Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mold:: One More Reason To Build With Steel Framing

Caricato da

Ishwarya SrikanthTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mold:: One More Reason To Build With Steel Framing

Caricato da

Ishwarya SrikanthCopyright:

Formati disponibili

VOL.

1 ISSUE 5

MOLD: ONE MORE REASON TO

BUILD WITH STEEL FRAMING

Danger lurks in buildings, where moisture can penetrate and

accumulate on mold-susceptible materials. In this environment,

mold spores can readily feed on nutrient sources and grow to

adversely affect the air we breath - inside the building. While

exposure to mold and resulting health effects are not well

documented, the understanding that mold and mycotoxins

can help trigger illnesses ranging from allergies to lung cancer

among inhabitants is clear.

Consequently, this highly controversial subject continues to

instigate increasing litigation, insurance rates, health care

costs, not to mention huge remediation costs and loss of

income. What we are left with is not only a massive clean-up,

but a massive public outcry for better constructed buildings.

Bottom line: If we build mold-resistant structures, we will live

and work in healthier environments. Doing that must be practical

and economically feasible, using the knowledge and technology

we have today.

While there is no practical way to eliminate all mold and mold

spores in the indoor environment, there is a way to control it.

In order to grow, mold needs a nutrient source, appropriate

temperature, and moisture. First, lets consider moisture the

biggest culprit.

Moisture & Mold Growth

For mold to grow in buildings, sufficient moisture is required

for a period of time. Three primary factors influence the

amount of moisture available for mold growth:

Building tightness not allowing moisture to escape to the

outside,

Liquid water moisture infiltration from the outside due to

leaky window/door openings, leaky roofs, no flashing,

blocked gutters, foundation leaks, plumbing leaks, and

Condensation on mold susceptible materials, resulting from

water vapor begun inside or outside the building.

What is Mold?

Tight Buildings

Mold is a fungus, with tens of thousands of known strains in

construction environments, which produce tiny spores to

reproduce on surfaces such as wood, paper, carpet and foods.

Mold spores are rampant in the air, both indoors and outdoors,

a fact that cannot be changed. But when excessive moisture,

sufficient food source, temperature, and other factors are

present, mold can grow, and digest whatever it grows on to survive.

For the last 30 years, buildings have been constructed with new

materials and production techniques, including thermal insulation,

mechanical HVAC (heating, ventilation and air conditioning)

systems, etc., to tighten them up in order to save energy.

Efforts to be more energy conscious have proven successful.

The total number of commercial buildings and amount of

occupied commercial floor space has dramatically increased

since 1979, but total energy consumption has remained flat.

Interestingly enough, this energy-saving trend also spurred on

an increase in moisture levels, in terms of relative humidity,

inside the building. As buildings became tighter, the amount of

air exchanged between the interior conditioned space and the

outdoors diminished, resulting in significantly less dilution of

moisture and indoor pollutants, such volatile organic compounds

(resulting from some species of mold), even carbon dioxide.

Copyright 2003. All rights reserved.

steelframingalliance.com

BUILD MOLD-RESISTANT HOMES WITH STEEL

VOL. 1 ISSUE 5

Leaky Buildings

Additionally, construction flaws, or simply older, less maintained

buildings, can permit the presence of unwanted moisture

inside. Leaks occur most often around window and door openings,

from the roof, because of missing or inadequate flashing, or

blocked or missing gutters. Water may also come from foundation

leaks, plumbing leaks, and a host of other sources.

When small cracks or openings are located in the drainage

path, large amounts of water can pass through. Typically

cracks occur at critical junctures like the base of window

openings, or roof and wall intersections, where they can do

the most damage. Regardless of the cause, unwanted water

infiltration must be prevented to control the growth of mold.

Mold-Susceptible Materials

Beyond leaks, water present in organic building materials at

the construction site is a recipe for mold disaster. For example,

wood framing, OSB, and gypboard wet from rain can provide ideal

conditions for mold growth once the materials are installed.

Other hosts for common indoor molds include building and

material substrates like window sills, walls, carpets, textiles,

wood, wallpaper glue, house dust, soil, paper, paint, and

food. Many of the mold types are fast growers on organic

materials that provide a nutrient source with enough water

and the right temperature.

Building Mold-Resistant Structures with Steel

Now that weve loosely defined mold and described ideal

environments for mold growth, lets consider how todays

steel framing construction technology can help mitigate the

instance and growth of mold in buildings.

First, structures must be built so that there is adequate ventilation,

while allowing for controlled environments inside the building to

be safe and energy efficient. Buildings must also be constructed

to prevent the infiltration of water, by resisting sagging and

other structural changes that may produce cracks and crevices

in the building envelope. And, the construction industry should

use materials that limit the sources of food for mold.

Steel framing is one important way to build homes and

non-residential buildings that can help resist the onset and

growth of mold. Steel framing members are dimensionally

Copyright 2003. All rights reserved.

straight and connected mechanically (screwed vs. nailed) offering

a tight envelope with no nail pops or drywall cracks (e.g. where

the roof meets the walls). Thus, the building structure is a

stronger and more resilient. Ventilation is efficiently built into

the design, and energy efficiency is maintained or increased

due to steels inorganic properties. Moisture does not get

into steel studs, substantially eliminating the expansion and

contraction of construction materials around windows and

doors, where leaks can occur. And steel does not provide a

food source for mold to grow.

With steel framing technology, building components are often

built off-site, in a controlled environment, and then erected on the

job site. Processes of building with steel framing have become

so efficient and economically feasible that builders are choosing

to use steel alone or with other building components such as

wood, cement, insulated concrete forms, among others.

Because steel is non-combustible, not to mention mold-resistant

structures, it enjoys a majority of the market share in interior

walls in non-residential construction, and recent significant

increases in floors and walls in residential construction. As

we get smar ter in building design and construction, uses of

light gauge steel framing will continue to grow. And mold, and

the adverse effects it creates in our indoor environments,

should not.

For more information about mold in the built environment,

visit the U.S. Environmental Protection Agency, www.epa.gov, or

HealthyHome.com, www.healthyhome.com, or the Foundation

of the Wall and Ceiling Industry, www.awci.org. For more

information about steel framing, visit the Steel Framing

Alliance, www.steelframingalliance.com.

Join the Steel Framing Alliance.

Call

202.785.2022

or Visit

steelframingalliance.com

Potrebbero piacerti anche

- List of Indian StandardsDocumento27 pagineList of Indian StandardsrockyminNessuna valutazione finora

- Basic Steps in Reliability AnalysisDocumento1 paginaBasic Steps in Reliability AnalysisIshwarya SrikanthNessuna valutazione finora

- Swagatham KrishnaDocumento1 paginaSwagatham KrishnaIshwarya Srikanth100% (2)

- Melakartha Raga ChartDocumento1 paginaMelakartha Raga ChartIshwarya SrikanthNessuna valutazione finora

- 72 Melakartha RagamalikaDocumento3 pagine72 Melakartha RagamalikaIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Monitoring sensors for structural healthDocumento7 pagineMonitoring sensors for structural healthIshwarya SrikanthNessuna valutazione finora

- Ada ModiDocumento2 pagineAda ModimounsamyNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- 72 Melakartha RagamalikaDocumento3 pagine72 Melakartha RagamalikaIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Scholarships and GrantsDocumento1 paginaScholarships and GrantsIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Materials Science: Fatigue AnalysisDocumento3 pagineMaterials Science: Fatigue AnalysisIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Materials Science: Fatigue AnalysisDocumento3 pagineMaterials Science: Fatigue AnalysisIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Vibration Fatigue Is ADocumento2 pagineVibration Fatigue Is AIshwarya SrikanthNessuna valutazione finora

- Materials Science: Fatigue AnalysisDocumento3 pagineMaterials Science: Fatigue AnalysisIshwarya SrikanthNessuna valutazione finora

- Materials Science: Fatigue AnalysisDocumento3 pagineMaterials Science: Fatigue AnalysisIshwarya SrikanthNessuna valutazione finora

- Materials Science: Fatigue AnalysisDocumento3 pagineMaterials Science: Fatigue AnalysisIshwarya SrikanthNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Filtros CowayDocumento44 pagineFiltros Cowaynitro279Nessuna valutazione finora

- Ferly Detailed Lesson Plan PpeDocumento7 pagineFerly Detailed Lesson Plan PpeFerlizadieflor Fabro De LunasNessuna valutazione finora

- BLDGDESIGN Lesson 6 - Plumbing Design (Part 2)Documento13 pagineBLDGDESIGN Lesson 6 - Plumbing Design (Part 2)Dough NutNessuna valutazione finora

- English: Admission Test For Science, Technology, Engineering and Mathematics (STEM)Documento34 pagineEnglish: Admission Test For Science, Technology, Engineering and Mathematics (STEM)KetIanCotalesNessuna valutazione finora

- Renewable and Sustainable Energy Reviews: M.S. Gu Ney, K. KaygusuzDocumento9 pagineRenewable and Sustainable Energy Reviews: M.S. Gu Ney, K. Kaygusuzcristian villegasNessuna valutazione finora

- REGISTERED SOLAR COMPANIES ZIMBABWEDocumento15 pagineREGISTERED SOLAR COMPANIES ZIMBABWENyasclemNessuna valutazione finora

- ADB - 1st Vol 1Documento140 pagineADB - 1st Vol 1Vishal KannaujiaNessuna valutazione finora

- TOEFL ReadingDocumento11 pagineTOEFL ReadingM.subhandi SubhandiNessuna valutazione finora

- Lagonoy High School Experiences TsunamisDocumento3 pagineLagonoy High School Experiences TsunamisJohn Mark Prestoza67% (3)

- Unicellular Protists with Nuclei and Varied FunctionsDocumento24 pagineUnicellular Protists with Nuclei and Varied FunctionsStem 21 - Suyat, Justine Kay N.Nessuna valutazione finora

- Vision: WWW - Visionias.inDocumento35 pagineVision: WWW - Visionias.inJyoti SharmaNessuna valutazione finora

- Tools and Equipment in AquacultureDocumento26 pagineTools and Equipment in AquacultureAmirah Benett100% (3)

- Rasco Intl Usd 2 ValvesDocumento16 pagineRasco Intl Usd 2 Valvesdaniela hritucNessuna valutazione finora

- PollutionDocumento15 paginePollutionamirrandhawa165Nessuna valutazione finora

- Biodiversity Ecosystems and Ecosystem Services Technical InputDocumento296 pagineBiodiversity Ecosystems and Ecosystem Services Technical InputPalash SwarnakarNessuna valutazione finora

- Q1 Describe The Natural Drainage of Indus DeltaDocumento2 pagineQ1 Describe The Natural Drainage of Indus DeltaAhmad Ahsan100% (1)

- VILLAGE SURVEY REPORT in PDF (1) ANU KUMARDocumento25 pagineVILLAGE SURVEY REPORT in PDF (1) ANU KUMARsalman100% (2)

- Explanation Text - Snow FlakesDocumento10 pagineExplanation Text - Snow FlakesLita Kurnia Wu100% (1)

- Air Cooled Chiller Pre Start-Up ChecklistDocumento2 pagineAir Cooled Chiller Pre Start-Up ChecklistM MiftakhNessuna valutazione finora

- Drainage EngineeringDocumento194 pagineDrainage EngineeringShobhit SinghNessuna valutazione finora

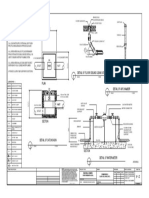

- Detail of Floor/ Ceiling Clean Out: Plumbing NotesDocumento1 paginaDetail of Floor/ Ceiling Clean Out: Plumbing NotesHana YeppeodaNessuna valutazione finora

- Ternate, Cavite Volume-2-THE-ZONING-ORDINANCEDocumento48 pagineTernate, Cavite Volume-2-THE-ZONING-ORDINANCEAlfie SeroteNessuna valutazione finora

- Literature Review On Microbiological Analysis of WaterDocumento5 pagineLiterature Review On Microbiological Analysis of WaterafmzxppzpvolufNessuna valutazione finora

- Soil-Cement Guide For Water Resources Applications: Dennis L. Richards and Hans R. Hadley, WEST Consultants, IncDocumento84 pagineSoil-Cement Guide For Water Resources Applications: Dennis L. Richards and Hans R. Hadley, WEST Consultants, IncAnshuman SinghNessuna valutazione finora

- DO Oxygen Solubility TableDocumento2 pagineDO Oxygen Solubility TableWinny WanNessuna valutazione finora

- Experiment No. 3 Distillation (Gurdiel)Documento2 pagineExperiment No. 3 Distillation (Gurdiel)Sophia Gurdiel0% (1)

- Assinment Hed-SolutionDocumento29 pagineAssinment Hed-SolutionAbiued EjigueNessuna valutazione finora

- INGLES 5 Mtra Susana - Condicionales - Unidad 1Documento18 pagineINGLES 5 Mtra Susana - Condicionales - Unidad 1Bray PerezNessuna valutazione finora

- Division 22 - PlumbingDocumento137 pagineDivision 22 - PlumbingCarl CrowNessuna valutazione finora

- TOTO General Catalog 2020Documento177 pagineTOTO General Catalog 2020Rohit KumarNessuna valutazione finora