Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Happy Pad

Caricato da

mailbkraoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Happy Pad

Caricato da

mailbkraoCopyright:

Formati disponibili

R.D.S.

Hkkjr ljdkj, jsy eU=zky;

GOVERNMENT OF INDIA

MINISTRY OF RAILWAYS

SPECIFICATION FOR

THERMOPLASTIC POLYURETHANE SPRING PADS (HAPPY PADS)

FOR LOCOMOTIVES

SPECIFICATION NO. MP- 0.40.99.01

(Revision - 01)

October 2006

vuq l a / kku vfHkdYi vkS j ekud la x Bu

y[ku&226 011

RESEARCH DESIGNS & STANDARDS ORGANISATION

LUCKNOW - 226 011

Cost (Rs).

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

CONTENTS

Sl. No.

Description

Page No.

1.

Scope

2.

Definition

3.

Instructions for Purchaser

5.

Minimum

Requirements

of

Infrastructure,

Manufacturing, Testing and Quality Control For

Approval of Firm

Material

6.

Dimensions and Tolerances

7.

Manufacturing Process and Finish

8.

Technical Requirements of Spring Pads

9.

Lot Size, Sampling and Confirmatory Tests

10.

Marking

11.

Packing

12.

Storage

4.

2

4

ANNEXURES

Sl. No.

I.

II.

III.

IV.

V.

VI.

VII.

VIII.

Drawing

No.

Description

Spring Pad (Secondary Suspension) for WDP1

(Steel to IS: 2062 Gr C)

Spring Pad (Secondary Suspension) for WDP3A &

WDP3AM

Spring Pad (Primary Suspension) for WDP4

Spring Pad (Primary Suspension) for WAP1 &

WAP4

Spring Pad (Secondary Suspension) for WAP1 &

WAP4

Spring Pad (Secondary Suspension) for WDP1

(To be used with Bogie Frame of Corten Steel to

IRS: M41)

Spring Pad (Primary Suspension) for WDM3D

(Without Compensating & Equalizer Arrangement)

Spring Pads for Locomotives with Broad Gauge

3-Axle Trimount Bogies

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

SK.VL- 279

SK.VL- 280

SK.VL- 281

SK.VL- 282

SK.VL- 283

SK.VL- 284

SK.VL- 291

SK.VL- 323

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

SPECIFICATION FOR

THERMOPLASTIC POLYURETHANE SPRING PADS (HAPPY PADS)

FOR LOCOMOTIVES

1.

2.

SCOPE

1.1

This Specification covers the technical requirements relating to material,

design and tests for Polyurethane Spring Pads used below and above the

helical coil springs of locomotives to enhance their life due to reduced

fretting and better shock absorption capability. It also includes minimum

requirements of manufacturing, testing and quality control for these pads.

However, this specification does not include all the necessary provisions

required for a supply contract.

1.2

During service, the spring pad is subjected to a compressive load of about

5 tonnes in static condition. In addition, the pad is also subjected to

dynamic load of about 1.5 tonnes.

1.3

The pad shall have excellent wear resistance and tear strength properties.

It shall be capable of withstanding wide climatic variations prevailing in the

country without deterioration and without any marked change in

characteristics.

1.4

This document draws reference to some of the relevant ASTM / ISO

specifications. Latest versions of these specifications shall be taken as

reference unless mentioned otherwise.

1.5

While preparing this specification, due consideration has been given to the

latest development in the field of polymeric materials & process

technologies and service requirements of Indian Railways.

DEFINITION

Wherever Inspecting Agency has been mentioned in this document, it shall be

taken as Authorized Inspecting Agency as mentioned in the Purchase Order.

3.

INSTRUCTIONS FOR PURCHASER

3.1

The tenderer shall be an RDSO Approved Vendor for supply of

Thermoplastic Polyurethane Spring Pads (Happy Pads) for locomotives.

3.2

Inspection of Spring Pads (Happy Pads) shall be carried out by RDSO. The

Purchaser shall clearly indicate this in the Purchase Order.

3.3

The material, manufacturing and testing of Spring Pads shall conform to

this specification. The Purchaser shall clearly indicate this in the Purchase

Order.

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page 1

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

4.

MINIMUM REQUIREMENTS OF INFRASTRUCTURE, MANUFACTURING,

TESTING & QUALITY CONTROL FOR APPROVAL OF FIRM

4.1

The firm should have acquired ISO:9000 series certification for

manufacturing of Thermoplastic Polyurethane spring pads for locomotives.

4.2

The manufacturer shall have at least the following infrastructure and

manufacturing facilities:

.1

Adequate space and covered

accommodate the following:

a.

b.

c.

d.

e.

.2

with

cemented

floor

to

Damp-free space for storage of raw materials

Manufacturing Activities

Finishing

Inspection and Testing

Storage and dispatch of finished products

One Injection Moulding Machine of minimum capacity of 500 gms with

control panel equipped with the following features:

a.

b.

c.

d.

e.

f.

g.

h.

i.

4.3

area

Microprocessor Controlled Machine

Minimum clamping force (locking tonnage) of 150 tonnes

PLC Controlled Mould Temperature Controller (MTC)

Auto Loader/ Hopper Dryer

Auto Visual Alarm

Mould Height Adjustment Facility

Hot Air Oven for Annealing the Finished Product

Cooling Water System

Desiccant Dryer of Dehumidifier Attached with Dew Point Meter

.3

At least one set of Injection mould.

.4

Suitable material and mould handling facilities like Chain Pulleys,

trolleys, Electric Hoists or other suitable equipment.

.5

Suitable tools, cutters, polishing files and Buffing Machine for

deflashing of moulded products.

.6

Electronic Weighing Machine of reputed make of a minimum 2 Kg.

capacity with an accuracy of at least 0.2%.

.7

The firm shall have facilities for maintenance and polishing of dies and

moulds.

Testing Facilities

.1

The manufacturer shall have atleast the following testing facilities and

other equipment installed in the laboratory with controlled temperature

and humidity for carrying out various tests specified under Para 8:

a.

b.

c.

d.

Tensile Testing Machine of adequate capacity

Load Compression Testing Machine with a capacity of at least 10

tonne

Equipment for humidity control of Laboratory

Shore A Hardness Tester

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page 2

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

e.

f.

g.

h.

i.

4.4

Melting Point Apparatus

Weighing Balance with Specific Gravity determination Kit

Muffle Furnace

Equipment to test Compression Set as per ASTM D -395

Melt Flow Index Tester

.2

The manufacturer shall have facilities for compressive load-deflection

characteristics test in accordance to the specification.

.3

Dies / moulds for preparation of various test specimens for the

relevant tests shall be available.

.4

All gauges required for checking of dimensions of spring pads shall be

available.

.5

The manufacturer shall have suitable jigs & fixtures for conducting

Load Deflection Test and other tests as per specification.

Quality Control Requirements

.1

The firm should have a system of easy traceability of the product from

raw material stage to finished product stage.

.2

Quality Assurance Plan (QAP) for the product detailing various

aspects and duly approved by RDSO should be available. The QAP

should include the following:

a.

b.

c.

d.

e.

f.

g.

h.

Organization chart

Process flow chart

Stage Inspection details

Various parameters to be maintained to ensure control

Policy of disposal of rejected spring pads

Mould repairs

Moulding Process Control

Identification Marking

The record of implementation of QAP should be maintained for

documentary evidence.

.3

The firm shall have a system to ensure that moulds are checked at

regular intervals. Also, it is ensured that dies/moulds are checked

dimensionally prior to release for production and records of these

checks are maintained.

.4

The calibration of the Testing/ Measuring Equipments / Weighing

machines should be done at least once in a year unless stated

otherwise.

.5

The firm should have a Quality Manual indicating the extent of control

over manufacturing and testing.

.6

The firm should have a system of regular submission of rejections,

detailing rejection rate, cause of rejection, corrective action taken etc.

on quarterly basis.

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page 3

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

4.5

4.6

.7

The firm should have a system of documentation in respect of

rejection at customer end, warranty replacement and failure of spring

pads in service.

.8

The firm should have a system of recording plant, machinery & control

equipments remaining out of service, nature of repairs done etc.

.9

Latest version of relevant specifications and drawings shall be

available with the firm.

Qualification and Training

.1

Training needs for all personnel should be identified. Regular training

should be organized covering personnel identified for a particular

period.

.2

The Inspection / Quality Control Section should be headed by a

graduate Engineer with at least 5 years experience or a Diploma

holder with at least 10 years experience.

.3

Inspection staff conducting non-destructive testing should be

adequately trained & qualified by recognized agency and should have

adequate experience.

.4

Laboratory and Shift Engineers shall have a minimum qualification

either a Diploma or a Degree in Engineering (Plastic, Mechanical or

Electrical).

Approval of Firm by RDSO for Supply of Spring Pads for Locomotives

The RDSO guidelines shall be followed for approval of a firm for supply of

spring pads for locomotive bogies to Railways.

5.

6.

MATERIAL

5.1

The material used in the manufacture of spring pads shall be

Thermoplastic Polyurethane (TPU) manufactured by M/s Bayer or any

other world-renowned primary manufacturer of this material.

5.2

Before offering the material for tests, the spring pad manufacturer shall

have a suitable tie-up in the form of a written Memorandum of

Understanding (MoU) with the raw material supplier covering supplies and

technical support.

5.3

The material shall conform to the properties given in Para 8.

5.4

Use of regenerated / re-constituted material is not permitted.

5.5

Unless and otherwise specified in the purchase order, the colour of spring

pad shall be natural colour of the TPU material.

DIMENSIONS AND TOLERANCES

The spring pad shall conform to the dimensions and tolerances as given in the

relevant RDSO drawing.

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page 4

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

7.

8.

MANUFACTURING PROCESS AND FINISH

7.1

The pad shall be manufactured by injection moulding only.

7.2

The spring pad shall be smooth, free from air bubbles, surface streaks,

splash marks, pinholes, voids, crazing, blistering etc. All the edges shall be

neatly finished and free from flash.

7.3

The machining on spring pads after moulding is permitted, if required.

However, the finished dimensions must conform to relevant RDSO

drawing.

TECHNICAL REQUIREMENTS OF SPRING PADS

8.1

Physical Properties

The physical properties of material of spring pad shall be checked from the

finished product wherever practicable and the remaining checks shall be

carried out from the test specimen prepared under the identical conditions

of moulding of spring pad using the same raw material. The checks shall

be conducted as per methods given in ASTM Standards mentioned below

and their values shall conform to the following limits:

Sl.

Test Method

Units

-

Permissible Limit

1.

Specific Gravity

ASTM D792

2.

Tensile Strength

Elongation at

Break

Hardness

Compression Set

at 800 1 0C for 24

(+0/-2) hours

ASTM D412

kg/cm2

250 (Minimum)

ASTM D412

300 (Minimum)

ASTM D2240

Shore A 85 95

ASTM D395

3.

4.

5.

8.2

Property

1.12 to 1.25

45 (Maximum)

Oil Resistance Test

The swelling as determined by the method given in IS: 3400 (Part VI) using

an immersion period of 72 (+0 / -2) hours at 100 10 C shall not be more

than the limits given below:

8.3

Sl.

Volume Swelling Medium

Permissible Limit

1.

In Lubrex -150

20 % (Maximum)

2.

In Grease (Servogem 2 or 3)

15 % (Maximum)

Resistance to Hydrolysis

After Hydrolysis on boiling in distilled water at atmospheric pressure for 72

(+0 / -2) hours, the tensile strength, elongation at break and hardness shall

not vary from the value obtained before boiling by more than the following

limits:

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page 5

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

8.4

Sl.

Property

Permissible Limit

1.

Tensile Strength

20 %

2.

Elongation at break

20%

3.

Hardness (Shore A)

Compressive Load-Deflection Test

The spring pad shall be subjected to three successive loadings up to 5

tonnes. During the fourth cycle, the spring pad shall be compressed with a

load of 50 kg and deflection taken as zero at this point. The deflection at

load of 5 tonnes shall then be recorded with the help of dial gauge(s) /

digital display. The deflection value shall not be less than 0.50 mm.

9.

LOT SIZE, SAMPLING AND CONFIRMATORY TESTS

9.1

The Inspecting Agency for the purpose of inspection of the product in

reference to a Purchase Order shall carry out the checks as given below:

.1

The Inspecting Agency shall verify the following aspects before

carrying out inspection of spring pads:

i.

The delivery period of the Purchase Order is valid.

ii.

Check the Internal inspection record carried out at various stages

of manufacture of the product by the firms quality control

department for the product being offered and confirm that the

results of the internal inspection records are in order.

iii. The measuring instruments, gauges, testing facilities, etc are in

working order and they are calibrated.

iv. The latest copies of all reference specifications mentioned in this

specification are available with the firm.

.2

The lot size of spring pads to be offered in one inspection shall be 500

nos. or full quantity if the order is for less than 500 nos.

.3

The sample size, which shall be randomly drawn by the Inspecting

Agency from each lot of spring pads offered for inspection for

verification of various properties is detailed below. The following tests

shall be carried out on the finished product wherever practicable and

the remaining checks shall be carried out from the test specimen

prepared under the identical conditions of moulding of spring pad using

the same raw material. The samples shall be tested as per the test

method specified in Para-8 and the values shall conform to the

corresponding permissible values.

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page 6

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

9.2

9.3

Sl.

Test

Sample Size

1.

2.

3.

4.

5.

6.

7.

8.

9.

10

11

Type of Elastomer

Visual Inspection

Dimensions

Specific Gravity

Tensile Strength

Elongation at Break

Hardness

Compression Set at 800 10C for 24 (+0/-2) hours

Oil Resistance Test

Resistance to Hydrolysis

Compressive Load-Deflection Test

02 Nos.

50 Nos.

50 Nos.

02 Nos.

02 Nos.

02 Nos.

10 Nos.

02 Nos.

02 Nos.

02 Nos.

10 Nos.

Acceptance Criteria

.1

The firm shall not withdraw the material offered for inspection during

the course of inspection. Any move by the firm in any way to withdraw

the material / interfere / hinder with the inspection, shall render

rejection of the entire quantity of material offered for inspection.

.2

If any sample fails in one or more criteria given in Para-6 of this

specification, double the sample size shall be drawn and tested against

the criteria in which the failure had occurred. If all the samples of

double sampling pass the criteria, the entire quantity shall be accepted.

.3

Failure of any sample of the double samples will, however, result in

rejection of the entire offered quantity. The intimation of the failure and

rejection shall also be sent to RDSO.

.4

In the event of rejection, the entire quantity offered for inspection shall

be made un-usable for railway application in presence of the

Inspecting Agency.

Stamping

The spring pad, which has been inspected and passed, shall be double

stamped by the Inspecting Agency. The entire quantity of spring pads from

which the sampling has been taken shall be stamped (single stamp mark)

by the Inspecting Agency. Double stamping mark is to identify the samples,

which were drawn for inspection for future reference in the event of any

dispute.

10. MARKING

Each spring pad shall be suitably marked containing the following information by

embossing with height of letters of 4 mm size at the location specified in relevant

drawing:

a.

Drawing number

b.

Manufacturers name (initial / trade mark)

c.

Month and Year of manufacture.

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page 7

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

11. PACKING

The spring pads shall be suitably packed in cardboard boxes to protect them

against damage during transit and storage.

12. STORAGE

The spring pads shall be stored in a cool and dry place.

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page 8

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

ANNEXURE- I

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

ANNEXURE- II

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page

ii

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

ANNEXURE- III

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page

iii

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

ANNEXURE- IV

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page iv

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

ANNEXURE- V

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

ANNEXURE- VI

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page vi

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

ANNEXURE- VII

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page vii

Specification for Thermoplastic Polyurethane Spring Pads (Happy Pads) for Locomotives

ANNEXURE- VIII

Motive Power Directorate (Vehicle Dynamics Group), RDSO, Lucknow

Specification No. MP-0.40.99.01, Rev.01 Oct.06

Page viii

Potrebbero piacerti anche

- National Interest Waiver Software EngineerDocumento15 pagineNational Interest Waiver Software EngineerFaha JavedNessuna valutazione finora

- Brenco - CTRBMDocumento48 pagineBrenco - CTRBMDevendra SinghNessuna valutazione finora

- Bogie Technical RequirementsDocumento8 pagineBogie Technical RequirementsAmit shahNessuna valutazione finora

- 2 LJZ 2 - Flow Monitoring DeviceDocumento6 pagine2 LJZ 2 - Flow Monitoring DeviceRenato Nato AlvarezNessuna valutazione finora

- SKF Nut Sockets PDFDocumento1 paginaSKF Nut Sockets PDFslipsittinNessuna valutazione finora

- Concepts of SubmarineDocumento17 pagineConcepts of Submarinemailbkrao0% (1)

- Fag Imp MRP 01-05-13Documento195 pagineFag Imp MRP 01-05-13Manoj ThomasNessuna valutazione finora

- Ace Group Rev 7Documento1 paginaAce Group Rev 7Tezso JacobNessuna valutazione finora

- Draft C-8527 Rev.1 Amend2Documento23 pagineDraft C-8527 Rev.1 Amend2Shivendra KumarNessuna valutazione finora

- Sikaflex - Auto: One Component Polyurethane Sealant Exclusively For CBRDocumento2 pagineSikaflex - Auto: One Component Polyurethane Sealant Exclusively For CBRDavid SudarmaNessuna valutazione finora

- Indian Railways: Ref: CG-WI-4.2-1-1 Ver.-1.0 Page 1 of 12 Date of Issue: June, 2020Documento12 pagineIndian Railways: Ref: CG-WI-4.2-1-1 Ver.-1.0 Page 1 of 12 Date of Issue: June, 2020Kathirasan Ramalingam100% (1)

- For Non-Account Holder BeneficiaryDocumento2 pagineFor Non-Account Holder BeneficiarySP CONTRACTORNessuna valutazione finora

- CATALOGUE 2010 EPK For Railway Indstry (Engl-German)Documento23 pagineCATALOGUE 2010 EPK For Railway Indstry (Engl-German)Razvan MarcuNessuna valutazione finora

- Drawings Section 6Documento114 pagineDrawings Section 6VivekDhameliyaNessuna valutazione finora

- TRF DrawingsDocumento4 pagineTRF DrawingssivaNessuna valutazione finora

- Shell Gadus S2 V220 2 (En) TDS GreaseDocumento2 pagineShell Gadus S2 V220 2 (En) TDS Greasekevin_lim90Nessuna valutazione finora

- The World Market For Diesel LocomotivesDocumento10 pagineThe World Market For Diesel LocomotivesPaul MaposaNessuna valutazione finora

- Hempel Warrington Loading PDFDocumento34 pagineHempel Warrington Loading PDFSyed Fakher Imam AbediNessuna valutazione finora

- Effast Product CatalogueDocumento76 pagineEffast Product CatalogueLynn Selfe0% (2)

- Catalog GRP 2019Documento86 pagineCatalog GRP 2019MadhaneNessuna valutazione finora

- Chapter 3 PDFDocumento17 pagineChapter 3 PDFAprameya TNessuna valutazione finora

- Rolamentos e Retentores - Falk-Type-YB,-YBTDocumento5 pagineRolamentos e Retentores - Falk-Type-YB,-YBTVendedorNessuna valutazione finora

- VSB6 Vehicle RegulationDocumento35 pagineVSB6 Vehicle Regulationct0720054858Nessuna valutazione finora

- SKF Bearings - Trouble-Free Operation PDFDocumento19 pagineSKF Bearings - Trouble-Free Operation PDFOwenNessuna valutazione finora

- Matunga - Technical Specifications-Pages-29-52Documento24 pagineMatunga - Technical Specifications-Pages-29-52JITENDRA SHRIVASTAVANessuna valutazione finora

- Lpo 1612tc - 62 Bs-IIIDocumento252 pagineLpo 1612tc - 62 Bs-IIIAnbarasanNessuna valutazione finora

- Agri Engine CatalogueDocumento48 pagineAgri Engine Cataloguevinwin1986100% (3)

- Ricci ClamshellDocumento12 pagineRicci ClamshellEmily MartiniNessuna valutazione finora

- Is 2062 2011 Hot Rolled Medium and High Tensile Structural SteelDocumento14 pagineIs 2062 2011 Hot Rolled Medium and High Tensile Structural SteelNarendra VermaNessuna valutazione finora

- Catalogue - Eng ACEITES HYUNDAI PDFDocumento33 pagineCatalogue - Eng ACEITES HYUNDAI PDFPEDRONessuna valutazione finora

- Initial Registration PRCDocumento2 pagineInitial Registration PRCJoan OlanteNessuna valutazione finora

- Cylindrical RollerDocumento25 pagineCylindrical Rollersatish kumar reddyNessuna valutazione finora

- GBS 1180 F12021 RevC Dimensión de Vagón de ChinalcoDocumento1 paginaGBS 1180 F12021 RevC Dimensión de Vagón de ChinalcoIsraelNessuna valutazione finora

- Avaya CTI Adapter - Salesforce - Com Integration Installation and Configuration GuideDocumento42 pagineAvaya CTI Adapter - Salesforce - Com Integration Installation and Configuration GuideanntNessuna valutazione finora

- TATA Trucks Tractor Trailers SpecificationsDocumento61 pagineTATA Trucks Tractor Trailers SpecificationsLandsky IndiaNessuna valutazione finora

- Mahindra 475 DI Tractor BUDNI TEST REPORTDocumento15 pagineMahindra 475 DI Tractor BUDNI TEST REPORTShyam Katare0% (1)

- BPW Drum Brake CatalogueDocumento45 pagineBPW Drum Brake Cataloguesharef18Nessuna valutazione finora

- PDS Hempadur Multi-Strength 35842 en-GBDocumento2 paginePDS Hempadur Multi-Strength 35842 en-GBIfrahimNessuna valutazione finora

- Grid-Lign Fl4011 1209 WebDocumento2 pagineGrid-Lign Fl4011 1209 WebRenzo Jo LaurentNessuna valutazione finora

- Cranes Hoists Winches Guide 4422 PDFDocumento7 pagineCranes Hoists Winches Guide 4422 PDFToni RenedoNessuna valutazione finora

- Technical Specification of Hot Coiled Helical Springs Used in LocomotivesDocumento23 pagineTechnical Specification of Hot Coiled Helical Springs Used in LocomotiveskishoreNessuna valutazione finora

- ISO Standard End-Suction Centrifugal Pumps NJK Series: PP-H PVDF Etfe PVDF CFRPVDFDocumento7 pagineISO Standard End-Suction Centrifugal Pumps NJK Series: PP-H PVDF Etfe PVDF CFRPVDFstar enggNessuna valutazione finora

- WL 00200 6 de enDocumento200 pagineWL 00200 6 de enaNessuna valutazione finora

- Project Report For UNOKEM - Unokem Resins Pvt. Ltd.Documento31 pagineProject Report For UNOKEM - Unokem Resins Pvt. Ltd.Rahul PancholiNessuna valutazione finora

- PME Application Requirement As Per CODEDocumento3 paginePME Application Requirement As Per CODEEbenezer NatoplagNessuna valutazione finora

- Agricultural Trailer - Methods of TestDocumento9 pagineAgricultural Trailer - Methods of TestEdsel Jay RaperNessuna valutazione finora

- As 3645-2010 Essential Requirements For Gas EquipmentDocumento8 pagineAs 3645-2010 Essential Requirements For Gas EquipmentSAI Global - APACNessuna valutazione finora

- Ashish NBC ReportDocumento14 pagineAshish NBC ReportBidurGujjarNessuna valutazione finora

- National IndustriesDocumento10 pagineNational IndustriesKishan makvanaNessuna valutazione finora

- Designing A Final Drive For A Tracked VehicleDocumento9 pagineDesigning A Final Drive For A Tracked VehicleIroshana Thushara KiriwattuduwaNessuna valutazione finora

- Piezas MecanicasDocumento96 paginePiezas MecanicasSebastian Arias100% (1)

- Ra Engineering Company ProfileDocumento11 pagineRa Engineering Company ProfileWamiq RiazNessuna valutazione finora

- QMS 32 - 2009Documento4 pagineQMS 32 - 2009Prasenjit PuriNessuna valutazione finora

- Hyd DamperDocumento12 pagineHyd DampermailbkraoNessuna valutazione finora

- PRSN94Documento18 paginePRSN94Mula SrikantNessuna valutazione finora

- QMS 27 2000 Rev. 0 - 2Documento6 pagineQMS 27 2000 Rev. 0 - 2Mohit SinghNessuna valutazione finora

- Research Designs & Standards Organisation: MS Word Export To Multiple PDF Files Software - Please Purchase LicenseDocumento3 pagineResearch Designs & Standards Organisation: MS Word Export To Multiple PDF Files Software - Please Purchase LicenseHarshavardhan KulkarniNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 9Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 9Sudhakar KarnanNessuna valutazione finora

- Concrete Batch PlantDocumento9 pagineConcrete Batch Plantjana0926Nessuna valutazione finora

- STR - 026-0Documento5 pagineSTR - 026-0SanjeevNessuna valutazione finora

- VRP-GRP-P-501 Proced Prep QCMD Ver 4 DossierDocumento7 pagineVRP-GRP-P-501 Proced Prep QCMD Ver 4 DossierrcerberoNessuna valutazione finora

- Pocket Guide to Preventing Process Plant Materials Mix-upsDa EverandPocket Guide to Preventing Process Plant Materials Mix-upsNessuna valutazione finora

- 144372311Documento201 pagine144372311mailbkraoNessuna valutazione finora

- 50T Drop Table SEC RailwayDocumento28 pagine50T Drop Table SEC RailwaymailbkraoNessuna valutazione finora

- 125 Ton Drop Table - SEC RailwayDocumento34 pagine125 Ton Drop Table - SEC RailwaymailbkraoNessuna valutazione finora

- Current Affairs Feb 2016Documento138 pagineCurrent Affairs Feb 2016mailbkraoNessuna valutazione finora

- MP Misc 255 April 10 Emd CommissioningDocumento6 pagineMP Misc 255 April 10 Emd CommissioningmailbkraoNessuna valutazione finora

- Move of GM LocoDocumento17 pagineMove of GM LocomailbkraoNessuna valutazione finora

- RSB Bolt LooseningDocumento5 pagineRSB Bolt LooseningmailbkraoNessuna valutazione finora

- Quantiatative Aptitude SampleDocumento27 pagineQuantiatative Aptitude SampleSivakumar MNessuna valutazione finora

- Non Metallic Bushes in Wdg3a LocoDocumento5 pagineNon Metallic Bushes in Wdg3a LocomailbkraoNessuna valutazione finora

- 40 Days SCHDocumento23 pagine40 Days SCHmailbkraoNessuna valutazione finora

- Weight of Loco-LHCDocumento1 paginaWeight of Loco-LHCmailbkraoNessuna valutazione finora

- Non Verbal ReasoningDocumento18 pagineNon Verbal ReasoningParesh Modi100% (3)

- Must Change Item in PohDocumento23 pagineMust Change Item in Pohmailbkrao100% (1)

- 40 Days SCHDocumento23 pagine40 Days SCHmailbkraoNessuna valutazione finora

- Fuel Tank CalibrationDocumento4 pagineFuel Tank CalibrationmailbkraoNessuna valutazione finora

- Mod Lub PinDocumento3 pagineMod Lub PinmailbkraoNessuna valutazione finora

- Conversion From S BRG To RSBDocumento3 pagineConversion From S BRG To RSBmailbkraoNessuna valutazione finora

- Cru BRG ModDocumento3 pagineCru BRG ModmailbkraoNessuna valutazione finora

- Eye Type DamperDocumento3 pagineEye Type DampermailbkraoNessuna valutazione finora

- Specification For FOG PASSDocumento15 pagineSpecification For FOG PASSmailbkraoNessuna valutazione finora

- Specification For FOG PASSDocumento15 pagineSpecification For FOG PASSmailbkraoNessuna valutazione finora

- TSED 201047 Nov 10Documento20 pagineTSED 201047 Nov 10mailbkraoNessuna valutazione finora

- Failure of PinionDocumento6 pagineFailure of PinionmailbkraoNessuna valutazione finora

- Bolts IdentificationDocumento4 pagineBolts IdentificationmailbkraoNessuna valutazione finora

- FlashLight DetailsDocumento28 pagineFlashLight DetailsmailbkraoNessuna valutazione finora

- Ver SineDocumento2 pagineVer SinemailbkraoNessuna valutazione finora

- Classi AccDocumento21 pagineClassi AccmailbkraoNessuna valutazione finora

- Accident EnquireiesDocumento33 pagineAccident EnquireiesmailbkraoNessuna valutazione finora

- How Transformers WorkDocumento15 pagineHow Transformers Worktim schroderNessuna valutazione finora

- Nominal GroupDocumento3 pagineNominal GroupSrourNessuna valutazione finora

- Engineering Ethics in Practice ShorterDocumento79 pagineEngineering Ethics in Practice ShorterPrashanta NaikNessuna valutazione finora

- Log and Antilog TableDocumento3 pagineLog and Antilog TableDeboshri BhattacharjeeNessuna valutazione finora

- Logistic RegressionDocumento7 pagineLogistic RegressionShashank JainNessuna valutazione finora

- CHAPTER 2 Part2 csc159Documento26 pagineCHAPTER 2 Part2 csc159Wan Syazwan ImanNessuna valutazione finora

- 123Documento3 pagine123Phoebe AradoNessuna valutazione finora

- Installing Surge Protective Devices With NEC Article 240 and Feeder Tap RuleDocumento2 pagineInstalling Surge Protective Devices With NEC Article 240 and Feeder Tap RuleJonathan Valverde RojasNessuna valutazione finora

- Dec 2-7 Week 4 Physics DLLDocumento3 pagineDec 2-7 Week 4 Physics DLLRicardo Acosta Subad100% (1)

- Ficha Tecnica Bomba Inyeccion MiniFlex EDocumento1 paginaFicha Tecnica Bomba Inyeccion MiniFlex Ejohn frader arrubla50% (2)

- 5steps To Finding Your Workflow: by Nathan LozeronDocumento35 pagine5steps To Finding Your Workflow: by Nathan Lozeronrehabbed100% (2)

- KRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerDocumento3 pagineKRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerJohan Sneider100% (1)

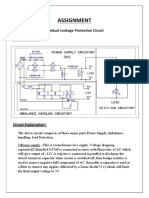

- Assignment: Residual Leakage Protection Circuit Circuit DiagramDocumento2 pagineAssignment: Residual Leakage Protection Circuit Circuit DiagramShivam ShrivastavaNessuna valutazione finora

- Wine TourismDocumento9 pagineWine Tourismyarashovanilufar1999Nessuna valutazione finora

- Names of Planner(s) : Style of Experience: (Whole Class, Small Group, Etc.) Lab: KindergartenDocumento4 pagineNames of Planner(s) : Style of Experience: (Whole Class, Small Group, Etc.) Lab: Kindergartenapi-428128701Nessuna valutazione finora

- Sheet-Metal Forming Processes: Group 9 PresentationDocumento90 pagineSheet-Metal Forming Processes: Group 9 PresentationjssrikantamurthyNessuna valutazione finora

- Hyundai SL760Documento203 pagineHyundai SL760Anonymous yjK3peI7100% (3)

- ChatGPT & EducationDocumento47 pagineChatGPT & EducationAn Lê Trường86% (7)

- School Based Management Contextualized Self Assessment and Validation Tool Region 3Documento29 pagineSchool Based Management Contextualized Self Assessment and Validation Tool Region 3Felisa AndamonNessuna valutazione finora

- Board of Technical Education (Student Marksheet)Documento2 pagineBoard of Technical Education (Student Marksheet)Manoj SainiNessuna valutazione finora

- Chapter 11 AssignmentDocumento2 pagineChapter 11 AssignmentsainothegamerNessuna valutazione finora

- TPDocumento10 pagineTPfaisal gaziNessuna valutazione finora

- Electronic Diversity Visa ProgrambDocumento1 paginaElectronic Diversity Visa Programbsamkimari5Nessuna valutazione finora

- TIA Guidelines SingaporeDocumento24 pagineTIA Guidelines SingaporeTahmidSaanidNessuna valutazione finora

- 2007 ATRA Seminar ManualDocumento272 pagine2007 ATRA Seminar Manualtroublezaur100% (3)

- Michael Clapis Cylinder BlocksDocumento5 pagineMichael Clapis Cylinder Blocksapi-734979884Nessuna valutazione finora

- Functions of Theory in ResearchDocumento2 pagineFunctions of Theory in ResearchJomariMolejonNessuna valutazione finora

- There Will Come Soft RainsDocumento8 pagineThere Will Come Soft RainsEng ProfNessuna valutazione finora