumento6 pagineMaterial Safety Data Sheet: Classified As HAZARDOUS SUBSTANCE, DANGEROUS GOODS According To The Criteria of NOHSCTanzeel LiaqatNessuna valutazione finora

- Sigma Thinner 91 - 92Documento7 pagineSigma Thinner 91 - 92mevansmetreelNessuna valutazione finora

- Acetic AnhydrideDocumento5 pagineAcetic AnhydrideChern YuanNessuna valutazione finora

- FormaldehydeDocumento7 pagineFormaldehydeAsih MiniartiNessuna valutazione finora

- Aluminum-Oxide A2844 Msds Us Cov DefaultDocumento6 pagineAluminum-Oxide A2844 Msds Us Cov DefaultBrockSamsomNessuna valutazione finora

- MSDS-RIPSTAR 156-Part 1Documento6 pagineMSDS-RIPSTAR 156-Part 1Ankita Baban GavadeNessuna valutazione finora

- Trichloroacetic AcidDocumento10 pagineTrichloroacetic Acidwillyvh99Nessuna valutazione finora

- Na HSO3Documento8 pagineNa HSO3Bao Duy NguyenNessuna valutazione finora

- 4090 F0931 MSDSDocumento9 pagine4090 F0931 MSDStoxicity230% (1)

- CalHypo Gran 65 MSDSDocumento9 pagineCalHypo Gran 65 MSDSAnisahicNessuna valutazione finora

- MSDS Degreaser - ID Red - 650mL (450g) - Spray CanDocumento3 pagineMSDS Degreaser - ID Red - 650mL (450g) - Spray CanGonza PfNessuna valutazione finora

- United Elchem PVC CementDocumento5 pagineUnited Elchem PVC CementstevierayoNessuna valutazione finora

- Material Safety Data Sheet: A264 Corrosion Inhibitor A264Documento9 pagineMaterial Safety Data Sheet: A264 Corrosion Inhibitor A264MasoudTeimooriNessuna valutazione finora

- CHIMEC 1038 MSDSDocumento6 pagineCHIMEC 1038 MSDSAnonymous LfeGI2hM0% (1)

- Material Safety Data Sheet for ISO VG 32/150 S.U.S. 734Documento7 pagineMaterial Safety Data Sheet for ISO VG 32/150 S.U.S. 734William Lopez AyalaNessuna valutazione finora

- Oleum EnglishDocumento10 pagineOleum Englishhyde2520015754Nessuna valutazione finora

- MSDS Cim PremixDocumento3 pagineMSDS Cim PremixKiệt Lê TuấnNessuna valutazione finora

- Methanol BP. PH - Eur MSDSDocumento9 pagineMethanol BP. PH - Eur MSDSshuvo.shahaNessuna valutazione finora

- Material Safety Data Sheet (MSDS) Hydrochloric AcidDocumento8 pagineMaterial Safety Data Sheet (MSDS) Hydrochloric AcidsaadNessuna valutazione finora

- 010 Ammonium PersulphateDocumento10 pagine010 Ammonium Persulphateeng20072007Nessuna valutazione finora

- Material Safety Data Sheet: Sulfuric Acid 98% Section 1 - Chemical Product and Company IdentificationDocumento8 pagineMaterial Safety Data Sheet: Sulfuric Acid 98% Section 1 - Chemical Product and Company IdentificationdurganagavenkatNessuna valutazione finora

- Asia Wd40 Aerosol Msds 2012Documento4 pagineAsia Wd40 Aerosol Msds 2012Sarliza JafarNessuna valutazione finora

- Formic MsdsDocumento6 pagineFormic Msdsapi-263411629Nessuna valutazione finora

- Msds Ac2oDocumento6 pagineMsds Ac2oArfin FardiansyahNessuna valutazione finora

- Acetic Anhydride MSDS: Section 1: Chemical Product and Company IdentificationDocumento6 pagineAcetic Anhydride MSDS: Section 1: Chemical Product and Company IdentificationAdri MuntahaNessuna valutazione finora

- Material Safety Data Sheet: I - Product IdentificationDocumento8 pagineMaterial Safety Data Sheet: I - Product IdentificationHaris OktaviantoNessuna valutazione finora

- Msds Fluorodyn Viton AdhesiveDocumento12 pagineMsds Fluorodyn Viton AdhesivemontsegranNessuna valutazione finora

- Sigma Paints 21-06Documento6 pagineSigma Paints 21-06Asela BollegalaNessuna valutazione finora

- Eastman 2380 Msds - SkySupplyUSADocumento13 pagineEastman 2380 Msds - SkySupplyUSASkySupplyUSANessuna valutazione finora

- DABCO BL 11 Safety DatasheetDocumento8 pagineDABCO BL 11 Safety DatasheetAlban TabakuNessuna valutazione finora

- Acidified Copper Sulfate, Subcutaneous-Rat LD50 43 MG X KGDocumento10 pagineAcidified Copper Sulfate, Subcutaneous-Rat LD50 43 MG X KGManuel DíazNessuna valutazione finora

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesDa EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNessuna valutazione finora

- The Health & Safety Guide for Film, TV & Theater, Second EditionDa EverandThe Health & Safety Guide for Film, TV & Theater, Second EditionValutazione: 4 su 5 stelle4/5 (1)

- Practical Patch Testing and Chemical Allergens in Contact DermatitisDa EverandPractical Patch Testing and Chemical Allergens in Contact DermatitisNessuna valutazione finora

- Gas Sweetening and Processing Field ManualDa EverandGas Sweetening and Processing Field ManualValutazione: 4 su 5 stelle4/5 (7)

- Pollution Control in Oil, Gas and Chemical PlantsDa EverandPollution Control in Oil, Gas and Chemical PlantsNessuna valutazione finora

- UC RangeDocumento2 pagineUC RangeanandakoeNessuna valutazione finora

- Nonlinear Ansys Tension Test Tutorial: 1. Preparing Element and Material ModelDocumento9 pagineNonlinear Ansys Tension Test Tutorial: 1. Preparing Element and Material ModelAniruddha KulkarniNessuna valutazione finora

- 1Documento1 pagina1anandakoeNessuna valutazione finora

- Sacinp - WHT BH2 JKT InplaceR2Documento1.527 pagineSacinp - WHT BH2 JKT InplaceR2anandakoeNessuna valutazione finora

- SaclstDocumento281 pagineSaclstanandakoeNessuna valutazione finora

- ANSYS Short Course: Tim Langlais Langlais@me - Umn.edu August 31, 1998Documento14 pagineANSYS Short Course: Tim Langlais Langlais@me - Umn.edu August 31, 1998Radu NeaguNessuna valutazione finora

- ContohDocumento13 pagineContohanandakoeNessuna valutazione finora

- Principles and Practice of Engineering CIVIL BREADTH and STRUCTURAL DEPTH ExamDocumento6 paginePrinciples and Practice of Engineering CIVIL BREADTH and STRUCTURAL DEPTH ExamanandakoeNessuna valutazione finora

- Jcninp Load - WHT-BH2Documento1 paginaJcninp Load - WHT-BH2anandakoeNessuna valutazione finora

- Limit LoadDocumento16 pagineLimit Load001tabNessuna valutazione finora

- Use of Simplified Structural Models To Predict Dynamic Response To Wave-In-Deck LoadsDocumento7 pagineUse of Simplified Structural Models To Predict Dynamic Response To Wave-In-Deck LoadsanandakoeNessuna valutazione finora

- Essential Ansys PDFDocumento9 pagineEssential Ansys PDFanandakoeNessuna valutazione finora

- LECTURE 7: Finite Element Methods in Fracture MechanicsDocumento7 pagineLECTURE 7: Finite Element Methods in Fracture MechanicsanandakoeNessuna valutazione finora

- ANSYS Example BeamBendDocumento6 pagineANSYS Example BeamBendhaitham08Nessuna valutazione finora

- Ansys Asas BrochureDocumento4 pagineAnsys Asas BrochureTomás CampoverdeNessuna valutazione finora

- Finite Element Analysis Ii Coursework: Areas of StudyDocumento1 paginaFinite Element Analysis Ii Coursework: Areas of StudyanandakoeNessuna valutazione finora

- Mathcad Tutorial: by Colorado State University StudentDocumento51 pagineMathcad Tutorial: by Colorado State University StudentDiana ScodreanuNessuna valutazione finora

- Stress Analysis Using ANSYSDocumento20 pagineStress Analysis Using ANSYSanandakoeNessuna valutazione finora

- ANSYS Computer RequirementsDocumento6 pagineANSYS Computer RequirementsSandeep ReddyNessuna valutazione finora

- Welds in Pro/E and ANSYS WorkbenchDocumento6 pagineWelds in Pro/E and ANSYS WorkbenchSandeep KadamNessuna valutazione finora

- Chap 16Documento50 pagineChap 16sarumaniNessuna valutazione finora

- 31Documento14 pagine31anandakoeNessuna valutazione finora

- MECH 387 Lab Exercise 9 Fatigue AnalysisDocumento19 pagineMECH 387 Lab Exercise 9 Fatigue AnalysisanandakoeNessuna valutazione finora

- Pipe Fea Using AnsysDocumento14 paginePipe Fea Using AnsysanandakoeNessuna valutazione finora

- 2 08-NonlinDocumento11 pagine2 08-NonlinanandakoeNessuna valutazione finora

- Findind Workbench Tutorial On GeometryDocumento3 pagineFindind Workbench Tutorial On Geometryhimanshuve1991Nessuna valutazione finora

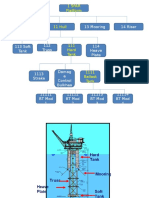

- 12 Topsides 13 Mooring 14 Riser: 1 Spar PlatformDocumento2 pagine12 Topsides 13 Mooring 14 Riser: 1 Spar PlatformanandakoeNessuna valutazione finora

- ANSYS Plasticity AnalysisDocumento9 pagineANSYS Plasticity Analysismiki156799Nessuna valutazione finora

- Er Be IDocumento8 pagineEr Be IanandakoeNessuna valutazione finora

- Sea Eye Tiger ROV System: Allied Marine & Equipment Sdn. BHDDocumento1 paginaSea Eye Tiger ROV System: Allied Marine & Equipment Sdn. BHDanandakoeNessuna valutazione finora

- Ot Guidelines Child SpecificDocumento34 pagineOt Guidelines Child Specific健康生活園Healthy Life Garden100% (1)

- Insomnia: What Is Insomnia? What Causes It?Documento4 pagineInsomnia: What Is Insomnia? What Causes It?Orive Ralina SegentaNessuna valutazione finora

- RCT 170407062212Documento42 pagineRCT 170407062212Ankita AgarwallNessuna valutazione finora

- Spinal Tuberculosis A Comprehensive Review For The Modern SpineDocumento13 pagineSpinal Tuberculosis A Comprehensive Review For The Modern SpineRaunik BansodNessuna valutazione finora

- Study Consipation Howaru-TransitDocumento8 pagineStudy Consipation Howaru-TransitMộc MộcNessuna valutazione finora

- Religious Coping Integration in CounselingDocumento2 pagineReligious Coping Integration in CounselingHemant KumarNessuna valutazione finora

- Spinal Cord InjuryDocumento30 pagineSpinal Cord InjuryKylie Golindang100% (9)

- Case Conceptualization and Treatment Plan - JackDocumento4 pagineCase Conceptualization and Treatment Plan - JackKrista Lyn0% (1)

- A Guide To The Casa de Dom InacioDocumento36 pagineA Guide To The Casa de Dom InacioChiriac CorinaNessuna valutazione finora

- COMMUNITY OPHTHALMOLOGY SOCIAL MARKETINGDocumento30 pagineCOMMUNITY OPHTHALMOLOGY SOCIAL MARKETINGaaNessuna valutazione finora

- Water Safety and Conservation Awareness SeminarDocumento16 pagineWater Safety and Conservation Awareness Seminaritskimheeey0% (1)

- Intentional Replantation Techniques: A Critical ReviewDocumento8 pagineIntentional Replantation Techniques: A Critical Reviewitsme543210100% (1)

- SAQ127 Indicators 3.2Documento4 pagineSAQ127 Indicators 3.2Edi Uchiha SutarmantoNessuna valutazione finora

- ALKESDocumento6 pagineALKESMuarrifa MuflihatiNessuna valutazione finora

- Nelson's MCQ'sDocumento150 pagineNelson's MCQ'sDrSheika Bawazir92% (38)

- Covid NCPDocumento6 pagineCovid NCPFrance Llana CueNessuna valutazione finora

- Roles of Laboratory ProfessionalsDocumento14 pagineRoles of Laboratory ProfessionalsOsama BakheetNessuna valutazione finora

- HMBDocumento41 pagineHMBakmal3501Nessuna valutazione finora

- NSS-12 Ammonium SulfateDocumento1 paginaNSS-12 Ammonium SulfateMoxzJr VianzNessuna valutazione finora

- 10 Gunas, 5 Elements & 3 Doshas SpectrumDocumento1 pagina10 Gunas, 5 Elements & 3 Doshas SpectrumAnonymous wu6RXu100% (1)

- Peckham Et Al-2019-Cochrane Database of Systematic ReviewsDocumento36 paginePeckham Et Al-2019-Cochrane Database of Systematic ReviewsYesica NievesNessuna valutazione finora

- Steal SyndromeDocumento5 pagineSteal SyndromeIrma SihotangNessuna valutazione finora

- HodgkinDocumento4 pagineHodgkinEunice Angela FulguerasNessuna valutazione finora

- Deficient Knowledge Nursing DiagnosisDocumento3 pagineDeficient Knowledge Nursing DiagnosisCalimlim KimNessuna valutazione finora

- 1384 3209 1 PBDocumento6 pagine1384 3209 1 PBRIL LoyolaNessuna valutazione finora

- Surgical Site Marking Protocols and PolicyDocumento8 pagineSurgical Site Marking Protocols and PolicyVitria Sari DewiNessuna valutazione finora

- A Rare Case of Factor X Deficiency AssociatedDocumento16 pagineA Rare Case of Factor X Deficiency AssociatedRoss Mark PerandosNessuna valutazione finora

- NCP Case PresDocumento5 pagineNCP Case Pressyd19Nessuna valutazione finora

- Placenta Previa MarginalDocumento50 paginePlacenta Previa MarginalMedy WedhanggaNessuna valutazione finora

- Wisdom TeethDocumento2 pagineWisdom TeethMr bondNessuna valutazione finora