Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

REMU XO CrossoverBucket

Caricato da

Scott GuimondCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

REMU XO CrossoverBucket

Caricato da

Scott GuimondCopyright:

Formati disponibili

Screening Technology & Amphibious Excavators

English

S creener - C rusher M odule

www.remu.fi

S creener C rusher

EN

module

It takes only ten minutes to connect your Crossover frame with the Screener - Crusher module. The ScreenerCrusher module is excellent choice when you need to grind lumpy material for example chemicals or just

topsoil that contains grass lumps. The Screener crusher module has crushing blades that effectively push

materials through the element and makes it finer. It can crush wooden sticks and roof tiles, but it is not

for crushing concrete or stones.

A pplications

Screener - Crusher module is widely used for:

Grinding

organic material like grass lumps

and roots for compost

mixing and aerating compost to accelerate

process

Grinding

various packed materials to be loose

again

Crushing

roof tiles

Compact

direct drive system based on high torque

radial piston motor

400

Smaller

20B

400cc,

that can take up to

Blade

thickness

Blade Type

Available blade Spacing

bar pressure.

drain oil flow for better efficiency

10

20

30

40

50

16

24

34

44

64

2304

power transmission chain

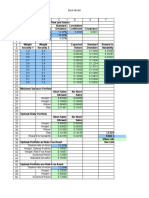

T echnical D ata

The Screener Crusher module comes on two different sizes depending on the XO frame bucket.

Metric units

tons

l/min

bar

Weight1

2

Including cleaning comb frames and combs

28 kg.

Height (D)

Depth (C)

Rotor width

(B)

Dimensions

Width (A)

Loader

Model

Max Hydraulic

Pressure

MinMax

Recommended Recommended

Carrier Size Hydraulic flow

cm

1

Modules weight differ from each others

depending on the blades type used. This

table indicate weight of modules with a blade

model 2304, with 30 mm spacing and 10 mm

thickness.

3

Including cleaning comb frames and combs

40 kg.

Kg

Total

weight with

SC2090

1,5

30-80

400

120

90

40

80

290 2

510 Kg

SC2150

40-80

400

180

150

40

80

415 3

730 Kg

XO Frame

Crossover Buckets

* Other rotor types available, please contact our sales person or your

nearest REMU dealer.

Excavator

REMU has a policy of continuing improvement, and reserves the right to change Materials and specifications without prior notice.

S pecifications

04/15

Screening Technology & Amphibious Excavators

Screening Technology & Amphibious Excavators

English

B lade S creen M odule

www.remu.fi

B lade S creen

EN

module

Just in ten minutes you can connect your Crossover frame with the Blade Screen module. The

Blade Screen module is an excellent choice when you need to screen top soil or use the bucket

as a padding tool. Function of the Blade Screen is based on rotating blades which can effectively

process even the moist top soil. Blade screen modules are available with several blade spacings to

produce the grain size you need.

A reas

of

A pplication

Blade Screen is widely used for:

Screening

Padding

Mixing

top soil

pipelines and cable excavations

soil, sand and fertilizers to get the

best mix for each use

Landscaping

Screening

stabilization

S pecifications

Compact

radial piston motor

Smaller

20B

400cc,

that can take up to

bar pressure.

400

Blade

thickness

Blade Type

direct drive system based on high torque

Available blade Spacing

10

20

30

40

50

16

24

34

44

64

10

20

30

40

50

16

24

34

44

64

2001

drain oil flow for better efficiency

power transmission chain

T echnical D ata

* Other rotor types available, please contact our sales person or your

nearest REMU dealer.

The Blade Screen module comes on two different sizes depending on the XO frame bucket.

Metric units

tons

l/min

bar

Weight1

2

Including cleaning comb frames and combs

28 kg.

Height (D)

Depth (C)

Rotor width

(B)

Dimensions

Width (A)

Loader

Model

Max Hydraulic

Pressure

MinMax

Recommended Recommended

Carrier Size Hydraulic flow

cm

2

Modules weight differ from each others

depending on the blades type used. This

table indicate weight of modules with a blade

model 2004, with 30 mm spacing and 10 mm

thickness.

3

Including cleaning comb frames and combs

40 kg.

Kg

Total

weight with

SB2090

1,5

30-80

400

120

90

40

80

265 2

480 Kg

SB2150

40-80

400

180

150

40

80

375 3

690 Kg

XO Frame

Crossover Buckets

2004

Excavator

REMU has a policy of continuing improvement, and reserves the right to change Materials and specifications without prior notice.

Soil

peat

04/15

Screening Technology & Amphibious Excavators

Screening Technology & Amphibious Excavators

English

V ibrating S creening M odule

www.remu.fi

V ibrating S creening

EN

module

It takes only ten minutes to connect your Crossover frame with the Vibrating Screening module. Function

of the Vibrating screening module is based on a vibrating movement in conjunction with a screening mesh.

Buy your vibrating module with multiple screening meshes to get several grain sizes with one screening

element. The Vibrating screening technique performs best when processed material is quite dry!

A pplications

Vibrating Screening module has many applications:

Separate

the sand out of the paving stones for

reuse

Screen

Shake

the sand or other loose and dry materials

the trashes and dirt out of recyclable

material

25

mm

50

mm

75

mm

T echnical D ata

The Vibrating Screening module comes on two different sizes depending on the XO frame bucket.

1

Modules weight differ from each others

depending on the screening mesh used.

Metric units

Max Hydraulic

Pressure

l/min

bar

Depth (C)

MinMax

Loader

tons

Width (A)

Model

Weight1

Height (D)

Dimensions

Meshs width (B)

Recommended Recommended

Carrier Size Hydraulic flow

cm

Kg

Total

weight with

SV2090

1,5

20-40

200

120

90

40

80

165

380 Kg

SV2150

20-40

200

180

150

40

80

190

510 Kg

XO Frame

Crossover Buckets

Depending on the application the required

end product size can be selected from the

standard mesh sizes available:

Excavator

REMU has a policy of continuing improvement, and reserves the right to change Materials and specifications without prior notice.

S pecifications

04/15

Screening Technology & Amphibious Excavators

Potrebbero piacerti anche

- REMU ScreeningBucketDocumento12 pagineREMU ScreeningBucketScott GuimondNessuna valutazione finora

- Allu D Screen CrusherDocumento8 pagineAllu D Screen Crusherrahman_1904Nessuna valutazione finora

- Crusher BucketDocumento2 pagineCrusher BucketMount MachineryNessuna valutazione finora

- 175E ManualDocumento19 pagine175E ManualRaimondas SaulNessuna valutazione finora

- Ozito Chainsaw PCS 305 Manual ED5 OnlineDocumento10 pagineOzito Chainsaw PCS 305 Manual ED5 Onlineuberwolfe0% (1)

- AHR6000LEDocumento38 pagineAHR6000LEthe707Nessuna valutazione finora

- CWS Forestry Power GrappleDocumento2 pagineCWS Forestry Power GrappleCWS Industries0% (1)

- Ajuste de 9A StrokerDocumento2 pagineAjuste de 9A Strokergonzalo hernandez aguilarNessuna valutazione finora

- Cut82hr Manual Parts (Cr9b-) 130712siDocumento43 pagineCut82hr Manual Parts (Cr9b-) 130712si2222222222222-242735Nessuna valutazione finora

- Bretec c2 OperationDocumento88 pagineBretec c2 OperationSerkanAlNessuna valutazione finora

- Osa SH25Documento58 pagineOsa SH25EvowithducadosNessuna valutazione finora

- Failure Code Display Algorithm For ECMVDocumento4 pagineFailure Code Display Algorithm For ECMValcowo100% (1)

- C1.5 Sebu8136-02 MDocumento37 pagineC1.5 Sebu8136-02 MMd ShNessuna valutazione finora

- Engine 125 2Documento392 pagineEngine 125 2Augusto OliveiraNessuna valutazione finora

- M1Documento6 pagineM1TamiCifuentesDiazNessuna valutazione finora

- Auger Operator Manual - English Revision 3Documento27 pagineAuger Operator Manual - English Revision 3Павел Хромов100% (1)

- Technical Data: Stabilizers/ Recyclers RS 460, RS 500Documento4 pagineTechnical Data: Stabilizers/ Recyclers RS 460, RS 500Sultan BudyNessuna valutazione finora

- CRS Manual (Operation)Documento23 pagineCRS Manual (Operation)Serhidra SASNessuna valutazione finora

- Rating Dozer BladesDocumento4 pagineRating Dozer BladesAdriana GrajedaNessuna valutazione finora

- MRP BearingsDocumento12 pagineMRP BearingssunilNessuna valutazione finora

- Engine PDFDocumento0 pagineEngine PDFpie031Nessuna valutazione finora

- Radiator Core Cleaning For D375A-6 (R5)Documento2 pagineRadiator Core Cleaning For D375A-6 (R5)alcowo100% (2)

- Log Grapple 90P ManualDocumento11 pagineLog Grapple 90P ManualsengoNessuna valutazione finora

- KOMAC Crusher MANUALDocumento41 pagineKOMAC Crusher MANUALhenry vegaNessuna valutazione finora

- RX 11 Chi̇cago BreakerDocumento20 pagineRX 11 Chi̇cago BreakerSerkanAlNessuna valutazione finora

- THK Automotive Pte LTD Dump MechanismDocumento2 pagineTHK Automotive Pte LTD Dump MechanismHugo RodriguezNessuna valutazione finora

- Performance Data: Soil Stabilizer / Asphalt Recycler MPH 125Documento2 paginePerformance Data: Soil Stabilizer / Asphalt Recycler MPH 125HandokoNessuna valutazione finora

- BTI Manual PDFDocumento95 pagineBTI Manual PDFErick Gonzales100% (1)

- Manual Xcentric CrusherDocumento68 pagineManual Xcentric CrusherChristopher LoAr100% (2)

- Mode Selection For D375A-6Documento2 pagineMode Selection For D375A-6alcowo100% (3)

- 10Pm ClinicDocumento31 pagine10Pm ClinicAnonymous ByaV1f100% (1)

- Full Line Guide Digital Only 17-05Documento47 pagineFull Line Guide Digital Only 17-05RIZA BAKIRNessuna valutazione finora

- Grapples: Safety, Operation & Maintenance ManualDocumento38 pagineGrapples: Safety, Operation & Maintenance ManualDATA LEGAL JKTINessuna valutazione finora

- 2015.04.10, Manual of Hydraulic SystemDocumento83 pagine2015.04.10, Manual of Hydraulic SystemVikram SinghNessuna valutazione finora

- Inspeccion Visual Ta1 Tractor d6r II (B)Documento7 pagineInspeccion Visual Ta1 Tractor d6r II (B)RAMON CALDERONNessuna valutazione finora

- MPH454 4pgDocumento4 pagineMPH454 4pgwalk002Nessuna valutazione finora

- Renr3726renr3726e96882 PDFDocumento1 paginaRenr3726renr3726e96882 PDFFrancisco Alvarado Huenquiao100% (1)

- Introduction of Bulldozers D85EX/PX-18Documento11 pagineIntroduction of Bulldozers D85EX/PX-18Andri WahyudiNessuna valutazione finora

- CRS Rock Splitter PDFDocumento2 pagineCRS Rock Splitter PDFHans Hans SadzNessuna valutazione finora

- Wr430gb00b BMP Cat Discl EngDocumento12 pagineWr430gb00b BMP Cat Discl EngJoseph BernardNessuna valutazione finora

- SM 140-2 PDFDocumento364 pagineSM 140-2 PDFCristian Ayte Lopez100% (2)

- Hydraulic BreakerDocumento6 pagineHydraulic Breakeraltacxa100% (1)

- Chainsaw ManualDocumento17 pagineChainsaw ManualflorinNessuna valutazione finora

- Visiting Report PT Musika Purbantara Utama 21 Januari 2020Documento14 pagineVisiting Report PT Musika Purbantara Utama 21 Januari 2020Daniel Garnando KristianNessuna valutazione finora

- Hazemag Hrs HVW en DD LowDocumento4 pagineHazemag Hrs HVW en DD Lowjose gomezNessuna valutazione finora

- H CM Attachment Catalogue 210623Documento18 pagineH CM Attachment Catalogue 210623hamdi galipNessuna valutazione finora

- araña3CR285DME Eng MANUAL-DE-OPERACIONDocumento20 paginearaña3CR285DME Eng MANUAL-DE-OPERACIONtincho_0026Nessuna valutazione finora

- Stage IV Emission StandardsDocumento18 pagineStage IV Emission StandardsGuptaNessuna valutazione finora

- Workshop ManualDocumento35 pagineWorkshop ManualConstantine P. ZigouritsasNessuna valutazione finora

- ZX138MF 5G Southeast Asia Lo 100619Documento5 pagineZX138MF 5G Southeast Asia Lo 100619Aldi NasohaNessuna valutazione finora

- Ex400-5, Ex400lc-5, Ex450lc-5 WMDocumento598 pagineEx400-5, Ex400lc-5, Ex450lc-5 WMAnonymous vxpVVAcjJ8Nessuna valutazione finora

- D50KSDocumento14 pagineD50KSglobalindosparepartsNessuna valutazione finora

- Catalogue Techmaflex UK USDocumento23 pagineCatalogue Techmaflex UK USAgustinus WaluyoNessuna valutazione finora

- SakaiDocumento2 pagineSakaiariNessuna valutazione finora

- Hitachi ZX330 Hydraulic ExcavatorDocumento2 pagineHitachi ZX330 Hydraulic ExcavatorFirstianto MnNessuna valutazione finora

- Operation & Parts Manual Document No: 0062-D-84 REV 0Documento31 pagineOperation & Parts Manual Document No: 0062-D-84 REV 0Simon manoenNessuna valutazione finora

- LC Meter Technical InformationDocumento22 pagineLC Meter Technical Informationzelda1022Nessuna valutazione finora

- Sales Manual - Comparison With 3a - Ps-En240Documento128 pagineSales Manual - Comparison With 3a - Ps-En240Halil Kara100% (1)

- Linearschwingsieb enDocumento12 pagineLinearschwingsieb enBrunoNessuna valutazione finora

- Screening Machines and Process Equipment 01Documento16 pagineScreening Machines and Process Equipment 01tafakorNessuna valutazione finora

- XTL7 20160429DDocumento2 pagineXTL7 20160429DScott GuimondNessuna valutazione finora

- XST 20160429DDocumento1 paginaXST 20160429DScott GuimondNessuna valutazione finora

- Xtu 20160429DDocumento1 paginaXtu 20160429DScott GuimondNessuna valutazione finora

- Telescopic Stick Extension: Features & BenefitsDocumento1 paginaTelescopic Stick Extension: Features & BenefitsScott GuimondNessuna valutazione finora

- XBX1 Loader Box Plow: Features and SpecsDocumento1 paginaXBX1 Loader Box Plow: Features and SpecsScott GuimondNessuna valutazione finora

- Mechanical Quick Attach Unit: Features & BenefitsDocumento1 paginaMechanical Quick Attach Unit: Features & BenefitsScott GuimondNessuna valutazione finora

- XPL1 Parallel-Link Stick Extension: Features and SpecsDocumento1 paginaXPL1 Parallel-Link Stick Extension: Features and SpecsScott GuimondNessuna valutazione finora

- GP (General Purpose) Buckets: Features and SpecsDocumento1 paginaGP (General Purpose) Buckets: Features and SpecsScott GuimondNessuna valutazione finora

- SHX Stump HarvesterDocumento2 pagineSHX Stump HarvesterScott GuimondNessuna valutazione finora

- HD (Heavy Duty) Buckets: Features and SpecsDocumento1 paginaHD (Heavy Duty) Buckets: Features and SpecsScott GuimondNessuna valutazione finora

- Engine Block Crusher (EBC) : Features & BenefitsDocumento1 paginaEngine Block Crusher (EBC) : Features & BenefitsScott GuimondNessuna valutazione finora

- EXT Engine Puller: Features & BenefitsDocumento1 paginaEXT Engine Puller: Features & BenefitsScott GuimondNessuna valutazione finora

- T-Rex Pulverizer: Features and BenefitsDocumento2 pagineT-Rex Pulverizer: Features and BenefitsScott GuimondNessuna valutazione finora

- Standard ExtensionDocumento1 paginaStandard ExtensionScott GuimondNessuna valutazione finora

- CP PlateCompactorsDocumento2 pagineCP PlateCompactorsScott GuimondNessuna valutazione finora

- XTU Tilt Unit: Put Our Expertise To Work For You!Documento1 paginaXTU Tilt Unit: Put Our Expertise To Work For You!Scott GuimondNessuna valutazione finora

- Torrent EX54Documento3 pagineTorrent EX54Scott GuimondNessuna valutazione finora

- Telescopic ExtensionDocumento1 paginaTelescopic ExtensionScott GuimondNessuna valutazione finora

- Loader Box PloWDocumento1 paginaLoader Box PloWScott GuimondNessuna valutazione finora

- SHX Stump HarvesterDocumento2 pagineSHX Stump HarvesterScott GuimondNessuna valutazione finora

- Uttarakhand District Factbook: Almora DistrictDocumento33 pagineUttarakhand District Factbook: Almora DistrictDatanet IndiaNessuna valutazione finora

- Tri-Partite Agreement AssociationDocumento9 pagineTri-Partite Agreement AssociationThiyagarjanNessuna valutazione finora

- Me N Mine Science X Ist TermDocumento101 pagineMe N Mine Science X Ist Termneelanshujain68% (19)

- Cleaning of Contact Points and Wiring HarnessesDocumento3 pagineCleaning of Contact Points and Wiring HarnessesRafa Montes MOralesNessuna valutazione finora

- Library PDFDocumento74 pagineLibrary PDFfumiNessuna valutazione finora

- Menu Siklus RSDocumento3 pagineMenu Siklus RSChika VionitaNessuna valutazione finora

- Desigo PX SeriesDocumento10 pagineDesigo PX SeriestemamNessuna valutazione finora

- Acuson P10Documento2 pagineAcuson P10anon-259218Nessuna valutazione finora

- List of Government Circuit Bungalow Nuwara EliyaDocumento4 pagineList of Government Circuit Bungalow Nuwara EliyaAsitha Kulasekera78% (9)

- Pressure Vessels SHO ProgrammeDocumento42 paginePressure Vessels SHO Programmehew ka yeeNessuna valutazione finora

- 10 Chapter 3 Occupancy Classification AnDocumento10 pagine10 Chapter 3 Occupancy Classification AnMatt BaronNessuna valutazione finora

- Kingdom of AnimaliaDocumento6 pagineKingdom of AnimaliaBen ZerepNessuna valutazione finora

- BKM 10e Ch07 Two Security ModelDocumento2 pagineBKM 10e Ch07 Two Security ModelJoe IammarinoNessuna valutazione finora

- EscheatmentDocumento58 pagineEscheatmentlaarigao100% (2)

- Thorley Amended Complaint (Signed)Documento13 pagineThorley Amended Complaint (Signed)Heather ClemenceauNessuna valutazione finora

- DR Hoon Park III - Indigenous Microorganism (IMO)Documento33 pagineDR Hoon Park III - Indigenous Microorganism (IMO)neofrieda79100% (1)

- Doingwell Coaching ServicesDocumento4 pagineDoingwell Coaching ServicesPaweł PawełNessuna valutazione finora

- ECC83/12AX7: Quick Reference DataDocumento4 pagineECC83/12AX7: Quick Reference DataLuisNessuna valutazione finora

- Building and Environment: Nabeel Ahmed Khan, Bishwajit BhattacharjeeDocumento19 pagineBuilding and Environment: Nabeel Ahmed Khan, Bishwajit Bhattacharjeemercyella prasetyaNessuna valutazione finora

- English PoemDocumento4 pagineEnglish Poemapi-276985258Nessuna valutazione finora

- Gay Costa Del Sol - 2010Documento2 pagineGay Costa Del Sol - 2010gayinfospainNessuna valutazione finora

- Article 1, The Role of Science and TechnologyDocumento3 pagineArticle 1, The Role of Science and TechnologyNSBMRNessuna valutazione finora

- RMP ContractDocumento181 pagineRMP ContractHillary AmistosoNessuna valutazione finora

- Coarse DispersionsDocumento35 pagineCoarse Dispersionsraju narayana padala0% (1)

- CARBOWAX™ Polyethylene Glycol (PEG) 1000Documento2 pagineCARBOWAX™ Polyethylene Glycol (PEG) 1000Anonymous vJPniV7Nessuna valutazione finora

- User Manual: 3603807 CONTACT US - 09501447202,8070690001Documento1 paginaUser Manual: 3603807 CONTACT US - 09501447202,8070690001Arokiaraj RajNessuna valutazione finora

- Energy Optimization of A Large Central Plant Chilled Water SystemDocumento24 pagineEnergy Optimization of A Large Central Plant Chilled Water Systemmuoi2002Nessuna valutazione finora

- TM - 1 1520 237 10 - CHG 10Documento841 pagineTM - 1 1520 237 10 - CHG 10johnharmuNessuna valutazione finora

- INTP Parents - 16personalitiesDocumento4 pagineINTP Parents - 16personalitiescelinelbNessuna valutazione finora

- Full Test Bank For Health Economics and Policy 7Th Edition Henderson PDF Docx Full Chapter ChapterDocumento34 pagineFull Test Bank For Health Economics and Policy 7Th Edition Henderson PDF Docx Full Chapter Chapterpeeepochaq15d100% (9)