Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MM2100 Case Study 11feb2016

Caricato da

kushar_geoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MM2100 Case Study 11feb2016

Caricato da

kushar_geoCopyright:

Formati disponibili

ORGANICA

MM2100 WWTP

Bekasi Fajar, INDONESIA

Detailed Case Study

Project Background

MM 2100 is one of the leading industrial park

in Indonesia

Located at Bekasi, West Java, Indonesia

Founded in 1989 spread over a total Area

1,350 hectares

Tenants comprising 320 companies with a total

of 135,000 employees

Existing centralized WWTP capacity of 27 MLD

operating at 20 MLD capacity

Unhappy tenants in the neighborhood of the

WWTP as the existing facility is emitting bad

odor

2016 Organica Water

Project Background

Project

Municipal WWTP; design, build

Population Served

200 000 equivalent

Project Type

Greenfield

Contract Award

March 2013

Hydraulic capacity

45 000 m3/day

Design Completion

October 2013

Construction Begins

January 2014

Expected Commissioning

September 2015

2016 Organica Water

Design Parameters

Parameter

Influent Average (mg/L)

Effluent/Limit (mg/L)

COD

1000

50

BOD

500

25

NH3-N

TKN

47

NO2-N

NO3-N

20

TSS

220

50

Water temperature

Min. 23oC

Max. 31oC

2016 Organica Water

Original Situation

2016 Organica Water

One of the leading industrial parks in

the country with high-profile multinational tenant/resident companies

Need for expanding WWTP capacity

to 45 MLD which required additional

land

Existing, traditional 27 MLD Activated

Sludge WWTP occupying prime real

estate in the industrial park (1.6

hectare site)

Existing WWTP - large, unsightly, and

emits bad

odors thus any

neighboring

tenants

negatively

impacted.

Huge buffer zone (which is not

available) required around WWTP

due to odors and negative aesthetics

5

Demand Drivers

Increase WWTP capacity

Remove need for buffer zone by

containing odors and improving

aesthetics

Small footprint to minimize land

requirement

Lower energy consumption (by

approximately 30%) for reducing

operating costs (client responsible for

operating plant)

Lower sludge generation (by

approximately 30%) to avoid disposal

issues

2016 Organica Water

Demand Drivers

WWTP Options

Capacity Land Occupied/

(MLD)

Required

(in Hectares)

Existing Plant

(Conventional

Approach)

27

Ultimate Capacity

Required

(Conventional)

45

Organica Solution

(under construction)

45

Additional Benefits

No need for buffer zone due to

odorless

and

aesthically

appealing installation

Lower energy consumption

resulting in significantly lower

operational costs, higher profit

by maintaining the same tariff

Client

recovers

complete

investment in Organica facility

by selling land occupied by

existing plant

2.0

4.0 4.5 *

1.5 **

* Land Available for additional capacity Only 2.0 Hectares

** Land Savings obtained by client by choosing Organica 2.5 hectares

2016 Organica Water

Organica Solution

2016 Organica Water

67% higher capacity in 30% lower

footprint than existing WWTP = 138%

improvement in capacity/area (twice the

capacity in less space - 1.2 hectares)

No need for buffer zone due to odorless

and aesthically appealing installation

Lower energy consumption and sludge

generation resulting in significantly lower

operational costs and site issues

New plant to be built on a small piece of

land already available resulting in:

No disruption in

wastewater

treatment

Land utilized by existing plant made

available for sale/lease (offsets costs

of new plant)

Existing M2100 WWTP 27 MLD

Future Site of Organica FCR

Existing CAS WWTP

2016 Organica Water

Paradigm Shift

The Paradigm Shift

2016 Organica Water

10

Series Of Food Chain Reactor Zones

The biological process takes place in a series of cascade reactors, with standard pretreatment at the beginning,

and phase separation (via Organica Disc Filters or Secondary Clarifiers) and final polishing at the end.

As water flows through from one reactor zone to the next, different ecologies will grow and adapt to the

conditions in each stage. This configuration allows the food chain effect to develop, as higher level organisms

become predators for the simpler organisms.

The result is enhanced removal efficiency and resiliency, while utilizing less energy and producing less sludge.

2016 Organica Water

11

11

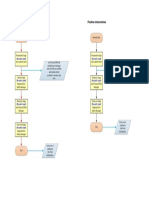

Process Scheme MM2100 Design

INFLUENT

Chemical

Pretreatment

Screen

3 mm

Areated Grit

Chamber

Organica

FCR

Coagulation

Flocculation

Organica

FCR

Coagulation

Flocculation

Disc Filter

Organica

FCR

Coagulation

Flocculation

Sludge

Storage

Ultra Violet

Disinfection

EFFLUENT

Container

Container

Transport

Mechanical

Sludge

Thickening

Sludge

Storage

Dewatering

Container

Transport

2016 Organica Water

13

Architectural Design Site Plan 45 MLD in 1.2 ha

2016 Organica Water

14

Architectural Design Section Views

2016 Organica Water

15

Construction site nearing completion

2016 Organica Water

16

Organica Discfilters Installed

2016 Organica Water

17

Shading Structures in Operation

2016 Organica Water

18

Front Stradale of the Facility

2016 Organica Water

19

Proposed Alternative Enclosure

2016 Organica Water

20

www.organicawater.com

info@organicawater.com

+ 36 1 455 8060

Potrebbero piacerti anche

- The X Factor 11Documento31 pagineThe X Factor 11writerguy78Nessuna valutazione finora

- Road ConstructionDocumento5 pagineRoad ConstructionmetincetinNessuna valutazione finora

- Physical Assessment For Stroke PatientDocumento4 paginePhysical Assessment For Stroke Patientdana75% (4)

- Saint Gobain PAM Cast Iron Drainage SystemsDocumento120 pagineSaint Gobain PAM Cast Iron Drainage SystemsParveez HusnooNessuna valutazione finora

- CMQ 5Documento1 paginaCMQ 5kalslingamNessuna valutazione finora

- Water Sanitation:: Contemporary Issues and SolutionsDocumento69 pagineWater Sanitation:: Contemporary Issues and SolutionswatercenterNessuna valutazione finora

- CMQ Practise TestDocumento1 paginaCMQ Practise TestkalslingamNessuna valutazione finora

- CMQ 4Documento1 paginaCMQ 4kalslingamNessuna valutazione finora

- C08-006 - UV Disinfection Options For Wastewater Treatment Plants - US PDFDocumento123 pagineC08-006 - UV Disinfection Options For Wastewater Treatment Plants - US PDFAbdelilah KadriNessuna valutazione finora

- Saep 287Documento13 pagineSaep 287OMER ELFADILNessuna valutazione finora

- Mental and Emotional Health PowerpointDocumento36 pagineMental and Emotional Health PowerpointYen Aduana86% (7)

- Biosolids MGMT Plan by Stantec Band CDocumento232 pagineBiosolids MGMT Plan by Stantec Band CAdrian FrantescuNessuna valutazione finora

- DY-1-20 Scrap Tires Recycling Pyrolysis Oil Plant of Doing GroupDocumento3 pagineDY-1-20 Scrap Tires Recycling Pyrolysis Oil Plant of Doing GrouppyrolysisoilNessuna valutazione finora

- Psychoanalisis and PaediatricsDocumento264 paginePsychoanalisis and PaediatricsBlackKNessuna valutazione finora

- Production and Implementation of Asphalt Mixtures Designed With Superpave SystemDocumento40 pagineProduction and Implementation of Asphalt Mixtures Designed With Superpave SystemAymanAlodainiNessuna valutazione finora

- Peza CheklistDocumento24 paginePeza CheklistAce Christian OcampoNessuna valutazione finora

- Drinking Water Well ConstDocumento7 pagineDrinking Water Well ConstBhuiyan RazonNessuna valutazione finora

- CMQ 3Documento2 pagineCMQ 3kalslingamNessuna valutazione finora

- WadiDocumento149 pagineWadi류태하Nessuna valutazione finora

- MGT 338 Employability & Entrepreneurship: 1.0 Executive SummaryDocumento21 pagineMGT 338 Employability & Entrepreneurship: 1.0 Executive Summaryeggie dan100% (1)

- Water Waste Water Engineering 9Documento93 pagineWater Waste Water Engineering 9ofreneo_joshua4437Nessuna valutazione finora

- Sydney Water Meter InstallationDocumento31 pagineSydney Water Meter InstallationAnnahuynhNessuna valutazione finora

- Ri LSADocumento88 pagineRi LSAAziz Rahman100% (1)

- Chap 16 Project FinanceDocumento104 pagineChap 16 Project Financekushar_geoNessuna valutazione finora

- Rice Husk Ash As A Partial Replacement of Cement in High Strength Concrete Containing Micro SilicaDocumento19 pagineRice Husk Ash As A Partial Replacement of Cement in High Strength Concrete Containing Micro SilicaLoraene Dela TorreNessuna valutazione finora

- Aldridge A Short Introduction To CounsellingDocumento22 pagineAldridge A Short Introduction To Counsellingbyron chieNessuna valutazione finora

- RubberDocumento36 pagineRubbermohanad ghanimNessuna valutazione finora

- Design Code and Specification Request Sheet DDPDocumento22 pagineDesign Code and Specification Request Sheet DDPShijo AntonyNessuna valutazione finora

- Design Report DraftDocumento11 pagineDesign Report DraftCastiel161Nessuna valutazione finora

- Packaged Plant Prefab Tank SPAN 1401 A1 Publication 2013 (Part2)Documento25 paginePackaged Plant Prefab Tank SPAN 1401 A1 Publication 2013 (Part2)gkjimNessuna valutazione finora

- Hydrogel Porous Membrane PoretexDocumento9 pagineHydrogel Porous Membrane PoretexAlek Lemkov100% (1)

- Method Statement of Potable Water and Firefighting Network ConstructionDocumento51 pagineMethod Statement of Potable Water and Firefighting Network Constructionmohdshahul543Nessuna valutazione finora

- CMQ 2Documento1 paginaCMQ 2kalslingamNessuna valutazione finora

- SeweageDocumento40 pagineSeweagemasahin100% (1)

- 360-Degree Waste Management, Volume 2: Biomedical, Pharmaceutical, Industrial Waste, and RemediationDa Everand360-Degree Waste Management, Volume 2: Biomedical, Pharmaceutical, Industrial Waste, and RemediationNishikant A. RautNessuna valutazione finora

- Organica FCR BrochureDocumento2 pagineOrganica FCR BrochureAhmed AsemNessuna valutazione finora

- Clean Ganga ProjectDocumento15 pagineClean Ganga ProjectRahul Ravi Singh100% (1)

- Food Chain ReactorDocumento3 pagineFood Chain ReactorkgmcvNessuna valutazione finora

- Bec Biodigester LatestDocumento42 pagineBec Biodigester LatestRahul Ravi SinghNessuna valutazione finora

- FoodWatch - Registration GuideDocumento10 pagineFoodWatch - Registration GuideAnonymous BZR3ZjP1Nessuna valutazione finora

- uPVC Tubewell Casing Screen Pipe SystemsDocumento6 pagineuPVC Tubewell Casing Screen Pipe Systemssaadpervaiz14Nessuna valutazione finora

- Turbodrain EnglDocumento8 pagineTurbodrain EnglIonut BuzescuNessuna valutazione finora

- Commissioning Strategy For The Anaerobic Sludge Digesters PDFDocumento8 pagineCommissioning Strategy For The Anaerobic Sludge Digesters PDFOktay Duygu AcaroğluNessuna valutazione finora

- Waterproofing: Waterstops For Expansion and Construction JointsDocumento27 pagineWaterproofing: Waterstops For Expansion and Construction JointsgarusingheNessuna valutazione finora

- Pre Cast WowDocumento12 paginePre Cast WowRod ManNessuna valutazione finora

- Compressor: Reciprocating Compressors (Edit) Main Article: Reciprocating CompressorDocumento17 pagineCompressor: Reciprocating Compressors (Edit) Main Article: Reciprocating Compressorraymart caluag0% (1)

- Free Download: Aci 309r 05Documento3 pagineFree Download: Aci 309r 05Shokhieb Showbad CarriebNessuna valutazione finora

- Dry Shake Color HardenerDocumento7 pagineDry Shake Color Hardenermyke_0101Nessuna valutazione finora

- KOSUN Decanter Centrifuge Process in DrillingDocumento2 pagineKOSUN Decanter Centrifuge Process in DrillingzmzmllllNessuna valutazione finora

- Foam Core PVC PipeDocumento9 pagineFoam Core PVC Pipe7140220Nessuna valutazione finora

- Appreciation LetterDocumento2 pagineAppreciation LetterGuru Prasad SinghNessuna valutazione finora

- Sri Balaji Pharma Limited Quality PolicyDocumento1 paginaSri Balaji Pharma Limited Quality PolicyChilaNessuna valutazione finora

- Project: Fiji Flood Recovery Project Site Location:Lomaloma Slip (9.5 KM From Natuasavu Junction) Type of FailureDocumento17 pagineProject: Fiji Flood Recovery Project Site Location:Lomaloma Slip (9.5 KM From Natuasavu Junction) Type of FailureRaghav chandraseskaranNessuna valutazione finora

- NCR RepairDocumento4 pagineNCR RepairPanruti S SathiyavendhanNessuna valutazione finora

- Pag-IBIG Housing Loan CalculatorDocumento2 paginePag-IBIG Housing Loan CalculatorkiraNessuna valutazione finora

- AQ Standards Report Draft 2 Dec FINALDocumento149 pagineAQ Standards Report Draft 2 Dec FINALbudhbudhNessuna valutazione finora

- Final DPR For Tallah TankDocumento75 pagineFinal DPR For Tallah TankSandeepan ChowdhuryNessuna valutazione finora

- Simba B en Inctrl Ver4Documento2 pagineSimba B en Inctrl Ver4Joao MinhoNessuna valutazione finora

- Materials Recovery FacilityDocumento3 pagineMaterials Recovery FacilityMoshe RubinNessuna valutazione finora

- Solutions For Underground ConstructionDocumento20 pagineSolutions For Underground ConstructionMarcos BarbozaNessuna valutazione finora

- NMMC Sewerage DPR PDFDocumento80 pagineNMMC Sewerage DPR PDFSmitesh AhireNessuna valutazione finora

- Pump ManualDocumento68 paginePump Manualsaid19712011Nessuna valutazione finora

- Tank Bottom Scraper Zickert - enDocumento22 pagineTank Bottom Scraper Zickert - enzxc007Nessuna valutazione finora

- Environmental Impact Assessment 2013 PDFDocumento119 pagineEnvironmental Impact Assessment 2013 PDFMit ShethNessuna valutazione finora

- Catchment ManagementDocumento4 pagineCatchment ManagementSachitha RajanNessuna valutazione finora

- Design—Operation Interactions at Large Treatment Plants: Proceedings of a Workshop Held in ViennaDa EverandDesign—Operation Interactions at Large Treatment Plants: Proceedings of a Workshop Held in ViennaS. H. JenkinsNessuna valutazione finora

- Material Handling Equipment World Summary: Market Values & Financials by CountryDa EverandMaterial Handling Equipment World Summary: Market Values & Financials by CountryNessuna valutazione finora

- Brickwork RetainingDocumento32 pagineBrickwork Retainingkushar_geoNessuna valutazione finora

- t02 Austroads LoadingsDocumento11 paginet02 Austroads Loadingskushar_geoNessuna valutazione finora

- Incident Reporting DiagramDocumento1 paginaIncident Reporting Diagramkushar_geoNessuna valutazione finora

- Member Assessment Guidance ICEDocumento17 pagineMember Assessment Guidance ICEkushar_geoNessuna valutazione finora

- Zincanode 304 pc142Documento3 pagineZincanode 304 pc142kushar_geoNessuna valutazione finora

- Circle of FifthDocumento3 pagineCircle of Fifthkushar_geoNessuna valutazione finora

- Note: This Is The Sample Document For The Related Job Only: Tank Erection ProcedureDocumento5 pagineNote: This Is The Sample Document For The Related Job Only: Tank Erection Procedurekushar_geoNessuna valutazione finora

- Keystone Wall PDFDocumento10 pagineKeystone Wall PDFkushar_geoNessuna valutazione finora

- Product CatalogDocumento16 pagineProduct Catalogkushar_geoNessuna valutazione finora

- Standard Visual Asses Unsealed Road Tmh12Documento77 pagineStandard Visual Asses Unsealed Road Tmh12kushar_geoNessuna valutazione finora

- Standard Visual Asses Unsealed Road Tmh12Documento77 pagineStandard Visual Asses Unsealed Road Tmh12kushar_geoNessuna valutazione finora

- TT Marl Soil Stab Report 10 11cDocumento1 paginaTT Marl Soil Stab Report 10 11ckushar_geoNessuna valutazione finora

- BCG - The Future of Jobs in The Era of AI - 2021 - NeiDocumento40 pagineBCG - The Future of Jobs in The Era of AI - 2021 - NeiHevertom FischerNessuna valutazione finora

- Thesis On Food Security PDFDocumento8 pagineThesis On Food Security PDFbsrf4d9d100% (2)

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDocumento8 pagineUniversity of Cambridge International Examinations General Certificate of Education Ordinary LevelKelvin SerimweNessuna valutazione finora

- Biology Notes CHPTR 14Documento7 pagineBiology Notes CHPTR 14Wan HasliraNessuna valutazione finora

- PI e UREA 15Documento2 paginePI e UREA 15dewi asnaniNessuna valutazione finora

- DNAlysis MygeneRx Sample ReportDocumento13 pagineDNAlysis MygeneRx Sample ReportTrustNessuna valutazione finora

- 1.causes For Neonatal Sepsis, Newborn Sepsis, Neonatal Infection, Sepsis TreatmentDocumento12 pagine1.causes For Neonatal Sepsis, Newborn Sepsis, Neonatal Infection, Sepsis TreatmentlardiyahNessuna valutazione finora

- Safeminds Flu Vaccination 0809Documento2 pagineSafeminds Flu Vaccination 0809XR500FinalNessuna valutazione finora

- N Vent Code ENDocumento28 pagineN Vent Code ENGwenn LecturaNessuna valutazione finora

- Mia Deal or No Deal 2.3.7.A1Documento2 pagineMia Deal or No Deal 2.3.7.A1bxnds. zay0% (1)

- P.E & Health G11-Q1-M7Documento13 pagineP.E & Health G11-Q1-M7John Gerald CantancioNessuna valutazione finora

- The Bold and The Beautiful. Influence of Body Size of Televised Media Models On Body Dissatisfaction and Actual Food IntakeDocumento8 pagineThe Bold and The Beautiful. Influence of Body Size of Televised Media Models On Body Dissatisfaction and Actual Food IntakeKATALINA IGNACIA AZÓCARNessuna valutazione finora

- New Trends in Mechanical VentilationDocumento4 pagineNew Trends in Mechanical Ventilationashley_castro_4Nessuna valutazione finora

- WHO Guidelines Hand Hygiene in Health CareDocumento270 pagineWHO Guidelines Hand Hygiene in Health CareÐr Salma100% (1)

- Mastoiditis - B.MDocumento25 pagineMastoiditis - B.MBwalya MunjiliNessuna valutazione finora

- EC Information Board-FormDocumento1 paginaEC Information Board-FormSARAH MAE MARAVILLANessuna valutazione finora

- Health Promotion and MaintenanceDocumento170 pagineHealth Promotion and Maintenancepopota100% (1)

- Hypnotherapy To Reduce Post-Stroke Muscle Tension in IndonesiaDocumento4 pagineHypnotherapy To Reduce Post-Stroke Muscle Tension in IndonesiaEndangAhmatNessuna valutazione finora

- Chemistry, Manufacturing and ControlDocumento11 pagineChemistry, Manufacturing and ControlHk HkNessuna valutazione finora

- Chest Drains Al-WPS OfficeDocumento16 pagineChest Drains Al-WPS OfficeisnainiviaNessuna valutazione finora

- Henry Schein Orthodontics Catalog - General SuppliesDocumento8 pagineHenry Schein Orthodontics Catalog - General SuppliesOrtho OrganizersNessuna valutazione finora

- Restobar FSDocumento58 pagineRestobar FSGabrielle Alonzo100% (1)

- Px. Abdomen RadiologiDocumento46 paginePx. Abdomen RadiologiwagigtnNessuna valutazione finora

- REPORTDocumento1 paginaREPORTFoamy Cloth BlueNessuna valutazione finora