Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

02 RR Griswold 811 Performance Curve Brochure

Caricato da

Alex WilmerCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

02 RR Griswold 811 Performance Curve Brochure

Caricato da

Alex WilmerCopyright:

Formati disponibili

griswold 811

performance curves

griswold pump companY

pump siZe

rpm

page #

pump siZe

rpm

page #

1 1/2 x 1 - 6AA

1800

3600

1

1

6 X 4 - 10G A80

1

1

1200

1800

3600

6

6

6

3 x 1 1/2 - 6AB

1800

3600

6 X 4 - 10H A80

1800

3600

1

1

1200

1800

6

7

3 x 2 - 6AC

LF 3 X 1 1/2 - 13 A20

LF 1 1/2 x 1 - 8AA

1800

3600

2

2

1800

3600

7

7

3 X 1 1/2 - 13 A20

1 1/2 X 1 - 8AA

1800

3600

2

2

1200

1800

3600

7

7

7

3 X 1 1/2 - 8AB

1800

3600

2

2

3 X 2 - 13 A30

1200

1800

3600

8

8

8

3 X 2 - 8 A60

1800

3600

3

3

4 X 3 - 13 A40

4 X 3 - 8 A70

1200

1800

3

3

1200

1800

3600

8

8

8

6 X 4 - 13 A80

4 X 3 - 8G A70

1800

3600

3

3

1200

1800

9

9

8 X 6 - 13 A90

LF 2 X 1 -10 A05

1800

3600

4

4

1200

1800

9

9

10 X 8 - 13 A100

2 X 1 - 10 A05

1800

3600

4

4

1200

1800

9

9

8 X 6 - 15 A110

3 X 1 1/2 - 10 A50

1800

3600

4

4

1200

1800

10

10

10 x 8 - 15 A120

3 X 2 - 10 A60

1200

1800

3600

5

5

5

900

1200

10

10

10 x 8 - 15 G A120

1200

1800

10

10

4 X 3 - 10 A70

1200

1800

3600

5

5

5

6 x 4 - 17 A105

6 x 4 - 17 A105

1200

1800

11

11

4 X 3 - 10H A40

1200

1800

6

6

811 Dimensional Data

8ll Specifications

12

Back Cover

griswold pump companY

1 1/2 x 1 - 6aa

1800 rpm

curve: G-1801

1 1/2 x 1 - 6aa

3600 rpm

curve: G-3601

3 x 1 1/2 - 6aB

1800 rpm

curve: G-1802

3 x 1 1/2 - 6aB

3600 rpm

curve: G-3602

curve: G-1803

3 x 2 - 6ac

3 x 2 - 6ac

1800 rpm

3600 rpm

curve: G-3603

griswold pump companY

lf1-1/2 x 1 - 8 aa

1800 rpm

lf1-1/2 x 1 - 8 aa

curve: GLF-1804

3600 rpm

curve: GLF-3604

1-1/2 x 1 - 8 aa

1800 rpm

curve: G-1804

1-1/2 x 1 - 8 aa

3600 rpm

curve: G-3604

3 x 1-1/2 - 8 aB

1800 rpm

curve: G-1805

3 x 1-1/2 - 8 aB

3600 rpm

curve: G-3605

griswold pump companY

3 x 2 - 8 a60

1800 rpm

curve: G-1807

3 x 2 - 8 a60

3600 rpm

curve: G-3607

4 x 3 - 8 a70

1200 rpm

curve: G-1208

4 x 3 - 8 a70

1800 rpm

curve: G-1808

curve: G-1809

4 x 3 - 8g a70

4 x 3 - 8g a70

1800 rpm

3600 rpm

curve: G-3609

griswold pump companY

lf2 x 1 - 10 a05

2 x 1 - 10 a05

1800 rpm

1800 rpm

3 x 1-1/2 - 10 a50

1800 rpm

lf2 x 1 - 10 a05

curve: GLF-1810

3600 rpm

curve: G-1810

2 x 1 - 10 a05

curve: G-1811

3 x 1-1/2 - 10 a50

3600 rpm

3600 rpm

curve: GLF-3610

curve: G-3610

curve: G-3611

griswold pump companY

3 x 2 - 10 a60

1200 rpm

curve: G-1212

3 x 2 - 10 a60

1800 rpm

curve: G-1812

3 x 2 - 10 a60

3600 rpm

curve: G-3612

4 x 3 - 10 a70

1200 rpm

curve: G-1213

4 x 3 - 10 a70

1800 rpm

curve: G-1813

4 x 3 - 10 a70

3600 rpm

curve: G-3613

griswold pump companY

4 x 3 - 10H a40

1200 rpm

curve: G-1214

4 x 3 - 10H a40

1800 rpm

curve: G-1814

6 x 4 - 10g a80

1200 rpm

curve: G-1215

6 x 4 - 10g a80

1800 rpm

curve: G-1815

6 x 4 - 10g a80

3600 rpm

curve: G-3615

6 x 4 - 10H a80

1200 rpm

curve: G-1216

griswold pump companY

6 x 4 - 10H a80

1800 rpm

lf 3 x 1-1/2 - 13 a20

3 x 1-1/2 - 13 a20

3600 rpm

1800 rpm

lf 3 x 1-1/2 - 13 a20

curve: G-1816

1800 rpm

curve: GLF-1817

curve: GLF-3617

3 x 1-1/2 - 13 a20

1200 rpm

curve: G-1217

curve: G-1817

3 x 1-1/2 - 13 a20

3600 rpm

curve: G-3617

griswold pump companY

3 x 2 - 13 a30

1200 rpm

curve: G-1218

3 x 2 - 13 a30

1800 rpm

curve: G-1818

3 x 2 - 13 a30

3600 rpm

curve: G-3618

4 x 3 - 13 a40

1200 rpm

curve: G-1219

4 x 3 - 13 a40

1800 rpm

curve: G-1819

4 x 3 - 13 a40

3600 rpm

curve: G-3619

griswold pump companY

6 x 4 - 13 a80

1200 rpm

curve: G-1220

6 x 4 - 13 a80

1800 rpm

curve: G-1820

8 x 6 - 13 a90

1200 rpm

curve: G-1221

8 x 6 - 13 a90

1800 rpm

curve: G-1821

curve: G-1222

10 x 8 - 13 a100

10 x 8 - 13 a100

1200 rpm

1800 rpm

curve: G-1822

griswold pump companY

8 x 6 - 15 a110

1200 rpm

curve: G-1223

8 x 6 - 15 a110

10 x 8 - 15 a120 900 rpm

curve: G-0824

10 x 8 - 15 a120 1200 rpm

curve: G-1224

10 x 8 - 15g a120 1200 rpm

curve: G-1225

10 x 8 - 15g a120 1800 rpm

curve: G-1825

10

1800 rpm

curve: G-1823

6 x 4 - 17 a105

1200 rpm

griswold pump companY

6 x 4 - 17 a105

curve: G-1227

11

1800 rpm

curve: G-1827

RO TAT ION

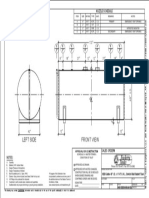

811 DIMENSIONAL DATA

12

RO

TA T

IO N

griswold pump companY

Model 811 ANSI B73.1 Specifications

1.0 Pump Design

1.1 The pump must conform in all respects to the latest edition of ANSI Specification B73.1M.

1.2 The pump should be back pullout design. A machined fit between the pullout assembly and the casing to insure alignment is

required.

1.3 Pump will be top centerline, self-venting discharge.

1.4 100% of the pump shall be manufactured in the USA excluding outside purchased items like bearings and hardware that may

ormay not be produced in the USA.

2.0 Casing

2.1 Class 150 pumps shall incorporate class 300 wall thickness as standard, extending casing life under corrosive / erosive

conditions.

2.2 Casing shall be machined as to accommodate a fully confined casing gasket to prevent leakage.

2.3 The casing shall be furnished with a minimum 1/8" corrosion allowance.

2.4 The pump casing, when produced in Ductile Iron, Stainless Steel or CD4Mcu, shall include a drain plug and a discharge

tap connection.

3.0 impeller

3.1 A fully open impeller shall be provided to facilitate the handling of solid and stringy material.

3.2 The impeller shall be self-tightening.

3.3 The impeller shall be furnished with back pump out vanes to reduce pressure in the seal chamber and to minimize axial thrust.

3.4 The pump shall be provided with an open impeller design to allow for re-establishment of original clearances and hydraulic

performance and efficiencies without pump disassembly.

3.5 Impeller connection to the shaft shall allow for metal-to-metal contact with a control squeeze Teflon o-ring.

3.6 The impeller shall be balanced to minimize vibration in accordance with ISO 1940 Grade 6.3 after final machining.

3.7 The impeller shall be produced with ultra-smooth investment castings to improve hydraulic and mechanical balance.

4.0 Bearing Frame and Adapter

4.1 Non-pressure retaining castings (bearing housing, medium - large - extra large bearing frames, frame feet) shall be produced

in cast iron with a minimum tensile strength of 30,000 lbs.

4.2 Pressure retaining castings (small bearing frame, all adapters) shall be produced in Ductile Iron with a minimum tensile

strength of 65,000 lbs.

4.3 Interior surfaces of all bearing frames shall be coated with a Fusion Bonded Epoxy Coating to provide for long-term quality

and cleanliness of the lubricating oil.

4.4 The bearing frames shall be assembled in a clean room environment to eliminate contamination.

4.5 The bearing frame and adapter mating surfaces must be machined with a register fit to guarantee precise alignment.

Additionally, dowel pins shall be utilized to eliminate torsion.

4.6 The bearing housing with adjusting bolts shall be provided to allow for axial adjustment of the impeller to regain hydraulic

performance and efficiencies without pump disassembly.

4.7 To minimize shaft misalignment due to flange loading on the pump, the frame foot, if separate from the bearing frame, shall

be rigidly attached at two points and constructed of cast iron with a minimum tensile strength of 30,000 lbs.

4.8 The shaft shall be provided to keep deflection within ANSI B73.1 limits at all operating points.

4.9 The shaft sleeve when provided will be hook type sleeve 316 stainless steel as a minimum or sleeveless solid shafts as an

option.

4.10 Bearing shall be designed for a minimum life (L10) of two years and a 10-year average life as required by the latest edition

of ANSI B73.1M specifications as manufactured by SKF or equal.

4.11 Radial and thrust bearings shall not be pressed onto the shaft. Bearings shall be installed utilizing stress-free bearing

induction heater.

4.12 To prevent thrust bearing loosening during pump operation, thrust bearings shall be positively locked to the shaft by means of

a locknut and lock washer.

4.13 To retain lubricant and prevent contamination, bronze Inpro labyrinth oil seals shall be provided.

4.14 A one-inch sight glass with reflective baffle shall be provided to monitor oil level and condition.

4.15 A magnetic drain plug shall be provided to collect damaging metallic particles.

4.16 Condition-monitoring sites shall be provided to facilitate consistent checking of vibration and temperature.

4.17 If lubricant cooling is required a finned tube-cooling element shall be provided.

4.18 In high load applications beyond ANSI 811M bearing frame limits an 811L frame shall be specified incorporating an oversized

shaft with an oil slinger, higher load carrying radial bearing and duplex angular contact thrust bearings.

5.0 seal chamber

5.1 Seal chambers shall be engineered to provide the optimum seal environment for heat dissipation, solids, trapped air and vapor.

6.0 Pump Bases

6.1 A rigid, high-strength base shall be provided to insure pump-to-motor shaft misalignment not to exceed 0.005" due to base

plate distortion.

7.0 Coupling Guard

7.1 A coupling guard shall be provided with the pump that conforms to both ANSI and OSHA requirements.

8.0 Warranty

8.1 Pumps shall be backed by a 3-year whole pump unconditional guarantee against defects in material and workmanship.

BC 7/07 C5312

Head Office:

6120 Davies Road

Edmonton, AB

T6E 4M9

Phone: (780) 485-2010 Toll Free: (866) 707-7867

Fax: (780) 485-1938

Calgary Drayton Valley Lethbridge

www.rotatingright.com

Potrebbero piacerti anche

- B-313 Series E-1510 Technical BrochureDocumento8 pagineB-313 Series E-1510 Technical BrochureAnonymous 7xHNgoKE6eNessuna valutazione finora

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- CI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsDocumento12 pagineCI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsAndre Gazali MalikNessuna valutazione finora

- Bomba Hidraulica Sp25Documento5 pagineBomba Hidraulica Sp25Javier SumozaNessuna valutazione finora

- 10 HP M2a Right Angle ManualDocumento21 pagine10 HP M2a Right Angle ManualSonthiMNessuna valutazione finora

- 3775 Triplex Plunger PumpDocumento2 pagine3775 Triplex Plunger PumpRoberto Esteban Cárdenas DNessuna valutazione finora

- 3656-3756 ML Brochure GouldsDocumento44 pagine3656-3756 ML Brochure Gouldsjulio.esc7Nessuna valutazione finora

- lt3 00032 2 A p24 p30sDocumento67 paginelt3 00032 2 A p24 p30sBruno SamaeianNessuna valutazione finora

- Bearing LayoutDocumento30 pagineBearing LayoutmayasfaresNessuna valutazione finora

- Vibratory Feeders and Conveyors PDFDocumento14 pagineVibratory Feeders and Conveyors PDFArnaldo BenitezNessuna valutazione finora

- Krima Screw Press Type RR: Cellwood Machinery AbDocumento3 pagineKrima Screw Press Type RR: Cellwood Machinery AbelcarpaneziNessuna valutazione finora

- M Technical ManualDocumento36 pagineM Technical ManualJuan Martin RomeroNessuna valutazione finora

- HH125 Smanual Completed - Master Updated 30-3-06Documento41 pagineHH125 Smanual Completed - Master Updated 30-3-06jacklyn ade putra0% (1)

- Catalog Mud Pump 25864Documento24 pagineCatalog Mud Pump 25864agus100% (1)

- Aurora 340 DsDocumento4 pagineAurora 340 DsdesuyaNessuna valutazione finora

- NissanDocumento3 pagineNissancrower_scribdNessuna valutazione finora

- Ra92100 1997-10Documento48 pagineRa92100 1997-10mmaldonado10Nessuna valutazione finora

- Dv300 STD MMDocumento40 pagineDv300 STD MMjacklyn ade putraNessuna valutazione finora

- Aurora PumpsDocumento12 pagineAurora PumpsM Alim Ur RahmanNessuna valutazione finora

- Pump Global Gear Service ManualDocumento41 paginePump Global Gear Service ManualAddis TesfayeNessuna valutazione finora

- Goulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610Documento40 pagineGoulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610Rous MeryNessuna valutazione finora

- Hansen p4 Qvrc2 Cun 9Documento21 pagineHansen p4 Qvrc2 Cun 9lcazac100% (1)

- Catalogo AlconDocumento27 pagineCatalogo Alconaku170% (1)

- Bulletin Technique Jaguar 3.4 38 1960Documento63 pagineBulletin Technique Jaguar 3.4 38 1960AlfajagNessuna valutazione finora

- Procedimiento de Pulido CrankshaftsDocumento19 pagineProcedimiento de Pulido CrankshaftsJavier Hector CayaNessuna valutazione finora

- Atlas 4WP2D Portable PoAtlas - 4WP2D - Portable - PowerWinch - WincheswerWinch - WinchesDocumento2 pagineAtlas 4WP2D Portable PoAtlas - 4WP2D - Portable - PowerWinch - WincheswerWinch - WinchesTunoNegro1Nessuna valutazione finora

- Nema ManDocumento416 pagineNema Manmetha.d8070Nessuna valutazione finora

- Imo ACGDocumento16 pagineImo ACGMiguel Ponce100% (1)

- 2300 Series ManualDocumento24 pagine2300 Series ManualJuprayNessuna valutazione finora

- Brochure BEGEMANN BS Pumps-Low ResolutionDocumento6 pagineBrochure BEGEMANN BS Pumps-Low ResolutionunknownsaylorNessuna valutazione finora

- Dokumen - Tips Dv200 Manual Master1Documento45 pagineDokumen - Tips Dv200 Manual Master1Fermín Duarte RodríguezNessuna valutazione finora

- Jost Catalogo INGLESDocumento227 pagineJost Catalogo INGLESMiguel F Salamanca100% (1)

- A500 Tech. BulletinDocumento3 pagineA500 Tech. BulletinIan McpheeNessuna valutazione finora

- SAI - GM Tech CatalogDocumento54 pagineSAI - GM Tech CatalogBoban SimicNessuna valutazione finora

- PSI PumpsDocumento12 paginePSI PumpsagiacomuzoNessuna valutazione finora

- Tech Data Sheet ENG-21 Version 2Documento3 pagineTech Data Sheet ENG-21 Version 2muhmmadafzal73Nessuna valutazione finora

- SwingClamp BottomFlangeDocumento4 pagineSwingClamp BottomFlangePeter CusimanoNessuna valutazione finora

- Bombas Goulds 3656-3756 ML PDFDocumento40 pagineBombas Goulds 3656-3756 ML PDFCesar Sialer DiazNessuna valutazione finora

- Amc CrowerDocumento3 pagineAmc CrowerPablo Etp100% (1)

- SAPP Series PumpsDocumento2 pagineSAPP Series Pumpssahildhingra100% (1)

- ArmstrongDocumento6 pagineArmstrongJorge Herrera100% (1)

- Bomba de Engranajes Catalogo JOYANGDocumento8 pagineBomba de Engranajes Catalogo JOYANGlizbethdiosesNessuna valutazione finora

- Manual EatonDocumento92 pagineManual Eatonruben_cruz_34100% (1)

- Agitator SizingDocumento4 pagineAgitator SizingArbee AquinoNessuna valutazione finora

- Phased Out Products: Gear Pumps and Motors General ProductsDocumento18 paginePhased Out Products: Gear Pumps and Motors General ProductsAndrei VladNessuna valutazione finora

- HRP Motor Sports Products and Services CatalogDocumento16 pagineHRP Motor Sports Products and Services CatalogGus McGrathNessuna valutazione finora

- Bell & Gossett 1510Documento8 pagineBell & Gossett 1510juan yenqueNessuna valutazione finora

- Copt ManualDocumento79 pagineCopt ManualPradeep Shukla94% (17)

- BAGFLODocumento68 pagineBAGFLOAlicia ViridianaNessuna valutazione finora

- AC 540 PumpsDocumento6 pagineAC 540 Pumpsjames_chan2178Nessuna valutazione finora

- EVMU-EVMUG - Instruction and OperationDocumento44 pagineEVMU-EVMUG - Instruction and OperationDavidThânNessuna valutazione finora

- Api 23 02Documento4 pagineApi 23 02montsegranNessuna valutazione finora

- b3311 722-2Documento7 pagineb3311 722-2Arnaldo BenitezNessuna valutazione finora

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDa EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesValutazione: 5 su 5 stelle5/5 (1)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsDa EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsValutazione: 5 su 5 stelle5/5 (2)

- Construction and Manufacture of AutomobilesDa EverandConstruction and Manufacture of AutomobilesValutazione: 5 su 5 stelle5/5 (1)

- Front View Left Side: Nozzle ScheduleDocumento1 paginaFront View Left Side: Nozzle ScheduleAlex WilmerNessuna valutazione finora

- Serie 3200B On The GoDocumento2 pagineSerie 3200B On The GoAlex WilmerNessuna valutazione finora

- Series Description: Universal Product Line: Cast Iron - Non-Jacketed PumpsDocumento15 pagineSeries Description: Universal Product Line: Cast Iron - Non-Jacketed PumpsAlex WilmerNessuna valutazione finora

- Piusi Usa BipumpDocumento2 paginePiusi Usa BipumpAlex WilmerNessuna valutazione finora

- CVC Steel Valvulas LunkenheimerDocumento28 pagineCVC Steel Valvulas LunkenheimerAlex WilmerNessuna valutazione finora

- Fig. 918TCP Overfill Alarm Box: Morrison Bros. Co. Specification SheetDocumento1 paginaFig. 918TCP Overfill Alarm Box: Morrison Bros. Co. Specification SheetAlex WilmerNessuna valutazione finora

- Usama Lab 6Documento8 pagineUsama Lab 6M mubeen riazNessuna valutazione finora

- Dive Scubapro - Air2 3rd - Maintenance ProcedureDocumento5 pagineDive Scubapro - Air2 3rd - Maintenance Proceduremanonpom100% (1)

- 5 Levels of Leadership AnswersDocumento4 pagine5 Levels of Leadership Answersk98hk8wnnbNessuna valutazione finora

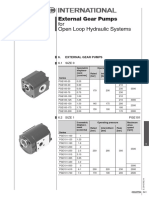

- External Gear Pumps For Open Loop Hydraulic SystemsDocumento2 pagineExternal Gear Pumps For Open Loop Hydraulic SystemsBlashko GjorgjievNessuna valutazione finora

- Daftar Isian 3 Number Plate, Danger Plate, Anti Climbing DeviceDocumento2 pagineDaftar Isian 3 Number Plate, Danger Plate, Anti Climbing DeviceMochammad Fauzian RafsyanzaniNessuna valutazione finora

- Vocabulary Levels Tests Versions 1 2Documento12 pagineVocabulary Levels Tests Versions 1 2Rangsiya PjewNessuna valutazione finora

- Sherman Notes PDFDocumento213 pagineSherman Notes PDFAbdul Hamid Bhatti100% (1)

- Nature'S Numbers: - BasicbooksDocumento39 pagineNature'S Numbers: - Basicbooksyeol pacisNessuna valutazione finora

- 17333Documento2 pagine17333Nithya RaviNessuna valutazione finora

- Erich Segal Doctors PDFDocumento2 pagineErich Segal Doctors PDFAlicia13% (8)

- P16mba7 1Documento4 pagineP16mba7 1Vishalatchi MNessuna valutazione finora

- Roman Helmet From SivacDocumento33 pagineRoman Helmet From SivacArachne DreamweaverNessuna valutazione finora

- Jaquar Sanitarywares PricelistDocumento8 pagineJaquar Sanitarywares PricelistAnil KumarNessuna valutazione finora

- Arquitectura Objectiva cl2002Documento9 pagineArquitectura Objectiva cl2002api-717600385Nessuna valutazione finora

- IN804 UV-VIS Nomenclature and UnitsDocumento5 pagineIN804 UV-VIS Nomenclature and UnitsAnurak OnnnoomNessuna valutazione finora

- KrautKramer DM4E DM4DL - ManualDocumento38 pagineKrautKramer DM4E DM4DL - ManualfdsgfdgNessuna valutazione finora

- Activity Diagram Airline Reservation System PDFDocumento4 pagineActivity Diagram Airline Reservation System PDFAnonymous zSn6IALuabNessuna valutazione finora

- Megger-Mjolner-600 Ds enDocumento5 pagineMegger-Mjolner-600 Ds enAmit Kumar KandiNessuna valutazione finora

- Avanti II 04-05Documento137 pagineAvanti II 04-05Donald SimsNessuna valutazione finora

- Filled System Temperature Recorders & Recorder Controllers: SpecificationDocumento2 pagineFilled System Temperature Recorders & Recorder Controllers: SpecificationdencryNessuna valutazione finora

- HPB Brochure 0708Documento12 pagineHPB Brochure 0708musaluddinNessuna valutazione finora

- Daftar Ebook Tentang LeanDocumento2 pagineDaftar Ebook Tentang LeanChilmar Buchari100% (1)

- Acr On Clean-Up DriveDocumento7 pagineAcr On Clean-Up DriveRichard ToliaoNessuna valutazione finora

- Cost Estimation and Specification of A Sewage Treatment PlantDocumento16 pagineCost Estimation and Specification of A Sewage Treatment Plantmsantosu000Nessuna valutazione finora

- SOM-based Generating of Association RulesDocumento5 pagineSOM-based Generating of Association RulesKishor PeddiNessuna valutazione finora

- ISMR B-School BrochureDocumento28 pagineISMR B-School Brochurerahul kantNessuna valutazione finora

- Shallow FoundationsDocumento44 pagineShallow FoundationsAjay SinghNessuna valutazione finora

- FOCGB5 Rtest 1-6BDocumento3 pagineFOCGB5 Rtest 1-6BM-DNessuna valutazione finora

- Rae Systems Parts List October 26 2010Documento2 pagineRae Systems Parts List October 26 2010Mike HastingsNessuna valutazione finora

- EV METER - EV1 and EV3Documento2 pagineEV METER - EV1 and EV3Nguyen DucNessuna valutazione finora