Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Separation & Purification of Crude Glycerol

Caricato da

Balvinder SinghDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Separation & Purification of Crude Glycerol

Caricato da

Balvinder SinghCopyright:

Formati disponibili

This article was downloaded by: [Universiti Kebangsaan Malaysia], [Wan Isahak]

On: 11 October 2014, At: 00:22

Publisher: Taylor & Francis

Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House,

37-41 Mortimer Street, London W1T 3JH, UK

Separation & Purification Reviews

Publication details, including instructions for authors and subscription information:

http://www.tandfonline.com/loi/lspr20

Recovery and Purification of Crude Glycerol from

Vegetable Oil Transesterification

ab

Wan Nor Roslam Wan Isahak , Zatil Amali Che Ramli , Manal Ismail , Jamaliah Mohd Jahim

& Mohd Ambar Yarmo

a

Department of Chemical Engineering and Process, Faculty of Engineering and Built

Environment, Universiti Kebangsaan Malaysia, Bangi, Malaysia

b

School of Chemical Sciences and Food Technology, Faculty of Science and Technology,

Universiti Kebangsaan Malaysia, Bangi, Malaysia

Accepted author version posted online: 11 Feb 2014.Published online: 10 Oct 2014.

To cite this article: Wan Nor Roslam Wan Isahak, Zatil Amali Che Ramli, Manal Ismail, Jamaliah Mohd Jahim & Mohd Ambar

Yarmo (2015) Recovery and Purification of Crude Glycerol from Vegetable Oil Transesterification, Separation & Purification

Reviews, 44:3, 250-267, DOI: 10.1080/15422119.2013.851696

To link to this article: http://dx.doi.org/10.1080/15422119.2013.851696

PLEASE SCROLL DOWN FOR ARTICLE

Taylor & Francis makes every effort to ensure the accuracy of all the information (the Content) contained

in the publications on our platform. However, Taylor & Francis, our agents, and our licensors make no

representations or warranties whatsoever as to the accuracy, completeness, or suitability for any purpose of the

Content. Any opinions and views expressed in this publication are the opinions and views of the authors, and

are not the views of or endorsed by Taylor & Francis. The accuracy of the Content should not be relied upon and

should be independently verified with primary sources of information. Taylor and Francis shall not be liable for

any losses, actions, claims, proceedings, demands, costs, expenses, damages, and other liabilities whatsoever

or howsoever caused arising directly or indirectly in connection with, in relation to or arising out of the use of

the Content.

This article may be used for research, teaching, and private study purposes. Any substantial or systematic

reproduction, redistribution, reselling, loan, sub-licensing, systematic supply, or distribution in any

form to anyone is expressly forbidden. Terms & Conditions of access and use can be found at http://

www.tandfonline.com/page/terms-and-conditions

Separation & Purification Reviews, 44: 250267, 2015

Copyright Taylor & Francis Group, LLC

ISSN: 1542-2119 print / 1542-2127 online

DOI: 10.1080/15422119.2013.851696

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

Recovery and Purification of Crude Glycerol from

Vegetable Oil Transesterification

Wan Nor Roslam Wan Isahak,1,2 Zatil Amali Che Ramli,2 Manal Ismail,1

Jamaliah Mohd Jahim,1 and Mohd Ambar Yarmo2

1

Department of Chemical Engineering and Process, Faculty of Engineering and Built Environment,

Universiti Kebangsaan Malaysia, Bangi, Malaysia

2

School of Chemical Sciences and Food Technology, Faculty of Science and Technology, Universiti

Kebangsaan Malaysia, Bangi, Malaysia

This article reviews the purification techniques involved in producing high-purity glycerol in

the biodiesel industry. Utilization of glycerol by-products (contains less than 50 wt.% of glycerol and the remaining contents are water, salts, unreacted alcohol and catalyst) in biodiesel

production affords greener and less costly processes. Research has focused on several purification steps that are capable of producing high-purity glycerol. Various new techniques for

purifying glycerol promise better quality and lower cost and technologies are required to fulfil

increasing worldwide demand. Neutralization, ultrafiltration, the use of ion exchange resins,

vacuum distillation and other methods have been utilized in single or multiple stages. Recent

studies have demonstrated that the combination of more than one technique produces high-purity glycerol (>99.2%). Purifications cost can be as low as 0.149 USD$/kg. For many

applications, high-purity glycerol is more useful. In some cases, it is even necessary, particularly in the fields of hydrogen production, methanol production, pharmaceuticals and food

additives.

Keywords: Crude glycerol, purification, ion exchange resins, separation technique, ultrafiltration, vacuum distillation

BACKGROUND

Glycerol, or glycerine, or 1,2,3-propanetriol, can be produced from the transesterification or hydrolysis of natural

fats, vegetable oils or petrochemicals (1). In Malaysian

biodiesel processes, palm oil is the primary raw material

from which glycerol is produced as a transesterification byproduct. In these processes, palm oil is treated with methanol

and a basic homogeneous catalyst. Alternatively, acidic,

basic or enzymatic heterogeneous catalysts are used because

of their ease of separation from the products.

Received 19 August 2011, Accepted 30 September 2013.

Address correspondence to Mohd Ambar Yarmo, School of Chemical

Sciences and Food Technology, Faculty of Science and Technology,

Universiti Kebangsaan Malaysia, Bangi 43600, Malaysia. E-mail:

ambar@ukm.my

Crude glycerol production from biodiesel conversion is

increasing yearly. From 2008 to 20011, total worldwide

crude glycerol output increased from 2.06 to 2.88 million tonnes (2,3). The global demand for glycerol was

1,995.5 kilo tons in 2011 and is expected to reach

3,060.4 kilo tons by 2018, growing at a Compounded Annual

Growth Rate (CAGR) of 6.3% from 2012 to 2018 (4).

The Malaysian palm-based oleochemical industry is growing rapidly and produces products such as fatty acid methyl

esters (FAMEs), fatty alcohols and crude glycerol (5,6).

The abundant crude glycerol generated by this industry

affords a great opportunity for scientists to explore new glycerol applications. High-purity glycerol finds wide use as

an ingredient or processing aid in healthcare products, fuel

additives, lubricants, personal care products, cosmetics and

food (7,8).

However, the glycerol produced as a by-product of transesterification from biodiesel processes is not pure enough for

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

GLYCEROL RECOVERY FROM VEGETABLE OIL

direct use in high-tech applications. To overcome this problem, numerous treatments are required to remove impurities.

Moreover, the manufacturing and pharmaceutical industries have increasingly demanded high-quality, food-grade

glycerol because of its superior physical properties, low

contamination and odorlessness (9).

Therefore, an effective, efficient glycerol purification

process is needed to minimise production costs, minimise

industrial waste and maximise the utility of biodiesel industrial processes. Because of the enormous demand for the

production of glycerol from biodiesel waste, we have

thoroughly reviewed vegetable oil transesterification and

hydrolysis as a glycerol synthetic route. Various purification methods for producing high-purity glycerol are herein

discussed, and some glycerol conversion processes are

summarized.

CHEMICAL COMPOSITION OF CRUDE

GLYCEROL

The factors that influence the quality of crude glycerol

derived from biodiesel production processes include catalyst type and quantity, recovery methods, unreacted methanol

and other impurities. For example, a crude glycerol extracted

from sunflower oil biodiesel had a composition (w/w) of

30% glycerol, 50% methanol, 13% soap, 2% moisture,

2-3% salts (primarily sodium and potassium) and 23%

other impurities (7). In contrast, Hansen et al. (10) reported

glycerol contents of 38 to 96% in a set of 11 crude glycerol samples collected from 7 different Australian biodiesel

producers. Some of those samples contained more than

14% methanol and 29% ash. Because most biodiesel production uses low-grade methanol and homogeneous alkaline catalysts (sodium methoxide or potassium hydroxide),

the quality of the afforded glycerol is poor (11). Saman

et al. identified several contaminants in crude glycerol

methanol, soaps, catalysts, salts, non-glycerol organic matter

and excessive water (12).

Even when identical feedstocks were employed, the

crude glycerol produced from alkali- and lipase-catalyzed

transesterifications was reported to differ in purity (13).

For biodiesel production that utilized homogeneous alkaline catalysts, the crude glycerol produced contained 5 to

7% salts (14), making conventional purification techniques

more costly. Heterogeneous processes using enzymes and

solid metal-oxide catalysts have been promoted as alternatives that afford higher-quality crude glycerol. However,

with heterogeneous catalysts, impurities present in natural

raw feedstocks tend to accumulate in the glycerol phase.

Therefore, purification remains a requirement for meeting

current standards. Moreover, each contaminant requires a

different method of removal.

251

PRODUCTION OF GLYCEROL FROM

VEGETABLE OIL

The two primary processes for biodiesel production are

hydrolysis and transesterification. Hydrolysis refers to a

chemical reaction in which water molecules are split into

oxygen and hydroxide anions, whereas a biodiesel transesterification refers to a reaction that occurs between a triglyceride or fat and an alcohol to form alkyl esters (biodiesel

fuel) and glycerol (Figure 1). The theoretical stoichiometric ratio of alcohol to lipids for these transesterifications is

3:1. In reality, a 6:1 ratio is necessary to achieve practical

yields. The alcohol molecules displace the triglyceride (triacylglycerol) molecules in forming an ester. This process is

also known as alcoholysis because cleavage of an alcohol

is involved. Most biodiesel producers utilize homogeneous

alkaline catalysts such as sodium hydroxide or potassium

hydroxide (15). These catalysts also saponify the starting

materials into foams. Consequently, yields decrease, and

major problems in catalyst recovery, product separation and

product purification are encountered (1618).

Transesterification requires an alcohol. Methanol and

ethanol are the most frequently used alcohols for biodiesel

transesterification reactions; propanol and butanol are also

widely employed. For environmentally friendly processes,

ethanol is chosen because it can be derived from agricultural products or other renewable resources. Alternatively,

methanol is chosen for its lower cost, high polarity and short

alkyl chain (19).

Hydrolysis Processes

Vegetable oil hydrolysis is achieved using an acid or base

catalyst and produces glycerol and free fatty acids or soaps.

Base-catalyzed ester hydrolysis is commonly called saponification. Both processes are shown in Figure 2. The performances of various vegetable oil hydrolyses are summarized

in Table 1. In previous studies, Hammond and Inmok (20)

reported that lipase split triglycerides into free fatty acids

and glycerol. Their hydrolyses were performed with 17 to

44% moisture, and water was applied by various suitable

techniques, e.g., soaking and spraying.

Hydrolysis without a catalyst at 270350 C, 20 MPa and

a water/oil feed ratio of 50/50 (v/v) afforded approximately

FIGURE 1 Transesterification process that produces alkyl esters and

glycerol.

252

W. N. R. WAN ISAHAK ET AL.

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

Homogeneous Catalytic Systems

FIGURE 2 Hydrolytic processes: a) acid-catalyzed hydrolysis and b)

base-catalyzed hydrolysis (saponification).

90% biodiesel and 10% glycerol (25,26). The water concentration was sufficient for both hydrolysis and triglyceride

cracking (24,27,28). Commonly, vegetable oil hydrolysis

involves the use of rotating hydrothermal reactors operated

at high temperatures and pressures. Several companies in

Malaysia namely, Cognis Oleochemical Industries, FPG

Oleochemicals Sdn Bhd and Pacific Oleochemicals Sdn

Bhd are using this catalyst-free hydrolytic technology in

their biodiesel production processes. The basic scheme for

biodiesel and glycerol production via transesterification is

shown in Figure 3.

Transesterification Reactions

In transesterification, basic, acidic or enzymatic catalysts are

employed (29,30). Major differences exist between homogeneous and heterogeneous catalysts in terms of activity,

product separation and production cost (31). In Malaysia,

transesterification reactions are widely applied in biodiesel

production by Malaysian Palm Oil Board, Golden Hope

Plantation Sdn Bhd and Emery Oleochemicals. The other

international companies such as P & G Chemicals (USA) and

BASF Chemical (Germany) also produced glycerol in huge

volume. Unfortunately, the glycerol produced by their processes is low in quality and thus limited in utility. The poor

glycerol quality provided by these companies is attributed to

difficult separations and the high costs associated with the

development of purification techniques.

The most active catalysts, alkaline metal alkoxides such

as sodium methoxide (CH3 ONa), are commonly used in

methanolyses because of their high conversions (>98%),

short reaction times (approximately 30 minutes) and low

molar concentrations (0.5 mole %). However, anhydrous

requirements have rendered those catalysts inappropriate for

typical industrial processes (18). Moreover, the separation

of the homogeneous catalyst from the glycerol mixture has

been cost-prohibitive (32). Transesterification reactions are

also performed using acid catalysts. In many cases, the reactions with acid catalysts have been reported to be slower

than the reactions with base catalysts. However, acid catalysts exhibit high activity at high temperatures and high

oil-to-alcohol ratios. Among the catalysts reported in the literature, trifluoroacetic acid was been observed to perform the

best, affording 98.4% conversion in 5 hours with an alcoholto-oil molar ratio of 20:1 and at a reaction temperature of

120 C (33).

Catalytic sodium hydroxide was observed to produce side

reactions and form sodium soaps easily. This sodium soap

formation was also observed when catalytic sodium methylate was employed in the presence of trace water amounts.

These sodium soaps were soluble in the glycerol phase. The

soaps required neutralization to fatty acids and decantation

(34). Furthermore, even when a water-free alcohol/oil mixture was used, some water was introduced into the reactor

system by the deprotonation of the alcohol by hydroxide. The

presence of water enabled hydrolysis and resulted in soap

formation. This undesirable saponification reaction reduced

fatty acid methyl ester yields and considerably hindered

glycerol recovery due to emulsion formation (18). The performances of various homogeneous catalysts are shown in

Table 2.

Heterogeneous Catalytic Systems

The heterogeneous catalysts of vegetable oil transesterification can be categorized as either acidic or basic. Alkali

catalysts are commonly used in transesterification and

exhibit higher activities than acidic catalysts. Furthermore,

basic catalysts have afforded particularly high conversions

TABLE 1

Performance of various vegetable oil hydrolytic processes

Type of catalyst/reaction

Lipase-catalyzed hydrolysis

Lipase-catalyzed hydrolysis

Base-catalyzed hydrolysis

Acid-catalyzed hydrolysis

Non-catalyzed hydrolysis

Molar ratio

(Oil: water)

Temperature

( C)

Time (h)

Conversion

(%)

References

1:20

40

27

100

190

270350

2

5

3

8

15 min

95

88

98

99.4

100

(20)

(21)

(22)

(23)

(24)

GLYCEROL RECOVERY FROM VEGETABLE OIL

253

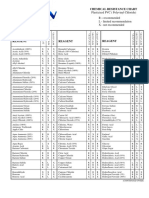

TABLE 2

Homogeneous catalysts in glycerol production

Type of catalyst/reaction

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

Homogeneous basic

NaOH

KOH

NaOCH3

Homogeneous acidic

AlCl3 and ZnCl2

H2 SO4

H2 SO4

H2 SO4

Trifluoroacetic acid

Temperature ( C)

Time (h)

Conversion (%)

References

6:1

6:1

6:1

45

60

60

0.25

1

2

98

100

97.1

(35)

(36)

(37)

24 : 1

50 : 1

20 : 1

245 : 1

20 : 1

110

80

95

70

120

18

4

20

4

5

98

97

>90

99

98.4

(38)

(39)

(40)

(41)

(33)

Molar ratio

when supported on alumina, metal or zeolites. A comparatively high reaction temperature is required to achieve only a

slow reaction rate in acid-catalyzed transesterifications.

Previous studies have reported that vegetable oil transesterification using heterogeneous acid catalysts is not a practical process because it requires high temperatures, lengthy

reaction times and large catalyst charges. In addition, synthesizing the catalysts was reported to be complicated and

uneconomical. Catalyst leaching also presented a risk of

product contamination. These drawbacks led to higher separation costs and created additional problems we will not discuss. However, the solid acid catalysts could be regenerated

and reused.

Supported basic heterogeneous catalysts, such as potassium hydroxide on alumina (KOH/Al2 O3 ), have exhibited high activities and basicity (11). One optimized

KOH/Al2 O3 reaction afforded 90.54% diesel and 9.46%

glycerol. Arzamendi et al. (42) reported conversions up to

99% when sodium hydroxide on alumina (KOH/Al2 O3 ) was

employed. The high conversions resulted from the catalysts

high number of active sites and the catalysts basicity.

FIGURE 3

Sparingly soluble catalysts such as calcium oxide, sodium

methoxide and barium hydroxide have exhibited high activities for rapeseed oil transesterification (43). During vegetable oil transesterification using calcium oxide, calcium

glyceroxide was produced through the reaction of calcium

oxide with glycerol. This by-product created more active

sites and thus enhanced the reaction rate (44). The activities of heterogeneously catalyzed reactions are listed in

Table 3.

The Supercritical Methanol System

Transesterification reactions using basic or acidic catalysts are relatively time-consuming and require complex

separations, resulting in high production costs and energy

consumption. To overcome these problems, supercritical

methanol (SCM) has been proposed for catalyst-free vegetable oil transesterifications (5759). Whereas vegetable

oil transesterifications with regular methanol are biphasic

reactions, the lower dielectric constant of supercritical

methanol results in a one-phase reaction solution. The single

Basic scheme for biodiesel and glycerol production.

254

W. N. R. WAN ISAHAK ET AL.

TABLE 3

Various heterogeneous catalytic systems employed in glycerol production

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

Type of catalyst/reaction

Molar ratio

Temperature ( C)

Time (h)

Conversion (%)

References

65:1

12:1

15:1

65:1

12:1

30:1

20:1

9:1

18:1

60

65

<70

60

65

60

120

60

170

3

5

23

5

3

1

1

30 min

12

94

94

91.07

97

95

94

98.6

97.3

92.5

(45)

(46)

(47)

(48)

(49)

(50)

(51)

(52)

(53)

10:1

20:1

12:1

80

60

150200

2

1

3

97.1

100

9

(54)

(56)

(55)

Heterogeneous basic

Ca (NO3 ) 2 /Al2 O3

CaO/Al2 O3

KOH/Al2 O3

Mg-Al hydrotalcite

CaO

CaO/ZnO

Sulfated zirconia

Sr-Mg

Alum (KAl (SO4 )2 12H2 O)

Heterogeneous acidic

p-Toluenesulfonic acid (PTSA)

Metal acetates and stearic acid

Silicotungstic acid

Immobilized Enzyme Catalytic System

phase allows for a short reaction time (60). Compared with

catalytic processes carried out at atmospheric pressure, the

non-catalytic SCM process involves a considerably simpler

purification step, a lower reaction time and lower energy.

In addition, the SCM method is more environmentally

friendly.

In investigating product separation problems, Hawash

et al. (61) reported that a non-catalytic transesterification

reaction using supercritical methanol afforded a 100% ester

yield within four minutes. However, a reaction temperature

of 593 K and a reaction pressure of 8.4 MPa were necessary.

Moreover, a high molar ratio of methanol to oil was utilized

(61,62). Although high, the cost of the SCM process could

be offset because this reaction produces high-purity methyl

esters (99.6%) and glycerol (96.5%) (63). Glycerol production using the SCM technique is summarized in Table 4.

The transesterification reaction is also performed using

enzyme catalysts. Lipase is the most efficient and active

enzyme for the reaction. To immobilize the enzyme, the

carbodiimide activation method is the most effective. The

penicillium expansum lipase (PEL) systems discussed by

Yang et al. (66) and Xu and Ma (67) are summarized in

Table 5.

Nanoparticle Catalytic Systems

Over the past three years, nanoparticle heterogeneous catalysts have been used in vegetable oil transesterifications

to easily separate the catalyst from the glycerol phase.

The activity and performance was reported to increase

TABLE 4

Transesterification using supercritical methanol (SCM)

Type of catalyst/reaction

SCM

SCM

SCM

NaOH in SCM

KOH in SCM

Molar ratio

(MeOH:Oil)

Temperature ( C)

Time (min)

Conversion (%)

References

43:1

45:1

36:1

41:1

250300

320

350

250

287

715

4

5

8

30

98

100

96

98

>98

(58)

(61)

(64)

(65)

(63)

TABLE 5

Performance of transesterification reactions using immobilized enzymes as catalysts

Type of catalyst/reaction

Immobilized lipase NOVO435

Immobilized lipase on magnetic

nanoparticles

Molar ratio

Temperature ( C)

Time (h)

Conversion (%)

References

2.2:1

1:1

43

45

36

25

100

94

(91)

(67)

GLYCEROL RECOVERY FROM VEGETABLE OIL

255

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

TABLE 6

Performance of transesterification reactions using nanoparticle catalysts

Type of catalyst/reaction

Molar ratio

Temperature ( C)

Time (h)

Conversion (%)

References

KF-loaded nano--Al2 O3

CaO nanopowder

Nano-MgO

Nanocrystalline CaO

15:1

15:1

36:1

27:1

65

65

240

Room temperature

8

2.5

16 min

97.7

94

99.28

99

(68)

(69)

(70)

(71)

PRODUCTS SEPARATION AND CATALYST

RECOVERY STAGE

for nano-sized catalytic particles because of their higher

surface area and availability of active sites. Boz et al.

(68) demonstrated KF-loaded nano--Al2 O3 as a versatile catalyst for transesterification. The catalytic performance of various nanoparticle catalysts is summarized in

Table 6.

Homogeneous catalysts are the most active catalysts for

the vegetable oil transesterification reaction. However, the

higher residual catalyst amounts associated with these catalysts compared with those encountered in heterogeneous processes lead to higher separation costs. Furthermore, unlike

heterogeneous catalysts, homogeneous catalysts cannot be

recycled for reuse because they remain in the product. One

technique for removing excess homogeneous catalyst is a

titrative method by which the acid or base catalyst is converted into its salt (38). Because of their ease of separation

and ability to be regenerated, heterogeneous catalysts are

good, clean and cost-effective alternatives for producing

FAMEs and glycerol from vegetable oils. The solid catalyst can be removed by filtration, resulting in a less complex

recovery of biodiesel and glycerol (78,79).

Recovering glycerol from FAME phases was studied by

Saleh et al. (80). The researchers found that an ultrafiltration

technique successfully separated the small amount of glycerol contained in the FAME phase. Temperature significantly

increased water solubility in various commercial biodiesels

(81). Consequently, using higher temperatures increased

glycerol solubility in FAMEs and made the subsequent separations more challenging. Wang et al. (81) reported that using

ceramic membrane separation at 60 C reduced the glycerol

dissolved in FAME; however, this result was achieved only

after removing the methanol.

For glycerol produced by vegetable oil transesterification

with an ionic liquid, the catalyst can be separated from the

product mixture by a crystallization and freezing technique

based on the boiling-point differences between glycerol and

the ionic liquid (72). The glycerol producers using super

Ionic Liquid (ILs) Catalytic Systems

In other works, immidazolium-based ionic liquids and multiphase acidic or basic conditions have been used to produce glycerol from vegetable oil transesterification. High

yields of biodiesel (>98%) were afforded from soybean

oil transesterification when the ionic liquid 1-n-butyl3-methylimidazolium bis (trifluoromethylsulphonyl) imide

(BMI.NTf2 ), alcohols and K2 CO3 or sulphuric acid were

used (72). The lack of a solid catalyst resulted in a clean

process. However, this catalytic process was not practical

because of the high IL cost and difficulty in handling.

Interestingly, Vidya and Chadha (73) reported that

hydrophobic ILs such as [Bmim]PF6 and [Bmim]NTf2

were better media for vegetable oil transesterifications

than the hydrophilic [Bmim]BF4 . They also indicated

that the IL anions strongly affected the catalytic performance of Pseudomonas cepacia lipase (73). Comparing

two hydrophobic ILs, [Bmim]NTf2 performed better than

[Bmim]PF6 . The higher viscosity of [Bmim]PF6 limited

mass transfer of the substrates and products to and from the

enzyme active sites and thus led to lower catalytic activity

(76). Isahak et al. (77) reported that the use of ionic liquids,

namely choline chloride, produced higher-quality biodiesels

and glycerol. The activities of various ionic liquid catalysts

are summarized in Table 7.

TABLE 7

Performance of transesterification reactions using ionic liquids as catalysts

Type of catalyst/reaction

[Bmim]NTf2

[Bmim]PF6

[C3 mim]Cl

N-Methyl-2-pyrrolidone

hydrogen sulphate

Molar ratio

(MeOH:Oil)

Temperature ( C)

Time (h)

Conversion (%)

References

7.5:1

1:1

2:1

70

50

80

80

1.5

24

3

3

>98

98

96

95

(72)

(73)

(74)

(75)

256

W. N. R. WAN ISAHAK ET AL.

critical methanol (SCM) and hydrolysis were not apprehensive of any excess catalyst. However, unreacted triglyceride

remained in the product mixtures. To remove the unreacted material, a solvent extraction method that involves

overnight separation into layers based on weight and polarity

can be used. Otherwise, a centrifugation technique must be

employed to separate the products.

Nanoparticle Catalyst Recovery Processes

Nanoparticle catalysts are difficult to remove using conventional filtration. Polymeric membranes can recover nanoparticle catalysts. The filtration efficiency depends on the membrane size. The nanoparticle catalysts used for vegetable oil

transesterification processes resist separation and recovery.

However, centrifugation has been demonstrated to separate

these catalysts from products at high recovery levels (70).

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

Homogeneous Catalyst Recovery Processes

The homogeneous catalysts remain in the product after transesterification; therefore, the homogeneous catalysts are not

reusable. However, transition metal homogeneous catalysts

can be recovered by using a zeolite membrane that has a crystalline structure with pores smaller than those of transition

metal catalysts (82). Alternatively, homogeneous catalysts

can be neutralized into salts, and the salts can then be

removed by filtration. Catalyst removal after acid washing

is discussed later.

Heterogeneous Catalyst Recovery Processes

Few studies of heterogeneous catalyst regeneration exist.

Solid-phase heterogeneous vegetable oil transesterification catalysts can generally be recycled a few times

without adverse effects. They can be removed easily from the products by filtration or centrifugation

(42,56,68,83,84). Commonly, the heterogeneous catalysts

are then washed with organic solvent and drying overnight

(8587). Following re-calcination under N2 after an extensive methanol wash, the catalysts are ready for additional

reactions (88,89). Some researchers report that heterogeneous catalysts can be reused without any treatment and

without any significant loss in activity (90).

Supercritical Methanol Recovery Process

Catalyst-free supercritical methanol transesterification is

performed to increase the reaction rate and thus shorten the

reaction time. However, the excess SCM required leads to

some difficulty in separation. The problem can be overcome

by an evaporation and layer separation technique (63).

Ionic Liquid Catalyst Recovery Process

Ionic liquids are efficient and versatile catalysts because

of their physicochemical properties. Ionic liquids are salts

that consist of easily separated anions and cations. Because

of melting-point differences between the ionic liquids and

remainder of the reaction chemicals, freezing techniques

are common methods for separating ionic liquids from the

products and unreacted starting material (72,73).

CRUDE GLYCEROL RECOVERY PROCESS

Here, glycerol recovery from hydrolysis, saponification and

transesterification reactions is reviewed. Various practical

methods and techniques have been used for glycerol recovery

and enrichment.

Hydrolysis

Hydrolysis is divided into two processes: acid-catalyzed

hydrolysis and base-catalyzed hydrolysis (saponification).

The reaction produces two layers of product that can be

separated by using a separating funnel or by decantation.

Homogenous catalysts can be recovered by neutralization to

salts and centrifugation (22); heterogeneous catalysts can be

removed by filtration. Crude glycerol is obtained from the

lower phase by removing water through vacuum distillation

(23). An advanced glycerol recovery technique was developed by modification of an ionic liquid-glycerol mixture to

form deep eutectic solvents (DES). The synthesized DES

was used to extract the glycerol from the biodiesel (92).

Transesterification Reaction

Immobilized Enzyme Catalyst Recovery Process

Immobilized enzymes are efficient catalysts for vegetable oil

transesterification. However, the production costs are high

and require catalyst reuse. Otherwise, difficulties in handling are the primary problems associates with immobilized

enzymes. For reuse, the enzyme is isolated using centrifugation. The recovered lipase is washed with organic solvents

and is then ready for another reaction (68,91).

Theoretically, the glycerol of vegetable oil transesterification

constitutes approximately 10% of the products. Typically,

however, the recovered glycerol constitutes only 9 to 9.6%

of the products (Table 8). In an effective biodiesel production process, only small amounts of the unreacted starting

materials remain in the glycerol phase. Glycerol is also an

important by-product in soap production. When fats and

oils are saponified by caustic soda in the soap production

GLYCEROL RECOVERY FROM VEGETABLE OIL

TABLE 8

Typical percentages of transesterification products

Products of transesterification

Percentage range (%)

References

Biodiesel

Glycerol

Unreacted products (methanol,

MG, DG, TG)

9091

9.09.6

0.41.0

(11,93,94)

(93,94,95,96,97)

(11,93,98,99)

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

Note: MG: Monoglyceride, DG: Diglyceride, TG: Triglyceride.

process, glycerol is dissolved in the soap lye and in the crude

soap as an impurity.

Glycerol from fats and oil in soap manufacturing usually comprise approximately 10% of the total products.

Recovering usable materials is vital to the profitability of

any soap production process. Unfortunately, many smalland medium-scale soap producers discard the lye. The specific recovery technique employed is critical to recovering

glycerol from spent soap lye. The liquor that remains after

soap manufacture must be allowed to settle for 20 minutes

after stirring. The clear phase is decanted and discarded,

and the remaining phase is heat treated at 60 C in a conical

flask (100).

The basic and acidic catalysts employed for glycerol production by transesterification are recovered via chemical

treatment. Either sulphuric acid (H2 SO4 ) or sodium hydroxide (NaOH) are used to neutralize the catalysts to salts. For

example, H2 SO4 neutralizes NaOH in glycerol samples to

sodium sulphate (Na2 SO4 ). Fortunately, Na2 SO4 has low solubility in the aqueous glycerol solution, which is saturated

with sodium chloride (NaCl). Indeed, NaCl remains primarily in the glycerol layer (101,102). Hence, the Na2 SO4 salts

can be removed by decantation and filtration.

The highest glycerol yields are obtained by the bleaching

recovery technique (100). Bleaching (alkaline system) both

purifies the glycerol and further saponifies the free triglycerides (103). The amount of recovered glycerol depends

on the recovery point and on the purification stage during

which the technique is utilized (104). The variation in glycerol recovery amounts obtained across the soap industry is

due to the different soap types of lye and methods of treatment employed. For example, during the recovery stages,

glycerol can be lost through washing, graining and desalting. Moreover, if a temperature of 60 C is exceeded during

treatment, side reactions may occur. Glycerol decomposes to

acrolein at higher temperatures (>140 C).

The crude glycerol derived from vegetable oil can

be recovered from the biodiesel phase by centrifugation.

Centrifugation is followed by hydrochloric acid treatment

to convert any contaminant soaps to free acids or salts

(105,106). Methanol and water contaminants are removed

by distillation (107). Afterward, the glycerol layer is neutralized with caustic soda, producing 80% (w/w) crude glycerol.

Next, some glycerol purification processes are presented.

In addition, a recovery technique that employs fixed silica

257

gel beds to adsorb glycerol from methanol-free biodiesel

streams is discussed (108).

OVERVIEW OF GLYCEROL PURIFICATION

For many years, glycerol has been purified to make it more

useful for various manufacturing activities. Crude glycerol

is obtained as a by-product from three different processes:

soap manufacture, fatty acid production and fatty ester production (109). High-purity glycerol is used commercially in

pharmaceuticals, food processing, lubrication and cosmetics.

For use as animal food, several glycerol purification steps are

required to remove impurities (110).

The purity of crude glycerol obtained from vegetable oil

transesterification depends on three parameters: the type of

catalyst used, the amount of excess alcohol and the conversion achieved (111). The purity ranges of crude glycerol

produced by transesterification using homogeneous catalysts, heterogeneous catalysts and supercritical methanol

(SCM) are 5570%, 7585%, and 96.5%, respectively (112).

Currently, much attention is being focussed on employing green catalytic transesterification processes to convert

bio-renewable vegetable oils to commodity chemicals and

clean fuels. These reactions are performed at lower temperatures and atmospheric pressure using homogeneous or

heterogeneous catalysts and excess methanol. However, the

excessive unreacted methanol presents a problem. Methanol

is dangerous and can adversely affect human health and the

environment. To overcome this problem, the excess methanol

is recovered by processes such as evaporation and recycled

to the reactor for additional transesterification cycles.

Crude glycerol contains 20.2% glycerol, 6.6% fatty acids

(as soap) and 64.3% salt. Thus, 91.1% of crude glycerol

residue consists of components that are potentially useful

for other applications (113). According to van Gerpen et al.

(114), crude glycerol obtained by transesterification is composed of 50 wt.% or less glycerol. The remaining contents

are primarily water, salts, unreacted alcohol and catalyst.

To produce high-quality glycerol, these contaminants must

be removed.

Purification Techniques for Glycerol Synthesized with

Inorganic Catalysts

Recently, crude glycerol separation and purification activities have expanded considerably, and academic institutions

have explored more innovative methods, theories and process

designs in these respects.

Salt Separation

For crude glycerol derived with an alkaline catalyst, treatment begins by neutralization using certain acids. This

technique efficiently removes alkaline matter, including

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

258

W. N. R. WAN ISAHAK ET AL.

excess catalyst and the abundant soaps formed during transesterification processes employing homogeneous catalysts.

The neutralization separates the reaction mixture into three

phases using a strong- or medium-strength mineral. The

three phases consist of the catalyst in the bottom phase, the

neutralized glycerol and methanol in the middle phase and

the free fatty acids (FFAs) in the top phase (115).

Acids are used to neutralize excess alkaline catalysts,

whereas bases are used to neutralize acidic catalysts.

Sometimes, hydrochloric or sulphuric acid is employed in a

re-neutralization step and produces sodium chloride or potassium sulphate, respectively (97). However, using phosphoric

acid is more environmentally friendly. Phosphoric acid neutralizations produce a phosphate salt that is widely used as

a fertilizer. Sulphuric and hydrochloric acids produce environmentally harmful substances during neutralization. The

amount and concentration of acids used in neutralization

exert major effects on the separation time and the removal

of free fatty acids and salts (116).

Usually, the crude glycerol is reacted with greater than

1 mole of 85 wt.% sulphuric acid. Afterward, sodium borohydride or sodium hydroxide solution is added to neutralize

the excess acid and to remove colored impurities. Hajek

and Skopal (93) demonstrated that sequential neutralizations or saponifications could yield 84% purity glycerol.

Furthermore, Kongjao et al. (117) asserted that acidifying

the crude glycerol with mineral acids (such as sulphuric

acid) converted soap impurities into insoluble fatty acids

according to reaction (1).

RCOONa + H2 SO4 RCOOH + Na+ + SO2

4

(1)

Crystallization or Precipitation

In another separation technique, catalyst salts in solution after acidic treatment are removed by precipitation as

hydroxyapatite (HAP). The co-addition of lime (Ca(OH)2 )

and phosphoric acid to the pre-treated glycerol results in

calcium apatite (Ca5 (PO4 )3 (OH)) formation. This chemical

reaction removes solubilized catalyst from glycerol samples

(98). The reaction and precipitation is driven by calciumion and hydroxide-ion attraction. Separation of the calcium

apatite by gravity or centrifugation removes nearly all of the

excess catalyst.

Methanol Removal and Recycling

Excess un-reacted methanol is a major contaminant in crude

glycerol. High methanol levels are toxic, particularly in animal feeds and pharmaceuticals. Methanol is inherently toxic

but not directly poisonous. Alcohol dehydrogenase enzyme

in the liver converts methanol to formic acid and formaldehyde, which causes blindness by the destruction of the

optic nerve (118). The excess methanol must be removed to

achieve the level deemed safe by the U.S. Food and Drug

Administration (FDA). Brockmann et al. (119) reported

TABLE 9

Standard glycerol characterization methods

Physical properties

Glycerol content

Density

Viscosity

Ash value

Acidity

Moisture content

Heat of combustion

United States

Pharmacopeia

(USP)

ASTM

European

Standard

Method

(EN)

USP 26

D5002-94

D445-96

D0482-03

D1093-98

D4377-00E01

D0240-92

14214

14214

References

(97)

(120)

(110)

(97)

(97)

(97)

(121)

excess methanol removal using a flash evaporation. This

technique, based on the boiling point of alcohols, removed

nearly 100% of the methanol. In summary, a methanol

removal step is needed to meet the general usage requirements set by international standards (ASTM and EN in

Table 9).

Removal of Solid Contaminants

Heterogeneous catalysts are better suited for glycerol production than homogeneous catalysts. Heterogeneous catalysts afford a considerably cleaner crude glycerol, and

heterogeneous catalysts can be easily removed by simple filtration. The disadvantages of heterogeneous catalysts

include their high cost and difficult syntheses. Homogeneous

catalysts are better focussed. However, neutralizing homogeneous catalysts produce more salt.

Furthermore, years ago, the Wurster and Sanger singleeffect glycerine evaporator was developed to overcome the

salt removal problem (122). The first of the three apparatuses

had a large chamber that functioned to collect salts. After

a neutralization, the entire mixture was dropped into a tank

with a false bottom comprising a filter bed of wire screen

and filter cloth. The crude glycerol was pumped away from

below the false bottom. The salt was washed with lye and

then with water. The wash liquors were pumped back into

the evaporator feed tank.

Depending on the crude glycerol content, this procedure

decreased the salt content to 0.5 to 2.0 wt.% (122). This

method for removing salt was used only in single-effect

evaporations. The second method, which is still extensively

used in small and moderately sized plants, has the evaporator

bottoms connected to salt filters, salt boxes or salt extractors.

For a double-effect evaporator, three salt extractors are typically used. The setup allows for both evaporators to drop salt

while one extractor is emptied. Salt is allowed to accumulate in the evaporator during the time required to steam, dry

and empty its extractor. Furthermore, this second apparatus

allows for the salt to be removed from the evaporators continuously and dyed. The third apparatus utilizes salt drums

and centrifuges for complete salt removal.

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

GLYCEROL RECOVERY FROM VEGETABLE OIL

Recently, Buenemann et al. (123) reported an advanced

technology for removing solids from crude glycerol. This

technique employs microfiltration or ultrafiltration using

ceramic-supported zirconia or alumina filters. The ceramic

material has a high mechanical resistance and tolerates a

wide range of temperatures and pH values. Theoretically, the

micro-sized catalysts and salts are easily isolated using these

ceramic-supported zirconia or alumina filter membranes

(124). This process has produced high-quality glycerol without any significant loss in yield.

Gomes et al. reported that ceramic membranes made of

tubular-type -Al2 O3 /TiO2 are able to purify glycerol to

high purity levels (125). The microfiltration process proposed by Gomes et al. consisted of two stages. First, a

3.5-kg mixture was prepared with a mass composition of

80% biodiesel, 10% alcohol and 10% glycerol. In the second stage, the membrane that yielded the best permeate flux

and free glycerol retention was identified. This microfiltration membrane has also been used to filter other micro-sized

materials from glycerol (126). Large glycerol streams can

be purified continuously, effectively and economically even

with frequent provenance changes. This technique has produced technical-grade glycerol (above 99.2 wt.%).

Saleh et al. (80) reported an ultrafiltration (UF) technique

for separating crude glycerol from the fatty acid methyl

ester (FAME) phase. This pressure-driven technique was performed using 1-100-nm membranes. Specifically, this UF

technique removed high-molecular-weight substances, colloidal materials, organic and inorganic molecules. The technique was employed in several other applications, including

virus prevention and bacteria and waste water recycling

(127). This application can effectively recover and separate crude glycerol from the FAME phase. In the Saleh

et al. study, adding a small amount of water (approximately

0.06 mass %) improved separation and efficiency (80).

Conversely, a nanofiltration technique was used to remove

1- to 100-nm particles in a high-viscosity separation (128).

Removing Ions and Colored Contaminants by

Adsorption

During the reaction, some catalysts dissolve into the reaction medium as free ions. To remove these free ions,

ion exchange resins have been used. Both column and

batch methods have been investigated (129). Synthetic ion

exchange resins have been produced commercially since the

1960s. Strong acid cation exchange resins and strong base

anion exchange resins, which fully ionise over the entire

pH range, are supported on three-dimensional polystyrene

cross-linked with an agent such as divinylbenzene. To convert the cross-liked polystyrene to a hydrogel with an ion

exchange capability, ionic functional groups are attached

to the polymeric network by a variety of chemical means.

For example, sulphonating a styrene-divinylbenzene copolymer permanently attaches sulphite (-SO3 ) groups, affording

259

a negatively charged matrix and exchangeable, mobile and

positive hydrogen ions (130). The specific linkages and

three-dimensional structures play important roles in adsorbing contaminants.

Two separate ion exchange resins can be used to exchange

cations for hydrogen ions (H+ ) and anions for hydroxyl ions

(OH ). The hydrogen and hydroxyl ions subsequently combine to form pure water, as shown in Figure 4. If maintaining

neutrality is desired, Na+ , Ca2+ , K+ or Mg2+ resins can be

utilized instead of H+ resins. Likewise, Cl , HCO3 , SO4 2

or NO3 resins can replace strongly basic OH resins. The

maximum ion exchange capacity of strong acid cation or

strong base anion exchangers is stoichiometric i.e., the

capacity is based on the equivalents of mobile charge within

the particular resins. Thus, one mol of H+ is one equivalent. One mole of Ca2+ is two equivalents. Anion and cation

exchange resins used together ensure that the ion exchange

resins capture both free anions and cations from the crude

glycerol sample, maximizing performance. This process has

produced glycerol of purities higher than 99.2%.

In another case, acidic ion exchange resin beads were

used to separate fatty acid salts and inorganic salts from

glycerol (131). This purification was effective when highquality resins consisting of 4 to 65 wt.% cross-linker were

used. Uniformity coefficients no greater than 1.15 were necessary to ensure that the glycerol passed through the bed

at a minimum flow rate of 0.3 bead volumes per hour. The

gel-type resins in this cross-linker range were more suitable

for the separation of soluble substances than resins with less

than 10% cross-linker. High cross-linking affected separation efficiency. Rezkallah (131) also claimed that the salts

and colored impurities eluted from the column earlier than

the glycerol. The afforded glycerol exhibited a considerably

lower ion and colored impurity content.

Amberlite-252, a strong acid cationic exchange resin, has

also been employed. Carmona et al. (132) reported that

the macroporous Amberlite could be used for sodium ion

removal from glycerol/water solutions containing high salt

concentrations. This resin was capable of yielding technicalgrade glycerol from many different processes. Purification

using Amberlit-252 was particularly efficient because of its

ability to be regenerated more than five times without any

significant loss of exchange capacity (129).

Distillation as a Single Purification Step

Many years ago, crude glycerol was purified using a simple distillation unit. As a result, the glycerol contained ash,

matter organic non-glycerol, water and soap (108). The

distillation was reported as a successful method for purifying crude glycerol that is similar in composition to the source

of commercial glycerol used today. An illuminating comparison of crude, purified and commercial-grade glycerol is

shown in Table 10. The corresponding analyses were performed based on standard methods: glycerol content ISO

260

W. N. R. WAN ISAHAK ET AL.

KCl in glycerol

solution

K+

Cl

H+

Cl

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

K+

H+

OH

OH

H+

OH

H+

OH

OH

H+

H+

OH

H2O

FIGURE 4 Schematic representation of ion exchange columns that shows sodium and chloride ions exchange for hydrogen and hydroxyl ions, respectively.

The latter ions combine to form water.

TABLE 10

Characterization of crude, purified and commercial-grade glycerol

Parameter

Glycerol content (%)

Moisture (%)

Ash (%)

Soap (%)

Acidity

pH value

Chloride (ppm)

Color (APHA)

Gross energy (Cal/g)

Crude glycerol

Purified glycerol

Commercial glycerol

References

6080

1.56.5

1.52.5

35

0.71.3

9.811.2

n.d

Dark

36853825

99.199.8

0.110.80

0.054

0.56

0.100.16

6.76.9

1.0

3445

58105831

99.299.98

0.140.29

<0.002

n.a

0.940.07

6.76.8

0.69.5

1.810.3

5832

(97)

(133)

(133)

(19)

(134)

(11)

(133)

(133)

(133)

2879-1975; ash content ISO 2098-1972; and matter organic

non-glycerol (MONG) ISO 2464-1973.

The ash in crude glycerol was primarily sodium catalyst

salts (96). During glycerol recovery, trace amounts of shortand medium-chain fatty acids were retained in the crude

glycerol (106,135). At the high distillation temperature, the

free sodium hydroxide reacted with the fatty acids, forming short- and medium-chain soaps. Higher pH levels, due to

the presence of more sodium hydroxide, resulted in greater

soap formation. Sodium hydroxide also catalyzed glycerol

polymerization to polyglycerol (136).

Many works have explored the distillation of the glycerol phase as a method for removing methanol (137). This

technique operates based on boiling points. Two or more

materials with different boiling points can be separated

using vacuum distillation, and this concept was applied to

glycerol purification. Before distillation, the glycerol was

acidified (134). The success of vacuum distillations depends

on temperature (T) and pressure (P). The crude glycerol was

successfully distilled at 120126 C and 4.0 101 to 4.0

102 mbar, producing 96.6% purity glycerol. The optimum pH for the distillation was less than 5, which obviated

foaming.

This technique is sensitive and must be monitored to avoid

undesirable reactions. Three possible reactions can reduce

the glycerol yield during distillation: polymerization, dehydration and oxidation. The polymerization of glycerol to

polyglycerol occurs readily at high pH values, excess NaOH

concentrations and high temperatures (>200 C) (136,138).

Glycerol dehydrates to acrolein (bp. 52 C) at low pH

GLYCEROL RECOVERY FROM VEGETABLE OIL

(99,139), and the acrolein accumulates in the cold trap during distillation. In addition, glycerol can oxidise to glycerose,

glyceraldehyde and dihydroxyacetone (140).

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

Recent Industrial Purification Processes

Recently, environmental issues have propelled the refinery

industry to develop new technologies for glycerol purification. Many techniques are combined into a single step or

a limited number of steps to enhance recovery and purification, e.g., soap splitting followed by salt and methanol

removal. Some separation techniques have employed vacuums because of glycerols heat sensitivity (glycerol decomposes at 180 C) (119).

As established methods, thes following technologies may

be used to further enhance the purity of glycerol after

the soap splitting step: fractional distillation, ion exchange,

adsorption, precipitation, extraction, crystallization and dialysis. The most common purification pathway, in sequential

order, is soap splitting, combined methanol/water removal,

fractional distillation, ion exchange (zeolite or resins) and

adsorption (active carbon powder) (120,131). Well-known

companies manufacture glycerol purification equipment. For

example, companies such as Desmetballestra and Buss-SMS

Canzler market ion exchange equipment. Other chemical

companies, such as Rohm & Haas and Lanxess, supply ion

exchange granulates, whereas Norit Company supplies powder and granulated activated carbon as glycerol bleaching

and decolorizing agents (119). Their activated carbon, with

its large surface area and high porosity, adsorbs pigments

and organic matter easily for large glycerol samples. Ion

exchange applications may be performed by either a column or batch technique (129). In addition, higher capacity

ion exchanges that will make high-purity glycerol production

more facile are being developed.

Many glycerol refinement plants exist today. Biodieselbased glycerol is manufactured in various grades by

treatment using single or multiple steps neutralization,

heating, condensing, refluxing and distillation (31,141).

Approximately 9095% of commercial glycerol is purified

to remove most impurities and increase market value. The

residual methanol in crude glycerol is removed easily using

evaporation and can be recycled to reduce the cost of purification. The final purification stage consists in using an

absorber to remove any soluble impurities in glycerol (111).

Purification of glycerol from biodiesel processing using

AMBERSEP BD50 technology (142), which employs an

ion exchange resin, is an effective and innovative process.

The biodiesel industry generates a tremendous amount of

crude glycerol. The crude glycerol that is produced as a byproduct in the transesterification process to make biodiesel

typically contains high levels of salts, stemming from the use

of homogeneous transesterification catalysts such as sodium

methylate (14). Most applications for glycerol require the

elimination of these salts. Indeed, the conventional methods

261

use to purify the crude glycerol are faced with high operating

costs and low efficiency.

For most applications in the food and pharmaceutical

sectors, crude glycerol needs be purified to pharmaceutical

grade. This high-quality grade can be realized by employing a combination of techniquese.g., heating, evaporation,

splitting, decantation, adsorption and vacuum distillation

(143). This combinatory process produces glycerol with a

purity greater than 99.5% from typical crude glycerol, which

contains a mixture of monoglycerides, diglycerides, triglycerides, methanol, water, fatty acid alkyl esters, catalyst and

salts. A flow diagram of a typical glycerol purification is

shown in Figure 5.

EET Corporations patented HEED technology can also

produce high-purity glycerol. This processing equipment

is an economical solution for glycerol purification in the

biodiesel and soap industries. By using EETs technology, crude glycerol from biodiesel and saponification processes can be refined to achieve the USP-grade quality

requirement of 99.7% purity (144). Alternatively, lowercost and intermediate-purity grades can be produced for

direct use or chemical conversion into other compounds

such as propylene glycol and ethylene glycol. In addition, EETs membrane-based technology avoids important

problems associated with stand-alone evaporation and distillation, such as foaming, cross-contamination, corrosion,

limited recovery and high costs in energy, maintenance and

operation.

The robustness of EETs technology allows it to be

applied to neutralized glycerol either before or after

methanol removal and over a range of feed compositions.

Other HEED applications include purification of refined

glycerol that has been distilled or evaporated but nevertheless contains residual salts or organic substances. EETs

glycerol purification process begins with a pre-treatment to

remove solids and fouling organics and to partially remove

color-causing organics.

The HEED (also known as HEEPM) system configuration combines customized automated controls and control

logic to provide the optimal desalting of a particular pretreated crude glycerol. This established technique produces

colorless glycerol with low salt content. The process is considered a good, efficient technique for producing high-purity

glycerol. However, its complicated technology contributes

to high production costs and therefore makes the systems

uneconomical. Efficient technologies need to be developed

to produce high-quality glycerol at a lower cost.

Disposing of crude glycerol is both costly and wasteful.

An applied technology for crude glycerol purification

was introduced by SRS Engineering Company (145).

Incorporated into SRSs high-purity glycerol purification

system (the SRXG-Series distillation column) is an ideal

combination of processing steps. The SRXG-Series system

produces high-purity glycerol without any significant loss in

yield. In summary, these technologies illustrate that investing

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

262

W. N. R. WAN ISAHAK ET AL.

FIGURE 5 General flow diagram for a high-purity glycerol manufacturing process.

in the development of purification technologies can eliminate disposal costs and provide a new venue for profit in

the form of purified glycerol. The SRS system was able to

purify crude glycerol to technical-grade glycerol (over 97%)

(145). Furthermore, the purification of crude glycerol with

high methanol and water content was successfully performed

by Rototherm mechanically agitated thin-film processors.

These thin-film processors can be operated continuously and

in combination with distillation. They can also be used with

products containing sensitive solids (146).

Cost Estimates for Glycerol Purification Processes

Some information for crude glycerol purification by different methods was provided and discussed in this subtopic.

However, not much paper published in cost estimation for

this process. Posada et al. (2011) was reported the glycerol purification achieved up to 98 wt.% by combination of

neutralization, centrifugation, evaporation and column distillation (147). During the purification process, methanol at

99 wt.% is recovered and thus for the economic assessment, two scenarios were analyzed. In the first scenario,

the obtained methanol is considered as a process waste.

In the second scenario the methanol is considered as a

co-product that could be recycled to the transesterification

process and an economic value is given to this stream. The

lowest cost for glycerol purification was obtained under the

second scenario conditions (0.149 USD/kg). In other work,

the enrichment process of crude glycerol was performed

via chemical extraction and physical adsorption processes

by Hunsom et al. (148). For the whole enrichment process, based on equal quantity of crude glycerol, it was

noticed that the adsorption process was cheapest process

(5.72 USD/L crude glycerol) while a combined process of

chemical extraction with n-C3 H7 OH and adsorption was the

most costly (17.1 USD/L crude glycerol).

Glycerol Conversion to Other Chemicals

Recently, numerous papers have been published on the

direct utilization of glycerol. For example, glycerol can be

converted into value-added products by pyrolysis, steam

gasification or catalytic treatment. Glycerol can be catalytically converted into many other liquid products, including

acetaldehyde, acrolein, formaldehyde and hydroxyacetone.

Buhler et al. (149) reported the production of methanol,

acetaldehyde, acrolein, allyl alcohol, acetone, ethanol, carbon dioxide, carbon monoxide and hydrogen from glycerol

under supercritical conditions.

Additionally, Kunkes et al. (150) reported the conversion

of glycerol to syngas (H2 , CO, CO2 ) using Re on Pt/C as

a catalyst. The syngas was subsequently used to produce

a series of alcohols (151,152). Thiruchitrambalam (153)

reported that glycerol can be completely converted into H2 rich syngas through pyrolysis at 800 C in a fixed-bed reactor.

Cortright et al. (154) reported H2 production from the aqueous phase carbohydrate reforming of glycerol over Pt/Al2 O3

catalysts. In this reaction, hydrogen (H2 ) was afforded in

64.8 mol% yield. Buhler et al. (149) produced allyl alcohol, acetaldehyde, acrolein, methanol, CO, CO2 and H2 by

treating glycerol under supercritical conditions. However, a

low glycerol conversion (0.431 wt.%) was reported in this

work.

Chaudhari and Bakhshi (155) converted glycerol to

hydrogen by steam gasification. The steam gasification was

performed at steam flow rates of 2.5, 5.0, and 10 g/h

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

GLYCEROL RECOVERY FROM VEGETABLE OIL

at 600 and 700 C. The glycerol flow rate was 4 g/h.

Approximately 80% conversion was achieved when a steam

flow rate of 10 g/h at 700 C was used. Chaudhari and

Bakhshi (155) illustrated that the steam gasification of glycerol does not produce liquid product at 600 and 700 C in a

fixed-bed reactor. In contrast, Stein and Antal (156) demonstrated that steam gasification of glycerol afforded acrolein

and acetaldehyde liquid products at 600675 C in a laminar

flow reactor.

High-purity glycerol can be reacted with oleic acid

to form monoacylglycerols and diacylglycerols, which are

widely used as biolubricant additives (157161). One acylglycerol synthesis reported was the esterification of glycerol

with lauric acid to form glycerol laurate (162). These compounds possess high potential for use as biolubricants.

CONCLUSIONS

In this review, we discovered that crude glycerol can be

easily recovered from biodiesel by centrifugation or gravitational settling. However, the challenge is purification of this

crude glycerol to food-grade glycerol. For most applications,

glycerol needs to be free of impurities particularly catalysts, salts and soap to avoid the formation of unwanted

by-products during manufacturing. Currently, the glycerol

purification process is expensive and is plagued with handling and separation problems. Many methods have been

employed to purify glycerol, including neutralization, splitting, heating, ultrafiltration, ion exchange chromatography

and vacuum distillation. The combination of more than one

of these techniques can successfully yield pharmaceuticalgrade glycerol, and recovered and purified glycerol has

been converted into many valuable products, e.g., methanol,

hydrogen, 1,3-propanediol, glycerol tert-butyl ether (GTBE).

FUNDING

The authors thank Universiti Kebangsaan Malaysia (UKM)

for funding this project under research grant number UKMGUP-BTK-08-14-306/Dana Lonjakan, LRGS/BU/2011/

USM-UKM/PG/02, DPP-2013-056 and DIP-2012-022.

REFERENCES

1. Morrison, L.R. (2001) Kirk-Othmer Encyclopedia of Chemical

Technology. Glycerol; John Wiley & Sons, Inc.: New York.

2. HB International SAS. (2012) The Oleoline Glycerine Market

Report.

http://www.oleoline.com/wp-content/uploads/products/

reports/Dec2012_462181.pdf (accessed July 18, 2013)

3. Biodiesel 2020. (2008) Global market survey, feedstock trend

and forecasts. Emerging Markets Online 2nd edition. http://www.

healthtech.com/biodiesel2020 (accessed March 21, 2012).

263

4. Transparency Market Research. (2013) Glycerol Market by Source

(Biodiesel, Fatty Acids & Fatty Alcohols), by Applications (Personal

Care, Alkyd Resins, Polyether Polyols, Others), Downstream

Opportunities (Propylene Glycol, Epichlorohydrin, 1, 3 Propanediol

and Others)Global Industry Analysis, Size, Share, Trends, Growth

and Forecast, 20122018. [http://www.biodieselmagazine.com/

articles/9004/report-glycerol-market-expected-to-reach-2-1-billionin-2018] (accessed May 14, 2013)

5. Croy, C. and Dotson, K. (1995) Glycerine. INFORM, 6: 11041118.

6. Mohtar, Y., Tang, T.S., and Salmiah, A. (2001) Quality of basic

oleochemicals produced in Malaysia. INFORM, 12: 529536.

7. Ash, M. and Ash, I. (2004) Handbook of Preservatives. Synapse Info.

Resources: New York.

8. Ooi, T.L., Leong, W.L., and Radzuan, J. (1993) Potential source of

sterols from a palm kernel oil methyl ester residue of an oleochemical

plant. PORIM Bulletin, 27: 2537.

9. Kosmider, A., Leja, K., and Czaczyk, K. (2011) In G. Moentero

(ed.) Biodiesel-Quality, Emissions and By-products, v.l. Improved

Utilization of Crude Glycerol By-Product from Biodiesel Production,

InTech, Available from: http://www.intechopen.com/books/biodieselqualityemissions-and-by-products/improved-utilization-of-crudeglycerol-by-product-from-biodiesel-production

10. Hansen, C.F., Hernandez, A., Mullan, B.P., Moore, K., TrezonaMurray, M., King, R.H., and Pluske, J.R. (2009) A chemical analysis

of samples of crude glycerol from the production of biodiesel in

Australia, and the effects of feeding crude glycerol to growingfinishing pigs on performance, plasma metabolites and meat quality

at slaughter. Anim. Prod. Sci., 49: 154161.

11. Isahak, W.N.R.W., Ismail, M., Yarmo, M.A., Jahim, J.M., and

Salimon, J. (2010a) Purification of crude glycerol from transesterification RBD palm oil over homogeneous and heterogeneous catalysts

for the biolubricant preparation. J. Appl. Sci., 10: 25902595.

12. Saman, W.R.G., Nomura, N., Sato, S., and Matsumura, M. (2008) Pretreatment and utilization of raw glycerol from sunflower oil biodiesel

for growth and 1,3-propanediol production by Clostridium butyricum.

J. Chem. Technol. Biotechnol, 83: 10721080.

13. Mu, Y., Teng, H., Zhang, D.J., Wang, W., and Xiu, Z.L. (2006)

Microbial production of 1,3-propanediol by Klebsiella pneumonia

using crude glycerol from biodiesel preparations. Biotech. Lett., 28:

17551759.

14. Lancrenon, X. and Fedders, J. (2008) An innovation in glycerin

purification. Biodiesel Magazine. http://www.biodieselmagazine.

com/articles/2388/an-innovation-in-glycerin-purification/ (accessed

October 18, 2012).

15. Marchetti, J.M., Miguel, V.U., and Erazu, A.F. (2007) Possible

methods for biodiesel production. Renew. Sustain. Energy Rev., 11:

13001311.

16. Conceicao, M.M., Candeia, R.A., Dantas, H.J., Soledade, L.E.B.,

Fernandes Jr., V.J., and Souza, A.G. (2005) Rheological behavior of

castor oil biodiesel. Energy Fuel, 19: 21852188.

17. Berrios, M. and Skelton, R.L. (2008) Comparison of purification

methods for biodiesel. Chem. Eng. J., 144: 459465.

18. Fredman, B., Pryde, E.H., and Mounts, T.L. (1984) Variables affecting

the yields of fatty esters from transesterified vegetable oils. JAOCS,

61: 16381643.

19. Jitputti, J., Kitiyanan, B., Rangsunvigit, P., Bunyakiat, K., Attanatho,

L., and Jenvanitpanakul, P. (2006) Transesterification of crude palm

kernel oil and crude coconut oil by different solid catalysts. Chem.

Eng. J., 116: 6166.

20. Hammond, E.G. and Inmok, L. (1992) Process for enzymatic hydrolysis of fatty acid triglycerides with oat caryopses. U.S. Patent No.

5089403, February 18, 1992.

21. Ting, W.J., Tung, K.Y., Giridhar, R., and Wu, W.T. (2006) Application

of binary immobilized Candida rugosa lipase for hydrolysis of soybean oil. J. Mol. Catal. B: Enzymatic, 42: 3238.

Downloaded by [Universiti Kebangsaan Malaysia], [Wan Isahak] at 00:22 11 October 2014

264

W. N. R. WAN ISAHAK ET AL.

22. Bhatkhande, B.S. and Samant, S.D. (1998) Ultrasound assisted

PTC catalyzed saponification of vegetable oils using aqueous alkali.

Ultrason. Sonochem., 5: 712.

23. Satyarthi, J.K., Srinivas, D., and Ratnasamy, P. (2010) Hydrolysis of

vegetable oils and fats to fatty acids over solid acid catalysts. Appl.

Catal. A: Gen., 391: 427435.

24. Khuwijitjaru, P., Fujii, T., Adachi, S., Kimura, Y., and Matsuno, R.

(2004) Kinetics on the hydrolysis of fatty acid esters in subcritical

water. Chem. Eng. J., 99:14.

25. Minami, E. and Saka, S. (2006) Kinetics of hydrolysis and methyl

esterification for biodiesel production in two-step supercritical

methanol process. Fuel, 85: 24792483.

26. King, J.W., Holliday, R.L., and List, G.R. (1999) Hydrolysis of

soybean oil in a subcritical water flow reactor. Green Chem., 1:

261.

27. Alenezi, R., Leeke, G.A., Santos, R.C.D., and Khan, A.R. (2009)

Hydrolysis kinetics of sunflower oil under subcritical water conditions. Chem. Eng. Res. Des., 87: 867873.

28. Holliday, R.L. and King, J.W. (1997) Hydrolysis of vegetable oil in

sub- and supercritical water. Ind. Eng. Chem. Res., 36: 932.

29. Ma, F., Clements, L.D. and Hanna, M.A. (1998) The effects of catalyst, free fatty acids, and water on transesterification of beef tallow.

Amer. Soc. Agri. Eng., 41: 12611264.

30. Isahak, W.N.R.W., Ismail, M., Jahim, J.M., Salimon, J., and Yarmo,

M.A. (2012a) Characterization and performance of three promising heterogeneous catalysts in transesterification of palm oil. Chem.

Papers, 66: 178187.

31. Knothe, G., Van Gerpen, J., and Krahl, J. (2005) The Biodiesel

Handbook; AOCS Press: Champaign, Illinois.

32. Jeromin, L., Johannisbauer, W., Blum, S., Sedelies, R., Moormann,

H., Holfoth, B., and Plachenka, J. (1996) Glycerol water mixture from

hydrolysis of natural fats and oils passed through plate type separator, fat particles returned to hydrolysis reaction, liquid filtered through

membrane. U.S. Patent No. 5527974A, June 18, 1996.

33. Miao, X., Li, R., and Yao, H. (2009) Effective acid-catalyzed

transesterification for biodiesel production. Energy Convers. Mgmt.,

50: 26802684.

34. Hajek, M., Skopal, F., and Machek, J. (2006) Determination of free

glycerol in biodiesel. Eur. J. Lipid Sci. Technol., 108: 666669.

35. Leung, D.Y.C. and Guo, Y. (2006) Transesterification of neat and used

frying oil: Optimization for biodiesel product. Fuel Proc. Technol., 87:

883890.

36. Dias, J.M., Alvim-Ferraz, M.C.M., and Almeida, M.F. (2008)

Camparison of the performance of different homogeneous alkali catalysts during transesterification of waste and virgin oils and evaluation

of biodiesel quality. Fuel, 87: 35723578.

37. Rashid, U., Anwar, F., Moser, B.R., and Ashraf, S. (2008) Production

of sunflower oil methyl esters by optimized alkali-catalyzed methanolysis. Biomass Bioenergy, 32: 12021205.

38. Soriano, Jr., N.U., Venditti, R., and Argyropolous, D.S. (2008)

Biodiesel synthesis via homogeneous Lewis acid-catalyzed transesterification. Fuel, 88: 560565.

39. Zhang, Y., Dube, M.A., Mclean, D.D., and Kates, M. (2003) Biodiesel

production from waste cooking oil: 1. Process design and technological assessment. Bioresour. Technol., 89: 116.

40. Zheng, S., Kates, M., Dube, M.A., and McLean, D.D. (2006) Acidcatalyzed production of biodiesel from waste frying oil. Biomass

Bioenergy, 30: 267272.

41. Wang, Y., Ou, S., Liu, P., Xue, F., and Tang, S. (2006) Comparison of

two different processes to synthesize biodiesel by waste cooking oil.

J. Mol. Catal. A: Chem., 252: 107112.

42. Arzamendi, G., Campo, I., Arguinarena, E., Sanchez, M., Montes,

M., and Gandia, L.M. (2007) Synthesis of biodiesel with heterogeneous NaOH/alumina catalysts: Comparison with homogeneous

NaOH. Chem. Eng. J., 134: 123130.

43. Gryglewicz, S. (1999) Rapeseed oil methyl esters preparation using

heterogeneous catalysts. Bioresour. Technol., 70: 249253.

44. Kouzu, M., Tsunomori, M., Yamanaka, S., and Hidaka, J. (2010) Solid

base catalysis of calcium oxide for a reaction to convert vegetable oil

into biodiesel. Adv. Powder Technol., 21: 488494.

45. Benjapornkulaphong, S., Ngancharussrivichai, C., and Bunyakiat, K.

(2008) Al2 O3 supported alkali and alkali earth metals oxides for transesterification of palm kernel and coconut oil. Chem. Eng. J., 145:

468474.