Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

h800 I0g2

Caricato da

Daniel NogueiraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

h800 I0g2

Caricato da

Daniel NogueiraCopyright:

Formati disponibili

INSTALLATION GUIDE

CURRENT MONITORING

TM

TM

800

Solid-Core On/Off Current Switch, Fixed Trip Point SPECIFICATIONS

RoHS

Compliant

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Follow safe electrical work practices. See NFPA 70E in the USA, or applicable local codes.

This equipment must only be installed and serviced by qualied electrical personnel.

Read, understand and follow the instructions before installing this product.

Turn o all power supplying equipment before working on or inside the equipment.

Use a properly rated voltage sensing device to conrm power is o.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

A qualified person is one who has skills and knowledge related to the construction and

operation of this electrical equipment and the installation, and has received safety

training to recognize and avoid the hazards involved.

NEC2009 Article 100

No responsibility is assumed by Veris Industries for any consequences arising out of the

use of this material.

This product is not intended for life or safety applications.

Do not install this product in hazardous or classied locations.

The installer is responsible for conformance to all applicable codes.

Mount this product inside a suitable re and electrical enclosure.

WIRING EXAMPLE

For CE compliance, conductor shall be insulated according to IEC610101:2010. The product design

provides for basic insulation only.

INSTALLATION

Disconnect and lock out power to the enclosure

containing the conductor to be monitored.

1. Locate a mounting surface for the removable mounting bracket that will allow the

monitored conductor to pass through the center window when it is installed and

that will keep the device at least (13 mm) from any uninsulated conductors.

Determine cable routing for the controller connection, allowing wiring to reach

the mounting location.

2. Drill holes to mount the bracket to the chosen surface using the included screws.

4. Route the conductor through the sensors center window and slip the assembly

into the mounting bracket.

5. Secure enclosure and reconnect power.

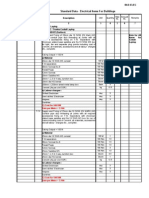

DIMENSIONS

Insulated Conductor Only

BUILDING AUTOMATION

CONTROLLER

POWER

SOURCE

Induced from monitored conductor

0.25 to 200 A Continuous

N.O. 1.0 A@30 VAC/DC, not polarity sensitive

600 VAC RMS (UL); 300 VAC (CE), insulated conductors only

Fixed at 0.25 A max.

50/60 Hz

-15 to 60C (5 to 140F)

10-90% RH non-condensing

Open switch represents 1+ M

Closed switch represents <200 m

0.2 to 2.1 mm2(24 to14 AWG)

0.4 to 0.5 N-m(3.5 to 4.4 in-lb)

UL508 E150462, CE:EN61010-1:2001

Cat. III, pollution degree 2

3. Wire the output connections and relay between the sensor and the controller

(solid-state contact).

NOTICE

Sensor Power

Amperage Range

Status Output Ratings

Insulation Class

Setpoint

Frequency

Temperature Range

Humidity Range

Off State Resistance

On State Resistance

Terminal Block Wire Size

Terminal Block Torque

Agency Approvals

Installation Category

DI

Removable/Adjustable Mounting Bracket

0.9"

(23 mm)

0 0.7"

(18 mm)

2.8"

(71 mm)

DI

0.4 x 0.2

Slot (x2)

1.7

(43 mm)

1.1"

(27 mm)

POWER

SOURCE

UNIT VENT HEATER

Z201984-0G

PAGE 1

2.3"

(58 mm)

2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com

12121

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Veris, and the Veris V logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

INSTALLATION GUIDE

H800

TM

PRODUCT OVERVIEW

TROUBLESHOOTING

The H800 is a current-sensitive switching device that monitors current (amperage) in

the conductor passing through it. A change in amperage in the monitored conducter

that crosses the switch threshold will cause the resistance of the status output to

change state, similar to the action of a mechanical switch. The threshold is fixed at

0.2 A or less. The status output is suitable for connection to building controllers or

other appropriate data acquisition equipment operating at up to 30 volts. The H800

requires no external power supply to generate its output.

Problem

No Reading at Controller

Solution

Check for control voltage at sensor (<30 V)

Check for amperage in monitored conductor (>0.25 A)

NOTES

For load currents greater than sensor maximum rating:

Use a 5 Amp (H68xx series) Current Transformer (CT) as shown. This technique can be

combined with wrapping (see below) to add range for a low current load on a high

current source.

> 200 A (Sensor max.)

240AA

250

300A:5A

4AA

4.2

H68xx-5A CT

DANGER: 5A CTs can present hazardous voltages.

Install CTs in accordance with manufacturer's instructions.

Terminate the CT secondary before applying current.

CAUTION

RISK OF EQUIPMENT DAMAGE

Derate the products maximum current for the number of turns

through the sensing window using the following formula.

Rated Max. Amps Number of Turns = Max. monitored Amps

e.g. : 100A 4 Turns = 25 Amps max. in monitored conductor

Failure to follow these instructions can result in overheating

and permanent equipment damage.

For load currents less than sensor minimum rating:

Wrap the monitored conductor through the center window and around the sensor

body to produce multiple turns. This increases the current measured by the

transducer.

Program the controller to

account for the extra turns,

e.g., if four turns pass through

the sensor (as shown), then

divide the normal controller

reading by 4.

< 0.25 A (Sensor Min.)

Z201984-0G

2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com

PAGE 2

4x

0.1A

0.5A

12121

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Veris, and the Veris V logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Robway SLI ManualDocumento135 pagineRobway SLI ManualBatagor H. Isan100% (1)

- Elce4012 4Documento8 pagineElce4012 4ameerNessuna valutazione finora

- OHareDocumento1 paginaOHareDaniel NogueiraNessuna valutazione finora

- Printing Configurations: GX-9100 Software Configuration Tool User's Guide D-1Documento7 paginePrinting Configurations: GX-9100 Software Configuration Tool User's Guide D-1Daniel NogueiraNessuna valutazione finora

- Facility Explorer 12011406Documento14 pagineFacility Explorer 12011406Daniel NogueiraNessuna valutazione finora

- fx20Documento3 paginefx20Daniel NogueiraNessuna valutazione finora

- Electronic Room Thermostat SRE06: Description FeaturesDocumento3 pagineElectronic Room Thermostat SRE06: Description FeaturesDaniel NogueiraNessuna valutazione finora

- FX20/FX60 Installation InstructionsDocumento20 pagineFX20/FX60 Installation InstructionsDaniel NogueiraNessuna valutazione finora

- Sensor de TemperaturaDocumento4 pagineSensor de TemperaturaDaniel NogueiraNessuna valutazione finora

- Straight Line Wiper ManualDocumento20 pagineStraight Line Wiper ManualIsmail HashmiNessuna valutazione finora

- Inventory of Training ResourcesDocumento4 pagineInventory of Training ResourcesTimothy John Natal MandiaNessuna valutazione finora

- Dvi 980 - 982 (En)Documento6 pagineDvi 980 - 982 (En)Jozo ĆurčićNessuna valutazione finora

- Tacuma. EcmDocumento105 pagineTacuma. EcmFelix VelasquezNessuna valutazione finora

- MIL-HNBK-5400 - Electronic Equipment, AirborneDocumento91 pagineMIL-HNBK-5400 - Electronic Equipment, AirbornegamillosNessuna valutazione finora

- NRG10A ManualDocumento25 pagineNRG10A ManualfreddyNessuna valutazione finora

- User's Manual: Series 982Documento141 pagineUser's Manual: Series 982kmpoulos100% (1)

- Andhra Pradesh Cinemas (Regulation) Act, 1955Documento141 pagineAndhra Pradesh Cinemas (Regulation) Act, 1955Jaganath RathNessuna valutazione finora

- Electrical Installation and Maintenance: Quarter 3Documento12 pagineElectrical Installation and Maintenance: Quarter 3AV Montes100% (2)

- Instruction Manual: Fuji Electric Co., Ltd. INR-SI47-1894-EDocumento56 pagineInstruction Manual: Fuji Electric Co., Ltd. INR-SI47-1894-EXosé Nel Piedra FernándezNessuna valutazione finora

- VantageDocumento36 pagineVantagehsaeed786Nessuna valutazione finora

- SOP MAINTENANCE FINAL - Part2Documento55 pagineSOP MAINTENANCE FINAL - Part2mansoorNessuna valutazione finora

- Jcy1700 SeDocumento98 pagineJcy1700 SeMarx QuebralNessuna valutazione finora

- Monte Carlo Yachts 76 FlybridgeDocumento19 pagineMonte Carlo Yachts 76 FlybridgeBui Duy ThanhNessuna valutazione finora

- LF06P2 - W4F-830-P Discontinued: Product DatasheetDocumento6 pagineLF06P2 - W4F-830-P Discontinued: Product DatasheetgeocaustasNessuna valutazione finora

- PWD Registered Electrical ContractorDocumento7 paginePWD Registered Electrical ContractorGnanavel GNessuna valutazione finora

- TUV SolarDocumento85 pagineTUV Solarajimon 00971Nessuna valutazione finora

- Positioner 3582Documento44 paginePositioner 3582DineshNessuna valutazione finora

- Sx4 S Cross e BrochureDocumento17 pagineSx4 S Cross e Brochurewawawa1100% (1)

- R4 - Restore A VIntage Sewing Machine Guide Sample PDFDocumento13 pagineR4 - Restore A VIntage Sewing Machine Guide Sample PDFMike CryerNessuna valutazione finora

- Revised Standard Data For ElectrificationDocumento120 pagineRevised Standard Data For ElectrificationKishore Ainavilli100% (1)

- SG Eco EN 2.1.0Documento49 pagineSG Eco EN 2.1.0Mikhail YudhiantaraNessuna valutazione finora

- Gasboy - Schedule Operation ManualDocumento26 pagineGasboy - Schedule Operation ManualJennerJimenezNessuna valutazione finora

- Marque: Delonghi Reference: Ec 151B Noir CodicDocumento14 pagineMarque: Delonghi Reference: Ec 151B Noir CodicbellahceneNessuna valutazione finora

- H Proc Notices Notices 035 K Notice Doc 34100 604021603Documento8 pagineH Proc Notices Notices 035 K Notice Doc 34100 604021603Mohammed MustafaNessuna valutazione finora

- Catalog Axol UteDocumento247 pagineCatalog Axol Uteradu dermideNessuna valutazione finora

- TM F 2020fDocumento45 pagineTM F 2020fMatthew BennettNessuna valutazione finora

- Installation, Operation and Maintenance Guide: For Indoor/Outdoor Single Phase Encapsulated TransformersDocumento247 pagineInstallation, Operation and Maintenance Guide: For Indoor/Outdoor Single Phase Encapsulated TransformersFlaKo Man La AmeNazaNessuna valutazione finora