Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Zeppelin Systems Technology Center For The Plastic Industry PDF

Caricato da

RamakrisnanMeenakshiSundaramRamaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Zeppelin Systems Technology Center For The Plastic Industry PDF

Caricato da

RamakrisnanMeenakshiSundaramRamaCopyright:

Formati disponibili

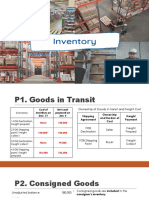

ENSURING TECHNOLOGY LEADERSHIP

Research and development at Zeppelin

The Technology Center in Friedrichshafen

www.zeppelin.com

ENGINEERING YOUR SUCCESS

Zeppelin Systems, the world leading plant manufacturer for high quality bulk

material handling, has remarkably grown over the past 60 years. We cover

the demands of a wide range of industries and supply all plant manufacturing

services from one single source, whether basic engineering, in-house production of components, final assembly or comprehensive after sales service.

Thanks to our financial strength and our global network we have long been

a reliable partner for our customers.

Every Zeppelin plant is developed according to the clients specific

requirements and realized thanks to our customized innovative

processes and technologies.

The knowledge we have acquired over more than 60 years of plant

manufacturing and the worlds largest network for bulk material

handling are the key to providing ideal solutions whatever the

challenge. After all, your success is our goal.

Zeppelin plant engineering

business fields

Polymer Plants

Plants for plastics producers and forwarders

Plastics Processing & Rubber Plants

Plants for the plastics processing and rubber industry

Reimelt Food Technology

Plants for the food, confectionery and bakery industry

Henschel Mixing Technology

Mixers, extruders and compounders

Liquids Processing

Plants for the beverages industry

Silos & Filters

Silo technology and filters

Components

Diverter valves, rotary feeders, separators

After Sales Service

Assembly, maintenance and spare parts

Quality Service

Services in quality management

A COMPETITIVE EDGE REQUIRES HARD WORK

Technological leadership is based on extensive research and development. Our activities

in the worlds largest network for bulk material handling ensure your success.

l

Rubber Techno

log

and

s

y,

al

F

ic

Zeppelins network of technology centers

rie

sha

fe n

uuu

ich

dr

Research and

development

nn Trials on an industrial scale

nn Verification of plant design

nn Development of new products and processes

nn Bulk material analysis

m e l t F d Te c h n

oo

t

tt

Rei

de

rm

ark

se

l Mixing Techno

log

che

s

n

y,

e

K

H

lastics,

P

t

C

he

t

m

t

as

ol o

,

gy

Friedrichshafen, Germany

Plastics, chemical, rubber and

carbon black industry

Rdermark, Germany

Food industry

Kassel, Germany

Mixing and compounding

So Paulo

Plastics, mineral and

cement industry

Premium bulk material whether plastic pellets, powders or bulk material

for the food industry are in safe hands

with Zeppelin.

In addition to outstanding staff, you will find the worlds largest

Technology Center for handling bulk material for the plastics,

chemicals and rubber industry at our location in Friedrichshafen,

Germany. Together with our test facilities in Rdermark and

Kassel, we cover the needs of the food industry as well as the

mixing and compounding sectors. Were ready to take on nearly

any challenge.

The core of our Friedrichshafen Technology Center are the two

test plants specially designed for processing pellets, powders and

additives.

Conveying of pellets by a rotary

feeder installed below a blending silo.

Discharge of powder

from a pressure vessel.

Scope of supply

WE FACILITATE YOUR CHOICE

Customer inquiry

Our work, your advantages:

Ensure

Reliability

Process optimization

Energy efficiency

Cost efficiency

The Zeppelin Technology Center in Friedrichshafen is

equipped with all the necessary process technology

components and systems. Our customers expect us

to analyze their products in detail as only those who

know their bulk material well can design plants

which are characterized by reliability, optimized processes, energy efficiency and cost efficient solutions.

We conduct full scale tests to avoid the uncertainties

of scale-up calculations. Special configurations can

be quickly installed. Our experts provide you with a

precise performance analysis as a solid basis for your

investment decision.

Our services

Conveying technology

nn Dense phase and dilute phase conveying of pellets and powders

- Nominal width: DN 65 225

- Conveying distance: 10 460 m

- Throughput: up to 200 t/h

nn Hydraulic conveying of pellets

nn Dense phase conveying of sensitive bulk material (bypass system)

nn Combined vacuum and pressure conveying of pellets and powders

nn Rotary feeders available in various sizes and types

(high pressure, medium pressure and blow-through types)

nn Pressure vessels

nn Feeding systems: Pump-Flow or Screw-Flow

Storage, discharge, blending and dosing technology

nn

nn

nn

nn

nn

Numerous modern test facilities guarantee

optimum results. Data is continuously recorded

by state-of-the-art measuring technology. We determine the relevant design parameters and issue

detailed test reports as basis for designing your

plant. We advise you in detail on all possibilities.

New developments and advanced technologies are

tested intensively.

Storage silos and vessels with various discharge systems

Different blender types for powders and pellets

Small component weighing unit for additives

Heating and cooling of bulk material

Degassing of bulk material

Sorting, separating, cleaning

nn

nn

nn

nn

Various separators for cleaning of pellets

Drum screeners or streamer separators

Pig system for pipe cleaning

Various filter systems and cyclones

Zeppelin customers have direct access to our Technology Centers to ensure the technological leadership

essential for their operational success wherever the

location of the plant.

Conveying technology

AS VERSATILE AS YOUR REQUIREMENTS

Conveying lines made from aluminium, stainless steel, PE-plastic and

rubber, with or without injection of secondary air are available for the

test runs. Secondary air is injected at interval points or slots with the

help of special bypass systems.

Dense phase conveying

0.3

one

Dilute phase conveying

Design of pneumatic conveying systems is based on the corresponding

phase diagram.

8

0.1

0.05

e y in g

se conv

ms = 50 t/h

ms = 30 t/h

ms = 10 t/h

ms = 0 t/h

min . v elo ci t y f o r d e n s e p h a

Differential pressure [MPag]

0.2

0.15

Ins

t ab

le z

0.25

0

0

10

20

Final gas velocity [m/s]

30

40

50

Twin-Tec systems (bypass)

in our Technology Center

Intraflow: internal bypass system in aluminium

or stainless steel pipes for conveying mineral bulk

material, PTA/CTA, etc.

Overflow: combined with PE or stainless steel pipes;

air injected at points every 0.5 to 1.0 m distance. For

sensitive powdery products such as carbon black, etc.

Airfloat: combined with stainless steel pipes; air

injection through slots to avoid dead spots in the

conveying of critical products such as silica.

9

Blending and homogenization silos

STATE-OF-THE-ART EQUIPMENT

IS A MUST

Zeppelin offers a large range of blending and homogenization

silos: available as new blender or for retrofitting existing silos.

Selection of the appropriate blender type always depends on the

product properties and the required blending quality.

We use different blender types for testing blending processes.

Our blenders are suitable for bulk material with good and poor

flowability e.g. powders, pellets, recycled products, dryblends and

compounds.

Multi-Pipe

Free-flowing products

Free-flowing pellets

()

Bulk material with poor flowability

Blender capacity [m]

10

2.5 / 30

Multi-Channel

Multi-Flow

Centro-Blend

Fluidized Bed Blender

()

4.5 / 30

4.5 / 30

2.5

suitable

4.5

() of limited suitability

not economic

11

11

11

Laboratories

KNOWLEDGE IS THE BASIS FOR SUCCESS

Zeppelin has been dealing with bulk material for many years. The

knowledge of bulk material properties and the experience we

have gained since our foundation is stored in our central database: one of the worlds largest bulk material libraries. Regular

maintenance and continuous growth of our database is ensured as

our customers regularly develop new products with yet unknown

properties.

Shear tests provide the basis for the optimum design of storage

and blending silos.

Zeppelin verifies the residual fines content using acknowledged

measuring methods and evaluates the effect of different conveying

methods.

12

The services of our laboratories

nn Shear tests with translational and ring shear testers

nn Determination of the bulk density

nn Measurement of time consolidation

nn Particle size analysis (by screening or with Camsizer)

nn Residual fines content by washing

nn Fluidization tests

nn Humidity measurement

nn Oedometer

Shear tests require much experience in the han

dling of bulk material having very different properties. Wall friction, internal friction and time

consolidation are important characteristics for

the reliable design of storage and blending silos.

Trials with different temperatures and humidity

levels are carried out in our climatic test chamber.

Classic screening processes and state-of-the-art

measuring equipment are available to quantify the

grain size distribution.

In order to determine the residual dust content of

pellets, the electrostatic forces bet ween the dust

particles and the pellets must be reduced. The

washing out method (e.g. FEM, ASTM) together

with the classification of the fines have proven

reliable.

Determination of humidity by titration.

13

MIXING AND COMPOUNDING

WITH ZEPPELIN

Automation

u

Cl

ni

ea

Do

si

uu

ng

Sto

rin

ing

lend

db

an

your success

uu

g

in

g

hin

eig

W

M

ix

uuu

14

Engineering

uu

ying

ve

on

uu

uuu

Henschel Mixing Technology, a business field of

Zeppelin, is located in Kassel, Germany, where

mixing and compounding systems up to complete

plants are designed and manufactured. The key

technologies are developed and manufactured

there as well.

The Kassel Technology Center offers facilities to the plastics

processing and chemical industries for testing the most important

operations of mechanical process engineering, particularly the

mixing technology. Adaptating machinery and equipment to

production parameters does not always suffice to improve our

customers products. We develop completely new methods for

producing and processing sensitive raw materials in cooperation

with and for the benefit of our customers. Results can be verified

directly in our state-of-the-art laboratories.

Many innovations could not have been realized without our Technology Center: several processes which have become standard

for mixing and processing were developed here. Todays quality

processing of hard and soft PVC could hardly be reached without

the Kassel Technology Center.

Our continuous research provides our customers with a leading

edge in fields such as metallic powder coatings, master batches,

materials used for battery production or ceramic powders.

15

Presented by:

nn Australia

nn Belgium

nn Brazil

nn China

nn France

nn Germany

nn India

nn Italy

nn Korea

nn Russia

nn Saudi Arabia

nn Singapore

nn United Kingdom

nn USA

Zeppelin Systems GmbH

Graf-Zeppelin-Platz 1

88045 Friedrichshafen

Germany

Tel.: +49 7541 202-02

Fax: +49 7541 202-491

zentral.fn@zeppelin.com

www.zeppelin.com

Zeppelin Systems GmbH | Subject to change | Edition 09/13 | 031101320 | www.lake-of-consens.com

Global presence

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Mrunal Economy Handouts PCB8 2023-24Documento901 pagineMrunal Economy Handouts PCB8 2023-24Adharsh Surendhiran100% (3)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- T3-Sample Answers-Consideration PDFDocumento10 pagineT3-Sample Answers-Consideration PDF--bolabolaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Jupiter Intelligence Report On Miami-Dade Climate RiskDocumento11 pagineJupiter Intelligence Report On Miami-Dade Climate RiskMiami HeraldNessuna valutazione finora

- 227 - Unrebutted Facts Regarding The IRSDocumento5 pagine227 - Unrebutted Facts Regarding The IRSDavid E Robinson100% (1)

- Government Support Options: Laura Kiwelu Norton Rose FulbrightDocumento15 pagineGovernment Support Options: Laura Kiwelu Norton Rose FulbrightE BNessuna valutazione finora

- Fin 580 WK 2 Paper - Team CDocumento5 pagineFin 580 WK 2 Paper - Team Cchad salcidoNessuna valutazione finora

- Credit Risk ManagementDocumento4 pagineCredit Risk ManagementinspectorsufiNessuna valutazione finora

- Aavas FinanciersDocumento8 pagineAavas FinanciersSirish GopalanNessuna valutazione finora

- CFAP 6 AARS Winter 2017Documento3 pagineCFAP 6 AARS Winter 2017shakilNessuna valutazione finora

- LatAm Fintech Landscape - 2023Documento3 pagineLatAm Fintech Landscape - 2023Bruno Gonçalves MirandaNessuna valutazione finora

- CBSE Class 12 Economics Sample Paper (For 2014)Documento19 pagineCBSE Class 12 Economics Sample Paper (For 2014)cbsesamplepaperNessuna valutazione finora

- Analysis On The Proposed Property Tax AssessmentDocumento32 pagineAnalysis On The Proposed Property Tax AssessmentAB AgostoNessuna valutazione finora

- Chapter 6Documento17 pagineChapter 6MM M83% (6)

- Document ManagementDocumento55 pagineDocument Managementrtarak100% (1)

- Major Assignment #3Documento17 pagineMajor Assignment #3Elijah GeniesseNessuna valutazione finora

- BCOMQPOCT18Documento383 pagineBCOMQPOCT18SHRIKANT C. DUDHALNessuna valutazione finora

- SS 2 SlidesDocumento31 pagineSS 2 SlidesDart BaneNessuna valutazione finora

- Accounting and FinanceDocumento5 pagineAccounting and FinanceHtoo Wai Lin AungNessuna valutazione finora

- Financial AidDocumento1 paginaFinancial Aidshb100% (1)

- Sebi Grade A Exam: Paper 2 Questions With SolutionsDocumento34 pagineSebi Grade A Exam: Paper 2 Questions With SolutionsnitinNessuna valutazione finora

- Jacob Investigates Bretton FraudDocumento2 pagineJacob Investigates Bretton FraudMilcah De GuzmanNessuna valutazione finora

- Fabm2: Quarter 1 Module 1.2 New Normal ABM For Grade 12Documento19 pagineFabm2: Quarter 1 Module 1.2 New Normal ABM For Grade 12Janna Gunio0% (1)

- Role of Derivatives in Economic Growth and DevelopmentDocumento22 pagineRole of Derivatives in Economic Growth and DevelopmentKanika AnejaNessuna valutazione finora

- How To Apply For A Rental Property - Rent - Ray White AscotDocumento2 pagineHow To Apply For A Rental Property - Rent - Ray White AscotRRWERERRNessuna valutazione finora

- Taxmann - Budget Highlights 2022-2023Documento42 pagineTaxmann - Budget Highlights 2022-2023Jinang JainNessuna valutazione finora

- FRM 2015 Part 1 Practice ExamDocumento47 pagineFRM 2015 Part 1 Practice ExamVitor SalgadoNessuna valutazione finora

- Comparison of Equity Mutual FundsDocumento29 pagineComparison of Equity Mutual Fundsabhishekbehal5012Nessuna valutazione finora

- Hersey K Delynn PayStubDocumento1 paginaHersey K Delynn PayStubSharon JonesNessuna valutazione finora

- Duty Free v1Documento76 pagineDuty Free v1Vasu SrinivasNessuna valutazione finora

- Central Surety and Lnsurance Company, Inc. vs. UbayDocumento5 pagineCentral Surety and Lnsurance Company, Inc. vs. UbayMarianne RegaladoNessuna valutazione finora