Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hy 25 Valves

Caricato da

ZoebairDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hy 25 Valves

Caricato da

ZoebairCopyright:

Formati disponibili

HYDRONEWS 25 Top story

05

Valves

Lifetime safety and reliability

In addition to butterfly and spherical

v a l v e s d e s c r i b e d h e re i n A N D R I T Z

HYDROs product range includes other

valve types, like ring gates and cone

valves.

Butterfly Valves

Design Head [m]

alves have withstood the

operating conditions within

hydropower plants for more

than a century and they fulfill various important tasks; from safety

elements in powerhouses or penstocks to tight sealing in waterways

for maintenance purposes on hydraulic machinery.

Spherical Valves

Diameter [mm]

Design range of shutoff valves within ANDRITZ HYDRO

Design

At the design stage, safety and functionality during operation come first.

Analytical verifications are made based

on customer requirements, and international standards (e.g. ASME), as well as

ANDRITZ HYDRO internal instructions.

Modern ANDRITZ HYDRO valves offer

numerous innovative technical features,

which appeal to customers.

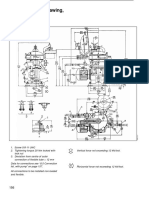

Exploded view:

main components of butterfly valve

Spherical valves are mainly used in high

head applications, whereas butterfly

valves are selected for the low to medium head range. Indicative design limits

for each valve type are shown in the diagram above.

Both valves allow flow in both directions

and fit perfectly for the use in the waterways of reversible pump turbines. They

can be equipped with service and maintenance seals to allow significant reduction in plant downtime during maintenance.

Exploded view: main components of spherical valve

06

Top story HYDRONEWS 25

Among other features, ANDRITZ

HYDRO now offers an auto-oscillation

(self-excited pressure pulsation with increasing amplitudes, which can lead to

penstock rupture) detection device. By

opening or closing of the maintenance

seal the oscillating system is de-tuned

and damages due to auto-oscillation

can be prevented. This function can either be performed fully automatically or

manually after an alarm.

Recently, the design of the butterfly

main inlet valve for HPP Cerro del

guila in Peru (DN 3150mm/PN 36bar)

was completed. In this high pressure

application ANDRITZ HYDRO achieved

a substantial reduction in the valve head

losses of approximately 15%. This

could be managed after several optimization loops by the utilization of CFD

(Computational Fluid Dynamics) calculation programs and by taking existing

model test results from the standard

valve disc geometry as a basis.

Furthermore, this design features leakage monitoring of the maintenance seal,

which allows operators to check its

tightness before dismantling, thus increasing safety for maintenance staff.

CFD plot for head loss analysis at lattice type

valve disc

The spherical valve for HPP Teesta Urja

in India (DN 1,900 mm/PN 90 bar) is

exposed to high concentrations of aggressive sediments in the river water

and consequently subject to erosion

damage. Therefore essential components of the service and maintenance

seals were furnished with a tungstencarbide coating, which ensures a significant extension of the maintenance interval.

Manufacturing, installation and

commissioning

Nominated ANDRITZ HYDRO technical

competence centers for spherical and

butterfly valves are located in Ravensburg, Germany and Linz, Austria. The

strictest requirements are enforced concerning material and fabrication quality

as well as machining tolerances during

the manufacturing process.

Main components can be made either

from castings, forged or welded structures based on size and pressure rating

criteria.

Finite element analysis plot for stress and deformation verification

Simulation of pressure pulsation due to auto-oscillation

Valve opening

Penstock pressure [mwc]

Modern narrow gap welding techniques

(e.g. submerged arc or electron beam)

are applied on thick walled items to ensure competitive manufacturing costs.

These reduce the required quantity of

filler material and, incidentally, minimize

welding distortions too.

Time [sec]

Functionality of single components as

well as the overall system are checked

during workshop assembly (including

pressure and tightness tests) to ensure

smooth installation of the valves at site.

Commissioning ensures the correct setup and optimization of operational parameters, for example tuning of the

valve closing times to prevent unacceptable penstock water hammer.

HYDRONEWS 25 Top story

s Spherical valve for HPP Herdecke during assembly in the workshop

Service

Valves are exposed to high loads during

operation but the years of operation are

less critical than the effective number of

load changes. Nowadays hydraulic

machinery and their valves are subject

to an increased number of start/stop

cycles due to changes in the grid demands, however their layout and design

was calculated for far fewer cycles.

Therefore valve maintenance and rehabilitation are becoming even more essential to guarantee both the operational safety and the availability of the entire

hydropower plant.

Condition assessments of important

components and design improvements

can be made in cooperation with customers in a pre-service phase to optimize the rehabilitation and its duration. For example, at the total overhaul

of the spherical valves at HPP Herdecke

in Germany (DN 3,300 mm/PN 28 bar/

170 tons), where all components had to

undergo non-destructive testing and

documentation. Wear and defective

areas were assessed referring to functional safety and rectification measures,

which were discussed and defined with

the customer. Following the completion

of the overhaul and the valve re-assembly, final tightness and functional tests

were immediately performed in the

workshop, whereupon a drop-tight

rating could be reached.

s Spherical valve for HPP Herdecke: completion

of tightness testing after service

With this valve service our customer

can rely on safe and undisturbed operation in the upcoming years.

TECHNICAL DATA

Projects currently under execution:

The global ANDRITZ HYDRO valve

fleet covers more than 3,500 installed

units. Due to one century of valve experience in combination with constant

research and development efforts, every size, pressure rating and technical

challenge can be managed individually,

be it for new applications or service

tasks.

Andreas Rippl

Phone: +49 (751) 29511 538

andreas.rippl@andritz.com

Markus Meisinger

Phone: +43 (732) 6986 73158

markus.meisinger@andritz.com

Cerro del guila:

3 butterfly valves

Nominal diameter: 3,150mm

Design pressure: 36bar

Nant de Drance:

2 butterfly valves

Nominal diameter: 6,000mm

Design pressure: 10bar

Upper Tamakoshi:

1 spherical valve

Nominal diameter: 2,500mm

Design pressure: 90bar

Teesta Urja:

6 spherical valves

Nominal diameter: 1,900mm

Design pressure: 89.3bar

07

Potrebbero piacerti anche

- CS20 Instruction Manual: Inverted Vertical Turning CellDocumento83 pagineCS20 Instruction Manual: Inverted Vertical Turning CellHenryNessuna valutazione finora

- Welding Procedure Specification's (WPS)Documento29 pagineWelding Procedure Specification's (WPS)Malik Haroon100% (1)

- Service Manual BW161Documento1.174 pagineService Manual BW161Danila1991Nessuna valutazione finora

- M14Cent Pump VibDocumento49 pagineM14Cent Pump VibBhargav Chaudhari100% (1)

- ABS - Guide For Certification of Offshore Mooring Chain PDFDocumento55 pagineABS - Guide For Certification of Offshore Mooring Chain PDFIbrahim RahmatullahNessuna valutazione finora

- Main Hoist Motor Power CalculationsDocumento2 pagineMain Hoist Motor Power CalculationsJerson Arismendi PinzónNessuna valutazione finora

- High Strength Sheet Steel, 180 Mpa Through 700 Mpa Yield StrengthsDocumento18 pagineHigh Strength Sheet Steel, 180 Mpa Through 700 Mpa Yield StrengthsRicardo UriasNessuna valutazione finora

- Gmsi10 Um013 - en PDocumento216 pagineGmsi10 Um013 - en PAnonymous XM3KoTUTgNessuna valutazione finora

- QC Piping Inspector Notes Part-IDocumento39 pagineQC Piping Inspector Notes Part-Imanojballa100% (1)

- Customer Presentation LEWA EcoflowDocumento35 pagineCustomer Presentation LEWA EcoflowMohammed ShallabyNessuna valutazione finora

- Iso 2954 2012 en PDFDocumento8 pagineIso 2954 2012 en PDFJulio CastilloNessuna valutazione finora

- Boiler Tube Oxide-Scale Thickness Measurement - GEIT Application PDFDocumento2 pagineBoiler Tube Oxide-Scale Thickness Measurement - GEIT Application PDFrhinemineNessuna valutazione finora

- Mathcad - Fatigue Failure Example - 3 PDFDocumento39 pagineMathcad - Fatigue Failure Example - 3 PDFnonton gaconNessuna valutazione finora

- Common Causes of Piping VibrationDocumento2 pagineCommon Causes of Piping VibrationTg TarroNessuna valutazione finora

- Mistri Khola Hydroelectric Project (42Mw), Myagdi Procedure For Water Filling Test Water Filling TestDocumento3 pagineMistri Khola Hydroelectric Project (42Mw), Myagdi Procedure For Water Filling Test Water Filling TestSaransh MoolNessuna valutazione finora

- Systematic Approach To Solving Vibration ProblemsDocumento24 pagineSystematic Approach To Solving Vibration Problemsantok09Nessuna valutazione finora

- Pamphlet 5 - Edition 9 - January 2017Documento30 paginePamphlet 5 - Edition 9 - January 2017Comercial AySNessuna valutazione finora

- CA6NMDocumento2 pagineCA6NMjoene3Nessuna valutazione finora

- Dam Failure Part 2Documento83 pagineDam Failure Part 2박래건Nessuna valutazione finora

- Jsa - Sample Hot Tapping PDFDocumento4 pagineJsa - Sample Hot Tapping PDFrongohcoleman100% (1)

- A Comparison of BS en 287 Part 1 and ISO 9606Documento3 pagineA Comparison of BS en 287 Part 1 and ISO 9606Joe ClarkeNessuna valutazione finora

- Structural Health MonitoringDa EverandStructural Health MonitoringDaniel BalageasNessuna valutazione finora

- API 650 12th - 2013Documento4 pagineAPI 650 12th - 2013mohamed100% (1)

- t3369 Francis Turbine ScreenDocumento8 paginet3369 Francis Turbine ScreenluizbarbieriNessuna valutazione finora

- Hydropower Practice and Application PDFDocumento332 pagineHydropower Practice and Application PDFbagastcNessuna valutazione finora

- Standard For Hydraulic Turbine and Generator Shaft Couplings and Shaft Runout TolerancesDocumento22 pagineStandard For Hydraulic Turbine and Generator Shaft Couplings and Shaft Runout Toleranceschecho_mdz100% (1)

- Pfi Es-48Documento7 paginePfi Es-48Ecruz Cruz LNessuna valutazione finora

- Welcome To Advance Steel 2018Documento169 pagineWelcome To Advance Steel 2018mohamedhaniNessuna valutazione finora

- Mesauring Hydro TurbinesDocumento8 pagineMesauring Hydro TurbinesJenny Cecilia Ureña ZuriNessuna valutazione finora

- Improving Concrete Containment Structures Associated With Fixed-Cone ValvesDocumento49 pagineImproving Concrete Containment Structures Associated With Fixed-Cone Valvesnb_norooziNessuna valutazione finora

- Air in Pipelines PDFDocumento92 pagineAir in Pipelines PDFJoelCristobalNessuna valutazione finora

- Investmech (Design of Welded Pressure Equipment) TN R0.0 PDFDocumento65 pagineInvestmech (Design of Welded Pressure Equipment) TN R0.0 PDFHungManhNessuna valutazione finora

- Norma Is - Iso.7919.5.2005 PDFDocumento22 pagineNorma Is - Iso.7919.5.2005 PDFRafael García100% (1)

- 2.2 GL For Hydraulic Design of SHP PDFDocumento117 pagine2.2 GL For Hydraulic Design of SHP PDFChristian HerreraNessuna valutazione finora

- Website Tech Note 1 v5Documento6 pagineWebsite Tech Note 1 v5a350Nessuna valutazione finora

- Din19704 2Documento10 pagineDin19704 2Ilana Barbie HdzNessuna valutazione finora

- Iso 8528-6-2005Documento17 pagineIso 8528-6-2005Ihsan Neydin MalmsteenNessuna valutazione finora

- 13480-5 - 2017 - EN-Inspection and TestingDocumento34 pagine13480-5 - 2017 - EN-Inspection and TestingPaulo VidasinhaNessuna valutazione finora

- As 5081-2008 Hydraulically Operated Automatic Control Valves For Waterworks PurposesDocumento7 pagineAs 5081-2008 Hydraulically Operated Automatic Control Valves For Waterworks PurposesSAI Global - APACNessuna valutazione finora

- ASTM A312 A312M Standard Specification For Seamless Welded and Heavily Cold Worked Austenitic Stainless Steel PipesDocumento12 pagineASTM A312 A312M Standard Specification For Seamless Welded and Heavily Cold Worked Austenitic Stainless Steel Pipesessai expertiseNessuna valutazione finora

- BR N-1594 D - Non Destructive Testing - UltrasonicDocumento20 pagineBR N-1594 D - Non Destructive Testing - UltrasonicJose Alejandro Mansutti GNessuna valutazione finora

- Tyco - Sintakote - Design - Manual - Nov2004editionDocumento140 pagineTyco - Sintakote - Design - Manual - Nov2004editionmottmac50% (2)

- ch10Documento44 paginech10PGPNessuna valutazione finora

- Is 4721Documento7 pagineIs 4721dak2anshulNessuna valutazione finora

- Lateral Vibration of Hydro Turbine-Generator Rotor With Varying Stiffness of Guide BearingsDocumento15 pagineLateral Vibration of Hydro Turbine-Generator Rotor With Varying Stiffness of Guide BearingsstevebensonNessuna valutazione finora

- Basic Valve & SizingDocumento8 pagineBasic Valve & SizingRio Ananda PutraNessuna valutazione finora

- Ejma 10th Edition The Latest Revision 5 PDF FreeDocumento2 pagineEjma 10th Edition The Latest Revision 5 PDF FreeSgk ManikandanNessuna valutazione finora

- Virtual Model Test For A Francis Turbine: Home Search Collections Journals About Contact Us My IopscienceDocumento11 pagineVirtual Model Test For A Francis Turbine: Home Search Collections Journals About Contact Us My Iopsciencecojo_drNessuna valutazione finora

- CECTDocumento1 paginaCECTHIGINIOLEONNessuna valutazione finora

- FILE Is - Iso.1940.2.1997Documento22 pagineFILE Is - Iso.1940.2.1997NalinAnshNessuna valutazione finora

- Dynamic Analysis of Rotor Shaft Systems With Viscoelastically Supported BearingsDocumento18 pagineDynamic Analysis of Rotor Shaft Systems With Viscoelastically Supported Bearingsmtajik2Nessuna valutazione finora

- Vibrosystm Inc. Montreal, Canada: ©vibrosystm 2009. All Rights ReservedDocumento143 pagineVibrosystm Inc. Montreal, Canada: ©vibrosystm 2009. All Rights ReservedJavier CasteloNessuna valutazione finora

- CKD Blansko EngineeringDocumento38 pagineCKD Blansko EngineeringVishal ChauhanNessuna valutazione finora

- Passive Vibration Control in Rotor Dynamics Optimization of Composed Support Using Viscoelastic MaterialsDocumento14 paginePassive Vibration Control in Rotor Dynamics Optimization of Composed Support Using Viscoelastic Materialsmohdsolihat1Nessuna valutazione finora

- 07MnMoVR Steel chn786s1 - T PDFDocumento11 pagine07MnMoVR Steel chn786s1 - T PDFAnonymous AkzeMHNTUyNessuna valutazione finora

- Performance of TBEA Hengyang in VietnamDocumento18 paginePerformance of TBEA Hengyang in VietnamNam Hoai LeNessuna valutazione finora

- Operation and Maintenance Manual: Turbine Inlet Butterfly ValvesDocumento16 pagineOperation and Maintenance Manual: Turbine Inlet Butterfly ValvesKemal GokovicNessuna valutazione finora

- BS1747-1 :1969Documento14 pagineBS1747-1 :1969Jessica FarrugiaNessuna valutazione finora

- High Strength Steels PDFDocumento4 pagineHigh Strength Steels PDFPremnath YadavNessuna valutazione finora

- Review of The Performance of High Strength Steels Used OffshoreDocumento130 pagineReview of The Performance of High Strength Steels Used OffshoreElias Kapa100% (1)

- Vibration Monitoring and Risk Analysis System For Process Piping - Case Study 613Documento4 pagineVibration Monitoring and Risk Analysis System For Process Piping - Case Study 613vellore2kNessuna valutazione finora

- Paper 75 - Ellis - Hazards XVIIDocumento11 paginePaper 75 - Ellis - Hazards XVIINitesh KirnakeNessuna valutazione finora

- m571c XL Cat d7g Web Spec SheetDocumento2 paginem571c XL Cat d7g Web Spec SheetRahmat RiskiNessuna valutazione finora

- Dam Gates Control DesignDocumento45 pagineDam Gates Control DesignjemtanNessuna valutazione finora

- Hydraulic Control Butterfly Valve For Hydropower StationDocumento11 pagineHydraulic Control Butterfly Valve For Hydropower StationSimonONessuna valutazione finora

- Holiday Detector PoroTest 7 enDocumento4 pagineHoliday Detector PoroTest 7 enabcNessuna valutazione finora

- PDFDocumento8 paginePDFajefniNessuna valutazione finora

- Draft IS 4721Documento10 pagineDraft IS 4721rajfabNessuna valutazione finora

- Vorecon Variable Speed Planetary Gear PDFDocumento40 pagineVorecon Variable Speed Planetary Gear PDFsandy4u2k2Nessuna valutazione finora

- Hydrodynamic ScrewsDocumento8 pagineHydrodynamic Screwsarrester97Nessuna valutazione finora

- Vibration ChartDocumento1 paginaVibration ChartdilkisunoNessuna valutazione finora

- Axial Control Valve BrochureDocumento9 pagineAxial Control Valve BrochureJeromeNessuna valutazione finora

- APGA Code of Practice For Upstream PE Gathering Lines in The CSG IndustryDocumento174 pagineAPGA Code of Practice For Upstream PE Gathering Lines in The CSG Industrydamian o'connorNessuna valutazione finora

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987Da EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNessuna valutazione finora

- International Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsDocumento9 pagineInternational Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsZoebairNessuna valutazione finora

- TurbinesDocumento19 pagineTurbinesSamarakoon BandaNessuna valutazione finora

- Type of ThreadDocumento13 pagineType of ThreadVils ArabadzhievaNessuna valutazione finora

- Spring-Supported Thrust BearingsDocumento4 pagineSpring-Supported Thrust BearingsZoebairNessuna valutazione finora

- Appendix B - 20100903 - 145453Documento25 pagineAppendix B - 20100903 - 145453AkoKhalediNessuna valutazione finora

- 90 Series (ET1590) InstructionsDocumento24 pagine90 Series (ET1590) InstructionsZoebairNessuna valutazione finora

- Structures and Mechanisms ClassificationsDocumento1 paginaStructures and Mechanisms ClassificationsminakirolosNessuna valutazione finora

- 1 12 (End)Documento17 pagine1 12 (End)ZoebairNessuna valutazione finora

- ENZX TechDocumento30 pagineENZX TechZoebairNessuna valutazione finora

- Installation and Operating Procedures: Manual Grease InterceptorsDocumento8 pagineInstallation and Operating Procedures: Manual Grease InterceptorsZoebairNessuna valutazione finora

- Quality Conference TTL KUDocumento6 pagineQuality Conference TTL KUZoebairNessuna valutazione finora

- 1 Technical Data Sheets TurbineDocumento7 pagine1 Technical Data Sheets TurbineZoebairNessuna valutazione finora

- Ratle Enm Reply Tecnical Prebid Points 080212Documento42 pagineRatle Enm Reply Tecnical Prebid Points 080212ZoebairNessuna valutazione finora

- Calculate The Number of Extinguishers Needed in A BuildingDocumento3 pagineCalculate The Number of Extinguishers Needed in A BuildingZoebairNessuna valutazione finora

- 1 - Layout of H-FrancisDocumento1 pagina1 - Layout of H-FrancisZoebairNessuna valutazione finora

- 8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0Documento1 pagina8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0ZoebairNessuna valutazione finora

- Solutions EngDocumento6 pagineSolutions EngZoebairNessuna valutazione finora

- Scada SystemDocumento1 paginaScada SystemZoebairNessuna valutazione finora

- Datasheet TurbineDocumento2 pagineDatasheet TurbineZoebairNessuna valutazione finora

- Indigenous ManufacturersDocumento6 pagineIndigenous ManufacturersZoebairNessuna valutazione finora

- Load AcceptanceDocumento2 pagineLoad AcceptanceZoebairNessuna valutazione finora

- PJPR0 V 200 Ucturing 0 Data 0 SheetDocumento3 paginePJPR0 V 200 Ucturing 0 Data 0 SheetZoebairNessuna valutazione finora

- PJPR0 V 200 Ucturing 0 Data 0 SheetDocumento3 paginePJPR0 V 200 Ucturing 0 Data 0 SheetZoebairNessuna valutazione finora

- 3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalDocumento2 pagine3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalThanadkitBunkaewNessuna valutazione finora

- 3 Tables Friction Loss AquacultureDocumento10 pagine3 Tables Friction Loss AquacultureZoebairNessuna valutazione finora

- Hy 25 ValvesDocumento3 pagineHy 25 ValvesZoebairNessuna valutazione finora

- Construction Specification 71-Water Control Gates: Instructions For UseDocumento2 pagineConstruction Specification 71-Water Control Gates: Instructions For UseZoebairNessuna valutazione finora

- CEE 331: Fluid Mechanics, Homework Set 2, SolutionsDocumento7 pagineCEE 331: Fluid Mechanics, Homework Set 2, SolutionsZoebairNessuna valutazione finora

- Offshore Mooring Chain Cables and AccessoriesDocumento8 pagineOffshore Mooring Chain Cables and Accessoriesscofiel1Nessuna valutazione finora

- Aws A5Documento5 pagineAws A5Omid BeygiNessuna valutazione finora

- High Purity Piping Systems: AsahiDocumento20 pagineHigh Purity Piping Systems: AsahiJOSE GABRIELNessuna valutazione finora

- Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General ApplicationDocumento4 pagineSteel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General Applicationعصام السامرائيNessuna valutazione finora

- ManualDocumento6 pagineManualDaniel NúñezNessuna valutazione finora

- GEA Shell and Tube Heat Exchangers For The Oil and Gas IndustryDocumento10 pagineGEA Shell and Tube Heat Exchangers For The Oil and Gas IndustryMauricio Huerta JaraNessuna valutazione finora

- Note: This Is The Sample Document For The Related Job Only: Tank Erection ProcedureDocumento5 pagineNote: This Is The Sample Document For The Related Job Only: Tank Erection Procedurekushar_geoNessuna valutazione finora

- Materials Today: Proceedings: G. Elatharasan, R. Manikandan, G. KarthikeyanDocumento11 pagineMaterials Today: Proceedings: G. Elatharasan, R. Manikandan, G. KarthikeyanAHMED SAMIR ALEMDARNessuna valutazione finora

- Advances in Welding and Joining Technologies Unit 7 Week 5 MicrojoiningDocumento3 pagineAdvances in Welding and Joining Technologies Unit 7 Week 5 MicrojoiningPurushottam SharmaNessuna valutazione finora

- KCA Bladder Tanks en 2010Documento11 pagineKCA Bladder Tanks en 2010NovancyNessuna valutazione finora

- Joint-Site StructureFriction Welding Method As A Tool For Drive PinionDocumento7 pagineJoint-Site StructureFriction Welding Method As A Tool For Drive PinionmarianechluNessuna valutazione finora

- Miyachi Welder Thermocouple Welder Technical ManualDocumento28 pagineMiyachi Welder Thermocouple Welder Technical ManualBSC-566731Nessuna valutazione finora

- MCQ For Welding ShopDocumento6 pagineMCQ For Welding Shopsudhir guptaNessuna valutazione finora

- SAIC-W-2015 Rev 7 (NDE Selection)Documento17 pagineSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduNessuna valutazione finora

- Common Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsDocumento9 pagineCommon Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsradziNessuna valutazione finora

- Din 17174Documento7 pagineDin 17174djmattmNessuna valutazione finora

- Hpalloy X: High Performance Nickel Base Temp AlloyDocumento4 pagineHpalloy X: High Performance Nickel Base Temp AlloycandraNessuna valutazione finora