Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Technical Spec External Check List

Caricato da

osersCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Technical Spec External Check List

Caricato da

osersCopyright:

Formati disponibili

T&O Regional Engineering

LAST External Inspection Checklist

FORMAL EXTERNAL INSPECTION (FEI) CHECKLIST

Tank Inspection Checklist Instructions

Apply the following instructions to both the external and internal inspection checklists.

The inspector should complete the checklist to the best of the inspectors ability for the

conditions of the tank at the time of the inspection. After the inspection, the data will be

analyzed and a fitness-for-service evaluation performed. For the purpose of the field

inspection, the inspector shall grade the observed conditions as follows:

Condition Codes:

E

A concern was observed for the item under consideration. An E does

not mean that correction is required, but only that further evaluation is

needed

OK

No concern was observed

NA

The item does not apply for this tank

Take a photograph of any item graded E. In addition, the inspector is encouraged to

take photographs of every tank component including but not limited to the foundation,

tank appurtenances, nozzles, valves, impoundment area, bottom extension, accessways,

wind girder, platforms, fixed roof, and floating roof.

Revision Date: Oct2013May 2015

Page 1 of 10

T&O Regional Engineering

LAST External Inspection Checklist

LAST External Inspection Checklist

Terminal:

Tank Number:

Inspection Date:

1.0

FOUNDATION

1.1

GENERAL

1

Identify the type of foundation (concrete ring,

concrete slab, asphalt, crushed stone, earth,

etc.)

2

Measure bottom elevations (see API 653

Appendix B for extent of measurements).

3

Does debris, vegetation, or earth contacting the

tank?

4

Does the site drain away from the tank?

5

Check operating condition of the dike drains.

6

Inspect for cavities or erosion around the tank

CONCRETE RING

1

Inspect for spalled or cracked concrete,

particularly under backup bars used in buttwelded annular rings under the shell.

2

Inspect drain openings in ring, back of water

draw basins and top surface of ring for

indications of bottom leakage.

ASPHALT

1

Check for settling of tank into asphalt base.

2

Look for areas of broken asphalt or where rock

filler is exposed.

CATHODIC PROTECTION

1

Identify the type of cathodic protection system

utilized if any

2

Review cathodic protection potential readings.

LEAK DETECTION

1

Check interstitial monitoring ports for indications

of leaks

1.2

1.3

1.4

1.5

2.0

SHELL

2.1

EXTERNAL

1

Visually inspect the shell for paint failures, leaks,

distortions, and corrosion

2

Locate leaks with dimensions on a sketch and

photograph.

3

Clean the shell-to-bottom joint and visually

inspect the bottom and shell-to-bottom weld.

Perform a magnetic particle examination where

linear indications are visually identified.

4

Inspect the bottom-to-foundation seal, if any.

5

Record paint color

6

Record thickness measurements at 6 locations

for each shell plate in the first course.

7

Record the bottom thickness at two places on

each sketch plate or annular ring section.

8

Record the nameplate information.

9

Inspect and record electrical grounding of the

tank.

INTERNAL

1

Visually inspect for grooving, corrosion, pitting,

and coating failures.

RIVETED SHELLS

1

Inspect rivet heads for metal loss.

2

Have vertical seams been full fillet lap-welded?

2.2

2.3

Revision Date: Oct2013May 2015

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

Page 2 of 10

T&O Regional Engineering

LAST External Inspection Checklist

LAST External Inspection Checklist

3

2.4

2.5

2.6

2.7

If no record exists of vertical riveted seams,

dimension and sketch or photograph the rivet

pattern and record the number of rows, rivet

size, pitch, and whether the joint is butt-riveted

or lap-riveted.

WIND GIRDER

1

Inspect wind girder(s) (paint, corrosion),

especially at tack welds.

2

Inspect supports and support welds.

3

Does the wind girder have drain holes at low

points?

4

Record wind girder dimensions, including

thickness and elevation

ANCHORS

1

Inspect anchor bolts and chairs and record

dimensions, including spacing.

2

Inspect anchor bolts for stretching, corrosion, or

pull-out

SHELL INSULATION

1

Are there gaps in the insulation jacket that allow

precipitation to penetrate the insulation?

2

Record the insulation dimensions and type

3

Check for corrosion behind the insulation at

openings or damaged areas

4

Can water drain out from behind the insulation?

(typically the insulation stops 4 to 6 in. above

the shell to bottom weld. Is the insulation

caulked or sealed to the bottom extension?)

5

Inspect sealing of insulation around man holes

and nozzles

SHELL DIMENSIONS

1

Record the tank circumference and the elevation

at which the circumference was measured.

2

Record the shell height and the height of each

shell course

3

For double bottom tanks, measure and record

any shell offset between the shell and the dead

shell. Generally offset measurements are taken

at settlement survey locations.

3.0

SHELL APPURTENANCES

3.1

MAN HOLES AND NOZZLES

1

Inspect for cracks and leakage on welds at

nozzles, man holes, and reinforcing plates.

2

Inspect for shell plate dimpling around nozzles,

caused by excessive pipe deflection.

3

Inspect for flange leaks and leaks around

bolting.

4

Are telltale holes open to the atmosphere?

5

Record each nozzle and man hole associated

dimensions (size, reinforcing plate dimensions,

centerline elevation, telltale hole, weld spacing,

and circumferential location, thicknesses)

EXTERNAL PIPING

1

Inspect piping, flanges, and valves for leaks up

to the first flange, threaded joint, or welded

joint outside the tank.

2

Inspect fire fighting system components.

3

Is there anchored piping which would be

hazardous to shell connections during earth

movement?

4

Check that thermal pressure relief of piping to

the tank is present.

3.2

Revision Date: Oct2013May 2015

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

Page 3 of 10

T&O Regional Engineering

LAST External Inspection Checklist

LAST External Inspection Checklist

5

3.3

3.4

3.5

3.6

3.7

Check operation of regulators for tanks with

purge gas systems.

6

Check temperature indicators for damage.

7

Check welds on shell-mounted davit clips.

AUTOGAUGE SYSTEM

1

Inspect autogauge tape guide and lower sheave

housing (floating swings) for leaks.

2

Inspect autogauge head for damage and check

legibility.

3

Bump the checker on autogauge head to check

for proper movement of tape.

4

Identify size and construction material of

autogauge tape guide (floating roof tanks).

5

Ask operator if tape tends to hang up or suffer

other problems during floating roof movement

(floating roof tanks).

6

For board-type autogauges, inspect condition of

board and legibility.

7

Test freedom of movement of marker and float.

8

Record the product level.

SHELL-MOUNTED SAMPLE STATION

1

Inspect sample lines for function of valves and

plugging of lines, including drain or

return-to-tank line.

2

Check circulation pump for leaks and operating

problems.

3

Inspect bracing and supports for sample lines

and equipment.

HEATER (SHELL MAN HOLEY MOUNTED)

1

Inspect condensate drain for presence of

product indicating leakage.

MIXER

1

Inspect for proper mounting flange and support.

2

Inspect for leakage.

3

Inspect condition of power lines and connections

to mixer.

SWING LINES

1

Indicator: Check that the indicator moves in the

proper direction: Floating swing line indicators

show a lower level as cable is wound up on the

winch. Non-floating swing line indicators show

the opposite.

2

Cable: check for wear or fraying.

3

Does the floating suction board indicator have

top and bottom position markings on the shell

with written labels?

4.0

FIXED ROOF

4.1

GENERAL

1

Is the roof free of debris?

2

Record the roof type, roof slope, and roof-toshell connection dimensions.

3

For aluminum dome roofs, record the

manufacturer and serial number.

4

Record roof thickness measurements (steel

roofs). Take at least 10 thickness

measurements at a maximum spacing of 10 ft

along two perpendicular lines. If any thickness

is less than 0.09 in., measure 3 additional

thicknesses in a 100 in2 area around that

location.

ROOF CORROSION

1

For safety, before accessing the roof, check its

4.2

Revision Date: Oct2013May 2015

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

Page 4 of 10

T&O Regional Engineering

LAST External Inspection Checklist

LAST External Inspection Checklist

4.3

4.4

4.5

4.6

4.7

4.8

4.9

thickness ultrasonically or lightly use a ball peen

hammer to test the deck plate near its edge for

thinning. (Corrosion normally attacks the roof

plate at the edge and the rafters in the center of

the roof first.)

2

Visually inspect for paint failure, holes, pitting,

and corrosion.

ROOF DRAINAGE

1

Look for indication of standing water. (Significant

sagging may indicate rafter or foundation

failure, or overload.)

ROOF INSULATION

1

Visually inspect for cracks or leaks in the

insulation weather coat where precipitation

could penetrate the insulation.

2

Remove small sections of insulation and check

roof for corrosion. Check for corrosion near the

edges of the insulation.

SAMPLE HATCH

1

Inspect condition and operation of sample hatch

cover.

2

Check the condition of the seal inside the hatch

cover

3

Where sample hatch is used to reel gauge stock

level, check for marker and tab stating hold-off

distance.

4

Inspect the reinforcing pad where sample hatch

pipe penetrates the roof.

5

On floating roof sample hatch and recoil

systems, inspect operation of recoil reel and

condition of lines.

6

On ultra clean stocks such as JP4, check for

presence and condition of protective coating or

liner inside sample hatch (preventing rust from

pipe getting into sample).

SCAFFOLD SUPPORT

1

Inspect scaffold support for corrosion, wear, and

structural soundness. Record dimensions

AUTOGAUGE: INSPECTION HATCH AND GUIDES

1

Check the hatch for corrosion and missing bolts.

2

Inspect the tape guides and float guides wire

anchors

VENTS (ON ROOF AND AT TOP OF SHELL)

1

Record size, manufacturer, model number, and

number of manufactured vents, and dimensions

and number of other vents. Note if vents are

open or closed types.

2

For closed vents: check pallets and sealing

surfaces. Ensure proper movement and record

any weights that are present.

3

Are vents free of obstructions?

4

Check the condition of the emergency vent.

Record manufacturer, size, and model number.

5

Inspect the external condition of the flame

arrestor.

6

Record manufacturer, model number, size, and

quantity of all flame arrestors

OVERFLOW ALARM SYSTEM

1

Identify and record the types, manufacturer, and

model numbers of overfill protection devices.

2

Check overfill protection devices for signs of

damage.

3

Check with the operator to confirm that routine

Revision Date: Oct2013May 2015

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

Page 5 of 10

T&O Regional Engineering

LAST External Inspection Checklist

LAST External Inspection Checklist

testing of the overfill protection devices has

been performed.

5.0

FLOATING ROOF

External floating roof inspections shall be conducted from gaugers platform and from walking on the roof itself. The

exception is if the floating roof is made of aluminum or if the space on the roof is a permit-required confined space and the

inspector does not have adequate certification or training to enter that space.

5.1

GENERAL

E OK NA Comments:

1

Look for indications of standing liquid on top of

the roof. (Large standing liquid areas on a

floating roof indicate inadequate drainage design

or, if to one side, a non-level roof with possible

leaking pontoons.)

2

Visually inspect the floating roof top surface

(Corrosion, paint condition)

3

Check roof legs (damage, and that they all are

pinned at the same height).

4

If leg racks are present, check that leg

extensions are present in the racks.

5

Check that any grounding / static bond cables

from the fixed roof to the floating roof or on the

floating roof components are not frayed and are

properly attached

6

Are any portions of the topside of the floating

roof submerged or are its legs collapsed?

7

Are there any covers, lids, or seals that are not

closed?

8

Inspect lightning shunts, if applicable.

5.2

LEVEL OF FLOATING ROOF

E OK NA Comments:

1

At several locations, measure distance from roof

rim to the top of the shell. A variance in the

distances indicates a non-level roof with possible

shell out-of-round, out-of-plumb, leaking

pontoons, or hang-up.

5.3

GAS TEST ABOVE FLOATING ROOF

E OK NA Comments:

1

Test for explosive gas in the vapor space above

the floating roof. High concentrations could

indicate a leaking roof, leaking seal system, or

inadequate ventilation of the head space above

the internal floating roof.

5.4

RIM SEALS

E OK NA Comments:

1

Record the type of seal(s)

2

Inspect seals for holes, tears, or openings.

3

Inspect metallic parts for corrosion and wear.

4

Inspect secondary seals for signs of buckling or

indications that their angle with the shell is too

shallow.

5.5

GUIDEPOLE (A.K.A. GAUGEPOLE, GAUGEPIPE, WELLS)

E OK NA Comments:

1

Record the number and type of each well

(column, gauge pole, ladder, autogauge, etc.)

2

Does the gauge pole have a float inside?

3

Does the gauge pole have a pole wiper?

4

Check automatic gauge tape cable for wear or

fraying caused by rubbing on the gauge well

cover.

5

Inspect well seals.

6

Inspect the gauge pole for thinning, and record

the dimensions of the pole and its slots

7

Inspect roof guide for gauge well, particularly

the condition of the rollers.

8

Is the opening through the floating roof

equipped with a gasket between the sliding

cover and the rim?

Revision Date: Oct2013May 2015

Page 6 of 10

T&O Regional Engineering

LAST External Inspection Checklist

LAST External Inspection Checklist

9

5.6

5.7

5.8

5.9

Is the opening through the floating roof

equipped with a wiper gasket between the

sliding cover and the pole?

UNSLOTTED GUIDEPOLE

10

Is the guidepole equipped with a cover or cap on

the top of the pole?

SLOTTED GUIDEPOLE with FLOAT (no sleeve)

11

Is the float properly floating inside the

guidepole?

12

Is there a wiper gasket or seal around the rim of

the float?

13

Is the wiper around the rim of the float at or

above the height of the pole wiper?

SLOTTED GUIDEPOLE with SLEEVE (no float)

14

Is the sleeve attached to the cover or rim of the

guidepole well (the opening through the floating

roof)?

SLOTTED GUIDEPOLE NO FLOAT OR SLEEVE

15

Is the slotted guidepole equipped with a flexible

enclosure around the outside of the pole,

extending from the floating roof to the top of the

pole and with a cover on the top of the pole?

SAMPLE HATCH

1

When equipped with a reel opening device,

check its operation.

EMERGENCY ROOF DRAINS

1

For internal floating roofs: Do emergency roof

drains have seals covering at least 90% of the

opening?

VACUUM BREAKERS

1

Report number and type of vacuum breakers. If

high legs are set, check for setting of

mechanical breaker in high leg position.

2

If the floating roof is not landed on its legs, is

the vent closed?

HATCHES

1

For pontoon compartments, check that covers

are in place and static bond cables present

2

For internal floating roofs, are hatches bolted

closed?

6.0

ACCESSWAYS

6.1

RAILING (STAIRS, PLATFORMS, AND FIXED ROOFS)

1

Identify and report type (pipe, galvanized pipe,

square tube, angle) and dimensions of railing.

2

Inspect for corrosion and paint failure.

3

Inspect welds.

4

Identify sharp edges.

5

Inspect safety devices at openings in handrails

for integrity and operation.

PLATFORM

1

Inspect frame for corrosion and paint failure.

2

Inspect the attachment of frame to supports and

supports to tank for corrosion and weld failure.

3

Check reinforcing pads where supports are

attached to shell or roof.

4

Are flat-surface-to-flat-surface joints sealwelded?

5

Inspect walking surface for corrosion or holes

(not drain holes) and paint failure.

6

Inspect walking surface-to-frame attachments

for corrosion.

STAIRWAY AND LADDERS

6.2

6.3

Revision Date: Oct2013May 2015

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

OK

NA

Comments:

Page 7 of 10

T&O Regional Engineering

LAST External Inspection Checklist

LAST External Inspection Checklist

1

6.4

Check for any uneven or irregular spacing of

stair treads or ladder rungs.

2

Record average dimensions of stair treads and

ladder rungs.

3

Inspect stair treads or ladder rungs for

corrosion, paint failure, and weld failure.

4

Inspect stringers for corrosion, paint failure, and

weld failure. Inspect attachment of treads/rungs

to stringer.

5

Inspect support-to-shell welds and reinforcing

pads.

6

Inspect stringer attachment to concrete base, if

any.

ROLLING LADDER

1

Inspect rolling ladder stringers.

2

Identify type of ladder treads (square bar, round

bar, treads, self leveling treads).

3

Check for wear and corrosion where rolling

ladder attaches to gauging platform.

4

Inspect pivot bar for wear and integrity.

5

Inspect operation of self-leveling stairway

treads.

6

Inspect rolling ladder wheels for freedom of

movement, flat spots, and wear on axle.

7

Inspect alignment of rolling ladder with track on

the floating roof.

8

Inspect top surface of rolling ladder track for

wear by wheels. Record the length of unworn

track at each end of the track.

9

If the rolling ladder track extends to within 5 ft

of the edge of the roof on the far side, is there a

handrail on the top of the shell on that side?

10

Are static bond cables present, in good

condition, and properly secured to the rolling

ladder, tank, and floating roof?

OK

NA

Comments:

Rim Seal Gap Measurements (U.S. Air Rules-Regulated Tanks ONLY)

(Insert additional rows if necessary)

PRIMARY SEAL

SECONDARY SEAL

Gap Length

Maximum Gap Width

Gap Length

Maximum Gap Width

L (in.)

Wmax (in.)

L (in.)

Wmax (in.)

Rim Seal Condition

No

Yes Comment If No

Does the bottom of the (primary) shoe

extend into the liquid?

Does the top of the primary shoe extend

24 or more vertically above the liquid?

Are the rim seals free of holes, tears, or

other openings through the seal?

Revision Date: Oct2013May 2015

Page 8 of 10

T&O Regional Engineering

LAST External Inspection Checklist

Figure 1 - Fall Prevention Anchorage point

Nozzle Thickness:

Nozzle to Repad Filet:

Repad Thickness:

Repad Diameter:

Repad to Roof Filet:

Roof Thickness:

Revision Date: Oct2013May 2015

Page 9 of 10

T&O Regional Engineering

Revision Date: Oct2013May 2015

LAST External Inspection Checklist

Page 10 of 10

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- API 510 QuestionsDocumento20 pagineAPI 510 QuestionsPercyAlexanderNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- API 510 QuestionsDocumento8 pagineAPI 510 QuestionsTAYYAB FAROOQ100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- API 510 QuestionsDocumento20 pagineAPI 510 QuestionsPercyAlexanderNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- API 510 QuestionsDocumento20 pagineAPI 510 QuestionsPercyAlexanderNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- API 510 Study QuestionsDocumento49 pagineAPI 510 Study QuestionsMichael Clapham50% (4)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- 510 Closed Exam A, Rev 9Documento21 pagine510 Closed Exam A, Rev 9Pamela Lee100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 2018 Price List: Inspector (CAWI, CWI, SCWI)Documento1 pagina2018 Price List: Inspector (CAWI, CWI, SCWI)osersNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Check ListDocumento6 pagineCheck ListosersNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Tank M-28625 PhotoDocumento1 paginaTank M-28625 PhotoosersNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Tank T-41145 PhotoDocumento1 paginaTank T-41145 PhotoosersNessuna valutazione finora

- E 3.1b PDFDocumento20 pagineE 3.1b PDFosersNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Tank T-41145 PhotoDocumento1 paginaTank T-41145 PhotoosersNessuna valutazione finora

- Tank X-2568 PhotoDocumento1 paginaTank X-2568 PhotoosersNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Tank D-2112 PhotoDocumento1 paginaTank D-2112 PhotoosersNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- 74 06 650 563Documento8 pagine74 06 650 563osersNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Tank D-2112 PhotoDocumento1 paginaTank D-2112 PhotoosersNessuna valutazione finora

- QA - QC Plan For PEP 13-03-2017Documento16 pagineQA - QC Plan For PEP 13-03-2017osersNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- QA - QC Plan For PEP 13-03-2017Documento16 pagineQA - QC Plan For PEP 13-03-2017osersNessuna valutazione finora

- ITP For Fabrication & Erection of TanksDocumento20 pagineITP For Fabrication & Erection of TanksosersNessuna valutazione finora

- Tank D-2111 PhotoDocumento1 paginaTank D-2111 PhotoosersNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Storage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim GalalaDocumento10 pagineStorage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim Galalamarkfgt57% (7)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Spec05-Pro-ka-KC151a Contractor Quality Control Dated 10-19-98Documento4 pagineSpec05-Pro-ka-KC151a Contractor Quality Control Dated 10-19-98osersNessuna valutazione finora

- 1657-2013 (A1) PDFDocumento7 pagine1657-2013 (A1) PDFosersNessuna valutazione finora

- API Tank DesignDocumento189 pagineAPI Tank DesignDD3NZ91% (11)

- 10) Itp - Tank Fabrication PDFDocumento6 pagine10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- ITP For Fabrication & Erection of TanksDocumento20 pagineITP For Fabrication & Erection of TanksosersNessuna valutazione finora

- 10) Itp - Tank Fabrication PDFDocumento6 pagine10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- 10) Itp - Tank Fabrication PDFDocumento6 pagine10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- Inspection and Test Plan For Storage TankDocumento7 pagineInspection and Test Plan For Storage TankAhmed100% (5)

- 10) Itp - Tank Fabrication PDFDocumento6 pagine10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- Chord Tone Improvisation Part IDocumento38 pagineChord Tone Improvisation Part I2018 01097Nessuna valutazione finora

- Network Command - HPUXDocumento5 pagineNetwork Command - HPUXRashid NihalNessuna valutazione finora

- 1.project FullDocumento75 pagine1.project FullKolliparaDeepakNessuna valutazione finora

- DCM-I&II Lab Equipments ListDocumento2 pagineDCM-I&II Lab Equipments ListPrashant ChinamalliNessuna valutazione finora

- Spare Parts List: Hydraulic BreakerDocumento28 pagineSpare Parts List: Hydraulic BreakerTeknik MakinaNessuna valutazione finora

- 12th Maths EM Second Mid Term Exam 2023 Question Paper Thenkasi District English Medium PDF DownloadDocumento2 pagine12th Maths EM Second Mid Term Exam 2023 Question Paper Thenkasi District English Medium PDF Downloadharishsuriya1986Nessuna valutazione finora

- Chem 1211 Lab ReportDocumento9 pagineChem 1211 Lab Reportansleybarfield0% (1)

- DC Power Supply and Voltage RegulatorsDocumento73 pagineDC Power Supply and Voltage RegulatorsRalph Justine NevadoNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Pneumatic Conveying of Bulk Solids PDFDocumento231 paginePneumatic Conveying of Bulk Solids PDFCarloLopez100% (2)

- Week 1 Lesson 1 2nd QuarterDocumento2 pagineWeek 1 Lesson 1 2nd QuarterKristine Jewel MacatiagNessuna valutazione finora

- TrimLite™ UT20706 HomeliteDocumento7 pagineTrimLite™ UT20706 HomeliteBKVNessuna valutazione finora

- Dynamic Force AnalysisDocumento13 pagineDynamic Force AnalysisJakesNessuna valutazione finora

- Sap SCM TrainingDocumento5 pagineSap SCM TrainingGLOBAL TEQNessuna valutazione finora

- 1400 CFM TDocumento3 pagine1400 CFM TmahmadwasiNessuna valutazione finora

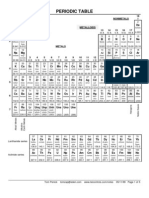

- Periodic Table and AtomsDocumento5 paginePeriodic Table and AtomsShoroff AliNessuna valutazione finora

- Incompressible Flow in Pipe Networks.Documento7 pagineIncompressible Flow in Pipe Networks.Ayub Ali WehelieNessuna valutazione finora

- Tutoriales Mastercam V8 6-11Documento128 pagineTutoriales Mastercam V8 6-11Eduardo Felix Ramirez PalaciosNessuna valutazione finora

- RRB JE CBT-2 Electronics Tech Paper With Key 31-8-2019 1st ShiftDocumento55 pagineRRB JE CBT-2 Electronics Tech Paper With Key 31-8-2019 1st ShiftKuldeep SinghNessuna valutazione finora

- 3 DB RDMDocumento49 pagine3 DB RDMfaisal shahzadNessuna valutazione finora

- Cheng-Yi Cheng - Yi: KBU 10A/15A/25A/35A SERIESDocumento2 pagineCheng-Yi Cheng - Yi: KBU 10A/15A/25A/35A SERIESThomas ThomasNessuna valutazione finora

- EP 1110-1-8 Vo2 PDFDocumento501 pagineEP 1110-1-8 Vo2 PDFyodiumhchltNessuna valutazione finora

- Meteorology Konu Konu Ayrılmış SorularDocumento278 pagineMeteorology Konu Konu Ayrılmış Sorularjames100% (1)

- Unit Exam 5Documento3 pagineUnit Exam 5Rose AstoNessuna valutazione finora

- CCNA2 Lab 7 3 8 enDocumento6 pagineCCNA2 Lab 7 3 8 enapi-3809703100% (1)

- Unit 07 Self-Test Chemistry Self TestDocumento2 pagineUnit 07 Self-Test Chemistry Self TestOluwatusin Ayo OluwatobiNessuna valutazione finora

- Abr Sinai Onshore Gas Pipeline PDFDocumento42 pagineAbr Sinai Onshore Gas Pipeline PDFhamza2085100% (1)

- Redox TitrationDocumento5 pagineRedox TitrationchristinaNessuna valutazione finora

- SM700 E WebDocumento4 pagineSM700 E WebrobertwebberNessuna valutazione finora

- PassivityDocumento15 paginePassivitySmarties AcademyNessuna valutazione finora

- Optimizing AOD Refractory PerformanceDocumento10 pagineOptimizing AOD Refractory PerformanceJulio PurezaNessuna valutazione finora