Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Technical Paper On District Cooling

Caricato da

garyckfanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Technical Paper On District Cooling

Caricato da

garyckfanCopyright:

Formati disponibili

Kai Tak Development (KTD), Energy

Efficiency

Implementation of District Cooling

System in Hong Kong:

Challenges and Experiences

1.

Ir Patrick CHEUNG, Ir LO Siu Kuen,

Ir MA Chun Yue

Electrical and Mechanical Services

Department

Government of the Hong Kong Special

Administrative Region

Since the operation of the Hong Kong

International Airport at Chep Lap Kok in

1998, the Government started to develop the

ex-Kai Tak International Airport and the

nearby areas into a new development area

Kai Tak Development (KTD). KTD is a

huge development spanning a total planning

area of 320 hectares. It comprises various

types of buildings including hospitals, hotels,

schools, commercial buildings, sport

facilities, residential buildings, government

buildings, etc. With the high cooling demand

and diversity of cooling load profiles, the

Government took the opportunity to

implement District Cooling System (DCS)

at KTD.

ABSTRACT

The Kai Tak Development (KTD) is a

huge development project spanning a total

area of over 320 hectares covering the

ex-airport and nearby areas in which there

has been a planned total of about 1.73

million square metres of public and private

non-domestic air-conditioned floor areas

requiring

a

large

demand

for

air-conditioning of about 284 megawatt of

refrigeration (MW). The Government aims

to promote energy saving and took the lead

to implement District Cooling System (DCS)

which could be considered the most energy

efficient air-conditioning system for the

development at KTD.

2.

BENEFITS

DCS consumes 35 percent and 20

percent less electricity as compared to

traditional

air-cooled

air-conditioning

systems and individual water-cooled

air-conditioning systems using cooling

towers respectively. With its high energy

efficiency, the implementation of DCS at

KTD will achieve estimated annual saving

of 85 million kilowatt-hour (kWh) in

electricity

consumption,

with

a

corresponding reduction of 59,500 tonnes of

carbon dioxide emissions per annum.

The project of DCS at KTD is to

construct a large scale centralized

air-conditioning system which would

produce chilled water at its central chiller

plants and distribute the chilled water to

consumer buildings in the KTD through an

underground water piping network. Apart

from constructing central chiller plant rooms,

the laying of underground water pipes is

another challenging task in view of the

uncertainty in underground conditions. The

operation of DCS is also one of the most

challenging tasks to be dealt with. Energy

efficiency as well as reliability of services

are both important. This paper aims to

present the challenges faced and also

experience

gained

during

the

implementation and operation of the DCS.

Apart from energy saving, DCS would

also bring along the following benefits to the

consumers:

a. Reduction in upfront capital cost for

installing chiller plants at their

buildings which account for about

5-10% of the total building cost;

b. More flexible building designs for

consumer buildings as they do not

need to install their own chillers and

the associated electrical equipment

Keywords: District Cooling System (DCS),

1

INTRODUCTION

Figure 1 - Kai Tak DCS North Plant

in their buildings;

The project will be implemented in

three phases. The construction works

commenced in February 2011. Phase I and II

include the construction of two plant rooms

and some pipeworks to enable the provision

of district cooling services to the Kai Tak

Cruise Terminal and Ching Long Shopping

Centre in the public rental housing in 2013.

Phase III includes further pipes laying works

and chiller installation to meet the cooling

demand growth in KTD. Phase I and II were

completed in 2013 and 2014 respectively.

Phase III commenced in mid 2013 and is

expected to be completed by 2022.

c. Mitigation of heat island effects in

KTD and elimination of noise and

vibration arising from the operation

of heat rejection equipment and

chillers of air-conditioning plants in

buildings as such equipment will no

longer be necessary for buildings

subscribing to district cooling

services; and

d. More adaptable air-conditioning

system to the varying demand as

compared

to

individual

air-conditioning systems. For each

individual building, cooling capacity

can be increased by requesting

additional cooling capacity from the

DCS without carrying out extensive

modification works for the building

in question.

3.

4.

RELIABILITY

To assure the consumers of a reliable

district cooling services, several design

features have been incorporated into the

DCS.

IMPLEMENTATION

4.1 Electricity Supply

The DCS at KTD comprises two central

chiller plants, namely the North Plant and

the South Plant cum seawater pump house,

underground chilled water distribution

piping network, seawater supply and

discharge pipes and consumer substations

located in the buildings to interface with the

buildings own chilled water circulation

systems. The total cooling capacity of the

DCS at KTD would be about 284 megawatt

of refrigeration (MWr) which could provide

about 1.73 million square metres of public

and private non-domestic air-conditioned

floor areas. The cooling capacities of the

North Plant and the South Plant would be

162 MWr and 122 MWr respectively. Both

plants are underground structures for the

chiller installations with aboveground

facilities at the North Plant. Upon

completion of the project, about 39

kilometres of underground chilled water

pipes would have been laid and there would

be around 60 buildings in KTD connected to

the DCS.

The electricity supply to the DCS plant

is such a robust arrangement that each

supply carries only 50% of the required

electrical load such that failure of any one of

the cable will result in no reduction in the

power supply condition.

To further

enhance the power supply reliability for

DCS, 11kV power supply fed from two

supply sources is adopted such that when

one source fails, the power supply will be

automatically switched over to the other

source.

4.2 Chilled Water Piping Network

The underground chilled water piping

network is designed to be in ring circuit

forming a dual-feed supply so that if the

supply from one side of the distribution

pipework is not available, chilled water can

still be supplied to the consumer buildings

from other side. Moreover, the whole

chilled water distribution piping network is

designed as a 3-pipe system such that when

2

closely monitor any water leakage point and

identify any fault signal due to broken cable.

one of the duty supply or return pipe is

damaged or under maintenance, the standby

pipe can be put in operation to maintain the

district cooling services.

Figure 2 - Prefabricated chilled water pipe

with leakage detection cables and

polyurethane insulation with HDPE outer

jacket

4.3 Chiller Plant

There are always at least one standby

chiller and chilled water pump such that if

any one of the chillers or pumps fails, the

standby equipment will be put in operation

to maintain full cooling capacity to serve the

consumers.

5.

DCS

PIPELINES

CHALLENGES

In general, open trench excavation

secured with sheet-pile walls are adopted for

the laying of DCS pipes. However, in some

locations, there are prohibitively existing

site constraints for constructing any open

trench. To surmount such construction

difficulties, trenchless excavation method

are adopted.

AND

The DCS pipelines (including chilled

water pipes and seawater pipes) are mostly

laid along the carriageway while branch

pipes and valve chambers are located in the

footpath in order to minimize conflict with

other underground utilities. Due to their

large sizes, the DCS pipes are normally laid

at the bottom among other underground

utilities.

Other than the congested underground

utilities, there are also various existing and

new structures including Kwun Tong Bypass,

Kai Tak Tunnel, box culverts, Kai Tak

Taxiway Bridge, Shatin-Central Link,

Central Kowloon Route and Kai Tak

Approach Channel in close proximity of the

DCS pipelines which are the constraints in

laying the DCS pipes.

The DCS chilled water pipes are

pre-fabricated with a pair of leakage

detection cables secured externally at 4

oclock and 8 oclock positions of the

pipeline, then annular insulated with

polyurethane foam and protected in an

extruded high density polyethylene (HDPE)

outer jacket. Polyurethane insulation

together with HDPE outer jacket are

considered with good thermal insulation

performance, mechanically stable and close

structure which provide good resistance to

moisture penetration for direct buried

application.

There are about 11 sections of DCS

pipelines to be constructed with trenchless

method at KTD, where open trench

excavation method is not practical or the

space required for laying of DCS pipes

above the existing structure is inadequate. In

which, about 1km of DCS pipes are

constructed or will be constructed by

heading method or hand dug tunnel. Over

5km of DCS pipes are constructed or will be

constructed by pipe jacking method with the

use of tunnel boring machines (TBMs). The

largest TBM size is 2,800mm in diameter

which is the largest one ever used in pipe

jacking in Hong Kong.

As most of the DCS pipelines are laid

underground, water leakage detection cables

fixed on the chilled water pipes allow

monitoring the condition of pipes

continuously and give early warning of any

water leakage. On site, leakage detection

panels are installed at an interval of

approximate 1.5 kilometres of pipe run to

In order to have smooth construction of

pipe

laying

works,

considerable

pre-construction precautionary measures to

identify the actual underground conditions

and to determine the appropriate type of

trenchless excavation method are necessary.

3

twice a day before and after any jacking

works. The alarm-alert-action (3As)

measures are adopted in ground movement

monitoring.

In view of this, the following measures will

be carried out before construction.

a.

Sufficient trial pits to expose and

verify the existence, extent, location

and elevation of all underground

utilities, natural or man-made

obstructions and structure; and

6.

AND

The cooling energy required by each

consumer building will be transferred from

the DCS to the individual buildings central

air-conditioning system via plate type heat

exchangers installed inside the substation of

the consumer buildings. The primary side of

the heat exchanger is connected to the DCS

distributing chilled water pipes and the

secondary side is connected to the

consumers chilled water system pipework.

b. Suitable underground detection

equipment are used to locate

underground utilities; to further

check the underground conditions

along the proposed pipe jacking

route; and to assess the feasibility

of the proposed route, locations and

inverts of jacking and receiving

pits.

The formation level of the Kai Tak

Development is generally at +5.0mPD

whilst the mean sea level in 50 year return

period is approximately +3.5mPD. As some

of the pipelines and excavation pits are as

low as (-)2mPD to (-)4mPD, the chance of

seepage of underground water is high. For

open trench excavation, the toe-in of the

sheet-pile wall need to be carefully

determined to prevent the inflow of

underground water from the bottom of the

trench. Installing grout curtain to control

groundwater inflow into the excavation, as

well as dewatering from inside the

cofferdam excavation for all excavation

levels are required. For trenchless

excavation method, ground treatment need

to be carried out to control ground water

flows to stabilize ground prior excavation.

Figure 4 - Distribution of district cooling

services

Under normal operating conditions, the

designed chilled water supply and return

temperatures are as follows:a.

At the primary chilled water side of

the heat exchanger, i.e. DCS side:

Supply Temperature = 5

Return Temperature = 13

b. At the secondary chilled water side

of the heat exchanger, i.e. consumer

side:

Figure 3 - Grout curtain and dewatering

provided at deep open trench for pipe laying

Supply Temperature = 6

Return Temperature = 14

It is desirable for both the DCS plant

operator and the consumers to meet the

above design conditions in order to achieve

energy efficient DCS plant operation and

reliable chilled water supply to the

consumers.

Due to deep excavation and trenchless

excavation

construction

involved,

establishment of settlement control points

and survey of the existing ground levels are

required to be set up for close monitoring of

the underground condition. Measurements at

settlement points are carried out at least

Since the commencement of district

cooling services in 2013, in some

4

DCS

OPERATION

CHALLENGES

control mechanism could be implemented

by programmable logic controller (PLC) or

similar mechanism.

circumstances like low load condition, it is

noted that when the chilled water return

temperature at the consumer side fall below

14, the temperature difference (Delta-T)

at DCS side and consumer side are reduced.

Accordingly, the chilled water flow rate as

compared to the design flow rate for a given

cooling load demand has to be increased. As

a result, more pumping energy is consumed

and the system efficiency is adversely

affected.

7.

CHARGING PRINCIPLES

The public and private non-domestic

building owners or their authorized agents in

KTD who have central air-conditioning

system of their buildings being subscribed to

district cooling services are required to pay

the district cooling services charges to the

Government. The District Cooling Services

Bill is being introduced to the Legislative

Council in 2014-15 to set the tariff

mechanism and tariff rate.

In order to enhance the energy

efficiency of the DCS, the consumers are

recommended to incorporate the following

design features in their chilled water system

of the consumer side.

The district cooling services tariff is

proposed to be set out with the following

charging principles.

6.1 Variable Flow Chilled Water

Variable flow chilled water system

together with two-way equal percentage

control valves for controlling all air handling

units (AHU) and fan coil units (FCU) should

be adopted. Each control valve should be

capable of controlling the flow throughout

the entire range of designed operating

conditions of the equipment.

a.

The district cooling services tariff

should be set at a competitive

level comparable to the cost of

individual

water-cooled

air-conditioning systems (WACS)

using cooling towers which is one

of

the

most

cost-effective

air-conditioning systems available

in the market;

b.

Both the capital and operating

costs should be recovered from the

consumers over the project life

which is estimated to be 30 years

as taxpayers should not subsidize

such air-conditioning charges;

c.

Price stability could be achieved

under the proposed charging

mechanism; and,

d.

The proposed charging mechanism

should be a simple charging

regime with common charge rates

for all consumers regardless of

their load profiles.

6.2 Temperature Oriented Control

Operation of the control valves for

controlling the AHU/ FCU should make

reference to the Return Air Temperature

(RAT). Since RAT represents the actual heat

load from the building, adjusting the control

valve based on the RAT instead supply air

temperature or off-coil temperature could

maintain the designed chilled water Delta-T.

Figure 5 Return air temperature control on

air handling units

6.3 Interlocking Control Mechanism

When the status of the AHU/ FCU is off,

the associated control valves should also be

closed in order to save energy and enhance

the systems efficiency. Such interlocking

8.

5

KEY TARIFF COMPONENTS

progressively. It is expected that the whole

project will be completed around 2022 and

will achieve an estimated annual saving of

85 million kilowatt-hour (kWh) in electricity

consumption.

In line with international practices, the

proposed tariff of district cooling services

comprise two major components, namely the

capacity charge and consumption charge:8.1 Capacity Charge

The capacity charge serves to cover the

capital cost of the DCS plant and equipment

and operation and maintenance (O&M) cost.

The capacity charge will be levied according

to the contract cooling capacity, which will

be determined by the consumer and agreed

by EMSD before the commencement of

district cooling services.

8.2 Consumption Charge

The consumption charge will be levied

to cover costs that will vary according to the

demand of the consumer. The major part of

the charge is the utility cost such as

electricity used to generate chilled water

being delivered to the consumer.

9.

TARIFF

MECHANISM

ADJUSTMENT

Having regard to the composition of the

two charges, the capacity charge rate is

proposed to be adjusted annually based on

the Composite Consumer Price Index while

the consumption charge rate is proposed to

be adjusted annually to take into account of

the change in electricity tariff rate.

10. CONCLUSIONS

Subsequent

to

the

project

commencement in early 2011 and the

completion of the early phases of the project,

the DCS at KTD has been providing

services to consumer buildings including

Kai Tak Cruise Terminal and Ching Long

Shopping Centre in the public rental housing

since 2013. The construction of the

remaining phase of the DCS project is in

progress and will be completed along with

the growing needs of air-conditioning of the

new buildings which are coming up

6

Figure 1 - Kai Tak DCS

D North Plant

P

Figure 2 - Prefabricated chilleed water pip

pe with leakage detectioon cables an

nd

polyureethane insullation with HDPE outeer jacket

Figure 3 - Grout

G

curtain

n and dewaatering provided at deep

p open trencch for pipe laying

ConsumerBuilding

CoolingSo

ource

(DCS Planttroom

)

Conssumer

Substtation

Heat Exchanger

(Insid

deBuilding)

To/From

mother

consum

mers

Distribution System

Figure 4 Distribuution of distrrict cooling services

Figgure 5 Retturn air tem

mperature co

ontrol on air handling u nits

Potrebbero piacerti anche

- Project Case Study: Musheireb Heart of Doha - DCPDocumento5 pagineProject Case Study: Musheireb Heart of Doha - DCPatiqulaNessuna valutazione finora

- IMPULSE District Cooling SystemDocumento41 pagineIMPULSE District Cooling SystemAshique Muhammed T MNessuna valutazione finora

- Evapco CatalogDocumento8 pagineEvapco Catalogcefa84Nessuna valutazione finora

- Thermal Energy Storage Tank DesignDocumento21 pagineThermal Energy Storage Tank DesignMuhammad MashhoodNessuna valutazione finora

- Stratified TES Tank ReportDocumento8 pagineStratified TES Tank ReportSomnath RangrejNessuna valutazione finora

- System Series - 04 Ice Storage System PDFDocumento121 pagineSystem Series - 04 Ice Storage System PDFpal_stephenNessuna valutazione finora

- 1289-Hari Prastowo-#2 Pipes Class & Thickness (Rev) Hand-OutDocumento17 pagine1289-Hari Prastowo-#2 Pipes Class & Thickness (Rev) Hand-OutSupriadi TansiNessuna valutazione finora

- MPD Dhs 1400 RCDDocumento2 pagineMPD Dhs 1400 RCDali_yy2003Nessuna valutazione finora

- Sea - TECH NC 16ADocumento32 pagineSea - TECH NC 16AReach HomeNessuna valutazione finora

- Waterinpipes FreezingDocumento12 pagineWaterinpipes FreezingWilliam IvansNessuna valutazione finora

- JT Assembly English A4Documento2 pagineJT Assembly English A4HectorNessuna valutazione finora

- Course O-5003 Centrifugal Pump Analysis For Petroleum ApplicationsDocumento70 pagineCourse O-5003 Centrifugal Pump Analysis For Petroleum ApplicationsPok Jak Salleh100% (1)

- Maintenance and Operation Manual Hydraulic Choke and Control ConsoleDocumento42 pagineMaintenance and Operation Manual Hydraulic Choke and Control ConsoleMehdi Hajd KacemNessuna valutazione finora

- Well Stimulation VesselDocumento8 pagineWell Stimulation VesselHossein ramezaniNessuna valutazione finora

- Design Gas LiftDocumento5 pagineDesign Gas LiftRima Apriani JamilahNessuna valutazione finora

- Cyclo TechDocumento27 pagineCyclo TechAli AliievNessuna valutazione finora

- Orifice Plate Calculator Flow Rate Pressure DropDocumento3 pagineOrifice Plate Calculator Flow Rate Pressure Dropredroom31100% (1)

- 1 - 5 Well Test Equipment 26.03.2015Documento49 pagine1 - 5 Well Test Equipment 26.03.2015Lakshman Kumar JulapalliNessuna valutazione finora

- Long Line Application CARRIER-R22Documento52 pagineLong Line Application CARRIER-R22Bruce OreNessuna valutazione finora

- SWT PreSolidsSeparation H011840 A4Documento2 pagineSWT PreSolidsSeparation H011840 A4slbclqrkNessuna valutazione finora

- Mueller Accu Therm PHEDocumento11 pagineMueller Accu Therm PHEAndiniPermanaNessuna valutazione finora

- Hybrid Ejector Refrigeration SystemDocumento17 pagineHybrid Ejector Refrigeration SystemAbhishek KumarNessuna valutazione finora

- Controlmanual HoneywellDocumento903 pagineControlmanual HoneywellDũng Nguyễn ThếNessuna valutazione finora

- Manual Tecnico - Primary Secondary PumbingDocumento54 pagineManual Tecnico - Primary Secondary Pumbingcarmen hernandezNessuna valutazione finora

- Method For Estimating Energy Savings Potential of Chilled-Water Plant Retro-CommissioningDocumento13 pagineMethod For Estimating Energy Savings Potential of Chilled-Water Plant Retro-CommissioningjoasobralNessuna valutazione finora

- Chiller Efficiency ConversionDocumento3 pagineChiller Efficiency Conversionsujan1980Nessuna valutazione finora

- District CoolingDocumento8 pagineDistrict Coolingmsn20091Nessuna valutazione finora

- Thermal Energy Storage TankDocumento24 pagineThermal Energy Storage Tankfahimafroz0% (1)

- Air RecieverDocumento9 pagineAir RecieverMichael Belmonte UrdanetaNessuna valutazione finora

- Industrial Energy Efficiency: Fast, Simple, ProvenDocumento77 pagineIndustrial Energy Efficiency: Fast, Simple, ProvenLim BrandonNessuna valutazione finora

- Petronas Pressol: Premium Grade Air Compressor OilsDocumento1 paginaPetronas Pressol: Premium Grade Air Compressor OilsMujeeb SiddiqueNessuna valutazione finora

- WCFX-E Series Water Chillers 70-1000 TRDocumento36 pagineWCFX-E Series Water Chillers 70-1000 TRhjmmNessuna valutazione finora

- Benefits of District CoolingDocumento13 pagineBenefits of District CoolingsyedahmedsabirNessuna valutazione finora

- QBH Ram Bop'S: 4-1/16" 15,000 Psi WPDocumento32 pagineQBH Ram Bop'S: 4-1/16" 15,000 Psi WPjuan olarte0% (1)

- JT Assembly English A4Documento2 pagineJT Assembly English A4kutikuppalaNessuna valutazione finora

- F Series - Floating Ball ValvesDocumento8 pagineF Series - Floating Ball ValvesCarlos Alberto Aguilera MendezNessuna valutazione finora

- Pre-Recorded Information: X X X X XDocumento3 paginePre-Recorded Information: X X X X XOscar BustosNessuna valutazione finora

- Model 5 Operating and Maintenance Manual - Low Water VolumeDocumento120 pagineModel 5 Operating and Maintenance Manual - Low Water VolumeJuan C FrancoNessuna valutazione finora

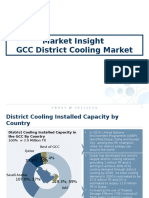

- Market Insight - District Cooling Market in GCCDocumento8 pagineMarket Insight - District Cooling Market in GCCAnonymous VovdmoI1y100% (1)

- Heating, Ventilating, Air ConditioningDocumento226 pagineHeating, Ventilating, Air Conditioningtacoma47Nessuna valutazione finora

- Sandface ScreenDocumento1 paginaSandface ScreenMoujahed FarésNessuna valutazione finora

- Cool Thermal Energy StorageDocumento3 pagineCool Thermal Energy StorageChloe WongNessuna valutazione finora

- Design of High Rate Blender Hydraulic Power Pack UDocumento9 pagineDesign of High Rate Blender Hydraulic Power Pack UShahab AliNessuna valutazione finora

- TESDocumento4 pagineTESkgaria79Nessuna valutazione finora

- Freezing Time 18-Inch Steel PipeDocumento3 pagineFreezing Time 18-Inch Steel Pipebrock100% (1)

- MHOD District Cooling - Arup 29-09-2011Documento52 pagineMHOD District Cooling - Arup 29-09-2011Mrityunjay MallikNessuna valutazione finora

- Fuel Oil SystemDocumento1 paginaFuel Oil SystemMuhammadMahfudNessuna valutazione finora

- Refrigerated CondensersDocumento29 pagineRefrigerated CondensersTRIQUERENessuna valutazione finora

- ASHRAE Journal SaveChillerPlantEnergyWithGuideline22 2008 - Feb 2010Documento4 pagineASHRAE Journal SaveChillerPlantEnergyWithGuideline22 2008 - Feb 2010WahidHamed100% (3)

- Shale Gas MaterialsDocumento502 pagineShale Gas MaterialsJaneColesNessuna valutazione finora

- District Cooling 2010Documento29 pagineDistrict Cooling 2010aviruch100% (1)

- Pumphouse: Station Design and LayoutDocumento34 paginePumphouse: Station Design and LayoutAswindana Ibnu SenaNessuna valutazione finora

- FIB Full Paper Final Rev1Documento9 pagineFIB Full Paper Final Rev1Anonymous cPhfqzNessuna valutazione finora

- Efficient DCS Options for Waste Heat Recovery, Combined Heat and Power, Free Cooling and Lake Source CoolingDocumento3 pagineEfficient DCS Options for Waste Heat Recovery, Combined Heat and Power, Free Cooling and Lake Source CoolingPriyanka ChadhaNessuna valutazione finora

- Guidelines for Building Power DistributionDocumento33 pagineGuidelines for Building Power DistributionMD Irshad AnsariNessuna valutazione finora

- OTC 15191 Case History of A 5 Zone Multi-Drop Hydraulic Control Intelligent Offshore Completion in BruneiDocumento7 pagineOTC 15191 Case History of A 5 Zone Multi-Drop Hydraulic Control Intelligent Offshore Completion in BruneihuongvieteventNessuna valutazione finora

- Mini ProDocumento26 pagineMini ProMurali KodamNessuna valutazione finora

- OTC 21382 Marginal Fields: Technology Enables Profitability / Marginal Fields and Their ChallengesDocumento7 pagineOTC 21382 Marginal Fields: Technology Enables Profitability / Marginal Fields and Their ChallengesFalokid RaboNessuna valutazione finora

- THERMOPLASTIC COMPOSITE PIPEDocumento11 pagineTHERMOPLASTIC COMPOSITE PIPERenanNessuna valutazione finora

- Mech 226 Exercise 3 Construction Green RoofsDocumento2 pagineMech 226 Exercise 3 Construction Green RoofsCarter FangNessuna valutazione finora

- Ductile Iron Pipe GuideDocumento12 pagineDuctile Iron Pipe GuidegaryckfanNessuna valutazione finora

- Steel Mains HandbookDocumento20 pagineSteel Mains HandbookgaryckfanNessuna valutazione finora

- FCDocumento8 pagineFCgaryckfanNessuna valutazione finora

- Cecs18 (2005)Documento58 pagineCecs18 (2005)garyckfanNessuna valutazione finora

- HVAC Coil Design Software for Wet and Dry CoilsDocumento5 pagineHVAC Coil Design Software for Wet and Dry CoilsgaryckfanNessuna valutazione finora

- Zone First) Zoning Design and Application GuideDocumento8 pagineZone First) Zoning Design and Application GuideSuat YilmazNessuna valutazione finora

- 13-Adv Materials Technologies - 2018 - Goh - Recent Progress in Additive Manufacturing of Fiber Reinforced Polymer CompositeDocumento22 pagine13-Adv Materials Technologies - 2018 - Goh - Recent Progress in Additive Manufacturing of Fiber Reinforced Polymer CompositeMuhammad TouheedNessuna valutazione finora

- Ritter Solar GMBH & Co. KGDocumento30 pagineRitter Solar GMBH & Co. KGMagdyNessuna valutazione finora

- Exhaust Pressure GovernorDocumento25 pagineExhaust Pressure GovernorHamilton MirandaNessuna valutazione finora

- Design of Sewer SystemDocumento8 pagineDesign of Sewer Systemknight912Nessuna valutazione finora

- 224 enDocumento1 pagina224 encvijo31Nessuna valutazione finora

- PIP STE05121 - Anchor Bolt Design GuideDocumento55 paginePIP STE05121 - Anchor Bolt Design Guidenistiana100% (4)

- Architecture March 2017Documento19 pagineArchitecture March 2017ArtdataNessuna valutazione finora

- Livorsi TTK1150EL TTK1050EL TTK1025EL TTK975EL TTK950EL TTK850EL TTK750EL Trim Tab With Electronic Sensors Installation Manual ENDocumento16 pagineLivorsi TTK1150EL TTK1050EL TTK1025EL TTK975EL TTK950EL TTK850EL TTK750EL Trim Tab With Electronic Sensors Installation Manual ENTerrence JonesNessuna valutazione finora

- Review of Specifications and Plan DetailsDocumento35 pagineReview of Specifications and Plan DetailsBondoc, Miles Jerome Z.Nessuna valutazione finora

- CKE6150 Spare Parts ManualDocumento74 pagineCKE6150 Spare Parts ManualVanessa RiveraNessuna valutazione finora

- Aipi - 03 02 018Documento57 pagineAipi - 03 02 018Kenan Sofu100% (3)

- The Ottoman Mosques in Macedonia: ZORAN PAVLOV, Art HistorianDocumento8 pagineThe Ottoman Mosques in Macedonia: ZORAN PAVLOV, Art HistorianZoran PavlovNessuna valutazione finora

- 32crmov12-10 : Steel GradeDocumento5 pagine32crmov12-10 : Steel Gradereza haghjooNessuna valutazione finora

- CHPB - Prospectus 2021Documento35 pagineCHPB - Prospectus 2021Madusanka WeebeddaNessuna valutazione finora

- Revit-MEP-HVAC-HYDRONIC PIPINGDocumento206 pagineRevit-MEP-HVAC-HYDRONIC PIPINGRagul0042100% (1)

- Bengalarchitecture 151030181750 Lva1 App6891Documento21 pagineBengalarchitecture 151030181750 Lva1 App6891Niriksha ShettyNessuna valutazione finora

- Bore LogDocumento4 pagineBore LogVardhanNessuna valutazione finora

- Chapter8 - Design Theory & Procedure PDFDocumento407 pagineChapter8 - Design Theory & Procedure PDFJunwhan KimNessuna valutazione finora

- Ingersoll Rand AC185D Operators ManualDocumento284 pagineIngersoll Rand AC185D Operators ManualAntonio Carrion100% (2)

- Horizontal & Extended Reach WellsDocumento18 pagineHorizontal & Extended Reach WellsRachid Touati100% (6)

- PAS 8810 2016 Tunnel Design Code of PracticeDocumento96 paginePAS 8810 2016 Tunnel Design Code of PracticeSérgio Bernardes86% (7)

- Fastenings For The Rehabilitation of Historical Structures-Abstract Standard FormatDocumento2 pagineFastenings For The Rehabilitation of Historical Structures-Abstract Standard FormatRay RamiloNessuna valutazione finora

- Catalogue Tylo Sauna RoomsDocumento28 pagineCatalogue Tylo Sauna RoomsVictor NguyễnNessuna valutazione finora

- Technical: ManualDocumento24 pagineTechnical: ManualRytis AmbrasasNessuna valutazione finora

- 1 PDFDocumento85 pagine1 PDFtim winkelmanNessuna valutazione finora

- Under Floor Insulation System: CompliesDocumento4 pagineUnder Floor Insulation System: CompliesJohn LiebermanNessuna valutazione finora

- Subsea Pipeline Engineering (Indonesia) - ElisaDocumento5 pagineSubsea Pipeline Engineering (Indonesia) - ElisaMheErdiantoNessuna valutazione finora

- Do CSG 25 Sep 2023Documento3 pagineDo CSG 25 Sep 2023cahbagus1267Nessuna valutazione finora

- 13 CIR VS MARUBENI (2001) G.R. No. 137377Documento12 pagine13 CIR VS MARUBENI (2001) G.R. No. 137377JanMarkMontedeRamosWongNessuna valutazione finora

- Ch17 ArchesDocumento45 pagineCh17 ArchesErnie ErnieNessuna valutazione finora