Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Generador Cat 3512b

Caricato da

carlucido247970Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Generador Cat 3512b

Caricato da

carlucido247970Copyright:

Formati disponibili

3512B

Generator

Continuous Power

Set

1800 rpm

1230 kW 60 Hz

SPECIFICATIONS

V-12, 4-Stroke-Cycle Watercooled Diesel

Boremm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . 170 (6.7)

Strokemm (in) . . . . . . . . . . . . . . . . . . . . . . . . 190 (7.5)

DisplacementL (cu in) . . . . . . . . . . . . . . . 51.8 (3,158)

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . 14:1

Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CF-4

Shown with

Optional Equipment

FEATURES

CAT DIESEL GENERATOR SETS

Factory designed, certified prototype tested with

torsional analysis. Production tested and

delivered to you in a package that is ready to be

connected to your fuel and power lines. EPG

Designer computer sizing available. Supported

100% by your Caterpillar dealer with warranty on

parts and labor. Extended warranty available in

some areas. The generator set was designed

and manufactured in an ISO 9001 compliant

facility. Generator set and components meet or

exceed the following specifications: AS1359,

AS2789, ABGSM TM3, BS4999, DIN6271,

DIN6280, EGSA101P, JEM1359, IEC 34/1,

ISO3046/1, ISO8528, NEMA MG1-22.

CATERPILLAR SR4B GENERATOR

Type. . . . Brushless, revolving field, solid-state exciter

Construction . . . . . . . . . Single bearing, close coupled

Three phase . . . . . . . . . . . . . . . . . . . . . . Wye connected

Insulation . . . . . . . . . . . . . . Class H with tropicalization

..........................................................and antiabrasion

Enclosure . . . . . . . . . . . . . . . . . . . . . . . . Drip proof IP 22

Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pilot shaft

Overspeed capability . . . . . . . . . . . . . . . . . . . . . . . 150%

Wave form . . . . . . . . . . . . . . . . Less than 5% deviation

Paralleling capability. . . . . . . . . . . . . . . . . standard with

adjustable voltage droop

Voltage regulator . . . . . . . . . . . . . 3 phase sensing with

......................................................1:1 Volts-per-Hertz

Voltage regulation . . . . . . . . . . . . . . . Less than 1/2%

Voltage gain . . . Adjustable to compensate for engine

............................................speed droop and line loss

RELIABLE, FUEL EFFICIENT DIESEL

The compact, four-stroke-cycle diesel engine

combines durability with minimum weight while

providing dependability and economy. The fuel

system operates on a variety of fuels.

CATERPILLAR SR4B GENERATOR

Single bearing, wye connected, static regulated,

brushless permanent magnet excited generator

designed to match the performance and output

characteristics of the Caterpillar diesel engine

that drives it.

EXCLUSIVE CATERPILLAR

VOLTAGE REGULATOR

Three-phase sensing and 1:1 or 2:1 Volts per

Hertz regulation give precise control, excellent

block loading, and constant voltage in the normal

operating range.

TIF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Less than 50

THF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Less than 3%

CATERPILLAR CONTROL PANEL

24 Volt DC Control

Terminal box mounted

Vibration isolated

NEMA 1/IP 23 enclosure

Electrically dead front

Lockable hinged door

Generator instruments meet ANSI C-39-1

Voltages Available

60 Hz

380, 480, 600, and 4160

(Adjustable a minimum of 10%)

Other voltages available consult your Caterpillar dealer.

Some voltages require derating.

3512B

STANDARD EQUIPMENT

Engine

Aftercooler

Air cleaner

regular duty

Breather, crankcase

Cooler, lubricating oil

Exhaust fitting and flange

Filters, right hand

fuel and

lubricating oil

Flywheel housing

SAE No.00

standard rotation

Fuel System

electronic controlled

unit injectors

Governor

ADEM electronic

control

Manifold, exhaust, dry

Oil pan, shallow

Pumps,

fuel transfer;

aftercooler water,

jacket water,

and lubricating oil

gear driven

Radiator

Rails, mounting

Shutoff, manual

Starting, electric, 24 Volt DC

Turbochargers

Vibration damper

Generator

SR4B brushless

permanent magnet

excited with VR3

voltage regulator

Space heaters

ELECTRONIC MODULAR

CONTROL PANEL (EMCP)

Standard Generator

Controls and Monitoring:

Ammeter/voltmeter phase

selector switch

Digital ammeter, voltmeter,

and frequency meter

Voltage adjust rheostat

Standard Engine

Controls and Monitoring:

Automatic/manual

start-stop control

Engine control switch for:

off/reset, auto start,

manual start, stop,

cooldown timer,

cycle cranking,

emergency stop

pushbutton

Safety shutoff protection

and LED indicators for:

High coolant temperature

Low oil pressure

Overcrank

Overspeed

Emergency stop

pushbutton

Caterpillar EMCP II

Electronic Modular Control Panel

The Electronic Modular Control Panel (EMCP) is a

generator-mounted control panel, available on all

Caterpillar packaged generator sets. It utilizes

environmentally sealed, solid-state, microprocessorbased modules for engine control and AC metering.

This new application of mature, high-tech electronics to

generator monitoring provides more features, accuracy

and reliability than present electro-mechanical and

many competitive panel systems.

GENERATOR SET

OPTIONAL EQUIPMENT

Engine

Air cleaners

Charging systems

Cooling systems

fan drives, radiators,

fans, expansion tanks

Control systems

governor, Woodward

2301A load share

Exhaust system

fittings, elbows,

flanges, muffler

Lube system

Mounting systems

Protection devices

Starting system

Generator

Oversized generators

Manual voltage control

RFI Filters

N level (VDE 875),

BS800, MIL Std 461B

Digital voltage regulator

2:1 volts per hertz VR3

Control Panel

Attachments for EMCP:

Auxiliary relay

Enclosure,

NEMA 12/IP 44

Governor speed switch

Illuminating lights

Installed speed sensing

governor (Woodward)

Low coolant level

Provision for:

alarm module

NFPA 99

alarm module

NFPA 110

Reverse power relay

Starting aid switch

Synchronizing lights

The EMCP provides these standard control and

monitoring features, many of which are options on

other panels:

Automatic/manual start-stop engine control with

programmable safety shutdowns and associated

flashing LED indicators for low oil pressure, high

coolant temperature, overspeed, overcrank and

emergency stop

Cycle cranking adjustable 1-60 second

crank/rest periods

Cooldown timer adjustable 0-30 minutes

Energized to run or shutdown fuel control systems

LCD digital readout for: Engine oil pressure;

coolant temperature; engine rpm; system DC volts;

engine running hours; system diagnostic codes;

generator AC volts; generator AC amps; and

generator frequency

Engine control switch

Ammeter-voltmeter phase selector switch

Emergency stop pushbutton

Indicator/display test switch

Voltage adjust potentiometer

Rugged NEMA 1/IP 23 cabinet.

3512B

GENERATOR SET

TECHNICAL DATA

3512B Continuous Power Generator Sets 1800 RPM

Power Rating @ 0.8 PF without Fan

EkW

1230

Power Rating @ 0.8 PF without Fan

kVA

1538

Engine Rating without Fan

bhp

1784

Generator Frame Size

696

Engine Lubricating Oil Capacity Requires CF-4 Oil

qts

350

Engine Coolant Capacity without Radiator

gal

42

System Backpressure (Max Allowable)

in water

27

Exhaust Flange Size (Internal Diameter) (Dual)

in

Low Emissions Version

Lo BSFC

Coolant to Aftercooler Temperature (Max)

85

140

195

195

Length

in

211

211

211

212

Width

in

64

64

64

92

Height

in

93

93

93

102

Shipping Weight

lbs

25,450

25,450

25,450

26,150

Engine Coolant Capacity with Radiator

gal

71

71

71

101

Separate Circuit Aftercooler

Aftercooler Cooling Circuit

Aftercooler Pump Coolant Flow

at 20 feet water head

gal

gal/min

9

153

9

153

9

153

N/A

N/A

gal/hr

88.3

88.1

85.5

85.1

lb/hr

g/hr

15.6

7085

18.6

8455

29.3

13,295

31.8

14,405

gal/hr

66.5

66.9

67.7

64.1

lb/hr

g/hr

11.7

5325

13.9

6285

16.8

7640

25.7

11655

100% Load

Fuel Consumption (100% load) with Fan

per ISO3046/1: +5%, -0% tolerance

*NOx emissions at ISO standard conditions:

+ or - 15% tolerance

75% Load

Fuel Consumption (75% load) with Fan

per ISO3046/1: +5%, -0% tolerance

*NOx emissions at ISO standard conditions:

+ or - 15% tolerance

50% Load

Fuel Consumption (50% load) with Fan

per ISO3046/1: +5%, -0% tolerance

*NOx emissions at ISO standard conditions:

+ or - 15% tolerance

gal/hr

46.0

46.2

48.2

45.6

lb/hr

g/hr

8.9

4025

11.4

5180

10.0

4540

14.3

6485

Combustion Air Inlet Flow Rate

ft3/min

4335

4325

4015

3980

Exhaust Gas Flow Rate

ft3/min

10,770

10,950

10,655

10,545

Heat Rejection to Jacket Water

BTU/min

32,700

32,700

32,300

31,845

Heat Rejection to Aftercooler

BTU/min

22,635

19,280

14,785

13,705

Heat Rejection to Exhaust (total)

BTU/min

77,910

76,435

77,910

75,295

Heat Rejection to Atmosphere from Engine

BTU/min

3925

3925

3925

3925

Heat Rejection to Atmosphere from Generator

BTU/min

3325

3325

3325

3325

Exhaust Gas Stack Temperature

Deg F

799

845

895

891

Deration for Engine

Altitude 3% per 1000 feet above

ft

4840

3035

2135

2380

* Note: For permitting see TMI data.

3512B

GENERATOR SET

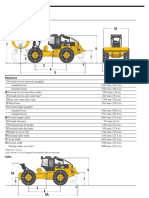

CONTINUOUS GEN SET PACKAGE TOP VIEW

02

Centerline of Engine

308 Oil Filter

03

Rear Face of Cylinder Block 401 Air Inlet

402 Exhaust

521 Conduit Entrance

520 Control and Power Panel

703 Customer Mounting Holes

For overall length see technical data section (page 3). Note: General configuration not to be used for installation.

See general dimension drawings for detail.

CONDITIONS AND DEFINITIONS

Continuous Output available without varying load

for an unlimited time. Continuous power in

accordance with ISO8528, ISO3046/1, AS2789,

DIN6271, and BS5514.

Ratings are based on SAE J1349 standard

conditions. These ratings also apply at ISO3046/1,

DIN6271, and BS5514 standard conditions.

Fuel rates are based on fuel oil of 35 API (16 C or

60 F) gravity having an LHV of 42 780 kJ/kg

(18,390 Btu/lb) when used at 29 C (85 F) and

weighing 838.9 g/L (7.001 lbs/U.S. gal.).

Lubricating oil requires CF-4 oil.

Additional ratings may be available for specific

customer requirements. Consult your Caterpillar

representative for details.

Materials and specifications are subject to change without notice.

LEHX5318 (5-95)

The International System of Units (SI) is used in this publication.

1995 Caterpillar

Printed in U.S.A.

Potrebbero piacerti anche

- Manual EA20S CaterpillarDocumento3 pagineManual EA20S CaterpillarHernán Peñafiel ReaNessuna valutazione finora

- Operation and Maintenance Manual: 3500B Series II and 3500C Marine Auxiliary EnginesDocumento136 pagineOperation and Maintenance Manual: 3500B Series II and 3500C Marine Auxiliary EnginesRuslanRumyantsev100% (1)

- Caterpillar C15 FTH000001Documento3 pagineCaterpillar C15 FTH000001Hendra MechanicNessuna valutazione finora

- DSE 7310 y 7320 USDocumento4 pagineDSE 7310 y 7320 USAngelo parraNessuna valutazione finora

- Operation and Maintenance Manual: 3406C Generator SetsDocumento168 pagineOperation and Maintenance Manual: 3406C Generator SetsJeneesh ShanmughanNessuna valutazione finora

- Marine Generator Set: 30.0 Ekw (60 HZ) at 1800 RPM 24.5 Ekw (50 HZ) at 1500 RPMDocumento2 pagineMarine Generator Set: 30.0 Ekw (60 HZ) at 1800 RPM 24.5 Ekw (50 HZ) at 1500 RPMByron CheleNessuna valutazione finora

- Tool Catalog P 4Documento15 pagineTool Catalog P 4cav4444Nessuna valutazione finora

- Motor Caterpillar 3512cDocumento16 pagineMotor Caterpillar 3512chugo1983100% (1)

- 03 Mechanical AdjustmentDocumento25 pagine03 Mechanical AdjustmentHải Lưu MinhNessuna valutazione finora

- Speed ControlDocumento7 pagineSpeed Controlayman akrabNessuna valutazione finora

- HC Tech ManualDocumento21 pagineHC Tech ManualparokotNessuna valutazione finora

- Instrument Panels For CENTRY™ and PT Marine EnginesDocumento12 pagineInstrument Panels For CENTRY™ and PT Marine EnginesjosephvanbacNessuna valutazione finora

- 3512 IND-C 1119bkWDocumento5 pagine3512 IND-C 1119bkWuripssNessuna valutazione finora

- Cat C32 ACERT Spec Sheet - CommercialDocumento13 pagineCat C32 ACERT Spec Sheet - CommercialMario Godoy100% (1)

- Testing For Excessive Cylinder Blowby in 3500 EnginesDocumento10 pagineTesting For Excessive Cylinder Blowby in 3500 EnginesPILAR MARTINEZNessuna valutazione finora

- ShutoffDocumento27 pagineShutoffSergio Andrés ArizaNessuna valutazione finora

- Nogva Marine Gearbox Ver.3.1Documento30 pagineNogva Marine Gearbox Ver.3.1cezar frasao67% (3)

- Engine specifications and maintenance proceduresDocumento7 pagineEngine specifications and maintenance proceduresAbel Alejandro Vera TriviñosNessuna valutazione finora

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Documento4 pagineDoosan Infracore Generator Engine: Ratings (KWM/PS)moisesNessuna valutazione finora

- Specsheet 3516 1825 kVA PrimeDocumento6 pagineSpecsheet 3516 1825 kVA PrimeYusman EkaNessuna valutazione finora

- Datasheet Stamford Alternator Hci544e 3 PhaseDocumento9 pagineDatasheet Stamford Alternator Hci544e 3 PhaseUjjal SarkarNessuna valutazione finora

- 974000-GENERIC - Trottle Position SenserDocumento7 pagine974000-GENERIC - Trottle Position SenserCarlos MataNessuna valutazione finora

- 3516C Marine Propulsion Engines PDFDocumento3 pagine3516C Marine Propulsion Engines PDFJose RoaNessuna valutazione finora

- 300-5617 Cooler Parts 2Documento2 pagine300-5617 Cooler Parts 2harikrishnanpd3327Nessuna valutazione finora

- FDocumento66 pagineFpandunugraha04Nessuna valutazione finora

- Renr5076 10 00 AllDocumento2 pagineRenr5076 10 00 AllAhmed MoustafaNessuna valutazione finora

- Technical Analysis of Kort Nozzle Application ForDocumento7 pagineTechnical Analysis of Kort Nozzle Application ForMuhammad KamranNessuna valutazione finora

- Esab Edw 510D-3Documento2 pagineEsab Edw 510D-3Allia AliNessuna valutazione finora

- Cat 3512 Sensor PositionDocumento9 pagineCat 3512 Sensor PositionMahmoud AlaaNessuna valutazione finora

- GVSP Governor Spec ReportDocumento2 pagineGVSP Governor Spec ReportJohn100% (1)

- Cat 3512C: Diesel Generator SetsDocumento4 pagineCat 3512C: Diesel Generator SetsJavier Delgado Rodríguez100% (1)

- Emcp II 3500b EngineDocumento10 pagineEmcp II 3500b Engineminhduc110100% (3)

- Valve Mechanism: Shutdown SISDocumento3 pagineValve Mechanism: Shutdown SISMoslem KhanlarpourNessuna valutazione finora

- 9 - Gas A&I G3500-G3300 Ignition, Starting and Engine Protection SystemsDocumento37 pagine9 - Gas A&I G3500-G3300 Ignition, Starting and Engine Protection Systemsosama100% (2)

- REHS4494-02 - Special InstructionDocumento12 pagineREHS4494-02 - Special InstructionmanuelNessuna valutazione finora

- Grupos Electronicos Diesel Cat 3512b 1360ekw Prime Lowbsfc PDFDocumento6 pagineGrupos Electronicos Diesel Cat 3512b 1360ekw Prime Lowbsfc PDFJesus AndradeNessuna valutazione finora

- BEVI Electrical Motor Manual enDocumento28 pagineBEVI Electrical Motor Manual enАндрейNessuna valutazione finora

- Tad 1641 GeDocumento2 pagineTad 1641 GeGiangDoNessuna valutazione finora

- Generator Bearing ServiceDocumento10 pagineGenerator Bearing ServiceMustafa A.W100% (1)

- HRP Thruster Systems: Instruction Manual ForDocumento28 pagineHRP Thruster Systems: Instruction Manual ForMustafa GözütokNessuna valutazione finora

- Caterpillar 3412 Marine Engine Details, Specs, Features & ExtrasDocumento5 pagineCaterpillar 3412 Marine Engine Details, Specs, Features & ExtrasTobias BengtsenNessuna valutazione finora

- Satellite Buoy Catalogue PDFDocumento2 pagineSatellite Buoy Catalogue PDFBenjy SmithNessuna valutazione finora

- 3512 Techdoc - Print - PageDocumento4 pagine3512 Techdoc - Print - Pagefromgod83100% (1)

- Catalogo de GeneradoresDocumento56 pagineCatalogo de GeneradoresNimrod TorrezNessuna valutazione finora

- CAT-Generator Maintenance InformationDocumento2 pagineCAT-Generator Maintenance Informationmehdi kamali0% (1)

- 3512C Oil Well Servicing EngineDocumento16 pagine3512C Oil Well Servicing EngineMaxiNessuna valutazione finora

- Weidmuller Analog Signal ConditionersDocumento65 pagineWeidmuller Analog Signal ConditionersCem AlpaslanNessuna valutazione finora

- MAN D2876 Medium Duty Marine EnginesDocumento4 pagineMAN D2876 Medium Duty Marine Enginesfajar saputra100% (1)

- 3412C 680kvaDocumento7 pagine3412C 680kvaHarry King Corral AvenidoNessuna valutazione finora

- Woodward GovernorDocumento5 pagineWoodward Governorveer_s100% (2)

- Module Converter PWMDocumento5 pagineModule Converter PWMJUAN JOSE VESGA RUEDANessuna valutazione finora

- Sebu6100-02 MDocumento74 pagineSebu6100-02 MSa CruCerNessuna valutazione finora

- Deflexión de CigueñalDocumento21 pagineDeflexión de CigueñalCatalina HuenumanNessuna valutazione finora

- Rodamientos de Alternadores CAT GILBERTO PANTOJADocumento16 pagineRodamientos de Alternadores CAT GILBERTO PANTOJAGilberto PantojaNessuna valutazione finora

- Engine Valve LashDocumento3 pagineEngine Valve LashImron Alif100% (3)

- Grupos Electronicos Diesel Cat n3306 225ekw PrimeDocumento4 pagineGrupos Electronicos Diesel Cat n3306 225ekw PrimejalexivanNessuna valutazione finora

- EPG CAT 3412 810 900 kVADocumento4 pagineEPG CAT 3412 810 900 kVAElad Shehori100% (1)

- Ficha Gerador Olympian GEP550Documento6 pagineFicha Gerador Olympian GEP550Geetha_jagadish30100% (1)

- 3412 Get Set SpecsDocumento4 pagine3412 Get Set Specslatranca100% (3)

- Garlock Blue Gard 3000 Data SheetDocumento1 paginaGarlock Blue Gard 3000 Data SheetMatheus TorresNessuna valutazione finora

- 793B V.S. 793CDocumento6 pagine793B V.S. 793Ccarlucido247970100% (1)

- Dimensions: GrappleDocumento3 pagineDimensions: Grapplecarlucido247970Nessuna valutazione finora

- Neumáticos Michelin XDRDocumento2 pagineNeumáticos Michelin XDRcarlucido247970Nessuna valutazione finora

- Neumáticos Michelin 44-80r57Documento4 pagineNeumáticos Michelin 44-80r57carlucido247970Nessuna valutazione finora

- Dimensions: GrappleDocumento3 pagineDimensions: Grapplecarlucido247970Nessuna valutazione finora

- Luces de Camiones CatDocumento6 pagineLuces de Camiones Catcarlucido247970Nessuna valutazione finora

- Salesgram: New Caterpillar 793C Modular Front EndDocumento2 pagineSalesgram: New Caterpillar 793C Modular Front Endcarlucido247970Nessuna valutazione finora

- Motor Cat C9-AcertDocumento4 pagineMotor Cat C9-Acertcarlucido247970100% (1)

- Motor Cat C7-AcertDocumento2 pagineMotor Cat C7-Acertcarlucido247970100% (2)

- G3304Documento8 pagineG3304carlucido247970Nessuna valutazione finora

- G3306Documento4 pagineG3306carlucido247970100% (1)

- Cat DEO: Caterpillar. The Difference CountsDocumento2 pagineCat DEO: Caterpillar. The Difference CountsMinaSaeedNessuna valutazione finora

- Motor Cat 3406-EDocumento2 pagineMotor Cat 3406-Ecarlucido247970100% (2)

- G3304BDocumento2 pagineG3304Bcarlucido247970Nessuna valutazione finora

- CuadrosDocumento1 paginaCuadroscarlucido247970Nessuna valutazione finora

- Decoder/Encoder ImplementationDocumento6 pagineDecoder/Encoder ImplementationLoers AntarioNessuna valutazione finora

- 15 Panel FabricationDocumento36 pagine15 Panel FabricationhkshahNessuna valutazione finora

- Mechanical Designer or PCB Designer or Electronics Packaging orDocumento4 pagineMechanical Designer or PCB Designer or Electronics Packaging orapi-121406632Nessuna valutazione finora

- Ac Machine MotorDocumento10 pagineAc Machine MotorPatoriku KunNessuna valutazione finora

- Edma3 LLDDocumento46 pagineEdma3 LLDfucking_bitchNessuna valutazione finora

- 21.1: On-Board Bus Device Driver Pseudocode ExamplesDocumento7 pagine21.1: On-Board Bus Device Driver Pseudocode ExamplesSoundarya SvsNessuna valutazione finora

- HIGH EFFICIENCY MULTICRYSTAL SOLAR MODULESDocumento2 pagineHIGH EFFICIENCY MULTICRYSTAL SOLAR MODULESAnonymous 7kJDSaNessuna valutazione finora

- Learning Element 3Documento17 pagineLearning Element 3niel lunaNessuna valutazione finora

- ELK-3 550 1HC0000742AFEnDocumento20 pagineELK-3 550 1HC0000742AFEnOnur FişekNessuna valutazione finora

- Literature Review On Solar MPPT SystemsDocumento8 pagineLiterature Review On Solar MPPT Systemsafmabkbhckmajg100% (1)

- Digital InstrumentsDocumento65 pagineDigital InstrumentsPramod PathadeNessuna valutazione finora

- Service Manual: Digital Video Camera RecorderDocumento95 pagineService Manual: Digital Video Camera RecorderDavid FearNessuna valutazione finora

- How electricity is generated and transmittedDocumento4 pagineHow electricity is generated and transmittedMark WoodNessuna valutazione finora

- Wireless Energy Transfer Powered Wireless Sensor Node For Green Iot: Design, Implementation & EvaluationDocumento27 pagineWireless Energy Transfer Powered Wireless Sensor Node For Green Iot: Design, Implementation & EvaluationManjunath RajashekaraNessuna valutazione finora

- Didactic Katalog 09 en Monitor 1Documento348 pagineDidactic Katalog 09 en Monitor 1leofocerNessuna valutazione finora

- M-Series Electromagnetic Flow Meter Converter: Installation, Operation and Maintenance ManualDocumento45 pagineM-Series Electromagnetic Flow Meter Converter: Installation, Operation and Maintenance ManualRodrigo CiezaNessuna valutazione finora

- Bill of Quantity Fire Alarm SystemDocumento2 pagineBill of Quantity Fire Alarm SystemWahyu ArdiansyahNessuna valutazione finora

- DC-DC Converter For EVDocumento6 pagineDC-DC Converter For EVSachin AngadiNessuna valutazione finora

- Transient Analysis of Synchronous Machines.Documento131 pagineTransient Analysis of Synchronous Machines.Gaurav SapkotaNessuna valutazione finora

- ADC DAC SlidesDocumento26 pagineADC DAC SlidesAnonymous 5JnIAXEVINessuna valutazione finora

- Secure Digital Acess System Using IbuttonDocumento4 pagineSecure Digital Acess System Using Ibuttonrama9942Nessuna valutazione finora

- Computer Graphics Unit1Documento88 pagineComputer Graphics Unit1computerstudentNessuna valutazione finora

- Iec 62271-111-2012 (Ieee C37.60)Documento134 pagineIec 62271-111-2012 (Ieee C37.60)Carlos Porras100% (2)

- AN4326Documento14 pagineAN4326hnooriNessuna valutazione finora

- DDCArv Ch1Documento96 pagineDDCArv Ch1Islamic & Science AcademyNessuna valutazione finora

- Electrical ConduitsDocumento8 pagineElectrical ConduitsFrisco Gabriel100% (1)

- S26KS512S Hflash PDFDocumento96 pagineS26KS512S Hflash PDFvibhaNessuna valutazione finora

- Voltronic Axpert MKSDocumento1 paginaVoltronic Axpert MKSMiguel CondoriNessuna valutazione finora

- Abit - M514 Schematics: Title Sheet ModifyDocumento35 pagineAbit - M514 Schematics: Title Sheet ModifyThắng PhạmNessuna valutazione finora

- Cub Loc Touch ManualDocumento484 pagineCub Loc Touch ManualvacsaaNessuna valutazione finora