Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Grooving Specifications 25 01

Caricato da

AndiniPermanaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Grooving Specifications 25 01

Caricato da

AndiniPermanaCopyright:

Formati disponibili

25.

01

STANDARD IPS GROOVE SPECIFICATIONS

Standard Groove Specifications

STANDARD ROLL GROOVE

SPECIFICATIONS FOR STEEL AND

OTHERIPS PIPE

B

E

OD

Roll grooving removes no metal, cold forming

a groove by the action of an upper male roll

being forced into pipe as it is rotated by a

lower female drive roll.

Roll groove configuration has rounded

edges which reduce the available pipe end

movement (expansion, contraction and

deflection).

NOTE: Coatings applied to the interior surfaces,

including bolt pad mating surfaces, of our grooved

and bolted plain end couplings should not exceed

0.010"/0.25mm. Also, the coating thickness applied to

the gasket seating surface and within the groove on

the pipe exterior should not exceed 0.010"/0.25mm.

Nominal

Size

Inches/mm

3/4

20

1

25

11/4

32

11/2

40

2

50

21/2

65

76.1mm

3

80

31/2

90

4

100

108.0mm

41/2

120

133.0mm

139.7mm

5

125

152.4mm

159.0mm

Pipe Outside Dia. O.D.

Tolerance

Basic

1.050

26.9

1.315

33.7

1.660

42.4

1.900

48.3

2.375

60.3

2.875

73.0

3.000

76.1

3.500

88.9

4.000

101.6

4.500

114.3

4.250

108.0

5.000

127.0

5.250

133.0

5.500

139.7

5.563

141.3

6.000

152.4

6.250

159.0

0.010

0.25

0.013

0.33

0.016

0.41

0.019

0.48

0.024

0.61

0.029

0.74

0.030

0.76

0.035

0.89

0.040

1.02

0.045

1.14

0.043

1.09

0.050

1.27

0.053

1.35

0.056

1.42

0.056

1.42

0.056

1.42

0.063

1.60

0.010

0.25

0.013

0.33

0.016

0.41

0.019

0.48

0.024

0.61

0.029

0.74

0.030

0.76

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

4

5

Dimensions Inches/millimeters

Groove Dia. C

Grv.

Gasket

Tol.

Seat - A Width - B

+0.000

0.03

0.03

+0.00

Basic

0.76

0.76

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.281

7.14

0.281

7.14

0.281

7.14

0.281

7.14

0.344

8.74

0.344

8.74

0.344

8.74

0.344

8.74

0.344

8.74

0.344

8.74

0.344

8.74

0.344

8.74

0.344

8.74

0.344

8.74

0.344

8.74

0.344

8.74

0.344

8.74

0.938

23.83

1.190

30.23

1.535

38.99

1.775

45.09

2.250

57.15

2.720

69.09

2.845

72.26

3.344

84.94

3.834

97.38

4.334

110.08

4.084

103.73

4.834

122.78

5.084

129.13

5.334

135.48

5.395

137.03

5.830

148.08

6.032

153.21

0.015

0.38

0.015

0.38

0.015

0.38

0.015

0.38

0.015

0.38

0.018

0.46

0.018

0.46

0.018

0.46

0.020

0.51

0.020

0.51

0.020

0.51

0.020

0.51

0.020

0.51

0.020

0.51

0.022

0.56

0.022

0.56

0.030

0.76

Groove

Depth D

(ref.)

Min.

Allow.

Wall Thk.

T

Max.

Allow.

Flare

Dia.

0.056

1.42

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.078

1.98

0.078

1.98

0.078

1.98

0.083

2.11

0.083

2.11

0.083

2.11

0.083

2.11

0.083

2.11

0.083

2.11

0.084

2.13

0.109

2.80

0.085

2.16

0.065

1.65

0.065

1.65

0.065

1.65

0.065

1.65

0.065

1.65

0.083

2.11

0.083

2.11

0.083

2.11

0.083

2.11

0.083

2.11

0.083

2.11

0.095

2.41

0.109

2.77

0.109

2.77

0.109

2.77

0.109

2.77

0.109

2.77

1.15

29.2

1.43

36.3

1.77

45.0

2.01

51.1

2.48

63.0

2.98

75.7

3.10

78.7

3.60

91.4

4.10

104.1

4.60

116.8

4.35

110.5

5.10

129.5

5.35

135.9

5.60

142.2

5.66

143.8

6.10

154.9

6.35

161.3

On roll grooved pipe, Allowable Pipe End Separation and Deflection from Centerline will be 1/2 values listed for cut

grooved pipe.

For 14 14"/350 600mm roll groove dimensions, request publication 25.09.

For 30 42"/750 1050mm roll groove dimensions contact Victaulic.

COLUMN 1: Nominal IPS Pipe size.

COLUMN 2: IPS outside diameter. The outside diameter of roll grooved pipe shall not vary more than the tolerance

listed. For IPS pipe the maximum allowable tolerance from square cut ends is 0.030" for 3/4 31/2"; 0.045" for 4 6"; and

0.060" for sizes 8" O.D. and above measured from true square line.

COLUMN 3: Gasket seat. The pipe surface shall be free from indentations, roll marks, and projections from the end

of the pipe to the groove, to provide a leak-tight seal for the gasket. All loose paint, scale, dirt, chips, grease and rust

must be removed. It continues to be Victaulics first recommendation that pipe be square cut. When using beveled

pipe contact Victaulic for details. Square cut pipe must be used with FlushSeal and EndSeal gaskets. Gasket seat A

is measured from the end of the pipe. IMPORTANT: Roll grooving of beveled end pipe may result in unacceptable pipe

end flare. See column 8.

COLUMN 4: Groove width. Bottom of groove to be free of loose dirt, chips, rust and scale that may interfere with

proper coupling assembly. Corners at bottom of groove must be radiused. For IPS steel pipe, .06R on 3/4 11/2", .08R on

2 6", .05R on 8" and up.

COLUMN 5: Groove outside diameter. The groove must be of uniform depth for the entire pipe circumference.

Groove must be maintained within the C diameter tolerance listed.

COLUMN 6: Groove depth. For reference only. Groove must conform to the groove diameter C listed.

COLUMN 7: Minimum allowable wall thickness. This is the minimum wall thickness which may be roll grooved.

COLUMN 8: Maximum allowable pipe end flare diameter. Measured at the most extreme pipe end diameter square

cut or beveled.

JOB/OWNER

CONTRACTOR

ENGINEER

System No.___________________________

Submitted By_________________________

Spec Sect_____________ Para___________

Location_ ____________________________

Date ________________________________

Approved_ ___________________________

Date ________________________________

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. 2008 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_E

25.01_1

25.01

STANDARD IPS GROOVE SPECIFICATIONS

Standard Groove Specifications

STANDARD ROLL GROOVE

SPECIFICATIONS FOR STEEL AND

OTHERIPS PIPE

B

E

Nominal

Size

Inches/mm

165.1mm

OD

6

150

203.2mm

8

200

D

Roll grooving removes no metal, cold forming

a groove by the action of an upper male roll

being forced into pipe as it is rotated by a

lower female drive roll.

Roll groove configuration has rounded

edges which reduce the available pipe end

movement (expansion, contraction and

deflection).

NOTE: Coatings applied to the interior surfaces,

including bolt pad mating surfaces, of our grooved

and bolted plain end couplings should not exceed

0.010"/0.25mm. Also, the coating thickness applied to

the gasket seating surface and within the groove on

the pipe exterior should not exceed 0.010"/0.25mm.

254.0mm

10

250

304.8mm

12

300

26O.D.

650

28O.D.

700

30O.D.

750

32O.D.

800

36O.D.

900

42O.D.

1050

Pipe Outside Dia. O.D.

Tolerance

Basic

6.500

165.1

6.625

168.3

8.000

203.2

8.625

219.1

10.000

254.0

10.750

273.0

12.000

304.8

12.750

323.9

26.00

660.4

28.00

711.0

30.00

762.0

32.00

813.0

36.00

914.0

42.00

1067.0

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.093

2.36

0.093

2.36

0.093

2.36

0.093

2.36

0.093

2.36

0.093

2.36

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

4

5

Dimensions Inches/millimeters

Groove Dia. C

Grv.

Gasket

Tol.

Seat - A Width - B

+0.000

0.03

0.03

+0.00

Basic

0.76

0.76

0.625

15.88

0.625

15.88

0.750

19.05

0.750

19.05

0.750

19.05

0.750

19.05

0.750

19.05

0.750

19.05

1.75

44.45

1.75

44.45

1.75

44.45

1.75

44.45

1.75

44.45

2.00

50.80

0.344

8.74

0.344

8.74

0.469

11.91

0.469

11.91

0.469

11.91

0.469

11.91

0.469

11.91

0.469

11.91

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

6.330

160.78

6.455

163.96

7.816

198.53

8.441

214.40

9.812

249.23

10.562

268.28

11.781

299.24

12.531

318.29

25.50

647.7

27.50

698.50

29.50

749.30

31.50

800.10

35.50

901.70

41.50

1054.10

0.022

0.56

0.022

0.56

0.025

0.64

0.025

0.64

0.027

0.69

0.027

0.69

0.030

0.76

0.030

0.76

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

Groove

Depth D

(ref.)

Min.

Allow.

Wall Thk.

T

Max.

Allow.

Flare

Dia.

0.085

2.16

0.085

2.16

0.092

2.34

0.092

2.34

0.094

2.39

0.094

2.39

0.109

2.77

0.109

2.77

0.250

6.35

0.250

6.35

0.250

6.35

0.250

6.35

0.250

6.35

0.250

6.35

0.109

2.77

0.109

2.77

0.109

2.77

0.109

2.77

0.134

3.40

0.134

3.40

0.156

3.96

0.156

3.96

0.250

6.35

0.250

6.35

0.250

6.35

0.250

6.35

0.250

6.35

0.250

6.35

6.60

167.6

6.73

170.9

8.17

207.5

8.80

223.5

10.17

258.3

10.92

277.4

12.17

309.1

12.92

328.2

26.20

665.5

28.20

716.3

30.20

767.1

32.20

817.9

36.20

919.5

42.20

1071.8

On roll grooved pipe, Allowable Pipe End Separation and Deflection from Centerline will be 1/2 values listed for cut

grooved pipe.

For 14 14"/350 600mm roll groove dimensions, request publication 25.09.

For 30 42"/750 1050mm roll groove dimensions contact Victaulic.

COLUMN 1: Nominal IPS Pipe size.

COLUMN 2: IPS outside diameter. The outside diameter of roll grooved pipe shall not vary more than the tolerance

listed. For IPS pipe the maximum allowable tolerance from square cut ends is 0.030" for 3/4 31/2"; 0.045" for 4 6"; and

0.060" for sizes 8" O.D. and above measured from true square line.

COLUMN 3: Gasket seat. The pipe surface shall be free from indentations, roll marks, and projections from the end

of the pipe to the groove, to provide a leak-tight seal for the gasket. All loose paint, scale, dirt, chips, grease and rust

must be removed. It continues to be Victaulics first recommendation that pipe be square cut. When using beveled

pipe contact Victaulic for details. Square cut pipe must be used with FlushSeal and EndSeal gaskets. Gasket seat A

is measured from the end of the pipe. IMPORTANT: Roll grooving of beveled end pipe may result in unacceptable pipe

end flare. See column 8.

COLUMN 4: Groove width. Bottom of groove to be free of loose dirt, chips, rust and scale that may interfere with

proper coupling assembly. Corners at bottom of groove must be radiused. For IPS steel pipe, .06R on 3/4 11/2", .08R on

2 6", .05R on 8" and up.

COLUMN 5: Groove outside diameter. The groove must be of uniform depth for the entire pipe circumference.

Groove must be maintained within the C diameter tolerance listed.

COLUMN 6: Groove depth. For reference only. Groove must conform to the groove diameter C listed.

COLUMN 7: Minimum allowable wall thickness. This is the minimum wall thickness which may be roll grooved.

COLUMN 8: Maximum allowable pipe end flare diameter. Measured at the most extreme pipe end diameter square

cut or beveled.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. 2008 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

25.01_2

REV_E

25.01

STANDARD IPS GROOVE SPECIFICATIONS

Standard Groove Specifications

STANDARD CUT GROOVE SPECIFICATIONS

FOR STEEL AND OTHER IPS PIPE

OD

Exaggerated for Clarity

Cut grooving standard steel pipe removes

less metal, to less depth, than threading,

maintaining the desired integrity of the pipe.

Nominal

Size

Inches/mm

3/4

20

1

25

11/4

32

11/2

40

2

50

21/2

65

76.1mm

3

80

31/2

90

4

100

41/2

120

139.7mm

5

125

152.4mm

165.1mm

6

150

203.2mm

8

200

254.0mm

10

250

304.8mm

12

300

2

Pipe Outside Dia. O.D.

Tolerance

Basic

1.050

26.9

1.315

33.7

1.660

42.4

1.900

48.3

2.375

60.3

2.875

73.0

3.000

76.1

3.500

88.9

4.000

101.6

4.500

114.3

5.000

127.0

5.500

139.7

5.563

141.3

6.000

152.4

6.500

165.1

6.625

168.3

8.000

203.2

8.625

219.1

10.000

254.0

10.750

273.0

12.000

304.8

12.750

323.9

0.010

0.25

0.013

0.33

0.016

0.41

0.019

0.48

0.024

0.61

0.029

0.74

0.030

0.76

0.035

0.89

0.040

1.02

0.045

1.14

0.050

1.27

0.056

1.42

0.056

1.42

0.056

1.42

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.010

0.25

0.013

0.33

0.016

0.41

0.019

0.48

0.024

0.61

0.029

0.74

0.030

0.76

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

3

4

5

Dimensions Inches/millimeters

Groove Dia. C

Grv.

Gasket Seat

Width - B

-A

Tol. +0.000

0.03

0.03

Basic

+0.00

0.76

0.76

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.750

19.05

0.750

19.05

0.750

19.05

0.750

19.05

0.750

19.05

0.750

19.05

0.313

7.95

0.313

7.95

0.313

7.95

0.313

7.95

0.313

7.95

0.313

7.95

0.313

7.95

0.313

7.95

0.313

7.95

0.375

9.53

0.375

9.53

0.375

9.53

0.375

9.53

0.375

9.53

0.375

9.53

0.375

9.53

0.438

11.13

0.438

11.13

0.500

12.70

0.500

12.70

0.500

12.70

0.500

12.70

0.938

23.83

1.190

30.23

1.535

38.99

1.775

45.09

2.250

57.15

2.720

69.09

2.845

72.26

3.344

84.94

3.834

97.38

4.334

110.08

4.834

122.78

5.334

135.48

5.395

137.03

5.830

148.08

6.330

160.78

6.455

163.96

7.816

198.53

8.441

214.40

9.812

249.23

10.562

268.28

11.781

299.24

12.531

318.29

0.015

0.38

0.015

0.38

0.015

0.38

0.015

0.38

0.015

0.38

0.018

0.46

0.018

0.46

0.018

0.46

0.020

0.51

0.020

0.51

0.020

0.51

0.020

0.51

0.020

0.51

0.022

0.56

0.022

0.56

0.022

0.56

0.022

0.56

0.025

0.64

0.025

0.64

0.027

0.69

0.027

0.69

0.030

0.76

Groove

Depth D

(ref.)

Min.

Allow.

Wall Thk.

T

0.056

1.42

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.078

1.98

0.078

1.98

0.078

1.98

0.083

2.11

0.083

2.11

0.083

2.11

0.083

2.11

0.084

2.13

0.085

2.16

0.085

2.16

0.085

2.16

0.092

2.34

0.092

2.34

0.094

2.39

0.094

2.39

0.109

2.77

0.109

2.77

0.113

2.87

0.133

3.38

0.140

3.56

0.145

3.68

0.154

3.91

0.188

4.78

0.188

4.78

0.188

4.78

0.188

4.78

0.203

5.16

0.203

5.16

0.203

5.16

0.203

5.16

0.219

5.56

0.219

5.56

0.219

5.56

0.238

6.05

0.238

6.05

0.250

6.35

0.250

6.35

0.279

7.09

0.279

7.09

* 9/16"/14mm width groove is required in sizes 22 24"/550 600mm in order to obtain the maximum allowable pipe end

movement listed in Performance Data Charts. 1/2"/12mm width groove will give 1/2 the maximum allowance shown for

22 24"/550 600mm. For double groove tool bit information, contact Victaulic.

COLUMN 1: Nominal IPS Pipe size.

COLUMN 2: IPS outside diameter. The outside diameter of cut grooved pipe shall not vary more than the tolerance

listed. For IPS pipe the maximum allowable tolerance from square cut ends to 0.030" for 3/4 31/2"; 0.045" for 4 6"; and

0.060" for sizes 8"O.D. and above measured from true square line.

COLUMN 3: Gasket seat. The pipe surface shall be free from indentations, roll marks, and projections from the end of the

pipe to the groove, to provide a leak-tight seal for the gasket. All loose paint, scale, dirt, chips, grease and rust must be

removed. It continues to be Victaulics first recommendation that pipe be square cut. When using beveled pipe contact

Victaulic for details. Square cut pipe must be used with FlushSeal and EndSeal gaskets. Gasket seat A is measured

from the end of the pipe.

COLUMN 4: Groove width. The bottom of groove to be free of loose dirt, chips, rust and scale that may interfere with

proper coupling assembly. Maximum permissible radius at bottom of groove is .015".

COLUMN 5: Groove outside diameter. The groove must be of uniform depth for the entire pipe circumference. Groove

must be maintained within the C diameter tolerance listed.

COLUMN 6: Groove depth. For reference only. Groove must conform to the groove diameter C listed.

COLUMN 7: Minimum allowable wall thickness. This is the minimum wall thickness which may be cut grooved.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. 2008 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_E

25.01_3

25.01

STANDARD IPS GROOVE SPECIFICATIONS

Standard Groove Specifications

STANDARD CUT GROOVE SPECIFICATIONS

FOR STEEL AND OTHER IPS PIPE

OD

Exaggerated for Clarity

Cut grooving standard steel pipe removes

less metal, to less depth, than threading,

maintaining the desired integrity of the pipe.

2

Pipe Outside Dia. O.D.

Tolerance

Nominal

Size

Inches/mm

Basic

14

350

15

375

16

100

18

450

20

500

22

550

24

600

26O.D.

650

28O.D.

700

30O.D.

750

32O.D.

800

36O.D.

900

42O.D.

1050

14.000

355.6

15.000

381.0

16.000

406.4

18.000

457.2

20.000

508.0

22.000

559.0

24.000

610.0

26.00

660.4

28.00

711.0

30.00

762.0

32.00

813.0

36.00

914.0

42.00

1067.0

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.093

2.36

0.093

2.36

0.093

2.36

0.093

2.36

0.093

2.36

0.093

2.36

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

0.031

0.79

3

4

5

Dimensions Inches/millimeters

Groove Dia. C

Grv.

Gasket Seat

Width - B

-A

Tol. +0.000

0.03

0.03

Basic

+0.00

0.76

0.76

0.938

23.83

0.938

23.83

0.938

23.83

1.000

25.40

1.000

25.40

1.000

25.40

1.000

25.40

1.75

44.45

1.75

44.45

1.75

44.45

1.75

44.45

1.75

44.45

2.00

50.80

0.500

12.70

0.500

12.70

0.500

12.70

0.500

12.70

0.500

12.70

0.563*

14.30

0.563*

14.30

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

13.781

350.04

14.781

375.44

15.781

400.84

17.781

451.64

19.781

502.44

21.656

550.06

23.656

600.86

25.50

647.7

27.50

698.50

29.50

749.30

31.50

800.10

35.50

901.70

41.50

1054.10

0.030

0.76

0.030

0.76

0.030

0.76

0.030

0.76

0.030

0.76

0.030

0.76

0.030

0.76

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

0.063

1.60

Groove

Depth D

(ref.)

Min.

Allow.

Wall Thk.

T

0.109

2.77

0.109

2.77

0.109

2.77

0.109

2.77

0.109

2.77

0.172

4.37

0.172

4.37

0.250

6.35

0.250

6.35

0.250

6.35

0.250

6.35

0.250

6.35

0.250

6.35

0.281

7.14

0.312

7.92

0.312

7.92

0.312

7.92

0.312

7.92

0.375

9.53

0.375

9.53

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

0.625

15.88

* 9/16"/14mm width groove is required in sizes 22 24"/550 600mm in order to obtain the maximum allowable pipe end

movement listed in Performance Data Charts. 1/2"/12mm width groove will give 1/2 the maximum allowance shown for

22 24"/550 600mm. For double groove tool bit information, contact Victaulic.

COLUMN 1: Nominal IPS Pipe size.

COLUMN 2: IPS outside diameter. The outside diameter of cut grooved pipe shall not vary more than the tolerance

listed. For IPS pipe the maximum allowable tolerance from square cut ends to 0.030" for 3/4 31/2"; 0.045" for 4 6"; and

0.060" for sizes 8"O.D. and above measured from true square line.

COLUMN 3: Gasket seat. The pipe surface shall be free from indentations, roll marks, and projections from the end of the

pipe to the groove, to provide a leak-tight seal for the gasket. All loose paint, scale, dirt, chips, grease and rust must be

removed. It continues to be Victaulics first recommendation that pipe be square cut. When using beveled pipe contact

Victaulic for details. Square cut pipe must be used with FlushSeal and EndSeal gaskets. Gasket seat A is measured

from the end of the pipe.

COLUMN 4: Groove width. The bottom of groove to be free of loose dirt, chips, rust and scale that may interfere with

proper coupling assembly. Maximum permissible radius at bottom of groove is .015".

COLUMN 5: Groove outside diameter. The groove must be of uniform depth for the entire pipe circumference. Groove

must be maintained within the C diameter tolerance listed.

COLUMN 6: Groove depth. For reference only. Groove must conform to the groove diameter C listed.

COLUMN 7: Minimum allowable wall thickness. This is the minimum wall thickness which may be cut grooved.

WARRANTY

Refer to the Warranty section of the current Price List or contact Victaulic for details.

NOTE

This product shall be manufactured by Victaulic or to Victaulic specifications. All products to be

installed in accordance with current Victaulic installation/assembly instructions. Victaulic reserves the

right to change product specifications, designs and standard equipment without notice and without

incurring obligations.

WCAS-7EUNXM

For complete contact information, visit www.victaulic.com

25.01

1687 REV E

UPDATED 7/2008

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. 2008 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

25.01

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

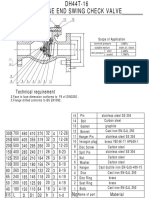

- Flanged End Swing Check Valves DIN3202 F6Documento2 pagineFlanged End Swing Check Valves DIN3202 F6AndiniPermanaNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- 02 P&ID Guide PDFDocumento9 pagine02 P&ID Guide PDFcharleselitb92Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- FM Approvals Certification MarksDocumento3 pagineFM Approvals Certification MarksAndiniPermanaNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Q 10Documento7 pagineQ 10AndiniPermanaNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- I PT101Documento2 pagineI PT101AndiniPermanaNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- FM Approvals Certification MarksDocumento3 pagineFM Approvals Certification MarksAndiniPermanaNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Toriconical Head Ver 1.1Documento4 pagineToriconical Head Ver 1.1Iqbal AhmadsNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Astm A36Documento7 pagineAstm A36Dianna LambertNessuna valutazione finora

- Abd El Rahman Et - AlDocumento11 pagineAbd El Rahman Et - AlAndiniPermanaNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- TuneUP 2014 SERIALESDocumento1 paginaTuneUP 2014 SERIALESPedro Pastor SanchezNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Friction Factor (Power Screw)Documento1 paginaFriction Factor (Power Screw)AndiniPermanaNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Effect of Pass Schedule On Cross-Sectional Shapes of Circular Seamless Pipes Reshaped Into Square Shapes by Hot Roll Sizing MillDocumento6 pagineEffect of Pass Schedule On Cross-Sectional Shapes of Circular Seamless Pipes Reshaped Into Square Shapes by Hot Roll Sizing MillAndiniPermanaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Power ScrewDocumento3 paginePower ScrewAndiniPermanaNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Power ScrewDocumento3 paginePower ScrewAndiniPermanaNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Wiki LeadDocumento13 pagineWiki LeadAndiniPermanaNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Malleable Iron CouplingDocumento1 paginaMalleable Iron CouplingAndiniPermanaNessuna valutazione finora

- Malleable Iron Unequal TeeDocumento1 paginaMalleable Iron Unequal TeeAndiniPermanaNessuna valutazione finora

- TGL P Attachment 11Documento1 paginaTGL P Attachment 11Omid BeygiNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Common Etchants PDFDocumento2 pagineCommon Etchants PDFAndiniPermanaNessuna valutazione finora

- Zinc Alloy ElementsDocumento3 pagineZinc Alloy ElementsAndiniPermanaNessuna valutazione finora

- Zinc Alloy Chemistry in The Foundry.Documento8 pagineZinc Alloy Chemistry in The Foundry.yips0001Nessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Permit To Work PolicyDocumento5 paginePermit To Work PolicyAndiniPermanaNessuna valutazione finora

- WWW - Sony.co - Uk Support en Product DSC-HX10V Specificatio PDFDocumento7 pagineWWW - Sony.co - Uk Support en Product DSC-HX10V Specificatio PDFAndiniPermanaNessuna valutazione finora

- WWW - Sony.co - Uk Support en Product DSC-WX100 Specificatio PDFDocumento5 pagineWWW - Sony.co - Uk Support en Product DSC-WX100 Specificatio PDFAndiniPermanaNessuna valutazione finora

- Air Cylinder FA100N130AO (Taiyo)Documento1 paginaAir Cylinder FA100N130AO (Taiyo)AndiniPermanaNessuna valutazione finora

- Air Cylinder FA100N300AO (Taiyo)Documento1 paginaAir Cylinder FA100N300AO (Taiyo)AndiniPermanaNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Hari Tanggal N K 19000 0 589000 1 11400 939000 2 26600 3 41800 5 79800 Income (/hari) 6 95000 7 117800 Save (/hari) 133000Documento2 pagineHari Tanggal N K 19000 0 589000 1 11400 939000 2 26600 3 41800 5 79800 Income (/hari) 6 95000 7 117800 Save (/hari) 133000AndiniPermanaNessuna valutazione finora

- Pressure Gauge 100Documento1 paginaPressure Gauge 100AndiniPermanaNessuna valutazione finora

- Tabel Toleransi: UNTUK POROS (Table 5.4, Ref. To NSK) Diameter (MM) TOLERANSI (0.001mm) Over Incl. MIN MAXDocumento1 paginaTabel Toleransi: UNTUK POROS (Table 5.4, Ref. To NSK) Diameter (MM) TOLERANSI (0.001mm) Over Incl. MIN MAXAndiniPermanaNessuna valutazione finora

- Pressure Gauge 150Documento1 paginaPressure Gauge 150AndiniPermanaNessuna valutazione finora

- Concentration Term Jee Main Selected 2Documento3 pagineConcentration Term Jee Main Selected 2aebafbigiNessuna valutazione finora

- What Is DrugDocumento9 pagineWhat Is DrugFebz CanutabNessuna valutazione finora

- Dredging BrochureDocumento11 pagineDredging Brochuremaxi galvanNessuna valutazione finora

- Ashrae 90.1 Tabelas e ComentáriosDocumento12 pagineAshrae 90.1 Tabelas e ComentáriosEmerson Borges SantanaNessuna valutazione finora

- Fischer Esterification of Benzyl AcetateDocumento3 pagineFischer Esterification of Benzyl AcetateMarjory CastilloNessuna valutazione finora

- Hygienic Air Handling Unit CatalogueDocumento27 pagineHygienic Air Handling Unit Cataloguemoataz medhatNessuna valutazione finora

- Barbicide MsdsDocumento3 pagineBarbicide MsdstudorcerneaNessuna valutazione finora

- BeerDocumento21 pagineBeermichol20140% (1)

- Deocument 9172Documento21 pagineDeocument 9172jeffrey.beach2560% (1)

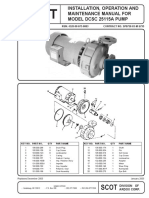

- Manual Maintenance Scot PumpDocumento4 pagineManual Maintenance Scot Pumpadrian suicaNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Unit 8 NotesDocumento2 pagineUnit 8 NotesRahna AzaamNessuna valutazione finora

- INOVYN™ PVC - Emulsion PVCDocumento9 pagineINOVYN™ PVC - Emulsion PVCM Waheed AtharNessuna valutazione finora

- Accesorios de Carga CROSBYDocumento52 pagineAccesorios de Carga CROSBYRodolfo AlboresNessuna valutazione finora

- Excipients PDFDocumento2 pagineExcipients PDFMarioNessuna valutazione finora

- Soal Latihan Promanu 2020Documento3 pagineSoal Latihan Promanu 2020Jabir 08Nessuna valutazione finora

- Haefele AH A4 Mar 15 8.12-8.24Documento13 pagineHaefele AH A4 Mar 15 8.12-8.24khurram1810Nessuna valutazione finora

- Lecture Notes Materials and Ecological EngineeringDocumento463 pagineLecture Notes Materials and Ecological EngineeringInhake AutechreNessuna valutazione finora

- Effect of Mixing On The Properties of Nanocarbon Containing Al2O3 C Continuous Casting RefractoriesDocumento8 pagineEffect of Mixing On The Properties of Nanocarbon Containing Al2O3 C Continuous Casting RefractoriesAnonymous gQyrTUHX38Nessuna valutazione finora

- Introduction To Surface EngineeringDocumento31 pagineIntroduction To Surface Engineeringlogeshboy007Nessuna valutazione finora

- 08 - Enriquecedor de Oxigeno AS-DDocumento61 pagine08 - Enriquecedor de Oxigeno AS-DCRISTIAN ALEXANDER SALDANA GARZONNessuna valutazione finora

- Expt 7 - Unit Cells (Virtual Lab)Documento9 pagineExpt 7 - Unit Cells (Virtual Lab)Angel De LoyolaNessuna valutazione finora

- United States Patent: (45) Date of Patent: Aug - 21, 2018Documento22 pagineUnited States Patent: (45) Date of Patent: Aug - 21, 2018RiskaNessuna valutazione finora

- Main PropulsionDocumento27 pagineMain PropulsionalsitorNessuna valutazione finora

- Geas FinalDocumento489 pagineGeas FinalroselleNessuna valutazione finora

- Engineering Vol 56 1893-10-06Documento33 pagineEngineering Vol 56 1893-10-06ian_newNessuna valutazione finora

- Iwcf NotesDocumento81 pagineIwcf NotesShraddhanand More100% (1)

- Comparative of Basement Waterproofing SODDocumento2 pagineComparative of Basement Waterproofing SODManoj BhonsleNessuna valutazione finora

- SUS302 Vs SUS304Documento3 pagineSUS302 Vs SUS304enrico susantoNessuna valutazione finora

- Preparation of Standard Solutions and Acid-Base TitrationDocumento4 paginePreparation of Standard Solutions and Acid-Base TitrationJhon Jasper ApanNessuna valutazione finora

- Cable Slickline 316 StainlessDocumento1 paginaCable Slickline 316 StainlessRafael EspinosaNessuna valutazione finora