Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Penn Right Angle

Caricato da

Hong You LeongDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Penn Right Angle

Caricato da

Hong You LeongCopyright:

Formati disponibili

RIGHT ANGLE CLINCH FASTENERS

BULLETIN

RA

413

R e v 114

RIGHT ANGLE CLINCH FASTENERS

PEM RANGLE fasteners provide strong right angle attachment points in sheet metal or PC boards. Types RAA and

RAS for metal are simply pressed into a rectangular mounting hole of the proper size. The Type SMTRA is installed

onto PC boards using standard surface mount techniques. The holding power of the fastener is unaffected by the

repeated tightening and loosening of the screw.

RANGLE fasteners are cost-effective replacements for:

bent edge tabs

bent center tabs

bent flanges

angle brackets

tack welds

loose hardware

PEM RANGLE fasteners provide many advantages over bent tabs and flanges, including:

more predictable designs

material savings

tighter design control

improved shielding characteristics

reduction of loose hardware

fewer assembly steps

unmarred panel surfaces

Type RAS for sheet metal is a

threaded right angle fastener that

accepts standard unified or metric

screws - PAGE 3

Type SMTRA right angle threaded

fasteners are installed on to PC

boards using standard surface mount

techniques. They accept standard

unified or metric screws - PAGE 5

Type RAA right angle fasteners

for sheet metal can accept thread

forming or self-tapping screws -

Material and finish specifications - PAGE 6

Installation - PAGES 6 - 7

PAGE 4

Performance data - PAGES 7 - 8

RANGLE

panel

support

RANGLE

edge

mounting

angle

brackets

bent

flanges

RANGLE center

mounting

RA-2 PennEngineering www.pemnet.com

tab

cutouts

Reverse

side

remains

flush with

RANGLE

fastener

Depending on placement

of the fastener within the

mounting hole, a slight

gap may be noticeable

along the non-clinching

edges of the fastener after

installation.

RIGHT ANGLE CLINCH FASTENERS

TYPE RAS - STEEL THREADED RIGHT ANGLE FASTENER

Metric part can be

identified by flat top

A

C

PART NUMBER DESIGNATION

G

RA

440 9 6

ZI

F

Type Material Thread Height Length Finish

Code Code

Code Code

Clinching profile may vary.

All dimensions are in inches.

UNIFIED

Thread

Size

Type

Fastener

Material

Thread

Code

Height

Code

.112-40

(#4-40)

RA

440

.138-32

(#6-32)

RA

632

10

.164-32

(#8-32)

RA

832

12

Length

Code

Length

L

.003

.121

6

8

.183

.246

.121

8

10

.246

.308

.183

9

12

.277

.371

Length

L

0.08

Min.

Sheet

Thickness

Hole Size

In Sheet

+.002

-.001

Min. Part Min. Dist.

Face to

HoleC/L

Edge

To Edge

K

M

A

.003

C

Nom.

D

Nom.

E

.006

Height

F

.006

.308

.250

.125

.370

.281

.406

.096

.040

.371

.300

.125

.433

.312

.462

.141

.040

.402

.350

.125

.464

.375

.550

.157

.040

G

Nom.

J

Nom.

9.78

2.87

G

Nom.

J

Nom.

.312 x .125

.040

.312 x .187

.312 x .250

.30

.375 x .125

.040

.375 x .250

.375 x .312

.35

.406 x .187

.040

.406 x .281

.406 x .375

Min.

Sheet

Thickness

Hole Size

In Sheet

+0.05

0.03

.35

.43

.50

.55

.40

.58

.65

METRIC

All dimensions are in millimeters.

Thread

Size x

Pitch

Type

Fastener

Material

Thread

Code

Height

Code

Length

Code

3

2.89

M3 x 0.5

RA

M3

3.89

5.89

M4 x 0.7

RA

M4

3.89

6.89

8.89

A

0.08

C

Nom.

D

Nom.

E

0.15

Height

F

0.15

7.89

6.35

3.18

9.47

Min. Part Min. Dist.

Face to HoleC/L

Edge

To Edge

K

M

8x3

1

8x4

7.6

1.02

8x6

10 x 4

1

10 x 7

9.1

10.7

10

9.89

8.89

3.18

11.48

13.21

4.06

1.02

10 x 9

14.7

16.3

PennEngineering www.pemnet.com

RA-3

RIGHT ANGLE CLINCH FASTENERS

TYPE RAA - ALUMINUM RIGHT ANGLE FASTENER

For use with thread forming screws

Metric part can be

identified by flat top

M

A

C

H

PART NUMBER DESIGNATION

RA

4 9 6

F

Patented

Type Material Screw Height Length

Code

Code

Size

Code

D

J

Clinching profile may vary.

UNIFIED

All dimensions are in inches.

Thread

Form

Screw

Size

Screw

Fastener Size Height

Type Material Code Code

#4-40

RA

6

8

.183

.246

#6-32

RA

10

8

10

#8-32

RA

12

9

12

Length

Length

L

Code .003

Min.

Sheet

Thickness

Hole Size

In Sheet

+.002

-.001

Min. Part Min. Dist.

Face to HoleC/L

G

H

J

Edge

To Edge

Nom. .007 Nom.

K

M

A

.003

B

.004

C

Nom.

D

Nom.

E

.006

Height

F

.006

.040

.312 x .187

.308

.312 x .250

.100

.250

.125

.368

.281

.389

.054

.096

.040

.35

.36

.246

.308

.040

.375 x .250

.371

.375 x .312

.123

.300

.125

.431

.312

.442

.066

.141

.040

.50

.55

.277

.371

.040

.406 x .281

.402

.406 x .375

.145

.350

.125

.462

.375

.525

.078

.157

.040

.58

.65

Min. Part Min. Dist.

Face to

HoleC/L

G

H

J

Edge

To Edge

Nom. 0.18 Nom.

K

M

METRIC

All dimensions are in millimeters.

Thread

Form

Screw

Size

Screw

Fastener Size Height

Type Material Code Code

Min.

Length Sheet

Length

L

ThickCode 0.08 ness

Hole Size

In Sheet

+0.05

0.03

A

0.08

B

0.1

C

Nom.

D

Nom.

E

0.15

Height

F

0.15

M3 x 0.5 RA

M3

4

6

3.89

5.89

8x4

8x6

7.89

2.77

6.35

3.18

9.42

9.27

1.5

2.87

1.02

9.1

10.7

M4 x 0.7 RA

M4

7

9

6.89

8.89

10 x 7

10 x 9

9.89

3.68

8.89

3.18

11.43

12.19 1.97

4.06

1.02

14.7

16.3

RA-4 PennEngineering www.pemnet.com

RIGHT ANGLE CLINCH FASTENERS

TYPE SMTRA - ReelFast SURFACE MOUNT RIGHT ANGLE (RANGLE) FASTENERS

Grooves

identify

unified

thread

G

J

SMTRA 256 8 6

Type

ET

Stencil Masking Examples

Thread Height Length Finish

Code Code Code Code

Patented

D

SP

N

P

PART NUMBER DESIGNATION

All dimensions are in inches.

UNIFIED

Thread

Size

.086-56

(#2-56)

.112-40

(#4-40)

.138-32

(#6-32)

.164-32

(#8-32)

Min.

Hole

Sheet

Size

ThickIn Sheet

ness +.003 .000

A

.006

B

.006

C

.006

D Height G J K N P SP

T

.006 F .006 Nom. Nom. Max. Max. .003 Nom.

.006

.188

.040

.053

.218

.040

.060

.140 .250 .345 .020 .030 .048 .040 .157 .105

.188

.040

.053

.250

.050

.065

.160 .281 .390 .020 .030 .048 .040 .188 .125

10

.250

.040

.053

.312

.050

.065

.205 .312 .450 .020 .030 .048 .040 .250 .145

12

.281

.040

.053

.375

.050

.075

.250 .375 .535 .020 .030 .048 .040 .312 .195

Min.

Sheet

Thickness

Hole

Size

In Sheet

+0.08

A

0.15

B

0.15

C

0.15

D Height G J K N P SP

T

0.15

F

0.15 Nom. Nom. Max. Max. 0.08 Nom.

0.15

Type

Thread

Code

Height

Code

Length

Code

Length

L

.005

SMTRA

256

SMTRA

440

SMTRA

632

SMTRA

832

METRIC

UNIFIED

METRIC

All dimensions are in millimeters.

Thread

Size x

Pitch

Type

M2 x 0.4

SMTRA

Thread Height Length Length

Code Code Code

L

0.13

M2

1.35

5.5

1.5

3.5 6 8.4

0.5

0.75

1.22

1 4

2.65

M2.5 x 0.45 SMTRA M25

1.35

5.5

1.5

3.5 6 8.4

0.5

0.75

1.22

1 4

2.65

M3 x 0.5

SMTRA

M3

1.35

6.35

1.25

1.65

4 7

9.75

0.5

0.75

1.22

1

4.75

3.2

M4 x 0.7

SMTRA

M4

1.35

9.53

1.25

1.65

6.35 9 13.1 0.5 0.75 1.22 1 7.9 4.8

Thread

Code

Pad Width Pad Length

PA

PL

Min.

Min.

Hole Spacing Hole Size

SH

In Sheet

.002

+.003 .000

256

.262

.171

.157

.053

440

.294

.171

.188

.053

632

.356

.233

.250

.053

832

.419

.264

.312

.053

Thread

Code

Pad Width Pad Length

PA

PL

Min.

Min.

4.57

Hole Spacing

SH

0.05

Hole Size

In Sheet

+0.08

1.35

M2

6.62

M25

6.62

4.57

1.35

M3

7.47

4.57

4.75

1.35

M4

10.65

6.57

7.9

1.35

PA

Part

Number

Parts Pitch Tape Width

Per Reel (mm) (mm)

SMTRA256-8-6

375

16

24

Solder Pad

SMTRA440-9-6

300

16

24

Can be flush

to edge. Plated

through hole not

required.

SMTRA632-10-8

200

20

32

SMTRA832-12-9

200

20

32

SMTRAM2-6-5

375

16

24

SMTRAM25-6-5

375

16

24

SMTRAM3-7-5

300

16

24

SMTRAM4-9-7

200

20

32

SH

PL

PennEngineering www.pemnet.com

RA-5

RIGHT ANGLE CLINCH FASTENERS

MATERIAL AND FINISH SPECIFICATIONS

Threads

Internal, ASME

B1.1, 2B ASME

B1.13M, 6H

Type

RAS

Standard Finishes (1)

Fastener Materials

6061-T6

Aluminum

Steel

Zinc

Diecast

RAA

Zinc Plated,

5m, Colorless

Electro-plated Bright Tin ASTM

B 545, Class A with

Clear Preservative Coating

Electro-plated Matte Tin ASTM

B 545, Class A with Clear

Preservative Coating, Annealed

SMTRA

Natural

Optional Finish

ZI

HRB 45 /

HB 84

or Less

HRB 60 /

HB 107

or Less

Part Number Codes for Finishes

For Use In Sheet Hardness:(2)

None

PC

Board

ET (3)

DT (3)

(1) See PEM Technical Support section of our web site for related plating standards and specifications.

(2) HRB - Hardness Rockwell B Scale. HB - Hardness Brinell.

(3) Optimal solderability life noted on packaging.

INSTALLATION

B

A

TYPES RAS and RAA

1. Prepare a properly sized rectangular mounting hole in the sheet.

Do not perform any secondary operations such as deburring.

2. Place the fastener through the mounting hole (preferably the

punch side) and into the anvil as shown in the drawing to the right.

3. With the installation punch and anvil surfaces parallel, apply a

squeezing force until the bottom of the fastener becomes flush

with the sheet.

L + .005/

0.13mm

Min.

ANVIL

METRIC

UNIFIED

PEMSERTER Installation Tooling

Anvil Dimensions (in.)

B

C

.001

.005

Screw or

Thread Size

Code

A

.001

4 / 440

.257

.313

6 / 632

.307

.376

8 / 832

.357

.407

Screw or

Thread Size

Code

A

0.03

M3

6.53

8.02

M4

9.07

10.03

PUNCH*

D

Min.

Anvil Part

Number

.100

.425

8002711

.100

.500

8002712

.100

.575

8003642

D

Min.

Anvil Part

Number

2.54

10.8

8002713

2.54

12.7

8002714

Anvil Dimensions (mm)

B

C

0.03

0.1

Punch Part

Number

8003076

Punch Part

Number

8003076

SHEET

C

ANVIL

* NOTE: The punch must be large enough to cover the

entire base of the fastener to ensure proper installation.

Installation tooling is available from PennEngineering.

MOUNTING HOLE EXAMPLES

Side 2

Hole

Hole

Example Example

#1

#2

Side 1

The mounting hole is defined by two dimensions. The two thick lines

shown must be straight for the entire length defined by Side 2 and

must be separated by the distance shown as Side 1 (Side 1 and

Side 2 are the two dimensions given for the mounting hole on pages 3

and 4). The illustration shows three examples (#1, #2, and #3) of how

it can be achieved. Example #4 in the lower right side will not work.

Hole

Hole

Example Example

#3

#4

RA-6 PennEngineering www.pemnet.com

Mounting

Hole

RIGHT ANGLE CLINCH FASTENERS

TYPE SMTRA

Flat top for

vacuum

pick up.

Solder paste applied

to pad on PCB.

Solder fastener in place using

standard surface mount techniques.

Undercut to accept solder fillet and

permit flush to edge installation.

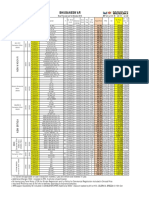

PERFORMANCE DATA(1)

METRIC

UNIFIED

TYPE RAS

Thread

Code

Height

Code

440

632

10

832

12

Thread

Code

Height

Code

M3

M4

Length

Code

5052-H34 Aluminum

Max. Rec. Tightening Installation Pushout

Torque (in. lbs.)

(lbs.)

(lbs.) (2)

4

6

8

4

8

10

6

9

12

13

17

17

20

21

21

20

23

30

Length

Code

1800

1800

2100

2000

2500

2800

2400

3300

3500

1.47

1.92

2.15

2.15

2.6

2.83

8

8

9.3

8.9

13.3

13.3

Cold-rolled Steel

Pull Thru Max. Rec. Tightening Installation Pushout

(lbs.)

Torque (in. lbs.)

(lbs.)

(lbs.) (2)

Side Load

(lbs.) (3)

100

145

180

100

190

230

140

195

260

7

8

13

7

12

16

15

16

20

80

80

80

85

85

85

100

100

100

16

17

17

20

26

26

27

29

35

2400

2400

3000

2500

3200

4000

3200

4200

4700

180

260

315

190

335

385

260

345

420

Cold-rolled Steel

Pull Thru Max. Rec. Tightening Installation Pushout

(N)

Torque (Nm)

(kN)

(N) (2)

Side Load

(N) (3)

423

534

756

556

890

1112

36

36

58

53

76

93

356

356

356

423

423

423

2.26

2.71

2.71

3.28

4.07

4.52

10.7

10.7

13.3

11.6

16

18.7

778

1001

1312

956

1512

1846

TYPE RAA

METRIC

UNIFIED

Screw

Size

Code

Thread Forming

Max. Rec.

Torque

Tightening Torque

(in. lbs.)

(in. lbs.)

Test Sheet

Material

Installation

(lbs.)

(2)

(3)

Pull

Thru

(lbs.)

6

10

5052-H34

Aluminum

1800

1800

140

180

8

13

80

80

5.5

5.5

11

17

5052-H34

Aluminum

2500

2500

175

235

12

16

85

85

6.5

8.0

18

20

5052-H34

Aluminum

3100

3100

205

255

13

21

105

105

Test Sheet

Material

Installation

(kN)

Pushout

(N)

Side Load

(N)

(2)

(3)

Pull

Thru

(N)

.56

1.02

5052-H34

Aluminum

7.1

7.1

556

756

27

44

356

356

2.26

2.83

5052-H34

Aluminum

13.3

13.3

890

1045

76

107

423

423

Height

Code

Length

Code

6

8

3

4

10

8

10

12

9

12

Screw

Size

Code

Height

Code

Length

Code

M3

4

6

.17

.23

M4

7

9

.56

.56

Thread Forming

Max. Rec.

Torque

Tightening Torque

(Nm)

(Nm)

Side Load

(lbs.) (3)

Pull Thru

(lbs.)

9

9

15

9

16

20

11

20

27

80

80

80

85

85

85

100

100

100

Side Load

(N) (3)

Pull Thru

(N)

40

40

67

44

80

116

356

356

356

423

423

423

Test Sheet Material

5052-H34 Aluminum

Max. Rec. Tightening Installation Pushout

Torque (Nm)

(kN)

(N) (2)

3

4

6

4

7

9

Test Sheet Material

Pushout

(lbs.)

Side Load

(lbs.)

PULL

THRU

PUSHOUT (2)

SIDE

LOAD (3)

1 /

25.4mm

SIDE VIEW

INSTALLATION

FORCE

(1) Installation values are for general reference only. Actual set up and installation should be performed using the visual indication method

described in this literature. Other performance values reported are averages when all proper installation parameters and procedures

are followed. Variations in mounting hole size, sheet material, and installation procedure may affect performance. Performance testing

this product in your application is recommended. We will be happy to provide technical assistance and/or samples for this purpose.

(2) Pushout test is conducted without side panel attached to RANGLE fastener.

(3) 1 / 25.4mm from screw centerline.

PennEngineering www.pemnet.com RA-7

RIGHT ANGLE CLINCH FASTENERS

PERFORMANCE DATA

METRIC

UNIFIED

TYPE SMTRA RANGLE FASTENERS WITH ET FINISH(1)(2)

Part

Number

Pullout

(lbs.)

Side Load

(lbs.)

SMTRA256-8-6

51.7

7.1

SMTRA440-9-6

89.5

10.8

SMTRA632-10-8

110.3

8.4

SMTRA832-12-9

137.2

21.2

Part

Number

Pullout

(N)

Side Load

(N)

SMTRAM2-6-5

418.2

56.8

SMTRAM25-6-5

216.5

SMTRAM3-7-5

257.6

SMTRAM4-9-7

369.3

73.3

TESTING CONDITIONS

Quad ZCR convection oven with 4 zones

Oven

Vias None

High Temp

518F / 270C

Board Finish

62% Sn, 38% Pb

Paste

Amtech NC559LF Sn96.5/3.0Ag/0.5Cu (SAC305)

Lead-free

Board

.062 thick, Single Layer FR-4

36.9

Stencil

.0067 / 0.17 mm thick

41.3

Screen Printer Ragin Manual Printer

(1) With lead-free paste. Average values of 30 test points. The data presented here is for general comparison purposes only. Actual performance is

dependent upon application variables. We will be happy to provide samples for you to install. If required, we can also test your installed hardware

and provide you with the performance data specific to your application.

(2) Further testing details can be found in our websites literature section.

PEM Circle

on Pedestal

(Registered Trademark)

Regulatory compliance information is available in Technical

Support section of our website.

2013 PennEngineering.

RA-8

Specifications subject to change without notice.

Check our website for the most current version of this bulletin.

Technical support e-mail: techsupport@pemnet.com

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Broadband Network ArchitecturesDocumento33 pagineBroadband Network ArchitecturesSundeel Bin Haleem100% (1)

- Moment Resisting Frames - Part2Documento70 pagineMoment Resisting Frames - Part2peterpaulw100% (1)

- Hubbell Catalog PDFDocumento52 pagineHubbell Catalog PDFpaulsiancasnNessuna valutazione finora

- 0 Item(s) : Country Level Duration No. Questions Cut Score Product Group Solution Available LanguagesDocumento3 pagine0 Item(s) : Country Level Duration No. Questions Cut Score Product Group Solution Available LanguageserczzoneNessuna valutazione finora

- Cisco Security Control Framework (SCF) ModelDocumento12 pagineCisco Security Control Framework (SCF) Modelravin.jugdav678Nessuna valutazione finora

- Gölz FS170RDocumento32 pagineGölz FS170RdrmassterNessuna valutazione finora

- LOTO NotesDocumento12 pagineLOTO NotesShirishNessuna valutazione finora

- Biffi Hydraulic ActuatorsDocumento28 pagineBiffi Hydraulic ActuatorsMuthu Kumar RNessuna valutazione finora

- Ecotec Exclusive User Manual 261415Documento16 pagineEcotec Exclusive User Manual 261415zula74Nessuna valutazione finora

- Din 1025-1Documento3 pagineDin 1025-1mistindustriyaNessuna valutazione finora

- Ieee STD c57Documento5 pagineIeee STD c57Budi Pujo SantosoNessuna valutazione finora

- Questions On Pricing Procedure in SAP SDDocumento5 pagineQuestions On Pricing Procedure in SAP SDAnand PattedNessuna valutazione finora

- HPE ProLiant DL380 Gen10 Server UKDoC HSTNS-5200-a50005003enwDocumento3 pagineHPE ProLiant DL380 Gen10 Server UKDoC HSTNS-5200-a50005003enwhesmaileeNessuna valutazione finora

- Windows Management Framework 4 0 Release NotesDocumento22 pagineWindows Management Framework 4 0 Release NotesJohn RofinNessuna valutazione finora

- Maintenance and TroubleshootingDocumento6 pagineMaintenance and TroubleshootingNmbvmbjhg JgjkgjNessuna valutazione finora

- Power ScrewsDocumento10 paginePower ScrewsamanggayamNessuna valutazione finora

- Recruitment SystemDocumento23 pagineRecruitment SystemGoverthanan3350% (6)

- RTN 910 Maintenance Guide (U2000) - (V100R003C03 01)Documento804 pagineRTN 910 Maintenance Guide (U2000) - (V100R003C03 01)Qiang Yang0% (1)

- VIPA System 200V ManualDocumento422 pagineVIPA System 200V Manualwww.otomasyonegitimi.comNessuna valutazione finora

- HCI634JDocumento8 pagineHCI634J3efooNessuna valutazione finora

- PHP Chat ScriptDocumento6 paginePHP Chat ScriptHarriesta0% (1)

- EN 45545-2 - Fire Protection On Railway Vehicles: Technical Information, January 2020Documento7 pagineEN 45545-2 - Fire Protection On Railway Vehicles: Technical Information, January 2020Abdelmajid HmNessuna valutazione finora

- Dealer Price List Oct 2019Documento2 pagineDealer Price List Oct 2019Pranab Kumar NayakNessuna valutazione finora

- SAP Security Interview QuestionsDocumento11 pagineSAP Security Interview Questionsveena7570% (1)

- GX Developer Version 8 Operating Manual Ib0800243elDocumento864 pagineGX Developer Version 8 Operating Manual Ib0800243elGelu BordeaNessuna valutazione finora

- An Introduction To The New Asme Standards On Nonmetallic Pressure Piping SystemsDocumento7 pagineAn Introduction To The New Asme Standards On Nonmetallic Pressure Piping SystemsJuan Junior Lostaunau AlvaNessuna valutazione finora

- 1992 The Ritz-Carlton Hotel CompanyDocumento2 pagine1992 The Ritz-Carlton Hotel CompanyMuhammad HakimNessuna valutazione finora

- Nihon Kohden TEC-5600 Defibrillator - Service ManualDocumento288 pagineNihon Kohden TEC-5600 Defibrillator - Service ManualPaola Del Cairo33% (3)

- Presentation On Bluetooth TechnologyDocumento19 paginePresentation On Bluetooth TechnologySolanki Bhowmick92% (12)

- DeLorean Owners ManualDocumento42 pagineDeLorean Owners Manualjvorzimmer100% (4)