Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hand Valves

Caricato da

Uzma HudliDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hand Valves

Caricato da

Uzma HudliCopyright:

Formati disponibili

VALVES

69

HERMETIC VALVES

APPLICATIONS

Hermetic valves are used in

systems operating with

hermetic compressors.

They can be used with

refrigerant fluids CFC, HCFC

and HFC.

These valves are available in

the following types:

shut-off valves with

2 connections: 6010/2 and

6012/22;

valves with 3 connections

(2 connections + 1

charging/manometer

connection): 6020;

monobloc valves with

3 connections (2 connections

+ 1 charging/manometer

connection):

6060, with right charging

connection;

6070, with left charging

connection.

The charging connection is shut

off by the back-seating of the

spindle.

MATERIALS

The materials used for the main

parts are:

ST-UNI EN 12165 - CW 617 N

hot-forged brass for the main

body;

especially treated steel for

the spindle;

aramidic and chloroprene

gaskets for the gland seal;

glass reinforced PBT for the

cap.

6010/2

6020

70

6010/2

6012/22

6060

6070/23M10

6070

6010/2

6012/22

1/4 1/4

1/4

Solder

[in.]

[mm]

MAX

pressure

Catalogue

Number

kv

Factor

TABLE 1 - General Characteristics

Connections

SAE flare

Fluid

Temperature

[C]

[m /h]

[bar]

min.

max

Dimensions [mm]

H1

H2

L1

L2

14

66

36

58

160

36

29

55,5

145

0,27

1/4

0,27

14

66

60 +130

H3

H4

H5

Weight

[g]

L3

P1

6020/222

1/4 1/4 1/4

0,39

25

51

61

115

62

360

6020/233

1/4 3/8 3/8

1,20

25

51

61

115

67

370

6020/244

1/4 1/2 1/2

2,20

26,5

52

68,5 127

77

520

26,5

52

68,5 127

79

530

30

6020/255

1/4 5/8 5/8

2,80

6060/22M6

1/4 1/4

0,46

6070/23M8

1/4 3/8

1,29

33,5 25,5

6070/23M10 1/4 3/8

10

1,38

6070/24M12 1/4 1/2

12

6070/25M16 1/4 5/8

16

60 +120

31

25,5 56,5

24

34

92

30,5 205

59

27

37

90

30,5 210

33,5 25,5

59

27

37

90

30,5 220

2,55

38,5 29,5

68

28

43,5 102 32,5 310

3,40

39,5 29,5

69

28

43,5 102 32,5 320

71

RECEIVER VALVES

APPLICATIONS

6120/33

Castel receiver valves can be

used for liquid receivers of

refrigerating systems operating

with refrigerant fluids CFC,

HCFC and HFC.

CONSTRUCTION

6110, 6120 and 6132 valves

have 90 angle connections.

6140 receiver valves have

connections at 120.

Type 6132 also has an

additional male connection

which can be closed by the

back seating of the spindle.

The materials used for the main

parts are:

ST-UNI EN 12165 - CW 617 N

hot-forged brass for the main

body;

especially treated steel for

the spindle;

aramidic and chloroprene

gaskets for gland seal;

reinforced glass PBT for cap.

6120

72

6110

TABLE 1 - General Characteristics

Catalogue

Number

Charging

Connections

SAE

Connections

SAE

flare

flare

kv

Factor

MAX

Pressure

[m /h]

[bar]

NPT

Fluid

Temperature

[C]

H1

H2

L1

1/4

1/4

0,44

72

48

27,5

110

6110/23

1/4

3/8

0,45

77

50

29

135

6110/32

3/8

1/4

1,35

77

50

31

130

6110/33

3/8

3/8

1,35

77

50

31

140

6110/43

1/2

3/8

2,40

88

55,5

34,5

220

6110/44

1/2

1/2

3,40

92

55,5

34,5

235

6110/54

5/8

1/2

3,30

92

55,5

34,5

245

6110/66

3/4

3/4

6,00

128

88

42,5

675

6120/22

1/4

1/4

0,44

6120/23

1/4

3/8

0,45

6120/33

3/8

3/8

6120/43

1/2

6120/44

60

max

Weight

[g]

6110/22

min

Dimensions

[mm]

+130

L2

27,5

72

48

110

30

77

50

130

1,35

30

80

50

140

3/8

2,40

30

93

55,5

225

1/2

1/2

2,40

33

93

55,5

305

6120/54

5/8

1/2

3,30

33

94

55,5

245

6120/66

3/4

3/4

6,00

40

129,5

88

670

56

29

94

64

240

56

29

97

64

250

6132/22

1/4

1/4

1/4

0,45

6132/33

1/4

3/8

3/8

1,20

30

60

+120

6132/44

1/4

1/2

1/2

2,20

63,5

36

114,5

77,5

375

6132/54

1/4

5/8

1/2

3,85

63,5

36

117,5

77,5

365

1/4

1/4

0,36

57

69

46

115

57

69

46

125

6140/22

60

6140/23

6132

1/4

3/8

0,36

+130

6140

73

STOP VALVES

6165/33

APPLICATIONS

6175/33

6165, 6175 and 6170 stop

valves are specially designed

for application on split air

conditioners.

They can be used with

refrigerant fluids CFC, HCFC

and HFC.

CONSTRUCTION

The very compact design of

these brass valves allows

minimum dimensional sizes and

the fixing flange complies with

current market requirements.

Valves 6170 and 6175 must be

completed with valve core

8394/A or 8394/B and cap and

gasket type 8392/A, to be

ordered separately.

The materials used for the main

parts are:

ST-UNI EN 12165 - CW 617 N

hot-forged brass for the

body;

TN-UNI EN 12164 - CW 614 N

brass for spindle and cap;

chloroprene rubber (CR) for

outer seal gaskets.

Only for the 6170 group of

valves, aramidic and

chloroprene gaskets for the

gland seals.

6165

6170

6175

TABLE 1 - General Characteristics

kv

Factor

SAE

flare

SAE

flare

MAX

Pressure

Charging

connections

[in.]

[mm]

[m /h]

[bar]

1/4

1/4

6165/33

3/8

3/8

6175/33

1/4

3/8

6175/44

1/4

Catalogue

Number

Way

6165/22

Connections

ODS

Fluid

Temperature

[C]

H1

H2

max

0,68

17

1,70

3/8

1,70

1/2

1/2

3,40

1/4

5/8

5/8

16

1/4

3/4

3/4

H3

Weight

[g]

L1

L2

L3

52

29

113

17

52

30,5

120

17

52

30,5

29

59,5

20

65

36

31

67

225

4,60

20

65

36

31

67

235

9,00

28,5

104

47

36

83

min

Dimensions [mm]

I

6175/55

74

6170/66

30

20

+110

12

6170/77

1/4

7/8

7/8

10,80

28,5

104

38

135

655

50

47

36

83

670

DIAPHRAGM VALVES

6210/4

APPLICATIONS

Castel diaphragm valves are

particularly suitable for use on

refrigerating systems operating

with refrigerant fluids CFC,

HCFC and HFC.

CONSTRUCTION

Diaphragm valves dont have

gland seal. External sealing is

ensured by thin metal discs

(diaphragms) ensuring hermetic

sealing of the area through

which the fluid flows.

The materials used for the main

parts are:

ST-UNI EN 12165 - CW 617 N

hot-forged brass for the body

and the cap;

nylon for the seat sealing

gasket;

harmonic steel for the spring.

SAE

NPT

flare

6210/2

1/4

ODS

[in.]

[mm]

6220/2

1/4

6210/3

3/8

MAX

Pressure

Catalogue

Number

kv

Factor

TABLE 1 - General Characteristics

Connections

Fluid

Temperature

[C]

[m3/h]

[bar]

min

max

Dimensions [mm]

d

0,28

H1

H2

L1

Weight

[g]

L2

36

58

68

54

200

53

195

74

325

61

300

1,00

6220/3

3/8

4,5

6210/4

1/2

52

78

1,30

6220/4

1/2

6210/5

5/8

72

335

53,5

38

70

305

78

340

71

300

98

655

1,80

6220/5

5/8

16

6210/6

3/4

6220/6

3/4

6220/7

7/8

6230/22

1/4

1/4

0,50

6230/33

3/8

3/8

1,40

6230/44

1/2

1/2

1,60

28

3,65

35

+ 90

6,2

60

86

1/4

0,35

6260/3

3/8

0,90

6260/4

1/2

1,35

50

580

645

82

34

280

82

37

86,5

4,5

92

94

52

6260/2

62,5

37

285

305

53,5

72

68

35

72

36

74

37

340

38

355

380

75

6210

6220

6260

6230

76

N.B. When the valve 6260 is closed, connections A-B are open

and C is stopped; when opened, all connections are open.

ROTALOCK VALVES

the spindle.

Couplings and gaskets have to

be ordered separately.

APPLICATIONS

Castel Rotalock valves can be

used for refrigerating systems

operating with refrigerant fluids

CFC, HCFC and HFC.

CONSTRUCTION

Rotalock valves can be

mounted with 7910 and 7990

gaskets, and ensure fast

installation and safe sealing.

Tightness is assured by the

torque of the ring on the

coupling. Before tightening it is

possible to turn the valve in

every direction. All Rotalock

valves have an additional male

connection which can be

excluded by the back sealing of

Valves

6310

6320

The materials used for the main

parts are:

for the valves:

ST-UNI EN 12165 - CW 617 N

hot-forged brass for the

main body;

especially treated steel for

the spindle and the ring;

aramidic and chloroprene

gaskets for the gland seal;

glass reinforced PBT for

cap.

for couplings:

steel for welding

for gaskets:

P.T.F.E.

Gasket

7990

Coupling

7910

6310/3

6310

6320

Catalogue

Number

Gasket

catalogue

number

kv

Factor

TABLE 1 - General Characteristics

Coupling

catalogue

number

Charging

connections

Connections

MAX

Pressures

SAE

flare

flare

[m3/h]

[bar]

1/4

1/4

SAE

Ring

Fluid

Temperature

[C]

[g]

H2

L1

L2

0,46

68,5

33,5

94

64

290

1/4

3/8 3/4 UNF 1,35

68,5

33,5

97

64

300

6310/4

1/4

1/2

1,35

68,5

33,5

97

64

300

6320/3

1/4

3/8

1,40

+120 69,5

34,5

97

64

330

1/4

1/2

6310/3

7910/6

7990/6

6320/4

7910/8

7990/8

30

60

max

Weight

H1

6310/2

min

Dimensions [mm]

3,10

72

36,5 114,5 77,5

400

1 UNS

6320/5

1/4

5/8

3,40

72

36,5 117,5 77,5

415

6320/6

1/4

3/4

3,40

72

36,5

425

118

77,5

77

CAPPED VALVES

APPLICATIONS

6410/4

Capped valves can be mounted

in any point of the refrigerating

system using refrigerant fluids

CFC, HCFC and HFC.

CONSTRUCTION

Capped valves consist of two

main parts: the body and the

spindle assembly.

The materials used for the main

parts are:

ST-UNI EN 12165 - CW 617 N

hot-forged brass for body;

especially treated steel for

spindle;

aramidic and chloroprene

gaskets for gland seal;

glass reinforced PBT for cap.

INSTALLATION

When mounting the 6420 valve,

the valve body must be

6410

78

soldered to the piping after

removal the spindle assembly.

6420

When the latter is repositioned,

the operation is completed.

TABLE 1 - General Characteristics

Connections

Catalogue

Number

6410/2

SAE Flare

male

female

[in.]

[mm]

1/4

kv

Factor

MAX

Pressures

[m3/h]

[bar]

Fluid

temperature

[C]

min

max

Dimensions [mm]

d

H1

H2

L1

Weight

[g]

L2

L3

P1

68

305

0,40

6420/2

1/4

57

300

6410/3

3/8

74

325

6420/3

3/8

61

305

6420/M10

10

61

305

6410/4

1/2

4,5 85,5 67 38 78

330

6420/M12

12

70

305

6420/4

1/2

6410/5

5/8

1,00

1,45

30

60

+120

70

305

78

330

1,70

6420/5

5/8

16

71

305

6410/6

3/4

98

695

6420/M18

18

92

700

6420/6

3/4

6,2 113 89,5 50 92

685

6420/M22

22

94

690

6420/7

7/8

94

690

6460/22A

1/4

1/4

3,50

0,35

4,5 85,5 67 38 97 34 51 35

395

6460/22A

79

GLOBE VALVES

APPLICATIONS

6510/9

Globe valves can be used on

refrigerating systems in order to

intercept the refrigerant fluids

CFC, HCFC and HFC.

CONSTRUCTION

Globe valves are manufactured

in two basic types: 6510 with

straight connections and 6530

with angle connections.

Valves 6520, which have

straight connections, are

supplied with flanges. In this

application, copper pipe is

soldered on a brass bush and

not directly on the valve.

Globe valves have large orifices

to keep the pressure drop to a

minimum. On the top of the

caps there is a square seat,

fitting it on the spindle it is

possible to use the cap as an

operating wrench.

The materials used for the main

parts are:

ST-UNI EN 12165 - CW 617 N

hot-forged brass for body,

plug and cap;

especially treated steel for

spindle;

aramidic and chloroprene

gaskets for gland seal;

chloroprene rubber (CR) for

outer seal gaskets;

P.T.F.E. for seat gasket.

80

6510

TABLE 1 - General Characteristics

Connections

Catalogue

Number

6510/M22

ODS

[in.]

[mm]

22

kv

Factor

MAX

Pressures

[m /h]

[bar]

Fluid

Temperature

[C]

min

Dimensions [mm]

max

H1

Weight

[g]

L

1415

7,1

6510/7

7/8

1420

22

6510/M28

94

136

28,5

100

60

28

1320

8,4

6510/9

1.1/8

6510/11

1.3/8

35

6510/13

1.5/8

1320

15,0

25

126

6510/M42

42

6510/17

2.1/8

54

40,0

6520/7

7/8

7,1

30

118

68

199

37

141

88

6520/9

1.1/8

8,4

6520/11

1.3/8

35

15

138

3620

215

42,5

173

104

136

28,5

170

60

94

35

126

166

34

185

68

24

138

199

37

217

88

5845

25

42

6520/17

2.1/8

54

6530/M22

22

3865

+100

4930

2150

30

6520/M42

1885

2280

23

1.5/8

34

3600

25

6520/13

166

5835

40,0

25

215

42,5

255

104

8705

1305

8,2

6530/7

7/8

1305

22

6530/M28

94

147

44,5

50

60

28

1240

9,1

6530/9

1.1/8

6530/11

1.3/8

35

6530/13

1.5/8

1240

18,7

25

126

165

52,5

59

68

1895

5165

38

6530/M42

42

6530/17

2.1/8

54

6520

30

48,5

138

238

65

86,5

104

5165

4900

6530

81

BALL VALVES

6590/M42

APPLICATIONS

6590 ball valves have been

exclusively designed and

manufactured for refrigerating

systems operating with

refrigerant fluids CFC, HCFC

and HFC.

CONSTRUCTION

The valve design ensures the

internal equilibrium of pressures

when the valve is closed,

permits the bi-directional flow

of the refrigerant and,

consequently, the assembly on

the plant without taking into

account the direction of the

refrigerant.

The assembling of the spindle

82

from the inside prevents any

risk of explosion.

The opening and closing of the

valve is realised by turning the

spindle one fourth of a turn.

A standstill in turning realises

either a full opening or a full

closing, moreover the arrow

printed on the spindle head

shows the flow direction.

Electric welding of the bodies

and O ring assembled on the

spindle prevent leaks.

The materials used for the main

parts are:

ST-UNI EN 12165 - CW 617 N

hot-forged brass for body;

ST-UNI EN 12165 - CW 617 N

chromium plated brass ball;

especially treated steel for

the spindle;

P.T.F.E. for ball gaskets;

chloroprene rubber (CR) for

outer seal gaskets;

solder copper connections;

glass reinforced PBT for cap.

TABLE 1 - General Characteristics

Connections

Catalogue

Number

6585/M6 (1)

ODS

[in.]

[mm]

Ball

port

kv

Factor

MAX

Pressure

[mm]

[m3/h]

[bar]

Fluid

Temperature [C]

min

max

Dimensions [mm]

A

Weight

[g]

F

260

0,8

6585/2 (1)

1/4

6590/3

3/8

260

265

3

6590/M10

10

6590/M12

12

6590/4

1/2

6591/5

5/8

16

6590/5

5/8

16

6590/M18

18

121

10

73

20

53

265

270

270

138

18

M5

285

380

141

15

14,5

390

80

24

56

6590/6

3/4

390

6591/7

7/8

22

177

400

6590/7

7/8

22

175

745

6591/M28

28

19

24

30

45

+150

95,5

27,5

68

760

206

6591/9

1.1/8

6590/M28

28

760

1000

206

6590/9

1.1/8

6591/11

1.3/8

35

6590/11

1.3/8

35

6591/13

1.5/8

6591/M42

42

6590/13

1.5/8

25

40

101,5

30

71,5

1000

248

1050

2000

32

68

247

117

38

79

2000

30

M6

2000

3100

262

6590/M42

42

6591/17

2.1/8

54

6590/17

2.1/8

54

38

2.5/8

130

45

85

292

3100

3150

5000

50

6591/21

100

178

303

150

55

95

5000

(1) Bodies without electric welding, chloroprene rubber (CR) for outer seal gasket.

83

COMPRESSOR VALVES

6640/4

APPLICATIONS

These valves are normally

mounted on the body of the

refrigerating compressor, on

both suction and discharge

sides. They can be used with

refrigerant fluids CFC, HCFC

and HFC.

CONSTRUCTION

Compressor valves have a

threaded connection that can

be used both as charging or

gauge connection. The

charging connection is cut off

by the back-seating of the

spindle. The compressor valves

are oval flanged with SAEFLARE connection to fit copper

pipes through a suitable nut.

6640

The materials used in the

construction of the main parts

are:

ST-UNI EN 12165 - CW 617 N

hot-forged brass for the

body, flange and bush;

especially treated steel for

the spindle;

aramidic and chloroprene

gaskets for the gland seal;

steel for the cap;

glass reinforced PBT for the

cap.

TABLE 1 - General Characteristics

Catalogue

Number

6640/3

Connections

SAE flare

Distance

between fixing

Flange

fixing

kv

Factor

MAX

Pressure

Fluid

Temperature

centers [mm]

[mm]

[m /h]

[bar]

[C]

3/8

Dimensions [mm]

D1

H1

H2

H3

2,33

Weight

[g]

L1

L2

36

110

395

38

112

405

42

116

420

42

116

440

-60

6640/4

1/2

2,85

4041

84

6640/5

5/8

9,5

30

3,50

14

15

52

58

+120

6640/6

3/4

3,70

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- El Bill PDFDocumento2 pagineEl Bill PDFvinodNessuna valutazione finora

- Navajo Hearing ProgramDocumento3 pagineNavajo Hearing Programjamesmith100000% (1)

- Small Gas Turbines 4 LubricationDocumento19 pagineSmall Gas Turbines 4 LubricationValBMSNessuna valutazione finora

- Consider Recycled Water PDFDocumento0 pagineConsider Recycled Water PDFAnonymous 1XHScfCINessuna valutazione finora

- Break Free - Nathaniel BrandenDocumento16 pagineBreak Free - Nathaniel Brandennbckudxtkudkuf50% (2)

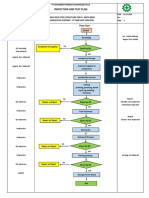

- Inspection and Test Plan: Flow Chart Start IncomingDocumento1 paginaInspection and Test Plan: Flow Chart Start IncomingSinden AyuNessuna valutazione finora

- Husqvarna 340/345/350 Operator's ManualDocumento47 pagineHusqvarna 340/345/350 Operator's ManualArtur MartinsNessuna valutazione finora

- Soil properties problemsDocumento2 pagineSoil properties problemsAldrin LampareroNessuna valutazione finora

- Evolution Chart 3Documento1 paginaEvolution Chart 3sasupraNessuna valutazione finora

- Baileys in 2009: Case Study Reference No 509-050-1Documento17 pagineBaileys in 2009: Case Study Reference No 509-050-1Ernesto KulasinNessuna valutazione finora

- Grade 9 P.EDocumento16 pagineGrade 9 P.EBrige SimeonNessuna valutazione finora

- INFORSHT Produktkatalog en Web 03.22Documento13 pagineINFORSHT Produktkatalog en Web 03.22lolNessuna valutazione finora

- Almond Milk Case Study Executive SummaryDocumento19 pagineAlmond Milk Case Study Executive Summarygauthamsindia307Nessuna valutazione finora

- Solucionario. Advanced Level.Documento68 pagineSolucionario. Advanced Level.Christian Delgado RamosNessuna valutazione finora

- Mole Concept: Chemfile Mini-Guide To Problem SolvingDocumento18 pagineMole Concept: Chemfile Mini-Guide To Problem SolvingNaren ParasharNessuna valutazione finora

- Limetas Maximos ResidualesDocumento27 pagineLimetas Maximos ResidualesXjoelx Olaya GonzalesNessuna valutazione finora

- PR Cuisine vs US CuisineDocumento2 paginePR Cuisine vs US CuisineJannette HernandezNessuna valutazione finora

- GDCR Final PDFDocumento311 pagineGDCR Final PDFHrushikesh PatelNessuna valutazione finora

- Ficha Tecnica StyrofoamDocumento2 pagineFicha Tecnica StyrofoamAceroMart - Tu Mejor Opcion en AceroNessuna valutazione finora

- Chambal Cable Stayed Bridge Connecting ShoresDocumento6 pagineChambal Cable Stayed Bridge Connecting Shoresafzal taiNessuna valutazione finora

- Generate Profits from Bottled Water Using Atmospheric Water GeneratorsDocumento20 pagineGenerate Profits from Bottled Water Using Atmospheric Water GeneratorsJose AndradeNessuna valutazione finora

- CanteenDocumento8 pagineCanteenmahesh4uNessuna valutazione finora

- Jee Main Sample Paper 5Documento19 pagineJee Main Sample Paper 5DavidNessuna valutazione finora

- Causes of DyspneaDocumento9 pagineCauses of DyspneaHanis Afiqah Violet MeowNessuna valutazione finora

- Euro 4 Standard PDFDocumento2 pagineEuro 4 Standard PDFCamellaNessuna valutazione finora

- Joyforce SDS - PVA Pellet - r2.ENDocumento3 pagineJoyforce SDS - PVA Pellet - r2.ENjituniNessuna valutazione finora

- Somali Guideline of InvestorsDocumento9 pagineSomali Guideline of InvestorsABDULLAHI HAGAR FARAH HERSI STUDENTNessuna valutazione finora

- Group 17-Solid State NMR - Questions-AnswersDocumento5 pagineGroup 17-Solid State NMR - Questions-AnswersOmkar AkulwarNessuna valutazione finora

- Company Law AssignmentDocumento5 pagineCompany Law AssignmentABISHEK SRIRAM S 17BLA1008Nessuna valutazione finora

- TESC CRC Office & Gym Roof Exterior PaintingDocumento6 pagineTESC CRC Office & Gym Roof Exterior PaintinghuasNessuna valutazione finora