Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Seikoh Giken Seikoh Giken SFP 550C

Caricato da

sleh_sbiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Seikoh Giken Seikoh Giken SFP 550C

Caricato da

sleh_sbiCopyright:

Formati disponibili

ngstrmLap

Seikoh Giken SFP-550 Polishing Instructions for Pre-Domed

or Pre-Angled Zirconia Ferrule Connectors

Fiber Optic Center, Inc., the global supplier of ngstrmLap, the most widely used lapping

film in the world, is also an industry leader in cost effective high performance ultra PC and angled single mode

polishing processes for volume assembly production.

Achieving consistent results that meet the demanding technical specifications for single mode systems

requires the optimization of many factors throughout the termination and testing process. These include:

suitable single mode fiber

suitable epoxy

proper mixing, application & curing of epoxy

connector quality & tolerances

pressure & time of polishing at each step

lapping film quality & consistency

lapping film grit sizes & materials

polishing solutions

adapter quality & tolerances

calibration & quality of test instruments &

reference cables

test methods & conditions

overall cleanliness

specific cleaning procedures

Instructions

When used with the SFP-550 and the materials listed below, the UPC and APC polishing processes

requires between 5-10 minutes for up to 20 or 32 2.5 mm connectors or up to 24 or 40 1.25 mm connectors:

1. Prior to loading connectors into the polishing

fixture, perform a quick de-nubbing or air

polish to remove the sharp edges from the

fiber and to get the fiber flush with the epoxy.

Ten to 15 small circles should be enough, but

will vary according to cleave length.

4. Use a minimal amount of distilled water to

adhere lapping films to rubber pads. Make

sure air bubbles are kept to minimum, and no

debris is trapped between the film and rubber

pad. A piece of double sided tape can be

used to help keep lapping film on the pads.

2. Use 70 or 80 durometer rubber pads for

2.5mm ferruled connectors, p/n PR5X-500-70

or 80, and 90 durometer rubber pads for the

1.25mm ferruled connectors, PR5X-480-90.

Use a separate rubber pad for each step.

Using the correct rubber pad will help create

the correct Radius of Curvature.

5. Between each polishing step flush out

connector end-faces, work-holder surface,

lapping film surface, bottom of rubber pad,

surface rubber pad rests on with de-ionized

water. Then wipe with lint-free wipe, and

blast with compressed or canned air, p/n

ES1217. Proper cleaning will help insure a

scratch, pit or defect free end-face.

3. Clean rubber pads with at least 99% pure

isopropyl alcohol and lint free wipes. ITW

Chemtronics 6704 Econowipes or CleanTex

604 lint free wipes are recommended to

insure no contamination occurs during the

cleaning process.

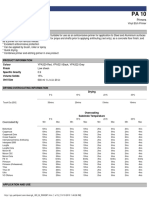

Technical Specifications

6. Refer to tables below for recommended

process. Please note processes are for preangled and pre-domed connectors.

SM UPC Back-Reflection

1

MM UPC Back-Reflection

1

SM APC Back-Reflection

1

SM/MM Insertion Loss

Fiber Height

Apex Offset

Radius of Curvature

=

=

=

=

=

=

=

-55dB or less

-35dB or less

-70dB or less

0.2db or less

Telcordia GR-326v3

50um or less

7-25mm

Typical results for high quality connector. Optical results are dependent on connector quality.

Fiber Optic Center, Inc.

Fiber Optic Center, Inc.

ngstrmLap SFP-550 Polishing Process Page 2

Polishing Timetables

2.5mm Polishing Process - Table 1.1

Polishing Step

Epoxy

Removal3

Rough Polish

Medium Polish

Final Polish4

Cleaning5

Material & Grit Size

Gray

Silicon Carbide

9 um

Orange

Diamond

5 um

Lavender

Diamond

1 um

White

SiO2, Sub-Micron

Brown

Flocked Pile, None

Pressure/Pad1

Material & Grit Size

Gray

Silicon Carbide

9 um

Lavender

Diamond

1 um

White

SiO2, Sub-Micron

Brown

Flocked Pile, None

Pressure/Pad1

Time

Fluid

Usage2

Part Number

PR5X-500-70

15-30 sec.

de-ionized

water

1-5

SC9T503N100

PR5X-500-70

60 sec.

de-ionized

water

10-30

D5BF503N1

PR5X-500-70

60 sec.

20-30

D1KT503N1

PR5X-500-70

60-90 sec.

SEQFPF503N100

PR5X-500-70

15-20 sec.

de-ionized

water

de-ionized

water

de-ionized

water

10

ABR60NC502N1

1.25mm Polishing Process - Table 1.2

Polishing Step

Epoxy

Removal3

Medium Polish

Final Polish4

Cleaning5

Time

Fluid

Usage2

Part Number

PR5X-480-90

15-30 sec.

de-ionized

water

1-5

SC9T503N100

PR5X-480-90

60 sec.

20-30

D1KT503N1

PR5X-480-90

60-90 sec.

SEQFPF503N100

PR5X-480-90

15-20 sec.

de-ionized

water

de-ionized

water

de-ionized

water

10

ABR60NC502N1

Final Polish Film Options

As a leader in single mode polishing, Fiber Optic Center, Inc. always looks for process improvements.

Most innovations occur at the final step. Some other final polish options that achieve superior results are as

follows:

Final Polish Options - Table 2

Polishing Step

Final Polish

Final Polish

Final Polish

Final Polish

Material & Grit Size

Translucent

SiO2, Sub-Micron

Translucent

SiO2, Sub-Micron

Yellow

SiO2, Sub-Micron

Light Blue

AlOx, 0.3 um

Pressure/Pad1

PR5X-500-70 (for 2.5 mm)

PR5X-480-90 (for 1.25 mm)

PR5X-500-70 (for 2.5 mm)

PR5X-480-90 (for 1.25 mm)

PR5X-500-70 (for 2.5 mm)

PR5X-480-90 (for 1.25 mm)

PR5X-500-70 (for 2.5 mm)

PR5X-480-90 (for 1.25 mm)

Time

60-90 sec.

60-90 sec.

90-120 sec.

15-30 sec.

Fluid

de-ionized

water

de-ionized

water

de-ionized

water

Ultra Polish

Solution

Usage2

Part Number

FOS-01

863XW-503N

ALG15XY503N100

CA03F502N100

Pressure is controlled by the thickness of the rubber pad and does not have to be adjusted when polishing differing numbers of connectors.

Usage estimates are conservative, and may vary. Flushing out lapping film with generous amounts of distilled water will increase the life of the

film.

3

Pressure and time will vary. Object is to only remove the epoxy and to stop as soon as epoxy is removed from all connectors.

4

Please note other final polish film options below. For Optimum MM polishing the SEQFPF should still be used, but for a more Economical

MM process, this step can either be eliminated, or substituted with the AlOx 0.3um film listed below.

5

Optional, but recommended, cleaning step.

2

Ordering Information

For more information on this or other products and their availability, please contact Fiber Optic Center, Inc. at (800) 4734237 or (508) 992-6464, fax at (508) 991-8876, or e-mail at sales@focenter.com.

ngstrmLap is a registered trademark of Fiber Optic CenterTM, Inc.

AL_Pol_Pro_550.doc

Rev. H

10/2007

Fiber Optic Center, Inc., 23 Centre Street, New Bedford, MA, 02740-6322, USA

E-mail: sales@focenter.com

Toll Free: (800) IS-FIBER or (800) 473-4237 Phone: (508) 992-6464 Fax: (508) 991-8876 Website: www.focenter.com

Potrebbero piacerti anche

- DS Barred Tee (Rev)Documento2 pagineDS Barred Tee (Rev)Advis100% (2)

- Casting Defect in Slab PDFDocumento55 pagineCasting Defect in Slab PDFBhoomaiah SunkenapalliNessuna valutazione finora

- Design of Welded StructuresDocumento837 pagineDesign of Welded StructuresManuelGonzalesNessuna valutazione finora

- Triaxial TestDocumento9 pagineTriaxial TestNani TirumalasettiNessuna valutazione finora

- Gasket Catalog - James WalkerDocumento52 pagineGasket Catalog - James WalkerJaime Lozano GonzálezNessuna valutazione finora

- Technical Installation Guide Above Below Ground DrainageDocumento44 pagineTechnical Installation Guide Above Below Ground DrainageChamara Chinthaka RanasingheNessuna valutazione finora

- Blasting and Coating ProcedureDocumento8 pagineBlasting and Coating Procedureaamirsaddiq100% (1)

- Special Steel Structures - Courses - 2013Documento253 pagineSpecial Steel Structures - Courses - 2013Largu George DanielNessuna valutazione finora

- Parker O RingDocumento0 pagineParker O RingRazvan C GoranNessuna valutazione finora

- GP 2 Diagnostic Test Answer KeyDocumento11 pagineGP 2 Diagnostic Test Answer KeyPatricia TorrecampoNessuna valutazione finora

- Fiber Polishing Handbook2Documento5 pagineFiber Polishing Handbook2Berrezeg MahieddineNessuna valutazione finora

- Parker Fulflo Poly Mate Filter CartridgeDocumento4 pagineParker Fulflo Poly Mate Filter CartridgeGithu OommenNessuna valutazione finora

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Documento3 pagineMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsNessuna valutazione finora

- Basic Process Requirement For PPG PVDF Approval Applicator EN Phuoc EditedDocumento10 pagineBasic Process Requirement For PPG PVDF Approval Applicator EN Phuoc EditedTheAnh TranNessuna valutazione finora

- Filtracion Alta PurezaDocumento2 pagineFiltracion Alta PurezaMaik GonzalezNessuna valutazione finora

- Semigloss 90 - 1210 PDSDocumento6 pagineSemigloss 90 - 1210 PDSPablo PuebloNessuna valutazione finora

- (P) SRFDocumento6 pagine(P) SRFYing Kei ChanNessuna valutazione finora

- TDS Ep100-20Documento2 pagineTDS Ep100-20radule021Nessuna valutazione finora

- CV1 - PR - B - Mipa TDSDocumento2 pagineCV1 - PR - B - Mipa TDSradule021Nessuna valutazione finora

- Filter Elements For Liquid Filters enDocumento22 pagineFilter Elements For Liquid Filters enTony Tony TonyNessuna valutazione finora

- Fosroc Polyurea FLMDocumento4 pagineFosroc Polyurea FLMVenkata Raju KalidindiNessuna valutazione finora

- Om 340Documento3 pagineOm 340RNessuna valutazione finora

- Amercoat® 240 / Sigmacover™ 240: Product Data SheetDocumento7 pagineAmercoat® 240 / Sigmacover™ 240: Product Data SheetAmila Udara GunasingheNessuna valutazione finora

- Clarify PDP740Series 1Documento2 pagineClarify PDP740Series 1nodyyyNessuna valutazione finora

- Carboguard 635 Thinned 50% - Sealer PDSDocumento5 pagineCarboguard 635 Thinned 50% - Sealer PDSjakeNessuna valutazione finora

- Clarify: 740 Premium SeriesDocumento7 pagineClarify: 740 Premium SeriesnodyyyNessuna valutazione finora

- SigmaPrime 200Documento7 pagineSigmaPrime 200amshivNessuna valutazione finora

- Alpha Om-338 Teknisk DatabladDocumento3 pagineAlpha Om-338 Teknisk Databladnormans00Nessuna valutazione finora

- Sonolastic - NP2 - Polyutherane Caulking SealantDocumento6 pagineSonolastic - NP2 - Polyutherane Caulking SealantOgbedande Awo Orunmila100% (1)

- 7-LINE® - 7-844 SERIES: Product Data SheetDocumento6 pagine7-LINE® - 7-844 SERIES: Product Data SheetJose Manuel Guizado SolisNessuna valutazione finora

- Simrit - Broșura Merkel PRW 1 Double WiperDocumento8 pagineSimrit - Broșura Merkel PRW 1 Double Wiperjo_rz_57Nessuna valutazione finora

- Data Sheet PP5 Filter CartridgesDocumento2 pagineData Sheet PP5 Filter Cartridgesnidiamejia1960Nessuna valutazione finora

- Jotafloor Traffic Deck System BrochureDocumento12 pagineJotafloor Traffic Deck System BrochurehutuguoNessuna valutazione finora

- Pitt Tech 90 712aDocumento7 paginePitt Tech 90 712aPablo PuebloNessuna valutazione finora

- AG 24400 Jota Etch Euk GBDocumento5 pagineAG 24400 Jota Etch Euk GBchusnadiantyNessuna valutazione finora

- Alpha: No-Clean Solder Paste (9098T)Documento3 pagineAlpha: No-Clean Solder Paste (9098T)behzadNessuna valutazione finora

- 7) PPG Amercoat 385 - Pds - AiDocumento4 pagine7) PPG Amercoat 385 - Pds - AididbeauNessuna valutazione finora

- Pttchem SP P 121 000 - Wrapping PDFDocumento12 paginePttchem SP P 121 000 - Wrapping PDFCivil FriendNessuna valutazione finora

- Acrolon 218 HSDocumento4 pagineAcrolon 218 HSAndres MoralesNessuna valutazione finora

- ABB Instrumentation: From The Leader in Remote Seal TransmittersDocumento26 pagineABB Instrumentation: From The Leader in Remote Seal TransmittersMorteza alizadehNessuna valutazione finora

- Amercoat® 385: Product Data SheetDocumento8 pagineAmercoat® 385: Product Data SheetSampath GaneshNessuna valutazione finora

- SigmaCover 280Documento5 pagineSigmaCover 280ajuhaseenNessuna valutazione finora

- Amercoat® 385: Product Data SheetDocumento8 pagineAmercoat® 385: Product Data SheetNizar BouchaalaNessuna valutazione finora

- 11 - SupaSep LGPDocumento8 pagine11 - SupaSep LGPDylan DooleyNessuna valutazione finora

- Pa 10Documento3 paginePa 10LymeParkNessuna valutazione finora

- Relative Exposure Factor Ti2294 Kodak Industrex Aa400Documento4 pagineRelative Exposure Factor Ti2294 Kodak Industrex Aa400Charles OnyechereNessuna valutazione finora

- Kata Logs P Nauti KaDocumento73 pagineKata Logs P Nauti KaSlobodan MaricicNessuna valutazione finora

- SonoShield HLM 5000 - Bitumen MembraneDocumento6 pagineSonoShield HLM 5000 - Bitumen MembraneOgbedande Awo OrunmilaNessuna valutazione finora

- B-1050 EL Resilient 2012-08Documento24 pagineB-1050 EL Resilient 2012-08Karthick VenkateshNessuna valutazione finora

- Application Guide - Jotafloor EP GlassFlakeDocumento8 pagineApplication Guide - Jotafloor EP GlassFlakeKenji TanNessuna valutazione finora

- 5200 DTM AcrylicDocumento4 pagine5200 DTM AcrylicMarshall BravestarNessuna valutazione finora

- MSDS Pelicula AA 400 Film-DataDocumento4 pagineMSDS Pelicula AA 400 Film-DataPercy Junior Berrios Muñoz100% (1)

- Amerlock® 400 Voc: Product Data SheetDocumento8 pagineAmerlock® 400 Voc: Product Data SheetCris gomezNessuna valutazione finora

- S-Mart Seal Material and Profile OverviewDocumento8 pagineS-Mart Seal Material and Profile OverviewTimon2005Nessuna valutazione finora

- Qualitek 381F No Clean Flux: Technical Specifications Technical Data SheetDocumento4 pagineQualitek 381F No Clean Flux: Technical Specifications Technical Data SheetteknoartistNessuna valutazione finora

- Pss 1-6f2bDocumento20 paginePss 1-6f2bEverton LuizNessuna valutazione finora

- Fos Roc Polyurea FLMDocumento4 pagineFos Roc Polyurea FLMAhmed TahaNessuna valutazione finora

- TM Egger Schichtstoff CPL HPL enDocumento3 pagineTM Egger Schichtstoff CPL HPL endarshak444Nessuna valutazione finora

- IPC/industry Standard of PCB and PCBA?: PCB Fabrication Steps: (Presentation-How-To-Build-Pcb)Documento3 pagineIPC/industry Standard of PCB and PCBA?: PCB Fabrication Steps: (Presentation-How-To-Build-Pcb)HenryNessuna valutazione finora

- Filmtec™ Membranes: Product Data SheetDocumento3 pagineFilmtec™ Membranes: Product Data Sheetcello loNessuna valutazione finora

- Polishing Process For Heatcure Fiber Optic Connectors: 1. GeneralDocumento4 paginePolishing Process For Heatcure Fiber Optic Connectors: 1. GeneralAbNessuna valutazione finora

- Sigmazinc 158Documento7 pagineSigmazinc 158JORGEALEXERNessuna valutazione finora

- Sikafloor 326 PDSDocumento10 pagineSikafloor 326 PDSLinsonlinsonNessuna valutazione finora

- Thin-Walled Pressure VesselsDocumento18 pagineThin-Walled Pressure Vesselsjomarie apolinarioNessuna valutazione finora

- Palm Oil Mill PipingDocumento4 paginePalm Oil Mill PipingmshkNessuna valutazione finora

- Expansion Joints For Power Stations Kompaflex BrochureDocumento8 pagineExpansion Joints For Power Stations Kompaflex Brochuremdt3eNessuna valutazione finora

- JAMB Chemistry Past Question 1983 2004Documento119 pagineJAMB Chemistry Past Question 1983 2004iamprecious2allNessuna valutazione finora

- VCS STD 5711 102 09 2005 Method Statement PDFDocumento4 pagineVCS STD 5711 102 09 2005 Method Statement PDFFadi MagdyNessuna valutazione finora

- ENG MasterGlenium ACE 30 TdsDocumento4 pagineENG MasterGlenium ACE 30 TdsPrateek ModyNessuna valutazione finora

- Investment Materials 1 - 2Documento53 pagineInvestment Materials 1 - 2AmniAzmiNessuna valutazione finora

- Solved Classied Past Papers Chapter 1 Rocks and Minerals and Their ExtractionDocumento29 pagineSolved Classied Past Papers Chapter 1 Rocks and Minerals and Their ExtractionWilliam IqbalNessuna valutazione finora

- Analisa Harga SatuanDocumento8 pagineAnalisa Harga SatuanMbeda NayNessuna valutazione finora

- Murex Oxy Cutting Poster 2008 PDFDocumento1 paginaMurex Oxy Cutting Poster 2008 PDFPCNessuna valutazione finora

- 2 Taefdxtoht 4 Oo 8 ADocumento16 pagine2 Taefdxtoht 4 Oo 8 AmelsabaeNessuna valutazione finora

- Fiber Optics PPT 2Documento14 pagineFiber Optics PPT 2Srijan pareekNessuna valutazione finora

- IqbaloDocumento64 pagineIqbaloAnonymous d6tUk8QZNessuna valutazione finora

- BOQ Office & CanteenDocumento4 pagineBOQ Office & CanteenSasanka SekharNessuna valutazione finora

- Comprehension Passage - Paper Bag DayDocumento2 pagineComprehension Passage - Paper Bag DayJagmeet DhillonNessuna valutazione finora

- Report On Fractional DistillationDocumento5 pagineReport On Fractional DistillationJackson YamangaNessuna valutazione finora

- 0620 s07 Ms 2Documento8 pagine0620 s07 Ms 2Varun PanickerNessuna valutazione finora

- 568 RR Thulasi - CMS Agro Madurai BOQDocumento30 pagine568 RR Thulasi - CMS Agro Madurai BOQEr S Thirumarai NathanNessuna valutazione finora

- Acid in GiDocumento23 pagineAcid in GiAsian Trans PowerNessuna valutazione finora

- BOYSEN QDE For Metal and WoodDocumento1 paginaBOYSEN QDE For Metal and WoodSTEENessuna valutazione finora

- Deionized Water: Application BulletinDocumento2 pagineDeionized Water: Application BulletinpinutaNessuna valutazione finora

- THE Formation of Late Magmatic Oxide Ores.: Alan M. BatemanDocumento23 pagineTHE Formation of Late Magmatic Oxide Ores.: Alan M. BatemanRorisang MalebyeNessuna valutazione finora

- Experiment 3: Neutralization Capacity of Commercial Antacid AcidDocumento10 pagineExperiment 3: Neutralization Capacity of Commercial Antacid AcidfizaNessuna valutazione finora

- IsuzuDocumento8 pagineIsuzuImam Zulkifli100% (1)