Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

API 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)

Caricato da

tutuionutTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

API 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)

Caricato da

tutuionutCopyright:

Formati disponibili

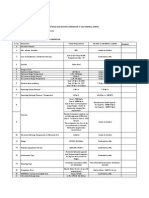

API 614Chapter 4 DATA SHEET

DRY GAS SEAL MODULE

SI UNITS

Applicable to

Proposal

Purchase

By:

Date:

Revision:

Site

Module supplier

NOTES:

Item No.:

Page: 1 of###

4

As built

For

Gas seal module for

Purchase Order No.

Job No.:

Module manufacturer

Date

Inquiry no.

Requisition No.

1. The party to complete the information is indicated as follows:

Purchaser

Vendor

Either, but by vendor if not by purchaser.

2. A dot * indicates the standard specifies a requirement, value, or criterion.

3. Designations in ( ) are applicable portions of the standard; numbers without a prefix are paragraph

numbers; those prefixed T are text figure numbers; those prefixed A are Appendix A Figure

numbers.

Drawing requirements

Component review

System responsibility: (2.1.2)

Vendor responsible for system

Vendor responsible for

Vendor responsible for scope

design

installation

of supply

Supply arrangement:

Separate modules for

Multiple package for

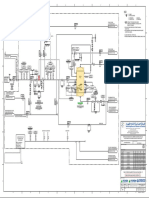

Basic system details: (see referenced Figures 4A-1 through 4A-4)

Dry gas seal type:

Double (4A-1)

Tandem with internal laby (4A-2)

Tandem (4A-3)

Single (4A-4)

Dry gas seal specifics:

Seal manufacturer

Seal gas hazardous (yes/no)

Seal gas composition:

MW =

Gas supply:

Pressure

Seal gas supply (2.1.11)

Buffer gas

Intermediate gas

Options

Basics

Seal gas filter module (4A-5a, 4A-5b)

Separation gas filter module (4A-5c)

Differential pressure control (4A-6a)

Flow control (4A-6b, 4A-6c, 4A-6d)

For option 4A2 (tandem with internal laby)

Differential pressure control (4A-7a)

Flow control (4A-7b, 4A-7c)

Material

Double blocks and bleeds (2.1.8)

319678971.xlsx

Seal model no.

Seal gas composition below or refer to

Seal serial no.

:

Gas

Mole pct.

Temperature

Flow

Description of gas

Outlet modules

Flow monitoringdiff. pressure (4A-8a)

Flow monitoringbackpressure (4A-8b)

Flow measuring (4A-8c)

Separation gas modules

Option (4A-9a, 4A-9b, 4A-9c)

Special requirements

Instrument test valves required

Page 1 of 10, Date Printed: 05/30/2016

API 614Chapter 4 DATA SHEET

DRY GAS SEAL MODULE

SI UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 2 of 4

By:

Date:

Revision:

As built

Supplier

Manufacturer

Purchase Order No.

Date

Inquiry no.

Requisition No.

Components:

Piping and tubing:

Tight shutoff

Tubing fittingsmfg.

Carbon steel slip-on flanges

__________

Heat tracing required by

model _______

purchaser

Through studs required

vendor

Continuous flow transfer valves

Service application

Gas

Common for coolers and filters

Strainer reg'd (2.4.3)

With lifting jack

Tight shutoff required

Rating: barg

Type

Materials: body

Manufacturer

Plug or ball

Model

Trim

Filters:

Service application:

Separation gas

Purchaser item no.

Design/test (barg)

Twin

Code construction/stamp (2.1.9)

Include option nos.

Material: case and top

Filtration level

Cartridges:

Manufacturer

Filter body diameter (mm)

Model

Testing:

Functional test (4.3.3.4)

319678971.xlsx, 4-20

Page 2 of 10, Date Printed: 05/30/2016

API 614Chapter 4 DATA SHEET

DRY GAS SEAL MODULE

SI UNITS

Applicable to

Proposal

Purchase

Furnish _______ extra sets of cartridges.

Coolers:

Service application

Item No.:

Page: 3 of 4

By:

Date:

Revision:

As built

Supplier

Purchase Order No.

Job No.:

Manufacturer

Date

Inquiry no.

Requisition No.

Per filter (extra over other spares).

Lube

Design/test shell side (barg)

Design/test tube side (barg)

Purchaser item nos.

Code construction/stamp (2.1.9)

Twin units

Tube water velocity and capacity (mps/m3/hr)

Include option nos.

Material: shell

Water side for steam heating

Channels and covers

Details on data sheet

Tube sheets and tubes

Water side corrosion allowance

Removable tube bundle

Manufacturer

U-bend tubes permitted

Model

Oil temperature control valve

TEMA class

Fouling factor water/oil side

Duty: Btu/hr

Tube: L/OD/BWG

319678971.xlsx, 4-21

Page 3 of 10, Date Printed: 05/30/2016

API 614Chapter 4 DATA SHEET

DRY GAS SEAL MODULE

SI UNITS

Applicable to

Proposal

Purchase

Supplier

Purchase Order No.

Shop inspection

Job No.:

Item No.:

Page: 4 of 4

By:

Date:

Revision:

As built

Manufacturer

Date

Inquiry no.

Requisition No.

Shop test

Compliance with inspectors checklist

Required

Required for system assemblies

Cleanliness

Cleanliness prior to closure

Four hour run

Required for major components

Check controls

Material certifications to be furnished

Changeover filters/coolers

Special examinations

One and two pump operation

Code construction/stamp

Sound level

Certified copies of all test logs and data

Hydro test assembled system

Witness

Use for complete unit system test

Certified copies of all test logs and data

319678971.xlsx, 4-22

Page 4 of 10, Date Printed: 05/30/2016

API 614Chapter 4 DATA SHEET

DRY GAS SEAL

SI UNITS

Applicable to

Proposal

Purchase

Job No.:

Seals for Item No.:

Page: 1 of 1

By:

Date:

Revision:

By:

As built

Gas seal supplier

Equipment manufacturer

Purchase Order No.

Date

Inquiry no.

Requisition No.

Dry gas seal design:

Rotational speed

_______________

Application

new

max. rpm

Rotation viewed from driver end

Maximum sealing pressure:

Settle out pressure

Vent pressurenormal/max

retrofit

Vendor drawing no.

CW

_____________ barg (2.1.6)

___________

barg

CCW

________ / ________

Equipment suction pressure (min/max)

Equipment discharge temperature

Process relief valve setting

normal operation

_____ / _____ barg

_________

_________

Seal maximum design pressure:

Leakage rates:

barg

_________________

barg

__________ barg

static

Primary vent

Secondary vent

Secondary vent for intermediate laby.

___________________

___________________

Comments:

319678971.xlsx, 4-23

Page 5 of 10, Date Printed: 05/30/2016

API 614Chapter 4 DATA SHEET

DRY GAS SEAL MODULE

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

By:

Date:

Revision:

Site

Module supplier

NOTES:

Item No.:

Page: 1 of 4

As built

For

Gas seal module for

Purchase Order No.

Job No.:

Module manufacturer

Date

Inquiry no.

Requisition No.

1. The party to complete the information is indicated as follows:

Purchaser

Vendor

Either, but by vendor if not by purchaser.

2. A dot * indicates the standard specifies a requirement, value, or criterion.

3. Designations in ( ) are applicable portions of the standard; numbers without a prefix are paragraph

numbers; those prefixed T are text figure numbers; those prefixed A are Appendix A Figure

numbers.

Drawing requirements

Component review

System responsibility: (2.1.2)

Vendor responsible for system

Vendor responsible for

Vendor responsible for scope

design

installation

of supply

Supply arrangement:

Separate modules for

Multiple package for

_____________________

Basic system details: (see referenced Figures 4A-1 through 4A-4)

Dry gas seal type:

Double (4A-1)

Tandem with internal laby (4A-2)

Tandem (4A-3)

Single (4A-4)

Dry gas seal specifics:

Seal manufacturer

Seal gas hazardous (yes/no)

Seal gas composition:

MW =

Gas supply:

Pressure

Seal gas supply (2.1.11)

Buffer gas

Intermediate gas

Options

Basics

Seal gas filter module (4A-5a, 4A-5b)

Separation gas filter module (4A-5c)

Differential pressure control (4A-6a)

Flow control (4A-6b, 4A-6c, 4A-6d)

For option 4A2 (tandem with internal laby)

Differential pressure control (4A-7a)

Flow control (4A-7b, 4A-7c)

Material

Double blocks and bleeds (2.1.8)

319678971.xlsx, 4-24

Seal model no.

Seal gas composition below or refer to

Seal serial no.

Gas

Mole pct.

Temperature

Flow

Description of gas

Outlet modules

Flow monitoringdiff. pressure (4A-8a)

Flow monitoringbackpressure (4A-8b)

Flow measuring (4A-8c)

Separation gas modules

Option (4A-9a, 4A-9b, 4A-9c)

Special requirements

Instrument test valves required

Page 1 of 10, Date Printed: 05/30/2016

API 614Chapter 4 DATA SHEET

DRY GAS SEAL MODULE

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 2 of 4

By:

Date:

Revision:

As built

Supplier

Manufacturer

Purchase Order No.

Date

Inquiry no.

Requisition No.

Components:

Piping and tubing:

Tight shutoff

Tubing fittingsmfg.

Carbon steel slip-on flanges

__________

Heat tracing required by

model

_______

purchaser

Through studs required

vendor

Continuous flow transfer valves

Service application

Gas

Common for coolers and filters

Strainer reg'd (2.4.3)

With lifting jack

Tight shutoff required

Rating: psig

Type

Materials: body

Manufacturer

Plug or ball

Model

Trim

Filters:

Service application:

Separation gas

Purchaser item no.

Design/test (psig)

Twin

Code construction/stamp (2.1.9)

Include option nos.

Material: case and top

Filtration level

Cartridges:

Manufacturer

Filter body diameter (in)

Model

Testing:

Functional test (4.3.3.4)

319678971.xlsx, 4-25

Page 2 of 10, Date Printed: 05/30/2016

API 614Chapter 4 DATA SHEET

DRY GAS SEAL MODULE

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

Furnish _______ extra sets of cartridges.

Coolers:

Service application

Item No.:

Page: 3 of 4

By:

Date:

Revision:

As built

Supplier

Purchase Order No.

Job No.:

Manufacturer

Date

Inquiry no.

Requisition No.

Per filter (extra over other spares).

Lube

Design/test shell side (psig)

Design/test tube side (psig)

Purchaser item nos.

Code construction/stamp (2.1.9)

Twin units

Tube water velocity and capacity (fps/gpm)

Include option nos.

Material: shell

Water side for steam heating

Channels and covers

Details on data sheet

Tube sheets and tubes

Water side corrosion allowance

Removable tube bundle

Manufacturer

U-bend tubes permitted

Model

Oil temperature control valve

TEMA class

Fouling factor water/oil side

Duty: Btu/hr

Tube: L/OD/BWG

319678971.xlsx, 4-26

Page 3 of 10, Date Printed: 05/30/2016

API 614Chapter 4 DATA SHEET

DRY GAS SEAL MODULE

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

Supplier

Purchase Order No.

Shop inspection

Job No.:

Item No.:

Page: 4 of 4

By:

Date:

Revision:

As built

Manufacturer

Date

Inquiry no.

Requisition No.

Shop test

Compliance with inspectors checklist

Required

Required for system assemblies

Cleanliness

Cleanliness prior to closure

Four hour run

Required for major components

Check controls

Material certifications to be furnished

Changeover filters/coolers

Special examinations

One and two pump operation

Code construction/stamp

Sound level

Certified copies of all test logs and data

Hydro test assembled system

Witness

Use for complete unit system test

Certified copies of all test logs and data

319678971.xlsx, 4-27

Page 4 of 10, Date Printed: 05/30/2016

API 614Chapter 4 DATA SHEET

DRY GAS SEAL

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

Job No.:

Seals for Item No.:

Page: 1 of 1

By:

Date:

Revision:

By:

As built

Gas seal supplier

Equipment manufacturer

Purchase Order No.

Date

Inquiry no.

Requisition No.

Dry gas seal design:

Rotational speed _____________

Application

max. rpm

new

Rotation viewed from driver end

Maximum sealing pressure:

Settle out pressure

Vent pressurenormal/max

retrofit

__________

_________________

Vendor drawing no.

CW

CCW

_________

Equipment suction pressure (min/max)

psig (2.1.6)

Equipment discharge temperature

psig

Process relief valve setting

psig

normal operation

______ / ______ psia

____________

___________

Seal maximum design pressure:

Leakage rates:

/ ______

____________

_________

psig

psig

static

Primary vent

Secondary vent

Secondary vent for intermediate laby.

__________________

__________________

Comments:

319678971.xlsx, 4-28

Page 5 of 10, Date Printed: 05/30/2016

Potrebbero piacerti anche

- Combustion Gas Turbine (Api 616-4Th) Data Sheet S I Units: Applicable ToDocumento10 pagineCombustion Gas Turbine (Api 616-4Th) Data Sheet S I Units: Applicable Totutuionut100% (1)

- CarbCalc 5eDocumento13 pagineCarbCalc 5eRizki HastutiNessuna valutazione finora

- Toyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpDocumento4 pagineToyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpNicolas Celis Perez100% (1)

- Sa 278Documento5 pagineSa 278AnilNessuna valutazione finora

- Singer Valve - Made in CanadaDocumento250 pagineSinger Valve - Made in Canadaprobetaspro132Nessuna valutazione finora

- Api 619 SiDocumento9 pagineApi 619 SitutuionutNessuna valutazione finora

- Api 673 SiDocumento11 pagineApi 673 Situtuionut100% (1)

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Documento9 pagineCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)tutuionutNessuna valutazione finora

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Documento17 pagineReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNessuna valutazione finora

- Boiler Operator Training PP PresentationDocumento44 pagineBoiler Operator Training PP PresentationANIL YADAVNessuna valutazione finora

- Spirometers Types and PrinciplesDocumento20 pagineSpirometers Types and PrinciplesGrupo APMNessuna valutazione finora

- Api 520 Api 610 Api 611Documento1 paginaApi 520 Api 610 Api 611santoshblonkarNessuna valutazione finora

- Reciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsDocumento10 pagineReciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsÆmanuel J Silva100% (1)

- SLM Avp ManualDocumento48 pagineSLM Avp Manualkeyur1109Nessuna valutazione finora

- Electrical Generators Rev3.1Documento115 pagineElectrical Generators Rev3.1genergiaNessuna valutazione finora

- Dry Screw Compressor CAGI Data Re2Documento15 pagineDry Screw Compressor CAGI Data Re2alaine1114Nessuna valutazione finora

- Valvula Mariposa Danais 150Documento15 pagineValvula Mariposa Danais 150Oscar CherroNessuna valutazione finora

- Comco Pipe Supply Company Green BookDocumento28 pagineComco Pipe Supply Company Green BookinfoNessuna valutazione finora

- Thomasssen Comp SelectionDocumento2 pagineThomasssen Comp Selectionmahesh_eilNessuna valutazione finora

- Turboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP CompDocumento6 pagineTurboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP ComptutuionutNessuna valutazione finora

- STORAGE AND HANDLING OF ANHYDROUS AMMONIA Part 78Documento10 pagineSTORAGE AND HANDLING OF ANHYDROUS AMMONIA Part 78mah_abdelaalNessuna valutazione finora

- CSI Jacketed Piping Catalog PDFDocumento24 pagineCSI Jacketed Piping Catalog PDFLeDzungNessuna valutazione finora

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsDocumento3 pagineSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- LP FlashDocumento6 pagineLP FlashMario Avalos Salazar100% (1)

- Astm F436.04 PDFDocumento6 pagineAstm F436.04 PDFWelington Volpatto MoraisNessuna valutazione finora

- Texas Flange - Product Catalog PDFDocumento47 pagineTexas Flange - Product Catalog PDFFranco Saenz SolisNessuna valutazione finora

- Welding Neck Flanges 1Documento3 pagineWelding Neck Flanges 1bikkelbobNessuna valutazione finora

- John Crane Dash BoardDocumento44 pagineJohn Crane Dash BoardYogaditya ModukuriNessuna valutazione finora

- FOAMGLAS Cellular Glass InsulationDocumento18 pagineFOAMGLAS Cellular Glass InsulationermizeNessuna valutazione finora

- Blank Thickness CalculatorDocumento5 pagineBlank Thickness CalculatorKelvin ThengNessuna valutazione finora

- ReciprocatingCompressorPower-US Field UnitsDocumento2 pagineReciprocatingCompressorPower-US Field UnitshihihiNessuna valutazione finora

- Asme B16.48Documento50 pagineAsme B16.48Ruben Dario DeaquizNessuna valutazione finora

- C18H0 UFAA78 ProposalDocumento9 pagineC18H0 UFAA78 Proposaledward baskaraNessuna valutazione finora

- Intergard 345 - DatasheetDocumento4 pagineIntergard 345 - DatasheetmanuthomasNessuna valutazione finora

- Datasheet DMV 347 HFGDocumento4 pagineDatasheet DMV 347 HFGClaudia MmsNessuna valutazione finora

- Side Mounted HandwheelDocumento20 pagineSide Mounted HandwheelaaaNessuna valutazione finora

- Centrifugal Compressor Power-US Field UnitsDocumento4 pagineCentrifugal Compressor Power-US Field UnitssurawutwijarnNessuna valutazione finora

- ASTM F 1718 - 99Documento7 pagineASTM F 1718 - 99Oh No PotatoNessuna valutazione finora

- Samson Valve Specification: Process DataDocumento49 pagineSamson Valve Specification: Process DataMuhammed TamerNessuna valutazione finora

- Ejemplo Tubesheet Asme UHXDocumento14 pagineEjemplo Tubesheet Asme UHXPedro Montes MarinNessuna valutazione finora

- Aço Sa 537 cl1Documento23 pagineAço Sa 537 cl1pcorreia68100% (1)

- Reactor DesignDocumento14 pagineReactor DesignAqib LatifNessuna valutazione finora

- ASHRAE Terminology - Complete ListDocumento298 pagineASHRAE Terminology - Complete Listwado11Nessuna valutazione finora

- Ansi b36.10 Seamless Pipe SizesDocumento2 pagineAnsi b36.10 Seamless Pipe SizesmohitNessuna valutazione finora

- Design of A High-Efficiency Hydrofoil Through The Use of Computational Fluid Dynamics and Multiobjective OptimizationDocumento13 pagineDesign of A High-Efficiency Hydrofoil Through The Use of Computational Fluid Dynamics and Multiobjective OptimizationKarlaHolzmeisterNessuna valutazione finora

- Asme - HeaderDocumento3 pagineAsme - HeaderReadersmoNessuna valutazione finora

- Bulk Air Eliminator R1Documento1 paginaBulk Air Eliminator R1hydrothermsNessuna valutazione finora

- Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocumento4 pagineChapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallReza SaeeNessuna valutazione finora

- Cálculo de Flare Api 560Documento9 pagineCálculo de Flare Api 560Lerida SalazarNessuna valutazione finora

- M&Y Gasket FactorsDocumento3 pagineM&Y Gasket FactorsGanesh.MahendraNessuna valutazione finora

- AMS - SLB-410-13 Cr-Stainless Steel-80 KSI Min Yield Strength, Unified SpecDocumento7 pagineAMS - SLB-410-13 Cr-Stainless Steel-80 KSI Min Yield Strength, Unified Speckrishna chiruNessuna valutazione finora

- Bolt Stress RevBDocumento50 pagineBolt Stress RevBMichael Walters100% (1)

- API 614-Chapter 2 DATA SHEET Special Purpose Oil System Si UnitsDocumento7 pagineAPI 614-Chapter 2 DATA SHEET Special Purpose Oil System Si UnitstutuionutNessuna valutazione finora

- 2009 02 M HD 319 0Documento5 pagine2009 02 M HD 319 0ZoebairNessuna valutazione finora

- API 614-Chapter 3 DATA SHEET General Purpose Oil System Si UnitsDocumento8 pagineAPI 614-Chapter 3 DATA SHEET General Purpose Oil System Si UnitstutuionutNessuna valutazione finora

- API 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentsDocumento3 pagineAPI 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentstutuionutNessuna valutazione finora

- Safety Relief Valve DatasheetDocumento1 paginaSafety Relief Valve Datasheetalmandhari330% (1)

- HD - Planta de PVCDocumento7 pagineHD - Planta de PVCDavid LapacaNessuna valutazione finora

- Specifications: To Plant Design and Economics For Chemical EngineersDocumento3 pagineSpecifications: To Plant Design and Economics For Chemical EngineersDharam RajgorNessuna valutazione finora

- Calculation For Reinforced PadDocumento4 pagineCalculation For Reinforced Padjsridhar_34750% (2)

- Native Data Sheet Asme b73.1Documento4 pagineNative Data Sheet Asme b73.1Akhmad Faruq Alhikami100% (1)

- Technical Comparison Format - Process Gas Reciprocating CompressorDocumento11 pagineTechnical Comparison Format - Process Gas Reciprocating CompressorAlvin Smith100% (1)

- Typical Flare PackageDocumento5 pagineTypical Flare PackageRahmat RiskiNessuna valutazione finora

- Specification For LP Gas Reciprocating Compressor PackageDocumento25 pagineSpecification For LP Gas Reciprocating Compressor Packageashok100% (1)

- HRD Hot Water Pump P001Documento6 pagineHRD Hot Water Pump P001nguyenquoc1988Nessuna valutazione finora

- EGE13B11Documento18 pagineEGE13B11Jhonny Rafael Blanco CauraNessuna valutazione finora

- Ip Pressure Transmitter Data SheetDocumento2 pagineIp Pressure Transmitter Data Sheetneurolepsia3790Nessuna valutazione finora

- New Steel Plate LNGDocumento7 pagineNew Steel Plate LNGtutuionutNessuna valutazione finora

- Technical Insulation - Cryolene PDFDocumento8 pagineTechnical Insulation - Cryolene PDFtutuionutNessuna valutazione finora

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocumento1 paginaRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutNessuna valutazione finora

- Speed Sensor Data Sheet: Customer Profile Speed SensorsDocumento2 pagineSpeed Sensor Data Sheet: Customer Profile Speed SensorstutuionutNessuna valutazione finora

- AZOBEDocumento4 pagineAZOBEtutuionutNessuna valutazione finora

- Turboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP CompDocumento6 pagineTurboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP ComptutuionutNessuna valutazione finora

- Reciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitsDocumento17 pagineReciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitstutuionutNessuna valutazione finora

- API 614-Chapter 3 DATA SHEET General Purpose Oil System Si UnitsDocumento8 pagineAPI 614-Chapter 3 DATA SHEET General Purpose Oil System Si UnitstutuionutNessuna valutazione finora

- Storage Tank Normal Venting Capacity CalculationsDocumento1 paginaStorage Tank Normal Venting Capacity CalculationstutuionutNessuna valutazione finora

- Special Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitsDocumento4 pagineSpecial Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitstutuionutNessuna valutazione finora

- API 614-Chapter 2 DATA SHEET Special Purpose Oil System Si UnitsDocumento7 pagineAPI 614-Chapter 2 DATA SHEET Special Purpose Oil System Si UnitstutuionutNessuna valutazione finora

- API 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentsDocumento3 pagineAPI 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentstutuionutNessuna valutazione finora

- Required System Performance - Purchaser: Elevated Flare Data Sheet No. 1 SI UnitsDocumento20 pagineRequired System Performance - Purchaser: Elevated Flare Data Sheet No. 1 SI UnitstutuionutNessuna valutazione finora

- Bfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingDocumento25 pagineBfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingtutuionutNessuna valutazione finora

- Tank 305Documento74 pagineTank 305tutuionutNessuna valutazione finora

- FDV Iom Carrier 30xwDocumento34 pagineFDV Iom Carrier 30xwnaeem shakirNessuna valutazione finora

- Open and Closed Air Refrigeration CyclesDocumento4 pagineOpen and Closed Air Refrigeration CyclesrajsharmarajNessuna valutazione finora

- Engineering Bernoulli Equation PDFDocumento19 pagineEngineering Bernoulli Equation PDFkhairul hisyamNessuna valutazione finora

- C C C CDocumento10 pagineC C C CMaarij RaheemNessuna valutazione finora

- Chapter 4 Frictional Losses in Hydraulic PipelinesDocumento56 pagineChapter 4 Frictional Losses in Hydraulic PipelinesTu Dang TrongNessuna valutazione finora

- FOAM TANK (1/2) : Fire Fighting Equipment Data SheetDocumento24 pagineFOAM TANK (1/2) : Fire Fighting Equipment Data SheetandinumailNessuna valutazione finora

- Introduction Flow MeterDocumento4 pagineIntroduction Flow MeterohdausNessuna valutazione finora

- Laboratory Measurement For PermeabilityDocumento17 pagineLaboratory Measurement For PermeabilityYudis TiraNessuna valutazione finora

- Utility List Gas Turbine GeneratorDocumento3 pagineUtility List Gas Turbine GeneratorBudi NurramadhanNessuna valutazione finora

- CH 23-Pyrophoric Iron SulphideDocumento3 pagineCH 23-Pyrophoric Iron SulphideAntonio AntonioNessuna valutazione finora

- D10 10Documento1 paginaD10 10mohamedNessuna valutazione finora

- Power Requirement (Agitator and High-Torque Stirrer)Documento8 paginePower Requirement (Agitator and High-Torque Stirrer)DozdiNessuna valutazione finora

- 49 CFR Part 180 Subpart C (Up To Date As of 8-04-2022)Documento25 pagine49 CFR Part 180 Subpart C (Up To Date As of 8-04-2022)Cristhian342Nessuna valutazione finora

- Regulation Pompe Hydraulique Linde BPRDocumento7 pagineRegulation Pompe Hydraulique Linde BPRusama zedanNessuna valutazione finora

- PSVDocumento8 paginePSVtetiospamNessuna valutazione finora

- Testcycle 1 For Nozzle 1 PDFDocumento28 pagineTestcycle 1 For Nozzle 1 PDFAnonymous bJZz94Nessuna valutazione finora

- Exercises of ch3 (w4) - AnswerDocumento6 pagineExercises of ch3 (w4) - AnswerNguyễn Nam AnhNessuna valutazione finora

- Worksheet 3.3Documento2 pagineWorksheet 3.3khodijahaminNessuna valutazione finora

- Mramco Sample CylinderDocumento1 paginaMramco Sample Cylinderi.q.francisco.danielmoraNessuna valutazione finora

- Coil Wound Heat Exchangers - tcm19 407186 PDFDocumento16 pagineCoil Wound Heat Exchangers - tcm19 407186 PDFpsnmurthy333Nessuna valutazione finora

- Engine Fuel SystemDocumento14 pagineEngine Fuel Systemusmankhanakbar100% (2)

- Quote Number:: Pressure Relief Valve Sizing & Selection ReportDocumento1 paginaQuote Number:: Pressure Relief Valve Sizing & Selection ReportJavier DelgadoNessuna valutazione finora

- Development of A Multi-Stage Choke Valve SizingDocumento221 pagineDevelopment of A Multi-Stage Choke Valve SizingsekharsamyNessuna valutazione finora

- Current Status of Hydrogen Liquefaction CostsDocumento10 pagineCurrent Status of Hydrogen Liquefaction CostsDilla WahabNessuna valutazione finora

- P&id NGSS PDFDocumento7 pagineP&id NGSS PDFHBNBILNessuna valutazione finora

- Rerynolds NumberDocumento8 pagineRerynolds NumberMonglen Z. CasiñoNessuna valutazione finora

- Numerical Analysis of A Hypersonic Turbulent and LDocumento13 pagineNumerical Analysis of A Hypersonic Turbulent and LDANUSH DATTHATHIREYAN KNessuna valutazione finora

- Low Pressure Effusion of GasesDocumento10 pagineLow Pressure Effusion of Gasesglen-576661Nessuna valutazione finora