Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Motor 60Z02152 - 04 (1) CAT3306

Caricato da

Ismael De Jesus AndradeTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Motor 60Z02152 - 04 (1) CAT3306

Caricato da

Ismael De Jesus AndradeCopyright:

Formati disponibili

966R WHEEL LOADER 58Z00001-UP (MACHINE) POWERED BY 3306 ENGINE(Z...

Page 1 of 4

Fechar o SIS

Tela anterior

produtos: ENGINE - MACHINE

Modelo: 3306 ENGINE - MACHINE 58Z

Configurao: 966R WHEEL LOADER 58Z00001-UP (MACHINE) POWERED

BY 3306 ENGINE

Desmontagem e Montagem

3306 VEHICULAR ENGINE FOR 966R WHEEL LOADER

Nmero de Mdia -SENR2410-00

Data de Publicao -01/08/1981

Data de Atualizao -11/10/2001

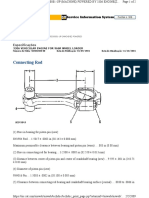

Crankshaft Main Bearings

SMCS - 1219-10

Remove And Install Crankshaft Main Bearings

start by:

a) remove oil pump

b) remove oil pan plate

1. Remove the No. 1, 3, 5 and 7 main bearing caps (1). Remove the crankshaft thrust bearing from the No. 7

main bearing.

2. Remove the lower half of the main bearing from the main bearing caps.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 29/1/2009

966R WHEEL LOADER 58Z00001-UP (MACHINE) POWERED BY 3306 ENGINE(Z...

Page 2 of 4

NOTICE

If the crankshaft is turned in the wrong direction, the tab on bearing

will be pushed between the crankshaft and bearing area in block which

can cause damage to the block or crankshaft.

3. Install tool (A) in the oil hole in the crankshaft journal and remove the upper half of the main bearing as

the crankshaft is turned and the main bearing is moved out of the cylinder block.

NOTE: Install the main bearings dry when the clearance checks are made. Put clean engine oil on the main

bearings for final assembly.

NOTICE

Make sure the upper and lower halves of the main bearings are

installed so the bearing tabs fit into the notch in cylinder block and the

main bearing caps.

4. Install new lower half of main bearings (2) in the main bearing caps. Use tool (A) and install the upper

half of the main bearings in the cylinder block.

5. Put clean oil on the thrust bearing and install a new thrust bearing for the No. 7 main bearing. Install the

thrust bearing with the identification "BLOCK SIDE" toward the cylinder block.

NOTE: When the bearing clearance is checked and the engine is in a vertical position, such as in the

vehicle, the crankshaft will have to be lifted up and held against the upper halves of the main bearings to get

a correct measurement with the Plastigage. The Plastigage will not hold the weight of the crankshaft and

give a correct indication. If the engine is in a horizontal position, it is not necessary to hold the crankshaft

up. Do not turn the crankshaft when the Plastigage is in position to check clearances.

6. Check the main bearing clearances with Plastigage (B) as follows:

a) Put a piece of Plastigage (B) on the surface of the lower half of the main bearing.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 29/1/2009

966R WHEEL LOADER 58Z00001-UP (MACHINE) POWERED BY 3306 ENGINE(Z...

Page 3 of 4

NOTICE

Make sure the part number on the main bearing cap is toward the

front of the engine and the number on the main bearing cap is the

same as the number on the cylinder block on the left side of each main

bearing cap.

NOTE: Do not turn the crankshaft when Plastigage (B) is in position.

b) Install main bearing caps (1) for No. 1, 3, 5 and 7 main bearings. Put clean engine oil on the bolt

threads and the face of the washers and install the bolts. Tighten the bolts to a torque of 30 3 lb. ft.

(40 4 Nm).

NOTICE

Do not use an impact wrench to tighten the bolts the additional 90.

c) Put a mark on each bolt and main bearing cap, then tighten the bolts 90 more.

d) Remove the main bearing caps for No. 1, 3, 5 and 7 main bearings. Remove Plastigage. The main

bearing clearance must be .0030 to .0065 in. (0.076 to 0.165 mm). Maximum permissible clearance

with used bearings is .010 in. (0.25 mm).

7. Install main bearing caps (1) and tighten the bolts as in Steps 6b and 6c.

8. Remove No. 2, 4 and 6 main bearing caps. Do Steps 2, 3, 4, 6 and 7 for the No. 2, 4 and 6 main bearings.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 29/1/2009

966R WHEEL LOADER 58Z00001-UP (MACHINE) POWERED BY 3306 ENGINE(Z...

Page 4 of 4

TYPICAL EXAMPLE

9. Check the crankshaft end play with tooling (C). The end play is controlled by the thrust bearings on the

No. 7 main bearing. End play with new bearings is .0025 to .0145 in. (0.064 to 0.368 mm). The maximum

permissible end play with used bearings is .025 in. (0.64 mm).

end by:

a) install oil pan plate

b) install oil pump

Direitos Autorais 1993 - 2009 Caterpillar Inc.

Todos os Direitos Reservados.

Rede Particular Para Licenciados SIS.

Thu Jan 29 16:13:22 UTC-0300 2009

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 29/1/2009

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- 12k Service ManualDocumento68 pagine12k Service ManualJ C Quality Woodstoves67% (3)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- CAT MOTOR 3306 PressDocumento39 pagineCAT MOTOR 3306 PressIsmael De Jesus Andrade100% (7)

- Motor 60Z02152 - 01 (1) CAT 3306 Engine DesignDocumento1 paginaMotor 60Z02152 - 01 (1) CAT 3306 Engine DesignIsmael De Jesus Andrade100% (1)

- Lazards Levelized Cost of Energy Analysis 9.0Documento20 pagineLazards Levelized Cost of Energy Analysis 9.0Matthew LevineNessuna valutazione finora

- Demag AC80-1Documento17 pagineDemag AC80-1Tuntun Tat100% (1)

- DownloadForMac SanDiskSecureAccessV3.0Documento1 paginaDownloadForMac SanDiskSecureAccessV3.0Gherca OvidiuNessuna valutazione finora

- SanDisk SecureAccessV3.0 QSG PDFDocumento25 pagineSanDisk SecureAccessV3.0 QSG PDFAnonymous SX8ODClMeNessuna valutazione finora

- Motor 60Z02152 - 10 (1) CAT 3306 Main & ConnectDocumento2 pagineMotor 60Z02152 - 10 (1) CAT 3306 Main & ConnectIsmael De Jesus AndradeNessuna valutazione finora

- User Multi6 Parts en-GB SCANIADocumento58 pagineUser Multi6 Parts en-GB SCANIAIsmael De Jesus Andrade100% (3)

- Motor 60Z02152 - 08 (1) CAT 3306 Liner ProjectionDocumento2 pagineMotor 60Z02152 - 08 (1) CAT 3306 Liner ProjectionIsmael De Jesus Andrade0% (1)

- Series 51 ServiceDocumento80 pagineSeries 51 ServiceIsmael De Jesus AndradeNessuna valutazione finora

- Plano de Teste Bomba Injetora 3642F800Documento3 paginePlano de Teste Bomba Injetora 3642F800Ismael De Jesus AndradeNessuna valutazione finora

- Motor 60Z02152 - 12 (1) CAT 3306 RodsDocumento2 pagineMotor 60Z02152 - 12 (1) CAT 3306 RodsIsmael De Jesus AndradeNessuna valutazione finora

- 3306 Engine Specs for 966R Wheel LoaderDocumento2 pagine3306 Engine Specs for 966R Wheel LoaderIsmael De Jesus Andrade100% (2)

- Motor 60Z02152 - 06 (1) CAT 3306Documento4 pagineMotor 60Z02152 - 06 (1) CAT 3306Ismael De Jesus AndradeNessuna valutazione finora

- Motor 60Z02152 - 07 (1) CAT 3306 LinersDocumento2 pagineMotor 60Z02152 - 07 (1) CAT 3306 LinersIsmael De Jesus AndradeNessuna valutazione finora

- Motor 60Z02152 - 05 (1) CAT 3306 Camshaft BearingsDocumento3 pagineMotor 60Z02152 - 05 (1) CAT 3306 Camshaft BearingsIsmael De Jesus AndradeNessuna valutazione finora

- Motor 60Z02152 - 03 (1) CAT3306 CrankshaftDocumento5 pagineMotor 60Z02152 - 03 (1) CAT3306 CrankshaftIsmael De Jesus AndradeNessuna valutazione finora

- Motor 60Z02152 - 03 (1) CAT3306 CrankshaftDocumento5 pagineMotor 60Z02152 - 03 (1) CAT3306 CrankshaftIsmael De Jesus AndradeNessuna valutazione finora

- Motor 60Z02152 - 02 (1) CAT 3306Documento4 pagineMotor 60Z02152 - 02 (1) CAT 3306Ismael De Jesus Andrade50% (2)

- Final Drive 3Documento8 pagineFinal Drive 3Ismael De Jesus AndradeNessuna valutazione finora

- Final Drive 2 (1) Cat d6Documento2 pagineFinal Drive 2 (1) Cat d6Ismael De Jesus Andrade67% (3)

- Adjustment For Final Drive BearingsDocumento3 pagineAdjustment For Final Drive BearingsIsmael De Jesus AndradeNessuna valutazione finora

- Acumuladores ParkerDocumento2 pagineAcumuladores ParkerIsmael De Jesus AndradeNessuna valutazione finora

- D6D Adjustment For Final Drive BearingsDocumento4 pagineD6D Adjustment For Final Drive BearingsIsmael De Jesus Andrade100% (1)

- Linelazer 3000: 308685K Instructions - Parts ListDocumento44 pagineLinelazer 3000: 308685K Instructions - Parts Listraj jangidNessuna valutazione finora

- LNG Technology OverviewDocumento52 pagineLNG Technology OverviewRama Moorthy100% (6)

- S12H-engine - PDF SPECSDocumento3 pagineS12H-engine - PDF SPECSMarcos Vinicio StizzioliNessuna valutazione finora

- Cummins C40 D6Documento4 pagineCummins C40 D6Carlos AngaritaNessuna valutazione finora

- Cep Sop KSKDocumento11 pagineCep Sop KSKSonratNessuna valutazione finora

- SWE600F发动机培训资料Documento215 pagineSWE600F发动机培训资料Feri AdvantureNessuna valutazione finora

- Engine TypesDocumento4 pagineEngine TypesRoss GrimmettNessuna valutazione finora

- Arklow RallyDocumento2 pagineArklow RallyDIEGONessuna valutazione finora

- MajorDocumento35 pagineMajorjgarciadocNessuna valutazione finora

- Fuel Oil AdditivesDocumento2 pagineFuel Oil AdditivesrajachemNessuna valutazione finora

- P1012-Fuel Pump Delivery Pressure Too High: Theory of OperationDocumento2 pagineP1012-Fuel Pump Delivery Pressure Too High: Theory of OperationYovani AcevedoNessuna valutazione finora

- Part Subtitusi Every 16 - 03 - 20Documento1 paginaPart Subtitusi Every 16 - 03 - 20Nacz92Nessuna valutazione finora

- Different Types of TankersDocumento10 pagineDifferent Types of TankersNestor HerreraNessuna valutazione finora

- Molten Carbonate Fuel Cell PresentationDocumento10 pagineMolten Carbonate Fuel Cell PresentationDeep GreyNessuna valutazione finora

- Oem Warranty Statement and Use of Biodiesel Blends Over 5 (b5)Documento3 pagineOem Warranty Statement and Use of Biodiesel Blends Over 5 (b5)Berani MatiNessuna valutazione finora

- Air Compressor Script AUX MACHDocumento5 pagineAir Compressor Script AUX MACHRalph Jay M. TaladroNessuna valutazione finora

- Discovery II Electrical Library PDFDocumento705 pagineDiscovery II Electrical Library PDFAndrei AndreiNessuna valutazione finora

- 93ZJ Secc 8D Ignition SystemsDocumento40 pagine93ZJ Secc 8D Ignition Systemshelgith74Nessuna valutazione finora

- Fluent 2D Simulation SI EngDocumento10 pagineFluent 2D Simulation SI EngSantosh TrimbakeNessuna valutazione finora

- Lubrication NotesDocumento31 pagineLubrication NotesRishab SharmaNessuna valutazione finora

- Ship To Ship LNG Transfer TechnologyDocumento54 pagineShip To Ship LNG Transfer Technologyarunengg100% (3)

- The Real Reason Toyota Won't Switch To EVDocumento8 pagineThe Real Reason Toyota Won't Switch To EVSirin AktarNessuna valutazione finora

- CompotecLine Hoses OIL MIC CompressedDocumento2 pagineCompotecLine Hoses OIL MIC CompressedAndrian HadianaNessuna valutazione finora

- Mohit KhandelwalDocumento15 pagineMohit KhandelwalMohitKhandelwalNessuna valutazione finora

- 2013 Fall Parts CatalogDocumento28 pagine2013 Fall Parts CatalogLucas Félix de AguiarNessuna valutazione finora

- Irs 1041 FormDocumento4 pagineIrs 1041 FormcaliechNessuna valutazione finora

- Saqib Rahim CVDocumento2 pagineSaqib Rahim CVayub abbasiNessuna valutazione finora