Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pneumatic Vs Electric Cost Calculator

Caricato da

Cazacu AndreiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pneumatic Vs Electric Cost Calculator

Caricato da

Cazacu AndreiCopyright:

Formati disponibili

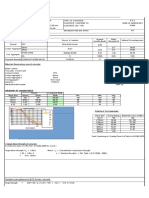

Cost Evaluation of Pneumatic and Electric Actuator Deployments

Version 1.01, March 2011

Purpose: This spreadsheet is intended to provide an approximate comparison of the total costs

Replacement costs, electrical energy consumption, and process improvement cost savings are

Organization: The spreadsheet has five tabs.

Instructions (this page)

Pneumatic Solution Cost Cost evaluation of pneumatic actuators and compressor

AC Actuator Solution Cost Cost evaluation for electric actuators that are powered by the AC lin

DC Actuator Solution Cost Cost evaluation of electric actuators that require DC power supplies

Electric Productivity Savings Calculation of cost reductions from man-hour savings and elimin

Summary Pneumatic vs. Electric side by side cost comparison of pneumatic and electric.

Each spreadsheet requires information to be input. These are shown as pink boxes. Each spread

Input requirements: When evaluating compressors, electric actuators, motors, controls, and po

for the devices handy. The more accurate the information input, the more useful the output wil

Limitations: The spreadsheet is only a generalization. While most applications employ a variety

average component, done for simplicity. The spreadsheet facilitates comparisons of compres

address how to size a compressor for a given installation of pneumatic actuators. That is beyon

toprovide a usefulestimate, but the results arenot guaranteed. To the maximum extent perm

the implied warranty of fitness for a particular purpose and the implied warranty of merchantab

ployments

comparison of the total costs of deploying electric and pneumatic actuators.

mprovement cost savings are taken into account.

and compressor

hat are powered by the AC line voltage

hat require DC power supplies

man-hour savings and elimination of lost production.

pneumatic and electric.

wn as pink boxes. Each spreadsheet provides output as well.

ors, motors, controls, and power supplies, it helps to have manufacturers specifications

he more useful the output will be.

applications employ a variety of components, the spreadsheet only allows input for an

ates comparisons of compressors, pneumatic cylinders, and actuators, but it does not

matic actuators. That is beyond the scope of this spreadsheet. The spreadsheet is meant

To the maximum extent permitted by law, all warranties, expressed or implied, including

plied warranty of merchantability areexpressly disclaimed.

Pneumatic Solution Annual Cost

Enter the criteria in the Input cells below to calculate the annual cost to operate a pneumatic solution.

Compressor Costs

kWh Electrical Cost

Hours per Week Full Load

Hours per Week Idling

Weeks per Year in Operation

Input

$0.00

0

0

0

Compressor Horse Power

% Compressor efficiency, full load

% Compressor efficiency, idle

0

0%

0%

Annual Full Load Use (Hours)

Number of Pneu Actuators

Avg Replacement cost of Pneu Actuators

Pneu Actuators Avg Life Yrs.

0

$0

0

Annual kWH Cost

Full Load

#N/A

Idle Load

#N/A

Annual kWH

#N/A

Annual Replacement Cost

#N/A

Total Annual Pneumatic System Cost

Cost per Pneumatic Device per Year

#N/A

#N/A

AC Powered Electric Actuator Solution Cost

Enter the criteria in the Input cells below to calculate the annual cost to operate an AC actuator solution.

kWh Electrical Cost

Operating Hours per Week

Total Operating Weeks per Year

Total Annual Operating Hours

% of Hours Operating at Full Load

% of Hours Operating at Idle Load

Input

$100.00

0

0

0

2%

98%

Number of AC Electric Actuators

Avg. Unit Cost of AC Powered All-in-One Elect Actuator

$0

Avg. cost of Modular Elect Actuator

Avg. Unit Cost of Motor

$0

$0

AC - All-in-One Actuator

Voltage input

Current Draw Amps - Full Load

Current Draw Amps - Idle (Not Off)

0

0

0

Electrical power consumption costs

Unit @ Full

Unit @ Idle

Per Unit Total

$0.00

$0.00

$0.00

Annual kWh Cost

Annual Replacement Cost

Total Annual Cost

$0.00

#N/A

#N/A

DC Powered Electric Actuator Solution Cost

Enter the criteria in the Input cells below to calculate the annual cost to operate a DC actuator solution.

kWh Electrical Cost

Operating Hours per Week

Total Operating Weeks per Year

Total Annual Operating Hours

% of Hours Operating at Full Load

% of Hours Operating at Idle Load

Input

$0.00

0

0

0

2%

98%

Number of DC Electric Actuators

Avg. unit cost of DC power supply

$0

Avg. Unit Cost of All-in-One DC Elect Actuator

$0

Avg. cost of Modular DC Elect Actuator

Avg. Unit Cost of Motor

Avg. Unit Cost of Controller

$0

$0

$0

Avg. Actuator Life (Yrs)

Avg. Motor Life (Yrs)

Avg. Controller and Power Supply Life (Yrs)

0

0

0

DC - All-in-One Actuator

Power Supply

Input voltage

Maximum current draw

Maximum output current

Actuator

Current Draw Amps - Full Load

Current Draw Amps - Idle (Not Off)

0

0

0

0

0

Electrical power consumption costs

Unit @ Full

Unit @ Idle

Per Unit Total

#N/A

#N/A

#N/A

Annual kWh Cost

Annual Replacement Cost

Total Annual Cost

DC Modular Actuator + Controller

Power Supply

Input voltage

Maximum current draw

Maximum output current

Controller

Current Draw Amps - Full Load

Max Current Output

Motor

Current Draw Amps - Full Load

Current Draw Amps Idle

0

0

0

0

0

#N/A

#N/A

Electrical power consumption costs

Unit @ Full

Unit @ Idle

Per Unit Total

#N/A

#N/A

#N/A

Annual kWh Cost

Annual Replacement Cost

Total Annual Cost

0

0

#N/A

#N/A

#N/A

#N/A

Additional Manufacturing or Other Electrical Solution Savings

For example: Ethernet control to your electric solution provides "Set-Up On the Fly", eliminating manual conversion.

Manufacturing Set Up Savings

Cost of labor

Number of People

Man Hour Labor Cost

Hour Saved per Week Per Man

Weeks per Year

Input

0

$0.00

0

0

Labor Savings

Cost of lost production

Production Rate (units/hour)

Cost per unit

0

$0.00

$0

Lost Product Opportunity in Dollars

Input other savings Dollars

$0

$0

Additional Electric Solution Annual Savings

$0

Summary Comparison of Pneumatic versus Electric Actuator Annual Operating Cost

Annual Cost - Electric

Annual Cost - Pneumatic

Actuator Annual

Operating Cost

Additional

Mfg. Savings

Total Solution

Cost

AC - All in One Actuator

#N/A

#N/A

#N/A

AC Modular Actuator + Controller

#N/A

#N/A

#N/A

DC - All in One Actuator

#N/A

#N/A

#N/A

DC Modular Actuator + Controller + Power Supply

#N/A

#N/A

#N/A

#N/A

Potrebbero piacerti anche

- Pneumatic Vs Electric Cost CalculatorDocumento7 paginePneumatic Vs Electric Cost CalculatorArindam GhosalNessuna valutazione finora

- Additive Manufacturing A Complete Guide - 2020 EditionDa EverandAdditive Manufacturing A Complete Guide - 2020 EditionNessuna valutazione finora

- Vacuum Conveyor For Industrial ApplicationDocumento4 pagineVacuum Conveyor For Industrial Applicationkrishna100% (1)

- Productivity and Reliability-Based Maintenance Management, Second EditionDa EverandProductivity and Reliability-Based Maintenance Management, Second EditionNessuna valutazione finora

- Advanced Process Control A Complete Guide - 2020 EditionDa EverandAdvanced Process Control A Complete Guide - 2020 EditionNessuna valutazione finora

- Dorner 3200 Vacuum ConveyorDocumento8 pagineDorner 3200 Vacuum ConveyorBobKatNessuna valutazione finora

- Plant Engineering and Design The Ultimate Step-By-Step GuideDa EverandPlant Engineering and Design The Ultimate Step-By-Step GuideNessuna valutazione finora

- Design—Operation Interactions at Large Treatment Plants: Proceedings of a Workshop Held in ViennaDa EverandDesign—Operation Interactions at Large Treatment Plants: Proceedings of a Workshop Held in ViennaS. H. JenkinsNessuna valutazione finora

- Insights into Chemical Engineering: Selected Papers of P.V. DanckwertsDa EverandInsights into Chemical Engineering: Selected Papers of P.V. DanckwertsNessuna valutazione finora

- ConveyingDocumento77 pagineConveyingJackNessuna valutazione finora

- Tutorial - Vane Pump Modeling in FLUENTDocumento32 pagineTutorial - Vane Pump Modeling in FLUENTMohamed Osman AbdallaNessuna valutazione finora

- Installing Machine Tools: Here's What To ConsiderDocumento1 paginaInstalling Machine Tools: Here's What To ConsiderMobile SunNessuna valutazione finora

- Flow Diagrams For Chemical Processes: Chemical Project Engineering and EconomicsDocumento31 pagineFlow Diagrams For Chemical Processes: Chemical Project Engineering and EconomicsSandipSingNessuna valutazione finora

- Meeting the Pump Users Needs: The Proceedings of the 12th International Pump Technical ConferenceDa EverandMeeting the Pump Users Needs: The Proceedings of the 12th International Pump Technical ConferenceNessuna valutazione finora

- Nanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationDa EverandNanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationNessuna valutazione finora

- Vertical MultiStage Pump Data SheetDocumento6 pagineVertical MultiStage Pump Data Sheetسمير البسيونى100% (1)

- 23 3 16 Delcos XL L Serie en UkDocumento80 pagine23 3 16 Delcos XL L Serie en UkChris MurrayNessuna valutazione finora

- Optimizing Pumping Systems P-IDocumento4 pagineOptimizing Pumping Systems P-Imatrix69Nessuna valutazione finora

- Practical Guidelines For Determining Electrical Area ClassificationDocumento17 paginePractical Guidelines For Determining Electrical Area ClassificationOmar AzzainNessuna valutazione finora

- CAIHE7 PreviewDocumento27 pagineCAIHE7 PreviewMohamedNessuna valutazione finora

- P280 ManualDocumento14 pagineP280 ManualzlatkozdihanNessuna valutazione finora

- Structural Health MonitoringDa EverandStructural Health MonitoringDaniel BalageasNessuna valutazione finora

- F2008-00 (2012) E1 Standard Guide For Qualitative Observations of Skimmer PerformanceDocumento9 pagineF2008-00 (2012) E1 Standard Guide For Qualitative Observations of Skimmer PerformanceHarry BradroccoNessuna valutazione finora

- Design of HydraulicsDocumento5 pagineDesign of HydraulicsNicole DavisNessuna valutazione finora

- Hydraulic Actuator SpecificationsDocumento3 pagineHydraulic Actuator SpecificationsRizky RamadhaniNessuna valutazione finora

- IIT-Intake and Exhaust Manifold DesignDocumento28 pagineIIT-Intake and Exhaust Manifold DesignVasudev GuptaNessuna valutazione finora

- Hyundai Electric ESS Project List-1Documento2 pagineHyundai Electric ESS Project List-1Rachmat HermawanNessuna valutazione finora

- PIC18FDocumento37 paginePIC18Fsitizarina78Nessuna valutazione finora

- 30xa602 FullloadDocumento1 pagina30xa602 Fullloadcalvin.bloodaxe4478Nessuna valutazione finora

- Motor Driven Pumps Process Pumps ProMinent Product Catalogue 2017 Volume 3Documento220 pagineMotor Driven Pumps Process Pumps ProMinent Product Catalogue 2017 Volume 3carlosmilfontNessuna valutazione finora

- P E F C R Uninterruptible Power Supply (UPS) : September 22, 2016Documento53 pagineP E F C R Uninterruptible Power Supply (UPS) : September 22, 2016Karim IsmailNessuna valutazione finora

- 13.belt Conveyor Design and Analysis PDFDocumento4 pagine13.belt Conveyor Design and Analysis PDFbrahmandaNessuna valutazione finora

- Sizing Technical Brief FinalDocumento3 pagineSizing Technical Brief FinalBelalNorNessuna valutazione finora

- Chapter 7: Process PlanningDocumento6 pagineChapter 7: Process Planningஅன்புடன் அஸ்வின்Nessuna valutazione finora

- Analog IO Module 1746 Installation ManualDocumento28 pagineAnalog IO Module 1746 Installation ManualWilBert Alcántara MatosNessuna valutazione finora

- Unidrive M Modular Installation Guide English Issue 7 (0478-0141-07) - Approved PDFDocumento158 pagineUnidrive M Modular Installation Guide English Issue 7 (0478-0141-07) - Approved PDFferiferiNessuna valutazione finora

- Intro To MechatronicsDocumento33 pagineIntro To MechatronicsQaasim MoudNessuna valutazione finora

- Danfoss Scroll CompressorsDocumento6 pagineDanfoss Scroll Compressorsfaizan abbasiNessuna valutazione finora

- Installation and Operating Manual For Pneumatic Control ValvesDocumento1 paginaInstallation and Operating Manual For Pneumatic Control ValvesFairos ZakariahNessuna valutazione finora

- App.5-MS For Stone ColumnDocumento6 pagineApp.5-MS For Stone ColumnMAJ1980Nessuna valutazione finora

- Hydraulic System:-: Chapter-2 Hydraulic, Pneumatic and Electrical Telemetry SystemsDocumento7 pagineHydraulic System:-: Chapter-2 Hydraulic, Pneumatic and Electrical Telemetry SystemsMayur ParmarNessuna valutazione finora

- GAVC 1200 Functional Description - 1518165531 - 687c34ad PDFDocumento21 pagineGAVC 1200 Functional Description - 1518165531 - 687c34ad PDFAhsan SiddiquiNessuna valutazione finora

- WELCOME To Cost & Evaluation Workbook by Peters, Timmerhaus and West. Accompanying Plant Design and Economics For Chemical Engineers, 5th EditionDocumento15 pagineWELCOME To Cost & Evaluation Workbook by Peters, Timmerhaus and West. Accompanying Plant Design and Economics For Chemical Engineers, 5th Editionxhche7Nessuna valutazione finora

- Ada 136220Documento231 pagineAda 136220Anonymous 9xvU1FNessuna valutazione finora

- Conveyor Belt PLC ProjectDocumento44 pagineConveyor Belt PLC ProjectM Tanzeel Qaisar DogarNessuna valutazione finora

- TRANSCO Profile - English 2012Documento24 pagineTRANSCO Profile - English 2012Zaher Mhd SharafNessuna valutazione finora

- Fluid Flow Basics OF Throttling ValvesDocumento43 pagineFluid Flow Basics OF Throttling ValvesSandro AraújoNessuna valutazione finora

- Lab 4 Pulley PDFDocumento4 pagineLab 4 Pulley PDFAngeloNessuna valutazione finora

- Alia AFC365 Flow ComputerDocumento4 pagineAlia AFC365 Flow ComputerRexCrazyMindNessuna valutazione finora

- Price List For WIKA PDFDocumento110 paginePrice List For WIKA PDFBrijesh Sharma100% (1)

- Spectrum Power Management Systems Load Calculation Tool: Input Line Current PDU Loads (In Amps)Documento1 paginaSpectrum Power Management Systems Load Calculation Tool: Input Line Current PDU Loads (In Amps)K.RamachandranNessuna valutazione finora

- Inst Cantitati Mar v1Documento4 pagineInst Cantitati Mar v1Cazacu AndreiNessuna valutazione finora

- Spectrum Power Management Systems Load Calculation Tool: Input Line Current PDU Loads (In Amps)Documento1 paginaSpectrum Power Management Systems Load Calculation Tool: Input Line Current PDU Loads (In Amps)K.RamachandranNessuna valutazione finora

- Home Electrical Bill / Energy Consumption / Electrical Load CalculatorDocumento21 pagineHome Electrical Bill / Energy Consumption / Electrical Load Calculatorsrabon1059Nessuna valutazione finora

- Ebsco Ebooks: Ebook Electrical Engineering CollectionDocumento2 pagineEbsco Ebooks: Ebook Electrical Engineering CollectionCazacu AndreiNessuna valutazione finora

- Arc FlashDocumento15 pagineArc FlashramlijavierNessuna valutazione finora

- D.G Size Calculation (22.8.12)Documento1 paginaD.G Size Calculation (22.8.12)Waleed Mohammed FekryNessuna valutazione finora

- Data Center Electrical Power Chain Assessment Tool Version 1. January 25, 2010Documento9 pagineData Center Electrical Power Chain Assessment Tool Version 1. January 25, 2010Mohan RajNessuna valutazione finora

- Electrical Poles Trasverse Load Calculation (22.8.12)Documento12 pagineElectrical Poles Trasverse Load Calculation (22.8.12)Waleed Mohammed FekryNessuna valutazione finora

- C.B Tripping Setting-Motor Data (28!5!11)Documento31 pagineC.B Tripping Setting-Motor Data (28!5!11)KIS610Nessuna valutazione finora

- AC Size Calculation (28!5!11)Documento4 pagineAC Size Calculation (28!5!11)jiguparmar1516Nessuna valutazione finora

- Icam Historical Buildings App Broc A4 LoresDocumento4 pagineIcam Historical Buildings App Broc A4 LoresCazacu AndreiNessuna valutazione finora

- Cable Size CalculationsDocumento4 pagineCable Size CalculationsSohail ANessuna valutazione finora

- Cable Design - New (22.8.12)Documento93 pagineCable Design - New (22.8.12)zanibabNessuna valutazione finora

- Icam Historical Buildings App Broc A4 LoresDocumento4 pagineIcam Historical Buildings App Broc A4 LoresCazacu AndreiNessuna valutazione finora

- Overheating and Fuel Ash Corrosion Failure of Boiler TubeDocumento18 pagineOverheating and Fuel Ash Corrosion Failure of Boiler TubeJackSparrow86Nessuna valutazione finora

- Mobrey CLT PDFDocumento18 pagineMobrey CLT PDFAnonymous Oydnu9Nessuna valutazione finora

- Spot Weld Growth On 304L Austenitic Stainless Steel For Equal and Unequal ThicknessesDocumento9 pagineSpot Weld Growth On 304L Austenitic Stainless Steel For Equal and Unequal ThicknessesAmin MojiriNessuna valutazione finora

- TDS Shell Gadus S2 V220 2Documento2 pagineTDS Shell Gadus S2 V220 2regisNessuna valutazione finora

- Science at The Environment Agency - Essay - United State Literature - Professor Mike DepledgeDocumento343 pagineScience at The Environment Agency - Essay - United State Literature - Professor Mike Depledgeadnan-hNessuna valutazione finora

- SPGR and Density Test MethodDocumento4 pagineSPGR and Density Test MethodDavid LicindoNessuna valutazione finora

- KDD Series CatalogueDocumento3 pagineKDD Series CatalogueIlyas Rangga RamadhanNessuna valutazione finora

- Concrete Proportion and Concrete MixtureDocumento12 pagineConcrete Proportion and Concrete MixtureEnrico luis EscobarNessuna valutazione finora

- Simulation of Draping, Infiltration and Curing of CompositesDocumento49 pagineSimulation of Draping, Infiltration and Curing of CompositesPeti Kovács100% (1)

- Ce 326 Principles of Environmental Engineering: SPRING 2010Documento2 pagineCe 326 Principles of Environmental Engineering: SPRING 2010Jorge Gomez RamirezNessuna valutazione finora

- 4 Ponchon Savarit MethodDocumento47 pagine4 Ponchon Savarit Methodivanlawms6745Nessuna valutazione finora

- M25 (PPC)Documento2 pagineM25 (PPC)Jagdev GuleriaNessuna valutazione finora

- Sample Problem #1Documento7 pagineSample Problem #1DozdiNessuna valutazione finora

- Manual JVC KW-XC828 PDFDocumento94 pagineManual JVC KW-XC828 PDFMassolo RoyNessuna valutazione finora

- Hybrid Geosynthetic Paving Mat For Highway ApplicationsDocumento4 pagineHybrid Geosynthetic Paving Mat For Highway ApplicationsmithileshNessuna valutazione finora

- TitaniumDocumento6 pagineTitaniumzonearthNessuna valutazione finora

- Manual For Accessory Kit To Electromagnetic Vibrator No. 2185.55Documento2 pagineManual For Accessory Kit To Electromagnetic Vibrator No. 2185.55Harry RamzaNessuna valutazione finora

- 500kW BG Specs - Patruus IL6 TWIN PACK Biogas - 2 X 250 BGDocumento7 pagine500kW BG Specs - Patruus IL6 TWIN PACK Biogas - 2 X 250 BGbinstartedNessuna valutazione finora

- "Preparation of Tamarind Paste": Seminar OnDocumento15 pagine"Preparation of Tamarind Paste": Seminar Onraja singamNessuna valutazione finora

- 2001 Drawworks EuroRig 5 0027 Sub Supplier GB Rev0Documento668 pagine2001 Drawworks EuroRig 5 0027 Sub Supplier GB Rev0Florin Stoica100% (4)

- Energy Conservation in Sugar IndustriesDocumento7 pagineEnergy Conservation in Sugar IndustriesKetty Puspa JayantiNessuna valutazione finora

- Type Mao Type Mbo Type Mci: W.AriyaratneDocumento1 paginaType Mao Type Mbo Type Mci: W.AriyaratneLeon ZhouNessuna valutazione finora

- Miniature Vane Shear Test AstmDocumento20 pagineMiniature Vane Shear Test Astmsitti.aNessuna valutazione finora

- MOJAVE Single Wide 2015Documento16 pagineMOJAVE Single Wide 2015Donnarose DiBenedettoNessuna valutazione finora

- C5210HP Technical DataDocumento9 pagineC5210HP Technical Data顏健軒Nessuna valutazione finora

- Description and Instructions For Water Leakage DetectorDocumento3 pagineDescription and Instructions For Water Leakage Detectorsaurabhjerps231221Nessuna valutazione finora

- Efficiency Criterion: Passive House Institute 64283 Darmstadt GermanyDocumento2 pagineEfficiency Criterion: Passive House Institute 64283 Darmstadt GermanylajharkaNessuna valutazione finora

- 002 MillingDocumento29 pagine002 MillingCindelle Mariae GomiegaNessuna valutazione finora

- HP Transformer OilsDocumento2 pagineHP Transformer OilsNoble Jose KunhiparaNessuna valutazione finora

- Rheovis As 1920Documento2 pagineRheovis As 1920Victor LopezNessuna valutazione finora