Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Introduction To Mechanical Engineering Design-6

Caricato da

Hamka HidayahTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Introduction To Mechanical Engineering Design-6

Caricato da

Hamka HidayahCopyright:

Formati disponibili

INTRODUCTION TO MECHANICAL ENGINEERING DESIGN (Extracted from ZAR)

Simply, design may be defined as to create something useful according to plan in structured steps leading to the desired result. The

something useful can be a process of devising a system, component, or process. It is an iterative decision making process in which basics

in science, mathematics and engineering are optimally applied.

Design tools, design criteria and design process

Students will be exposed to the design activity and process for understanding, creativity, innovativeness, decision making and utilization

of effective technological aids.

The design process steps is depicted in Figure 1.

Design Process:

1.

2.

3.

4.

5.

6.

7.

Identification of a need Problem recognition and definition

Market survey/analysis: Profit and economics:

Consumers needs

Information Search Data gathering

Past work

Criteria and Constraints Design requirements

Specified functions and Function structure

technical requirements geometry, kinematics,

forces, materials, assembly, maintainability,

ergonomics, recycling, etc

Economic factors, safety, reliability, aesthetics,

ethics, and social impacts

Concept generation Synthesis of configurations

Systematic techniques preliminary layouts

Creative ingenuity/ability form designs

Feasibility calculations

Alternative Solutions Evaluation of alternatives

Selection of optimum configuration

Manufacturing specifications

Selection of materials and dimensions

Optimization techniques

Complete form designs

Design Analysis and Experiment Comparison

8.

From A R Eide, R D Jenison, L H Mashaw, J L Northop,

Introduction to Enginering Design, MCGraw-Hill, International

Edition, Singapore, 1998

1. Identification of a need-start with broad or general leading to specific or start direct

to desired product [PO3]

2. Problem definition[PO1]

3. Search [PO10]

4. Constrains [PO1]

5. Criteria [PO1]

6. Alternative solutions-creativity, innovation[PO3]

7. Analysis-use of mathematics and science for performance of solution.[PO1]

Theoretical mathematical modeling

8. Decision [PO3]

Experimental mock-up, model, and prototype

Production

9. Specification

9.

Production drawings and production documents

10. Communication [PO7]

Detailed manufacturing instructions

Communication

Oral/Written-Graphics-internal & external: Format of written report-Cover page, Abstract, Table of contents, Body, and Conclusions

and Recommendations. Include Appendixes for further detail information so as not to

interrupt

write-up.

Figure

1 of

Steps

in design process

Oral presentation-Clarity, appropriate graphic displays etc. [Evaluation-content and subject knowledge, use of aids,

Summarize in 5 steps

1. Problem definition

2. Invention

3. Analysis

4. Decision

5. Implementation

Conceptual design-a product

Idea or concept is the initial or origin of the product. Airplane may come from observation of birds flying or a sailboat from a floating log.

The steps in conceptual design are given in Table 1.

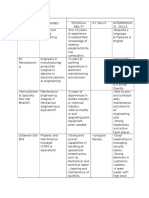

Table1: Steps in Conceptual Design Phase

Step 1

Identify Problems

Problem Statement

Benchmarking

QFD

PDS

Step 2

Gather Information

References

Electronic Media

Internet

Step 3

Step 4

Generating concepts

Brainstorming

Functional decomposition

Morphological chart

Concept Evaluation

Pugh concept

Decision Matrix

Taguchi Method

Preliminary Design Phase: Table 2 depicts the preliminary design steps.

Table2 Preliminary design Steps

Step 1

Product architecture

Arrangement of physical elements to carry out function

Design for human factor

Step 2

Configuration design

Modeling

Simulation

Materials selection

DFM, DFA

Step 3

Parametric design

Robust design

FMEA

Final dimension

Detail Design

Final Phase- Detail design

Process after Embodiment design

85% of product process completed

Waiting for final decision to be manufactured

Stages in Detail Design

Detail design phase consist of several stages:

Detail drawings

Qualification prototype testing

Bill of Materials (BOM)

Decision on make/buy

Detailed the product specification

Detailed cost estimate

Final Design review

Release to manufacturing/ production

Example of process of design: Identification of needs.

The example cited here is how selection of concept from various alternatives of

heating of a kiln for curing timber based on a broad idea on energy.

The followings maybe some recorded statements related the kiln operation:

Firewood is not as commercially available as it used to be.

The price of firewood has risen significantly.

People are now more willing to cut and split their own firewood than they were previously.

The small, inexpensive chain saw has made the cutting portion of the task

more acceptable, but splitting the wood is still a major problem.

So there is need inexpensive supply of firewood.

The followings are alternatives of obtaining firewood supply:

Purchase firewood from supplier.

Purchase standing timber to be cut for firewood.

Purchase trees that have been cut or that have fallen.

Hire a portion of the work done.

Design improved equipment to facilitate portion of the process.

L

C

PRESSURE WEDGE

IDEA SKETCH #3

(c)

Figure 2 Different sketches of pressure wedge

Some sketches of pressure wedges are shown in Figure 2. The equipment

is to split the log. Notice the different concepts and methods used in the process.

However if one looks at the overall broad area of need, then, the supply

of energy will be the main focus.

A broad spectrum of means to obtain energy is depicts in Figure 3. As indicated

the main sources are from fossil fuel, wind, geothermal, solar, nuclear and organic.

The sub-sources are also displayed. Figure 3 provides plentiful of alternatives of obtaining

heat. It opens up avenues for development in specialist areas and invention of new devices.

It provides comprehensive information of energy procurement methods, that is, a decision

tree pertaining to energy.

To further illustrate decision making in design, alternatives to convert rotational motion

to linear motion are shown in Figure 4.

The idea on concept design and decision making illustrated in Figures 2, 3 and 4 will be briefly

discussed in the classroom.

Figure 3 Energy decision tree

Figure 4 Several means of converting rotational to linear motion

Program Outcomes (PO):

PO1

Ability to acquire and apply knowledge of science and engineering fundamentals

PO2

Ability to acquire in-depth technical competencies in a specific engineering discipline

PO3

Ability to undertake problem identification, formulation and solution.

PO4

Ability to utilize systems approach to design and evaluate operational performance.

PO5

Ability to undertake the principles of design for sustainable development.

PO6

Ability to practice professional and ethical responsibilities and commitment to them

PO7

Ability to communicate effectively with engineers and the community at large.

PO8

Ability to function effectively individually and in a group

PO9

Ability to undertake social, cultural, global and environmental responsibilities of a professional engineer.

PO10

Ability to recognize the need to undertake life-long learning, and possessing or acquiring the capacity to do so.

PO11

Ability to demonstrate managerial and entrepreneurial skills.

PO12

Ability to demonstrate leadership skills.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Leaflet CycleManager Ep CycleManager ErDocumento7 pagineLeaflet CycleManager Ep CycleManager ErValeska ArdilesNessuna valutazione finora

- Calculation of The Current Transformer Accuracy Limit FactorDocumento14 pagineCalculation of The Current Transformer Accuracy Limit FactorWeiKiat Goh67% (3)

- 1 Introduction ToTQMDocumento108 pagine1 Introduction ToTQMHamka HidayahNessuna valutazione finora

- Receipt Final Draft 3Documento1 paginaReceipt Final Draft 3Hamka HidayahNessuna valutazione finora

- Cover Letter Shin EtsuDocumento1 paginaCover Letter Shin EtsuHamka HidayahNessuna valutazione finora

- SEM-contoh Thesis Kaj Saintifik 2013Documento41 pagineSEM-contoh Thesis Kaj Saintifik 2013Adelin SurayaNessuna valutazione finora

- 2 TQM-Role of The Quality System-NHSDocumento86 pagine2 TQM-Role of The Quality System-NHSHamka HidayahNessuna valutazione finora

- Fyp Second Examiner July 2016 Group 2Documento8 pagineFyp Second Examiner July 2016 Group 2Hamka HidayahNessuna valutazione finora

- Assignment Job AdvertisingDocumento16 pagineAssignment Job AdvertisingHamka HidayahNessuna valutazione finora

- Registration ProcedureDocumento2 pagineRegistration ProcedureHamka HidayahNessuna valutazione finora

- MEM678 Total Quality ManagementDocumento2 pagineMEM678 Total Quality ManagementHamka HidayahNessuna valutazione finora

- A 08 Ae 1 e 63 F 1 F 73 Fe 7Documento1 paginaA 08 Ae 1 e 63 F 1 F 73 Fe 7Hamka HidayahNessuna valutazione finora

- CV JuriDocumento10 pagineCV JuriHamka HidayahNessuna valutazione finora

- Assignment 1Documento10 pagineAssignment 1Hamka HidayahNessuna valutazione finora

- UITM FormDocumento2 pagineUITM FormBlipsy BlichNessuna valutazione finora

- ResumeDocumento3 pagineResumeHamka HidayahNessuna valutazione finora

- Introduction To MatlabDocumento32 pagineIntroduction To MatlabHamka HidayahNessuna valutazione finora

- Jobs Advertisement: Assignment 1Documento10 pagineJobs Advertisement: Assignment 1Hamka HidayahNessuna valutazione finora

- Jobs Advertising With WebsiteDocumento52 pagineJobs Advertising With WebsiteHamka HidayahNessuna valutazione finora

- Ch4 Data AcquisitionDocumento21 pagineCh4 Data AcquisitionHamka HidayahNessuna valutazione finora

- Part 1Documento5 paginePart 1Hamka HidayahNessuna valutazione finora

- Jobs Advertising With WebsiteDocumento52 pagineJobs Advertising With WebsiteHamka HidayahNessuna valutazione finora

- Millenium Mop: - Mohammad Syafiq Bin Ahadin (Leader) - Mohamad Hamka Bin Mohd Bilal - Adam Bin JalaludinDocumento18 pagineMillenium Mop: - Mohammad Syafiq Bin Ahadin (Leader) - Mohamad Hamka Bin Mohd Bilal - Adam Bin JalaludinHamka HidayahNessuna valutazione finora

- Part 1Documento5 paginePart 1Hamka HidayahNessuna valutazione finora

- Ch6 Dimension Units ConversionDocumento15 pagineCh6 Dimension Units ConversionHamka HidayahNessuna valutazione finora

- Assignment 1Documento10 pagineAssignment 1Hamka HidayahNessuna valutazione finora

- A5 - WSJ-1313s05Documento8 pagineA5 - WSJ-1313s05Hamka HidayahNessuna valutazione finora

- Contoh AbstractDocumento1 paginaContoh AbstractHamka HidayahNessuna valutazione finora

- Thesis WritingDocumento20 pagineThesis WritingHamka HidayahNessuna valutazione finora

- 600-FKM - Fyp (PPE-04) - FYP Poster Presentation EvaluationDocumento2 pagine600-FKM - Fyp (PPE-04) - FYP Poster Presentation EvaluationHamka HidayahNessuna valutazione finora

- Contoh Poster 1Documento1 paginaContoh Poster 1Hamka HidayahNessuna valutazione finora

- Microsoft Word - IRN Fab Transfer PCN NoticeDocumento22 pagineMicrosoft Word - IRN Fab Transfer PCN NoticeJadilson PradoNessuna valutazione finora

- Lecture 20Documento10 pagineLecture 20bilal5202050Nessuna valutazione finora

- CAT25256 EEPROM Serial 256-Kb SPI: DescriptionDocumento22 pagineCAT25256 EEPROM Serial 256-Kb SPI: DescriptionPolinho DonacimentoNessuna valutazione finora

- Adminstration of Intramusclar InjectionDocumento3 pagineAdminstration of Intramusclar InjectionDenise CastroNessuna valutazione finora

- Brock Planetary Declination SDocumento6 pagineBrock Planetary Declination SDositheus Seth100% (2)

- Eng Pipe DesignDocumento12 pagineEng Pipe DesignEsapermana Riyan100% (1)

- Digital Trail Camera: Instruction ManualDocumento20 pagineDigital Trail Camera: Instruction Manualdavid churaNessuna valutazione finora

- Mercedes (DTC) 976990001963 20220615144147Documento3 pagineMercedes (DTC) 976990001963 20220615144147YB MOTOR Nissan - Datsun SpecialistNessuna valutazione finora

- Under Pass Wing Wall (4.1m)Documento12 pagineUnder Pass Wing Wall (4.1m)Naveed NazNessuna valutazione finora

- TC AdvisoryDocumento1 paginaTC AdvisoryJerome DelfinoNessuna valutazione finora

- 2.4 Assembly ManualDocumento139 pagine2.4 Assembly Manualgustavo dlsNessuna valutazione finora

- EQ Cheat SheetDocumento7 pagineEQ Cheat SheetGabrielNessuna valutazione finora

- Notice: Environmental Statements Notice of Intent: Eldorado National Forest, CADocumento2 pagineNotice: Environmental Statements Notice of Intent: Eldorado National Forest, CAJustia.comNessuna valutazione finora

- Streamline SWR (S) - Rev - 00-04-2019 PDFDocumento2 pagineStreamline SWR (S) - Rev - 00-04-2019 PDFarjun 11Nessuna valutazione finora

- Amc 20-21Documento33 pagineAmc 20-21Vasco M C SantosNessuna valutazione finora

- IFIS - Intraoperative Floppy Iris Syndrome Wa Wa 27-09-2008Documento18 pagineIFIS - Intraoperative Floppy Iris Syndrome Wa Wa 27-09-2008JanuszNessuna valutazione finora

- Sindarin-English Dictionary - 2nd EditionDocumento192 pagineSindarin-English Dictionary - 2nd EditionNea Tan100% (1)

- ScilabDocumento4 pagineScilabAngeloLorenzoSalvadorTamayoNessuna valutazione finora

- Ays 082914 3331 PDFDocumento18 pagineAys 082914 3331 PDFFabian R. GoldmanNessuna valutazione finora

- BHLP Year Long Plan Required English Medium 2023 24 Batch Final 991676721629413Documento3 pagineBHLP Year Long Plan Required English Medium 2023 24 Batch Final 991676721629413A V GamingNessuna valutazione finora

- Bluforest, Inc. (OTC: BLUF) InvestigationDocumento5 pagineBluforest, Inc. (OTC: BLUF) Investigationfraudinstitute100% (1)

- z482 E3b en (3a2)Documento2 paginez482 E3b en (3a2)Gerencia General ServicesNessuna valutazione finora

- Coastal Management NotesDocumento2 pagineCoastal Management Notesapi-330338837Nessuna valutazione finora

- Fatigue Consideration in DesignDocumento3 pagineFatigue Consideration in DesigngouthamNessuna valutazione finora

- Vintage Tavern - PrintInspectionDocumento4 pagineVintage Tavern - PrintInspectionBryce AirgoodNessuna valutazione finora

- AVR Brosure Basler Decs 100Documento2 pagineAVR Brosure Basler Decs 100NikolayNessuna valutazione finora

- Lcnews227 - Nexera SeriesDocumento47 pagineLcnews227 - Nexera SeriesMuhammad RohmanNessuna valutazione finora

- Noxim MANUALDocumento5 pagineNoxim MANUALSAI NRUSIMHA DEEPAK BURRA SAI NRUSIMHA DEEPAK BURRANessuna valutazione finora