Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DC Pump Manual

Caricato da

Felipe UzabalCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DC Pump Manual

Caricato da

Felipe UzabalCopyright:

Formati disponibili

SHENWU

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

VR:1.1

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

Introduction

Thanks your purchase the SPC series of PV solar water pumps!

This instruction introduces the right installation and usage of SPC products. Please

read the instruction carefully before installation, application, maintenance and inspection.

Cautions

Upon opening please confirm water pump control system model, motor model is

consistent with your order. the product certificate, user manual and warranty and

other accessories are complete. If there is any breakage phenomenon, if found to be

damaged, missing or damage, please contact with the company or your supplier to

solve.

The differences between explanatory pictures and real products do caused by the great

varieties of SPC series pump.

Because the product upgrades and specification upgrades, as well as to improve the

accuracy, the instruction will be updated in a timely manner, please note the current

version is the latest version before reading.

If you have any query after reading this instruction, please contact our customer service.

Customer service Tel+86 132 0371 5884

-1-

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

SPC Operating and Maintenance Instruction

Contents

1. Security Information ----------------------------------------------------------- 3

2. Brief Description ---------------------------------------------------------------- 6

3. Product Introduction ----------------------------------------------------------- 6

4. Type Instruction ---------------------------------------------------------------- 7

5. SPC controller parameter ----------------------------------------------------- 7

6. Machine & Electricity installation ------------------------------------------- 8

7. Operation Declaration --------------------------------------------------------- 16

8. Working Conditions ------------------------------------------------------------- 17

9. Maintenance --------------------------------------------------------------------- 17

10.Trouble shooting ---------------------------------------------------------------- 18

Warranty Agreement---------------------------------------------------------------- 19

-2-

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

1. Security Information

Security DefinitionThere are two kinds of security attentions in this instruction:

DangerThe danger caused by the wrong operation on ones own, may lead to heavy hurt or death.

WarningThe danger may result in moderate hurt or minor injury, and equipments damage.

Before you install, adjust and maintenance this system, please read this chapter carefully, and please bring your

attentions to the safety rules in this chapter. Our company has nothing to do with any damage caused by violations.

1.1 Before installation

Danger

Please dont install when unpacking found controller waterlogged, components or parts damaged!

Please dont install when the real goods dont conform to the specifications in PL!

Please handle the equipment gently, protect the equipment from damage.

Please dont install or use when system control box installed components have defects or

deformation of the abnormal situation

Please dont touch controller components by hands, or there is electrostatic damage risk!

1.2 Installation

Danger

Please install controller indoors, or rain, moisture proof outdoor mounting bracket (or

installation covering)!

Controller installation area should away from combustible materials, or may cause a fire!

Installing the controller fixed supports or mounting screws must be solid, otherwise the device

my fall and lead to dangerous incidents!

Submersible pump installation should be install lifting rope for lift hole, does not allowed pump

motor cable pulling, or the cables may be pull apart, pump falls and other unpredictable danger!

Warning

Cant let the wire head, screws and other conductive objects fall into the controller; otherwise

it may cause damage to the controller.

Please install the control in the place with less shake and avoid direct sunlight.

Please note the installation location to ensure the cooling effect.

Please note the submersible depth of pump should no less than 0.5 meters, or may cause the

pump burned out

1.3 Wiring

-3-

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

Danger

Please carefully read the manual, and by professional electrical engineer operate, or may cause

a danger!

Before connection, please confirm the controller is without power, or may cause electric shock risk.

Please follow the manual figure and description to connect wires , otherwise may cause safety

accident

Pay attention to the cross-sectional area of power supply line and water pump connecting cable

can meet the real needs, or may cause safety accident!

Please according to the standard operate the controller in a right way; otherwise there is a risk

of electric shock!

Never be the input power is connected to the output terminals (U,V,W), take notice of the

terminals mark, dont pick the wrong line, or may cause a controller damage!

Note the DC input line (+), (-) polarity can not be reversed, or to cause the machine to burned or

more serious accidents!

If the pump cable joints under water, please make sure that the underwater joint waterproof

treatment is safe and reliable, otherwise it may result in damage to the equipment or more

serious safety accidents!

Ensure the distribution lines tally with the EMC requirements and local safety standard. The wire

size please refer to the manuals proposal, otherwise may occur safety accident!

Warning

Electric motor input lines (U V W) must be connected correctly, otherwise the motor run in

opposite direction. And the pump would not pump water.

Note the high or low position of water level sensor, to set right gap control, avoid frequent reboot.

1.4 Before power on

Danger

Ensure the input voltage in the rated voltage range of controller, otherwise may cause damage

to the machine or more serious consequences!

Please confirm all terminals connected firmly, without loosing and fastening wont cause big

contract resistance, otherwise may cause the dangerous risk!

Please dont use wet hands to touch the wires, terminals, switches, controllers, or may result in

damage to the equipment or cause unpredictable consequences!

Warning

Please confirm the output (U V W) wiring position is correct, otherwise the motor run reversely

or other accidents!

Check the external wiring whether has a short-circuit phenomenon, or may cause the controller

is damaged!

Dont need to make any pressure test on any part of controlleror may lead to the accident

Submerge the pump into the water for 15-20 minutes before first use. No dry runs. Or may cause

the pump burned out!

1.5 After power on

-4-

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

Danger

Dont use hands to touch controller wiring terminals, cables and etc, or there is a risk of electric

shock!

If the parameters need to be measured, please confirm and check whether the safety measures

is normal. Please attention any part of the body can not touch the charged terminal metal part,

otherwise may cause an electric shock risk!

If need to test and adjust machine, please note that the pump is completely immersed in the

water and well fixed, or may lead to unpredictable accidents!

Dont collate or pull cables after power on, or may cause dangerous risk!

Warning

Dont frequently switch controller, or it may cause damage to the machine!

1.6 In operation

Danger

Amateur technicians can not detect signal in operation, or it may cause personnel injury or

equipment damage

Please do not touch to test the temperature of the equipment, or may cause burns or other

accidents!

Warning

Avoid something or debris falls into the device, or it may cause damage to equipment or other

unpredictable accidents!

Dont take the contactor (air switch on-off method) to control the start-stop of device, or easily

damage the switch!

Please note the intermittent start-stop time should not be less than 2 minutes, or may cause

damage to the machine!

1.7 Maintenance

Danger

Dont repair and maintenance the charged equipment, or there is a risk of electric shock!

In equipment downtime and shut off external power supply after 2 minutes to make the

maintenance and repair, or the residual charge on capacitor may cause harm to human body!

Non-professionally trained technician can not repair or maintenance the controller, or may cause

personal injury or equipment damage!

2. Brief Description

-5-

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

PV water pumping system is mainly composed of: solar water pump controller, pump, solar array and corresponding

connecting pipelines and cables, as shown in Fig2.1. Mainly used for lifting water, lakes, rivers and other water sources,

and used for agricultural irrigation, aquaculture, city greening, living water supply, water conservancy project. PV

water pumping system highlights its advantages in those areas where rich in solar energy resources but lack of city

electricity supply. Our company produces the SPC series DC photovoltaic pump system having the advantages of

environmental protection, high efficiency, unattended, and maintenance-free characteristics, which is an ideal green

environmental protection product.

Fig2.1

schematic diagram of PV water pumping system

3. Product Introduction

The SPC series PV pump system consists of: solar water pump controller, DC motor, solar array and corresponding

connecting pipelines and cables. This series product has the following advantages:

The DC PM brushless motor increases the efficiency up to 25% in comparison with traditional AC motor.

Adopt stator and rotor double plastic patented technology to do plastic insulation waterproofing treatment.

Motor insulation degree is larger than 300M ohm; greatly enhance the safety and reliability of motor.

The water lubricated bearing, relative to conventional bearings, has the advantages of easy installation, no

environmental pollution.

The microprocessor controller has advantages of MPPT, double water level detection control; prevent dry play

protection, automatic operation (unattended), etc.

SPC series solar water pump controller can be driven by solar array or battery. Customers can choose to purchase

controller with charging function, and join the battery to compose a system working 24 hours. The company can tailor

the PV pump system based on the actual needs the user.

4. Type Instruction

-6-

SPC Operating and Maintenance Instruction

Controller Type

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

SPC-200

Rated power 200W

Solahero Pump Controller

Pump Type

SHP-0.7/30-24

Voltage

Max head

Max flow rate

Solahero Pump

5. SPC controller parameter

SPC controller size

Dimensions

Mode

Hole

Hole Position (mm)

mm

Dia(mm)

Volume

sizemm

SPC-200

218

174

125

94

200.5

218*174*109

SPC-300

218

174

125

94

200.5

218*174*109

SPC-1000

218

174

125

94

200.5

218*174*109

SPC-1500

288

174

125

94

270.5

288*174*109

SPC-2200

288

174

125

94

270.5

288*174*109

SPC-2800

288

174

125

94

270.5

288*174*109

SPC-4200

288

174

125

94

270.5

288*174*109

SPC controller electrical parameter

-7-

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

Rated power

Operation

Work voltage

Max input

Max power

Net weight

Gross weight

VoltageV

range V

voltageV

current A

kg

kg

SPC-200

200

24V

18-30V

36V

8A

1.51

1.95

SPC-300

300

36V

32-40V

45V

9A

1.51

1.95

SPC-1000

1000

48V

46-56V

65V

15A

1.53

1.97

SPC-1500

1500

110V

105-120V

180V

11A

2.44

SPC-2200

2200

280V

270-300V

380V

6A

2.05

2.49

SPC-3000

3000

290V

280-310V

380V

8A

2.05

2.49

SPC-4200

4200

300V

290-320V

380V

11A

2.05

2.49

Model

Warning:

The total Voc voltage of solar module should not exceed the maximum input voltage of the

selected controller, or may cause damage.

The total Vmp voltage of solar module should be in working voltage range of motor, or may cause

the machine damaged.

6. Machine and Electricity Installation

6.1 solar module installations

6.1.1

solar panel selection

Solar panel recommended configuration table

parameter

SPC-200

SPC-300

SPC-1000

SPC-1500

SPC-2200

SPC-2800

SPC-4200

Model

Maximum powerW

210W

300W

200W

195W

270W

300W

240W

Maximum

27.6V

38.16V

26.48V

36.75V

36.1V

35V

34.56V

Vmp

Open circuit voltageVoc

33V

44.64V

32.7V

45.4V

43.6V

41.3V

42.48

Maximum

7.6A

7.87A

7.45A

5.31A

7.48A

8.58A

6.96A

Imp

Required total quantity

1PCS

1PCS

4PCS

6PCS

8PCS

9PCS

18PCS

Power of solar arrayW

210W

300W

800W

1170W

2160W

2700W

4320W

power

power

voltage

current

6.1.2

solar panel installation

Small power solar panel to

recommend the use of column type

solar bracket as shown in Fig 6.1

-8-

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

Fig6.1 Column type solar bracket

Multiple solar panel to recommend the use of array type solar mounting as shown in Fig6.2:

Fig6.2 array type solar bracket

Solar array direction and elevation adjustments as shown in Fig6.3,first to adjust the light receiving horizontal area

face the direction of the sun at noon, then let the sun light (at noon) perpendicular to the light receiving area.

Noon

Noon

Solar panel

Morning

Vertical sun

Evening

Elevation

Solar panel

Horizontal plant

Fig6.3

The scientific method is: according to the actual local latitude and checking longitude, by checking table and actual

geographical situation calculate the horizontal installation direction and elevation, then install based on those

parameters.

warning

Unreasonable direction and elevation will reduce solar energy utilization ratio, thereby reduce

the efficiency of the system.

The elevation should change with the seasons and adjustment, especially in the high latitude

region should adjust the elevation angel to achieve the maximum solar utilization ratio.

6.2 SPC series controller installation

6.2.1

Installation environment

a) Environment temperature :The temperature has great influence on service life, do not allow it exceeds the

allowed temperature range-10 50.

-9-

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

b) Vertically mounted controller, where there is enough space for cooling.

c) Install in the place with less vibrationVibration should be less than 0.6G.

d) Avoid direct sunlight, humidity and water.

e) Avoid the corrosive, inflammable, explosive gases in air

f) Dont install in the grease and dusty place.

6.2.2 Controller installation

Mount the controller on the column bracket as shown in Fig6.4, on the wall, electric control boxes and other flat

surface as shown in Fig6.5.

Fig6.4 controller mounted on the column type bracke

- 10 -

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

Fig 6.5 Controller mounted on wall and electric control box

6.3 pump installation

6.3.1

a)

Pump installation steps

Prepare sufficient long hoisting cable according to the actual situation and let it go through the water pump

hoisting hole and fixed by chunk (as shown in Fig6.6). Another end of hoisting cable is fixed to the derrick reel

or fixing device.

Fig6.6 hoisting cable installation

b)

According to the actual situation prepare long enough waterproof 3 core cable( cable specifications with

reference to cable selection guide chapter),Let the cable head and pump lead line respectively pass through

the waterproof connector of water proof junction box and dock. And remark the U V W 3-phase identification

on docked waterproof cable. For more details please see under water connection guidance chapter.

c)

Prepare a suitable water pipes to meet real needs( note the nominal pressure of the water pipes and pipe

fittings should be greater than the actual working pressure).Wind the outside wire connector with plastic

stripe then screw it into the outlet of water pump and connect.

d)

Extend the cables of probe-type sensor or float sensor to appropriate length, underwater joint processing can

consult pump cable processing method. For more detailed mounting method please refer to the water level

sensor installation guide chapters.

- 11 -

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

e)

Strap the connected cables of sensor and water pump on the pipeline

at regular distance intervals

f)

Hold up the pump and pipeline and pull them slowly into the well through the hoisting cable, when the pump

to the appropriate height, please fix the hoisting cable to the manhole cover or the corresponding fixing

device.

g)

Connect the ground water supply pipeline with pump outlet pipeline. This pump installation is complete, the

next step for the electrical installation and debugging.

Warning

The steel wire rope tensile strength must meet the actual demand, or pump has falling damage!

Underwater wire water-proof treatment must be reliable, or it may cause water level judgment

errors and machine burn out.

Cant use water pump connecting cables or pipe to lift pump, or it may cause: water pump fall

well, machine damage and unpredictable accidents.

The steel wire rope fixing device must be safe, reliable, or pump has falling damage risk!

6.4 Electrical installation guide

6.4.1

cable selection table

DC input wire

Cables for pump

Water level detection

mm2

mm2

wiremm2

SPC-200

1.5

0.5-1.0

SPC-300

1.5

0.5-1.0

SPC-1000

0.5-1.0

SPC-1500

1.5

0.5-1.0

SPC-2200

1.5

0.5-1.0

SPC-3000

1.5

0.5-1.0

Type

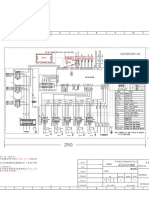

6.4.2 Terminal diagram

SPC series controller terminal diagram as shown in Fig 6.7, please correspond to actual models for electrical

connection:

Fig6.7 terminal diagram

6.4.3

Wiring diagram

SPC series controller without charge function type wiring diagram as shown in Fig 6.8:

- 12 -

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

Fig6.8 without charging function type wiring diagram

SPC series controller with charging function type wiring diagram as shown in Fig6.9

Fig6.9 with charging function type wiring diagram

6.4.4

a)

water level sensor installation guide

Controller can pick up 2 channel water level sensor, that the source (well, rivers, lakes and so on) water level

and water-filled water level sensor. Source water level sensor used to test whether water source is dry, prevent

pump anhydrous idling and damage. Water-filled water level sensor used to check the high cistern or water

tower is full filled with water or not, prevent water overflow waste. Source water level sensor is suggested to

install, or motor would be damaged! Water-filled water level sensor according to the actual situation to decide

whether or not to install.

b)

Water level sensor has a variety of specifications this handbook lists only floating ball type and probe type

water level sensor. Note: The well diameter less than 8 inches cannot use float ball type sensor, must use the

probe-type sensor.

c)

Source water level sensor installation: a, the float sensor installation as shown

in Fig 6.10 , the float sensor

suitable for wide surface water, diameter less than 60 CM wells can not be applied. B, the probe type sensor

wiring way (Fig 6.11).

Note: Dry water protection water level

should be higher than the water outlet of the water pump, and the

before restart to work, please assure the water capacity is enough for pump to work at least for 5 minutes.

- 13 -

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

Fig6.10 floats sensor wiring mode in water source

Fig 6.11 probe type sensor wiring mode in water source

d)

Water-filled sensor installation:

Float sensor wring mode as shown in Fig6.12.

Fig6.12 Float sensor wiring mode

6.4.5 under water terminal guidance

a)

Ordinary water and rive water usually have a low impedance electrical conductivity, and the cables of water

pump and sensors are too short to meet the actual demand, so when the cable joints immersed in water, wire

connection is needed to do waterproof treatment to avoid electric leakage accidents.

b)

Connection method Let the cable head and pump outlet line respectively pass through the junction box

waterproof connector and skinless butt, remark the

U V W 3-phase logo in docking waterproof cables ,do

insulation treatment with electrical tape and waterproof tape , then thread finishing into the junction box,

- 14 -

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

and the waterproof box interior space filled with waterproof silicone as attached Fig6.13 shows.

c)

Sensor cable connection referencemotor lead line and cable connections

Fig6.13 Motor lead wire and cable connection diagram

6.4.6 The wiring matters needing attention

a)

Please follow cable selection table recommended cable diameter. Other standard cable models please

conversion or query the corresponding cable parameters table, and the prerequisite for effective conductive

load area is not less than the recommended value. All the reference data in the table is based on the effective

conductive cross-sectional area unit.

b)

The wire connecting controller and pump can not be connected to the capacitor or surge absorbers, otherwise

it will cause the system often protected or even damage.

- 15 -

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

Danger

Note the positive and negative electrode must be connected correct, or may cause personal

injury or equipment damage!

Attention battery pole can not be short-circuited; otherwise it may cause injury or

unpredictable accidents!

Don't touch the machine terminals and cables after electrify, or get an electric shock risk!

Warning

Electric motor input lines (U V W) and controller terminal (U V W) must be connected correctly,

otherwise the motor would turn in opposite direction, and the pump would not pump water.

Attention the solar panel and battery connected to controller terminal under power, terminal

would make sparks. Suggested that connect the solar panel and battery to the controller

terminal after getting across the air switch.

7. Operation Declaration

7.1 Switch operation

SPC series of photovoltaic water pump and controller with intelligent, automatic unattended and other characteristics,

in the confirmation of all the machinery installation and electrical installation is correct, safe, accurate, only need to

open the controller terminal at the top of the power switch can be automatically run.

7.2 Display information:

SPC series of photovoltaic water pump controller display panel as shown in Fig 7.1, for the function of indication

information please see the indicator information table:

Fig7.1 SPC series of photovoltaic water pump controller display panel

- 16 -

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

Indicator information table

name

color

Definition of indicator light

POWER

Green

Power indicator

RUN

green

Running indicator

MPPT

green

MPPT indicator

ERROR

red

Error indicator

TANK FULL

red

Tank full indicator

SOURCE LOW

red

Water low (water dry) indicator

Danger

Before boot, check the wiring connection terminal is correct, whether there is loose, confirmed

no abnormal then to start, or may lead to unpredictable accidents.

Warning

Dont switch air switch to control the start-stop of the water pump, or my cause damage to air

switch or controller!

Dont let the water pump frequent start and stop, or easily cause damage to pump or controller.

8. Working conditions

Work environment temperature range-10 50

Environmental humidityLess than 95RHno water condensation

VibrationLess than 5.9/S 0.6g

The storage temperature-20 60

Reduce the outlet power when altitude > 1000 meters.

9. Maintenance

In order to ensure the reliable operation of the system and prolong the service life, need regular comprehensive

maintenance to pump and controller. Each year do at least one time preventive examination, include:

Boot sound and the voltage and current are abnormal, starting device is working Properly, the controller set up

multiple protections is normal movement, the main cable and control cable without aging crack, main contactor is

stuck oxidation or burr, insulation resistance against ground is too low, whether the balance of three-phase winding

resistance, stator and rotor are sweep chamber or scratches, controller water level sensor is normal or not reliable,

floating ball movement is reliable, bearing has no wear, impeller has no wear or abrasion cavitations, the shaft is rust

deformation or abrasion, motor internal and external fastening screws are loose, the pump inlet and the pump body

around without sedimentation or clogging.

- 17 -

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

10.Trouble shooting

No

Malfunction phenomena

reason

solution

Switch off the controller, use multi-meter to read the

Pump cant operate and

Wrong connection of solar panel

voltage of S and N end of controller, if the reading to

wires

close to the open voltage of solar panel, the connection

is right, otherwise, reconnect according to the manual.

controller led off

No sunshine or not enough

Controller switch off

Set controller switch on

Switch off the controller, use the multi-meter to read

Controller power Led on,

Run Led on, MPPT Led

2

flicking, several seconds

later, ERROR Led flick, then

the resistance of any two ends of UVVW, if the

3-phase UVW connects not well or

cables is broken.

connection is right, the resistance < 1otherwise, the

resistance is infinitee.g.the resistance of UV ends

is less <1the resistance of UW and VW is infinite, that

means cable W connects not well or is broken. Check

repeat those above

pipes and change bad pipes in time.

reaction.

Sunshine is not enough

3-phase UVW connects in wrong

order.

Switch off the controller and connect 3-phase as

instruction manual.

Controller Led and pump

Water leakage of pipes

work well, but no water

Not install water level sensor

outlet.

above the outlet of pump

Check and connect pipes correctly.

The head of pump cant meet the

real head

Install water level correctly as manual

Contact suppliers and change another type.

Lack of sunshine

Controller works well, flow

rate decrease dramatically.

Water leakage of pipes

Check and connect piles correctly

Wrong installation of water level

Install water level sensor correctly as instruction

sensor

manual.

Not install water level sensor or

water level too low.

Controller power Led on.

Error Led on.

TANK FULL Led on

Inlet of pump is obstructed

Remove the mesh veil of inlet and wash it.

Power of solar panel is too low

Increase the quantity of solar panel

Sunshine is not enough

Over voltage of solar panel

Change the right model of solar panel

tankor water toweris full of

Normal phenomenon, pump will rework after water

water and pump stop work

Water level decrease to the

SOURCE LOW Led on

dry-protection level.

Not install or wrong install the

water level sensor

SOURCE LOW Led on

Error Led on, SOURCE LOW

Led on

Close controller and wait the water level rise.

Water source level is low than the

inlet

Pump motor blank run

level decrease.

Wait water level to rise

Check and install water lever sensor

Wait water level to rise

Check and fix the pump

Controller will try to restart after 5 minutes (some

Sunshine is not enough

modes need 10 minutes later )

- 18 -

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

The Warranty agreement

1 Offer a three year warranty from the date of purchase.

2 Such as the following phenomenon in warranty period, will charge repair cost

Due to transportation, use or improper keeping( such as liquid inlet, external forces, falls) resulted in the

damage to the machine

Without accreditation from our company to repair, modification and maintenance resulted in machine

damage

Due to natural disasters (such as: lightning, earthquake, fire, flood and so on) and disasters resulted in damage

to the machine

Not according to the manual to operate and maintenance resulted in machine damage

Due to the fault of outside machine ( external equipment factors) resulted in damage

Warranty card and purchase invoices, both incomplete procedures

Wearing parts (such as pump head, oil seal) and accessories not covered under warranty, if there is damage,

need to purchase.

3 Product failure or damage, please fill out the warranty card in a correct and detailed way.

4 Product warranty cards, in general no replacement, please keep this card.

5 Warranty expires, in order to supply a lasting service to you, we will charge a repair cost.

6 Repair charges, will be in accordance with the latest repair list.

7 If there are questions in service process, please contact our company or our agents.

8 The right of final interpretation owe to our company.

Noted: Please provide your purchase vouchers before repairingIn order to facilitate

your custody, please affix the purchase vouchers in the space below.

Product warranty card

Product name

Type/number

Origin

Date of

purchase

Repair time

Fault

condition

Repair

results

- 19 -

SPC Operating and Maintenance Instruction

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

Product warranty card receipt

Customer

Tell

name

Address

Zip code

Type

Number

Date of

Purchase

purchase

origin

Fault

condition

Repair

results

Degree of

satisfaction

Customer

feedback

Zhengzhou Shenwu Electromechanical Industry Co., Ltd.

Sales Add: Unit 4, East Of No. 1 Building, Siyuetian, Yard 102, Guoji Road, Jinshui Dist., Zhengzhou, He'nan,

China (Mainland)

M.B:+86 132 0371 5884 Fax: +86 371 69137120 Email: shenlongpumps@aliyun.com

- 20 -

Potrebbero piacerti anche

- DI-149 Manual PDFDocumento30 pagineDI-149 Manual PDFFelipe UzabalNessuna valutazione finora

- CVT PDFDocumento212 pagineCVT PDFEdward PorterNessuna valutazione finora

- DI-149 Manual PDFDocumento30 pagineDI-149 Manual PDFFelipe UzabalNessuna valutazione finora

- Control System Technical Service Manual (2014.10.20) PDFDocumento290 pagineControl System Technical Service Manual (2014.10.20) PDFFelipe UzabalNessuna valutazione finora

- 1.NIM01 Connected To The Rooftop GuideDocumento1 pagina1.NIM01 Connected To The Rooftop GuideFelipe UzabalNessuna valutazione finora

- WEG Regulador Automatico de Tension Grt7 Th4 10040217 Manual EspanolDocumento54 pagineWEG Regulador Automatico de Tension Grt7 Th4 10040217 Manual EspanolforoNessuna valutazione finora

- WEG Regulador Automatico de Tension Grt7 Th4 10040217 Manual EspanolDocumento54 pagineWEG Regulador Automatico de Tension Grt7 Th4 10040217 Manual EspanolforoNessuna valutazione finora

- WEG Regulador Automatico de Tension Grt7 Th4 10040217 Manual EspanolDocumento54 pagineWEG Regulador Automatico de Tension Grt7 Th4 10040217 Manual EspanolforoNessuna valutazione finora

- Ccm15 Operation ManualDocumento48 pagineCcm15 Operation ManualFelipe Uzabal0% (1)

- Hoja Datos Tecnicos Panel FVDocumento2 pagineHoja Datos Tecnicos Panel FVFelipe UzabalNessuna valutazione finora

- A New Method For The C-Type Passive Filter Design PDFDocumento5 pagineA New Method For The C-Type Passive Filter Design PDFdes1982Nessuna valutazione finora

- Evaluación Reflector SchefflerDocumento6 pagineEvaluación Reflector SchefflerFelipe UzabalNessuna valutazione finora

- Midon Design: 1-Wire Application GuideDocumento44 pagineMidon Design: 1-Wire Application GuideFelipe UzabalNessuna valutazione finora

- Ir2530 2525 2520-smDocumento336 pagineIr2530 2525 2520-smRa'if SadikNessuna valutazione finora

- ER9 User ManualDocumento12 pagineER9 User ManualFelipe UzabalNessuna valutazione finora

- Midon Design: 1-Wire Application GuideDocumento44 pagineMidon Design: 1-Wire Application GuideFelipe UzabalNessuna valutazione finora

- Diseño de Instrumentos MeteorologicosDocumento170 pagineDiseño de Instrumentos MeteorologicosFelipe UzabalNessuna valutazione finora

- Calculos Aeromodelos 1Documento13 pagineCalculos Aeromodelos 1Felipe UzabalNessuna valutazione finora

- Calculos Aeromodelos 1Documento13 pagineCalculos Aeromodelos 1Felipe UzabalNessuna valutazione finora

- Manual Cumins OnanDocumento170 pagineManual Cumins OnanFelipe Uzabal100% (1)

- Ceta RamDocumento17 pagineCeta RamcowboyNessuna valutazione finora

- SchefflerDocumento5 pagineSchefflerFelipe UzabalNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- English2 Q2 Summative Assessment 4 2Documento4 pagineEnglish2 Q2 Summative Assessment 4 2ALNIE PANGANIBANNessuna valutazione finora

- 23001864Documento15 pagine23001864vinodsrawat33.asiNessuna valutazione finora

- BIO 201 Chapter 11 LectureDocumento34 pagineBIO 201 Chapter 11 LectureDrPearcyNessuna valutazione finora

- Kami Export - Subject Complements-1 PDFDocumento3 pagineKami Export - Subject Complements-1 PDFkcv kfdsaNessuna valutazione finora

- Maintenance Páginas-509-580Documento72 pagineMaintenance Páginas-509-580Alexandra Gabriela Pacheco PrietoNessuna valutazione finora

- Islam and Civilization (Analysis Study On The History of Civilization in Islam) Muhammad Hifdil IslamDocumento18 pagineIslam and Civilization (Analysis Study On The History of Civilization in Islam) Muhammad Hifdil IslamLoveth KonniaNessuna valutazione finora

- 2nd APJ Abdul Kalam Essay Writing CompetitionDocumento2 pagine2nd APJ Abdul Kalam Essay Writing CompetitionANURAG SINGHNessuna valutazione finora

- Javanese PeopleDocumento22 pagineJavanese PeopleDenisaNessuna valutazione finora

- Clinical Reviews: The Management of Children With Gastroenteritis and Dehydration in The Emergency DepartmentDocumento13 pagineClinical Reviews: The Management of Children With Gastroenteritis and Dehydration in The Emergency DepartmentRina Dewi AnggraeniNessuna valutazione finora

- DIVAR IP All-In-One 7000 3U Datasheet 51 en 66297110155Documento5 pagineDIVAR IP All-In-One 7000 3U Datasheet 51 en 66297110155Javier RochaNessuna valutazione finora

- ETR Series: A Full Spectrum of Products To Solve Your Application NeedsDocumento106 pagineETR Series: A Full Spectrum of Products To Solve Your Application Needs周小安Nessuna valutazione finora

- Management of DredgedExcavated SedimentDocumento17 pagineManagement of DredgedExcavated SedimentMan Ho LamNessuna valutazione finora

- Las Tech Drafting 3Q WKDocumento13 pagineLas Tech Drafting 3Q WKClemenda TuscanoNessuna valutazione finora

- Skincare Routine Order Cheat SheetDocumento10 pagineSkincare Routine Order Cheat SheetYel Salenga100% (3)

- Iec60227-3 (Ed2.1) en DDocumento6 pagineIec60227-3 (Ed2.1) en Duntuk donlod aaaNessuna valutazione finora

- Gondola CalculationDocumento6 pagineGondola CalculationBudi SusantoNessuna valutazione finora

- TM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 1Documento294 pagineTM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 1AdvocateNessuna valutazione finora

- Pellicon 2 Validation Guide PDFDocumento45 paginePellicon 2 Validation Guide PDFtakwahs12135Nessuna valutazione finora

- The Indian & The SnakeDocumento3 pagineThe Indian & The SnakeashvinNessuna valutazione finora

- Coffee Quality Manual by Abra Rand Nig Use IDocumento25 pagineCoffee Quality Manual by Abra Rand Nig Use IIpungNessuna valutazione finora

- RepaHeel Beeswax-Based Gel For Treating Heel Spurs Has Been Produced in EUDocumento2 pagineRepaHeel Beeswax-Based Gel For Treating Heel Spurs Has Been Produced in EUPR.comNessuna valutazione finora

- The 10 Most Famousfilipino Artists and Their MasterworksDocumento3 pagineThe 10 Most Famousfilipino Artists and Their MasterworksGina MagtibayNessuna valutazione finora

- Adriano Costa Sampaio: Electrical EngineerDocumento3 pagineAdriano Costa Sampaio: Electrical EngineeradrianorexNessuna valutazione finora

- Danika Cristoal 18aDocumento4 pagineDanika Cristoal 18aapi-462148990Nessuna valutazione finora

- 15 Benefits of CyclingDocumento8 pagine15 Benefits of CyclingJoycs PintoNessuna valutazione finora

- 1.1.3.12 Lab - Diagram A Real-World ProcessDocumento3 pagine1.1.3.12 Lab - Diagram A Real-World ProcessHalima AqraaNessuna valutazione finora

- Asaali - Project Estimation - Ce155p-2 - A73Documento7 pagineAsaali - Project Estimation - Ce155p-2 - A73Kandhalvi AsaaliNessuna valutazione finora

- 3M Novec 1230 Fire Protection Fluid FAQDocumento8 pagine3M Novec 1230 Fire Protection Fluid FAQEden CansonNessuna valutazione finora

- Bravo MRI II Operation ManualDocumento45 pagineBravo MRI II Operation ManualLuis100% (1)

- Concrete Super Structure ReportDocumento43 pagineConcrete Super Structure ReportLivian TeddyNessuna valutazione finora