Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Alfa Laval Fuel Oil Filter PDF

Caricato da

arifsanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Alfa Laval Fuel Oil Filter PDF

Caricato da

arifsanCopyright:

Formati disponibili

Fuel oil filter F-152 range

Continuously automatic backflushing fuel oil filter

The F-152 automatic filter range provides full-flow fine

filtration of heavy fuel oil (HFO) up to 700 cSt/50C.

Developed to cover all the requirements of modern two- and

four-stroke engines, the F-152 requires minimal investment

yet delivers highly reliable operation and true peace of mind.

Unique features

Robust disc-type filter elements.

Continuous backflushing driven by the filtered oil.

Constant pressure drop across the filter.

Filtered oil drives the backflushing process.

Compact and lightweight.

Cleaning of the backflushed oil by refiltration in the diversion chamber before recirculation in the system.

Removal of particles collected from the system at the filter.

Key benefits

Robust design reduces risk of the filter element cracking.

Continuous backflushing significantly prevents adhesion

of retained solids to filter surfaces, which results in:

No manual cleaning of filter elements.

Low and constant pressure drop across the filter

elements, which further reduces the risk of cracking.

Use of filtered oil for the backflushing process eliminates

the need for compressed air.

Installation is recommended on the circulation side (hot

loop) of the fuel oil system for maximum engine protection.

The robust design and elimination of colder backflush

media prevents thermal shock which can result in the

formation of asphaltenes.

Constant pressure drop across the filter, combined with the

pressure drop indicator, facilitates the detection of a malfunction in the fuel oil system.

Cleaning of backflushed flow enables recirculation of fuel

and reduces sludge volume to a minimum.

Automatic fuel oil filter shown with electrical motor.

It is easy to install in new fuel oil systems and to retrofit

existing ones.

There is no need for a sludge treatment unit (consumable

item or manual cleaning system). The diversion chamber

acts as an automatic maintenance-free sludge treatment

system, collecting particles backflushed from the full-flow

chamber and cleaning itself to concentrate sludge.

Rib

Filter frame

Upper half

Lower half

Filter element

Filter screen

Figure 1. Full-flow element.

Diesel engine protection

The fuel oil conditioning system includes filters to remove

solid particles that may have entered the system after the

separator, which is installed in the cleaning system. The filter

therefore prevents any potentially dangerous particles from

reaching the sensitive parts of the diesel engine fuel system.

To guarantee 100% full-flow protection, the filter should be

installed as close to the engine as possible.

Distributor drive

The distributor, which creates the backflushing and selfcleaning effect of the filter, is driven by an electric motor.

The shape of the distributor is optimized to provide the

best possible cleaning efficiency, which results in longer

periods of time between maintenance intervals.

Electric motor

Backflush clean oil

Diversion filter

elements

Full-flow filter

elements

Drain

(sludge)

from

diversion

chamber

Filtered oil

Oil inlet

Figure 2. Distributor.

Figure 3. Fully assembled filter showing full-flow and diversion

chamber filter elements and electric motor.

Key:

QCP

Q1

QE

Q3

=

=

=

=

Circulation pump capacity

Maximum capacity of the filter

Fuel oil flow to the engine

Flow of backflushed cleaned oil

P1

P2

P3

PD

=

=

=

=

Filter inlet pressure

Filter outlet pressure

Backflushed oil outlet pressure

Pressure in deaerator

Engine pressure

control valve

Return from engine

From diesel

engine

G3

To diesel

engine

P3

PD

=

P3

P2

QE

V21

Pressure

regulating

valve

Drain

P1

Q1

Deaerator

Circ.

pump

Recommended for

certain engines

Heater

Filter

QCP

Figure 4. Protective automatic fuel oil filter, shown on the hot side (circulation side) of the booster module.

Operating principle

The unfiltered oil is fed into the filter by means of the

distributor, which is driven by an electric motor on top of

the filter housing. The distributor rotates on a regular basis,

filling seven of the eight full-flow filtering columns. Solids

collect on the filter surface and the filtered oil flows to

the engine.

In the eighth column, the solids,which have been collected,

are removed by backflushing a small amount of the filtered oil

through a passage in the distributor to the diversion chamber.

This means that all of the columns are backflushed once

every time the distributor fully rotates, which occurs

approximately every one to two minutes.

The driving force for automatic backflushing is the difference

in pressure between the clean-oil outlet (P2) and the backflushed oil outlet (P3) of the filter. A flow sheet illustrating

the pressures, flow and capacity is shown in Figure 4.

A pressure drop indicator, drain cock and counter flanges

are provided as ancillary equipment. Options are available for

additional features, such as a drain valve with an automatic

timer. The Alfa Laval fuel oil filter is also available with a built-in

changeover valve and a built-in bypass filter (see Figure 5),

which enable operations to continue uninterrupted during

routine maintenance.

The backflushed oil, which contains the solids, enters the

diversion chamber and is filtered through seven of its the

eight columns before being directed back to the deaerator.

At the same time, backflushing by clean oil takes place in

the eighth column and solids settle to the bottom of the

diversion chamber, where they are periodically discharged

through the drain cock.

The pressure drop indicator is connected between the inlet

and outlet of the full-flow chamber. It provides a reading and

signals an alarm if, for any reason, the pressure drop reaches

a dangerous level.

Figure 5. Duplex automatic/manual fuel oil filter.

Height

Other Alfa Laval filtration products

Alfa Laval also manufactures filters for other engine room

applications, such as automatic filters both with and without

diversion chamber for lubricating oils, and manual indicator

and bypass filters.

After-sales support

Replacement components and after-sales service are

provided through a network of Alfa Laval subsidiaries and

representatives worldwide, including Marine Service Centres

in all major ports.

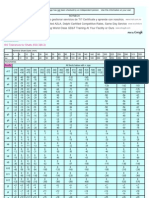

Technical data

Guidelines to overall dimensions

For flow rates up to 20 m3/h:

Height Length Width (mm):

or with the built on bypass:

For flow rates from 20 to 40 m3/h:

Height Length Width (mm):

or with the built on bypass:

900 250 250

900 660 250

1620 500 450

1620 1130 450

Filtration fineness

From 10 to 45 m absolute (corresponding to 6 to 30 m

nominal). This can be defined according to diesel engine

requirements and the specific application.

Installation

All Alfa Laval automatic fuel oil filters are designed for

installation in the engine room. Flanges are according to

DIN standards (JIS as option).

EMD00046EN 0709

How to contact Alfa Laval

Up-to-date Alfa Laval contact details

for all countries are always available on

our website at www.alfalaval.com

Technical documentation

Complete information and documentation for the main

components and the installation, operation and maintenance

of the filter is contained in the Instruction Book that accompanies delivery of each Alfa Laval filter. Your local Alfa Laval

company will be able to provide more details on the application and sizing of Alfa Laval automatic filters.

Alfa Laval reserves the right to change specifications without prior notification.

ALFA LAVAL is a trademark registered and owned by Alfa Laval Corporate AB.

th

Wid

Length

Data

Value

Filter outlet pressure (P2)

Min.

2 bar above pressure (P3)

Recommended

35 bar above pressure (P3)

Test pressure

30 bar

Max. viscosity in the filter

at normal operation (hot side)

75 cSt

Max. temperature in the filter

160C

Alarm p (P1P2)

0.8 bar

Housing material

Nodular cast iron

Filter screen material

Stainless steel

Heating method

Steam/hot water/thermal oil

Supply

110/220 V, 50/60 Hz,

single phase

Consumption

0.20 A (110 V), 0.10 A (220 V)

Protection

Class F, IP55, tropicalised

Potrebbero piacerti anche

- Basics of Brush PaintingDocumento2 pagineBasics of Brush Paintingjfhiga100% (1)

- Lehm0028 00Documento4 pagineLehm0028 00Aidel MustafaNessuna valutazione finora

- Separ Filter IndustrialDocumento25 pagineSepar Filter IndustrialNatanael HernandezNessuna valutazione finora

- 45m Ferry - Equipment List - Rev 1Documento3 pagine45m Ferry - Equipment List - Rev 1bdthanhvkct100% (1)

- Formación TécnicaDocumento250 pagineFormación Técnicajesus100% (1)

- The Effect of ShearDocumento11 pagineThe Effect of Shearanakren296Nessuna valutazione finora

- REXON Lubricating Oil Purifier Series TYADocumento24 pagineREXON Lubricating Oil Purifier Series TYApaola guzman ramirezNessuna valutazione finora

- Bukh DV 36-48 Workshop ManualDocumento196 pagineBukh DV 36-48 Workshop Manualasaturday85Nessuna valutazione finora

- Reverse Osmosis DETAILSDocumento38 pagineReverse Osmosis DETAILSgkdora574100% (1)

- Gear Box Oil Filtration in Cement Mills PDFDocumento2 pagineGear Box Oil Filtration in Cement Mills PDFShirish Patwardhan100% (1)

- Winch Motor CatalogDocumento10 pagineWinch Motor CatalogjorgekichiNessuna valutazione finora

- Water in Oil Monitoring SystemDocumento13 pagineWater in Oil Monitoring Systempapaki2100% (1)

- Fuel Oil FilterDocumento4 pagineFuel Oil FilterTrișcă Cristian AndreiNessuna valutazione finora

- FESX 520S-31CG Instruction BookDocumento254 pagineFESX 520S-31CG Instruction BookMohamed Korany100% (1)

- FUOOTECH Series TY Vacuum Turbine Oil PurifierDocumento15 pagineFUOOTECH Series TY Vacuum Turbine Oil PurifierKevin Chiang100% (1)

- Wagner Hydraulic SteeringDocumento5 pagineWagner Hydraulic SteeringJuan Vasquez Robles100% (1)

- H Service Data SheetDocumento8 pagineH Service Data SheetSamuel Sneddon-NelmesNessuna valutazione finora

- ISO - 286-2 Shaft Limits TolerancesDocumento2 pagineISO - 286-2 Shaft Limits TolerancesMixtli Garcia100% (1)

- SJ30FDocumento2 pagineSJ30FRizky Dwi100% (1)

- M17-B Steering Gear Final Drawing and Manual For Machinery PartDocumento85 pagineM17-B Steering Gear Final Drawing and Manual For Machinery PartAcruzb100% (1)

- Model Hh219Documento54 pagineModel Hh219helbertortiz100% (1)

- Se 05.2XDocumento81 pagineSe 05.2XCentrifugal Separator100% (1)

- Oily Water Separator Safety DevicesDocumento15 pagineOily Water Separator Safety DevicesMohammad Jahid Alam100% (6)

- T6 Mobile Sales HY29 0002 UKDocumento36 pagineT6 Mobile Sales HY29 0002 UKJose FernandezNessuna valutazione finora

- Installation Guide: HERSS - High Efficiency Scraper and Sealing System B&W - MC EnginesDocumento2 pagineInstallation Guide: HERSS - High Efficiency Scraper and Sealing System B&W - MC EnginesAbhishek Singh ChauhanNessuna valutazione finora

- Bs 5911-6Documento30 pagineBs 5911-6Sammy Kong0% (1)

- 520L0322 OMS Series 3 TI SaeDocumento8 pagine520L0322 OMS Series 3 TI Saeseaqu3st100% (1)

- Bomba de PistonDocumento22 pagineBomba de PistonAlexSora100% (1)

- Installation and Start-Up Information PV Series: Variable Displacement Axial Piston PumpDocumento14 pagineInstallation and Start-Up Information PV Series: Variable Displacement Axial Piston PumpAPURV GOYALNessuna valutazione finora

- MEK Marine Caterpillar Spare PartsDocumento6 pagineMEK Marine Caterpillar Spare PartsMEK MarineNessuna valutazione finora

- Donaldson Purify and Pressure FiltersDocumento132 pagineDonaldson Purify and Pressure FiltersCentral HydraulicsNessuna valutazione finora

- Continuous Rolling MillDocumento8 pagineContinuous Rolling Millrazen_inNessuna valutazione finora

- Alfa Laval Moatti: Filtration SolutionsDocumento21 pagineAlfa Laval Moatti: Filtration SolutionswalleyranNessuna valutazione finora

- Fuel Oil Handling SystemDocumento3 pagineFuel Oil Handling SystemPaulrajNessuna valutazione finora

- Emd00099en JWP26CDocumento4 pagineEmd00099en JWP26CLupu Ane MarieNessuna valutazione finora

- Disc Separator SpecificationDocumento4 pagineDisc Separator SpecificationyovanNessuna valutazione finora

- 52 Filtrex BrochureDocumento6 pagine52 Filtrex BrochureCvitaCvitićNessuna valutazione finora

- Westfalia Separator Seaprotectsolutions 997 1131 040Documento28 pagineWestfalia Separator Seaprotectsolutions 997 1131 040ronald_edinsonNessuna valutazione finora

- MEK Marine Separators Spare PartsDocumento6 pagineMEK Marine Separators Spare PartsMEK Marine100% (1)

- 13 SVC Systems Power Quality D 2008-03-12Documento10 pagine13 SVC Systems Power Quality D 2008-03-12satelite54100% (1)

- W-M-2421 - Otc 2Documento2 pagineW-M-2421 - Otc 2Danny AriasNessuna valutazione finora

- Devilbiss 8005 To 8015 Air Dryer ManualDocumento11 pagineDevilbiss 8005 To 8015 Air Dryer Manualamijoski6051Nessuna valutazione finora

- Alfie - Cleaning System For Liquids - Instruction Manual - 2016Documento80 pagineAlfie - Cleaning System For Liquids - Instruction Manual - 2016Centrifugal SeparatorNessuna valutazione finora

- Bilgemaster 200 PDFDocumento7 pagineBilgemaster 200 PDFbanerjeeamlanNessuna valutazione finora

- KleentekDocumento8 pagineKleenteksurawutwijarn100% (1)

- Service Kit Part List RH 133 Version D (SVC Kit 1 & 2)Documento1 paginaService Kit Part List RH 133 Version D (SVC Kit 1 & 2)ronny ArdiansyahNessuna valutazione finora

- 31 AHUsDocumento46 pagine31 AHUsZen LohNessuna valutazione finora

- 2007 Kobelco Stern Tube Seal Installation ManualDocumento18 pagine2007 Kobelco Stern Tube Seal Installation Manualvjmariner100% (1)

- Lidos Lwe Webservice: LTM 1120-1-015 Z23358 Z23358 927940923Documento1 paginaLidos Lwe Webservice: LTM 1120-1-015 Z23358 Z23358 927940923mohamedNessuna valutazione finora

- 0240 1183 4Documento12 pagine0240 1183 4Marko ŠkaraNessuna valutazione finora

- Page 670-814.pdf Lister Petter HR4a PDFDocumento145 paginePage 670-814.pdf Lister Petter HR4a PDFvoetsek007Nessuna valutazione finora

- Tranter PHE GCD-09 X 43Documento4 pagineTranter PHE GCD-09 X 43alokNessuna valutazione finora

- Nacos Platinum ASPDocumento21 pagineNacos Platinum ASPSpalatelu Iuliana100% (1)

- Low Voltage Products: Switches Rotary Cam Switches, Enclosed Cam Switches OM, ON and OLDocumento68 pagineLow Voltage Products: Switches Rotary Cam Switches, Enclosed Cam Switches OM, ON and OLFabianNessuna valutazione finora

- Petrobras Marine Lubricating Oils Equivalent ListDocumento10 paginePetrobras Marine Lubricating Oils Equivalent Listelizbanfavio8008Nessuna valutazione finora

- Arneson Surface Drives CatalogueDocumento12 pagineArneson Surface Drives CatalogueWoodsy12Nessuna valutazione finora

- 3512B B 861bkW 1155bhp 1200rpmDocumento6 pagine3512B B 861bkW 1155bhp 1200rpmFernandez Gonzalo100% (1)

- FCMDocumento4 pagineFCMMansoor Ahmad100% (1)

- 8555-9201-000 D10 Parameter Trouble Shooting Jan09Documento96 pagine8555-9201-000 D10 Parameter Trouble Shooting Jan0915120 Tanzim NabeedNessuna valutazione finora

- Kubota Super UDT2 Fluid PI SheetDocumento2 pagineKubota Super UDT2 Fluid PI Sheetcamilo ZambranoNessuna valutazione finora

- Danieli - List of Lubricants - Rev 2020Documento20 pagineDanieli - List of Lubricants - Rev 2020thienftuNessuna valutazione finora

- Oily Water Separator Inventory APRIL 2015Documento4 pagineOily Water Separator Inventory APRIL 2015Claudio SantellanesNessuna valutazione finora

- Operation Manual 1-SamgongDocumento61 pagineOperation Manual 1-Samgongdamianro1993100% (1)

- ManualDocumento38 pagineManualHernando HerreraNessuna valutazione finora

- Alfa Laval - Foodec 100, Leaflet PDFDocumento2 pagineAlfa Laval - Foodec 100, Leaflet PDFImad MhannaNessuna valutazione finora

- 7480J Section A (Mobile)Documento244 pagine7480J Section A (Mobile)Hoang Minh Hung100% (1)

- #4-c Eliminator AEBDocumento7 pagine#4-c Eliminator AEBBrandon Manrique GonzalesNessuna valutazione finora

- จำหน่าย Mann Oil Filters >Documento4 pagineจำหน่าย Mann Oil Filters >Parinpa KetarNessuna valutazione finora

- PureVent Centrifugal Oil Mist Separator Cleaning Crankcase Gas - 1009Documento4 paginePureVent Centrifugal Oil Mist Separator Cleaning Crankcase Gas - 1009Shivananda PatraNessuna valutazione finora

- HV Filter Carts 1Documento2 pagineHV Filter Carts 1paulpopNessuna valutazione finora

- Decree enDocumento9 pagineDecree enmalakayjr100% (1)

- TDS ASIA MACMAT R Polymeric - Rev14 20161129Documento1 paginaTDS ASIA MACMAT R Polymeric - Rev14 20161129Andrew Zapanta Jr.Nessuna valutazione finora

- Omron G8P 114P FD US DC12 DatasheetDocumento6 pagineOmron G8P 114P FD US DC12 DatasheetCorretaje ResidencialNessuna valutazione finora

- BSR 2019Documento109 pagineBSR 2019aflal100% (3)

- ASCO Series 230 Automatic Transfer Switch 2017Documento18 pagineASCO Series 230 Automatic Transfer Switch 2017Anonymous SDeSP1Nessuna valutazione finora

- User'S Manual: Multi-Function Compact InverterDocumento446 pagineUser'S Manual: Multi-Function Compact InverterjorgeulianaNessuna valutazione finora

- Preparation of Methylene Chloride (Greene 1879)Documento2 paginePreparation of Methylene Chloride (Greene 1879)j9cr4zrdxxNessuna valutazione finora

- High Performance Concrete With Partial Replacement of Cement by ALCCOFINE & Fly AshDocumento6 pagineHigh Performance Concrete With Partial Replacement of Cement by ALCCOFINE & Fly AshvitusstructuresNessuna valutazione finora

- Service Bulletin Trucks: Climate Unit Stepper Motor TestingDocumento5 pagineService Bulletin Trucks: Climate Unit Stepper Motor TestingWilson BuenoNessuna valutazione finora

- Stoichiometry: Previous Eamcet BitsDocumento7 pagineStoichiometry: Previous Eamcet BitswdwdwdwdwNessuna valutazione finora

- Interseal 670HS: Surface Tolerant EpoxyDocumento4 pagineInterseal 670HS: Surface Tolerant Epoxyhvdb72Nessuna valutazione finora

- What Really Happens To The Plastic You Throw Away?: Emma Bryce - TED-EdDocumento1 paginaWhat Really Happens To The Plastic You Throw Away?: Emma Bryce - TED-EdJennefer Gudao AranillaNessuna valutazione finora

- Upuuteg Aug2012Documento80 pagineUpuuteg Aug2012josipNessuna valutazione finora

- 240 - 241 - HB-280 B - 320 BSscreen - ENDocumento2 pagine240 - 241 - HB-280 B - 320 BSscreen - ENivanNessuna valutazione finora

- 2016 Oshima AlGaO-GaO - Unintentional Doping DOPEDDocumento4 pagine2016 Oshima AlGaO-GaO - Unintentional Doping DOPEDakashNessuna valutazione finora

- Project Report PDFDocumento15 pagineProject Report PDFabubakar09ectNessuna valutazione finora

- John Deere 7830Documento5 pagineJohn Deere 7830Ramiro GonzálezNessuna valutazione finora

- Panasonic 206 ManualDocumento40 paginePanasonic 206 ManualNikos Georgopoulos100% (1)

- DOP3025 02 UkDocumento60 pagineDOP3025 02 UkSegundo Francisco Jauregui ValenciaNessuna valutazione finora