Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

14 Lobatse Abattoir - 2

Caricato da

mcsfuvTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

14 Lobatse Abattoir - 2

Caricato da

mcsfuvCopyright:

Formati disponibili

IMPACT ASSESSMENT CASE STUDIES

FROM SOUTHERN AFRICA

David Parry, Ecosurv

Client:

Botswana Meat Commission

SAIEA

Southern African Institute for Environmental Assessment

... working for a better Africa

RETROSPECTIVE EIA OF THE LOBATSE ABATTOIR,

BOTSWANA

David Parry, Ecosurv

Client:

Botswana Meat Commission

RETROSPECTIVE EIA OF THE LOBATSE ABATTOIR, BOTSWANA

Aims of the Project

Brief description of the development

The Botswana Meat Commissions (BMC) abattoir

in Lobatse is the major livestock processing

facility in Botswana and has been operating since

1952. The abattoir was established before the

requirements for EIA and has expanded steadily

over time increasing its throughput and services.

The Botswana 2005 EIA Act had a specific section

requiring existing major industries and mines to

comply with the Act and undertake retrospective

EIAs. This approach has allowed the identification

of impacts from existing operations and

establishment of environmental management plans

to address the impacts identified.

The BMC abattoir is located in southern Botswana

in the town of Lobatse. The facility is designed

for a throughput of 170,000 cattle per annum, but

has in recent years operated below full capacity.

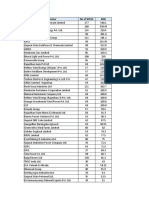

Figure 1: Layout of the Lobatse Abattoir (image from Google)

SAIEA 2009

David Parry, Ecosurv

Client:

Botswana Meat Commission

RETROSPECTIVE EIA OF THE LOBATSE ABATTOIR, BOTSWANA

Brief description of the development

During the period 1990-2006 the abattoir

slaughtered in the range of 80,000 to just over

120,000 cattle per annum.

The slaughtering process consists of the following

activities, which are carried out in different areas

of the abattoir:

Off-loading (receiving) and lairage (penning);

Stunning and sticking;

Hoof, head and hide removal and evisceration;

Red and rough offal sorting and removal;

Carcass halving and cold storage; and

By-products handling which includes skin

storage and rendering.

In general it takes between 3 and 3.9 m 3 of water

for each animal slaughtered. This leads to about

2 m 3 of waste water rich in blood, fats and solids

and 0.02 m 3 of paunch contents per slaughtered

animal being disposed of at the waste water

treatment works (WWTW).

SAIEA 2009

Figure 2: Layout of the existing abattoir waste water treatment works (image from Google)

David Parry, Ecosurv

Client:

Botswana Meat Commission

RETROSPECTIVE EIA OF THE LOBATSE ABATTOIR, BOTSWANA

Brief description

of the development

The BMC Abattoir Waste Water Treatment Works

was established in 1978, 26 years after the abattoir

started. It is not recorded how the abattoir effluent

was treated or disposed of prior to the construction

of the WWTW. Before a tannery was set up in

Lobatse, all hides produced by the abattoir were

salt-cured on site and sold to the South African

market.

Effluent is currently piped from the abattoir to

the WWTW where it is screened and then

discharged into a series of three anaerobic (AnO2)

ponds. It is pumped to bio-filters and then, via

clarifiers, flows to a holding pond. Final effluent

from this holding pond is pumped to the Lobatse

Town Council sewage works. The Meat

Commission owns the land on which the abattoir

and treatment works falls.

SAIEA 2009

Environmental setting

Biophysical environment

Lobatse is situated in the flat bottomed valley of

the ephemeral Peleng River and its tributaries.

Ten kilometres downstream from Lobatse the river

turns to the east and flows towards and eventually

into the Notwane River in South Africa, which is

one of the main feeder rivers for the Gaborone

Dam. The valley floor upon which most of the

town is situated is at about 1,200 m above sea

level with the surrounding hills rising to over

1400 m.

Socio-economic environment

Lobatse is one of the oldest towns in Botswana,

situated some 70 km south of Gaborone, close to

the border with South Africa. The agro-based

industries in Lobatse dominate the manufacturing

sector, with beef processing employing a

substantial number of the population in this town.

Other companies such as Lobatse Tiles, Lobatse

Clay works, sugar packaging industries, brewery

and milling contribute significantly to the

development of this town. The area occupied by

the town is approximately 40 km 2 and it is

surrounded by freehold farms.

The population of Lobatse is estimated to increase

to 31,000 by 2011 although the rate of growth

has declined from 6% (pre-1981) to 1.3% due to

emigration to other economic centres. The youth

(10-29 years old) account for almost half of the

towns population, putting considerable pressure

on the labour market.

The low-income areas of Peleng, Tsopeng and

Woodhall are not connected to the towns

sewerage system. As a result a quarter of the

households in the town use pit latrines. Where

services are available, the effluent waste is piped

to the council treatment works. Companies with

a heavy pollution load are required to

establishment a pre-treatment facility. BMC has

established such a pre-treatment plant to ensure

that the outflow meets the standards for effluent

disposal into sewerage systems. A trade effluent

agreement is in place.

Solid waste collection is the responsibility of the

Environmental Health Department of the Lobatse

Town Council (LTC). About 75% of the

households in Lobatse have a regular waste

collection service from the LTC. Most solid wastes

are disposed of at the council landfill.

David Parry, Ecosurv

Client:

Botswana Meat Commission

RETROSPECTIVE EIA OF THE LOBATSE ABATTOIR, BOTSWANA

Environmental setting

The Lobatse Town Council is responsible for the

management of the landfill and incinerator and

for the wastewater treatment works. The landfill

was established in 1994 and has an incinerator.

Due to the break down of equipment and the

incinerator, the landfill now appears to operate

as a dumpsite. The wastewater treatment works

uses the pond technology, and its outflow is used

for irrigation of lucerne (Figure 2 and 3).

Figure 3: Location of the key abattoir facilities within the Lobatse town environment

Nearly all of the urban population has full access

to piped or tapped potable water. The main sources

of water for households are private connections

SAIEA 2009

and to a lesser extent communal standpipes which

are being phased out.

David Parry, Ecosurv

Client:

Botswana Meat Commission

RETROSPECTIVE EIA OF THE LOBATSE ABATTOIR, BOTSWANA

Environmental setting

Meetings were convened with both members of

the public and selected government officers.

Notices for the meetings were placed in local

newspapers in both Setswana and English. The

initial public meeting was poorly attended and,

due to the importance of the EIA, the councillor

requested a further public meeting. The additional

public meeting allowed for far greater public

mobilisation.

Key concerns raised by the public were that

opportunities to re-use fly ash, cow dung and fats

were not being used, and that fly ash was being

disposed on in undesignated areas. Unexpectedly

there were no complaints of smell relating to the

rendering plant.

Unfortunately the public was unable to

differentiate between the abattoir operation and

the tannery operation. Public sentiment ran

strongly against the tannery (blamed for high

smell levels and pollution loads) whilst it was

positive towards the abattoir.

EIA process followed

Stakeholders all emphasised the importance of

the abattoir to the towns economy.The support

of the abattoir for local football was strongly

appreciated.

The BMC Lobatse abattoir, although fairly old,

has only relatively low to moderate environmental

and social impacts, this is largely due to the

facility meeting stringent EU standards.

Positive

BMC has 750 employees. Earnings by staff were

in the range of P40 to 70 million (including

retrenchment benefits) in the period 2005-2006.

During the period 2000-2006 BMC paid between

P100 to 200 million to livestock farmers

(producers) with an average of P124.6 million.

At the national level, beef is an important export

product for Botswana. In 2006, BMC exported

P328 million worth of beef and P35.8 million

worth of other cattle products. It is estimated that

around P200 million is associated with the Lobatse

abattoir and cannery (i.e. 55%).

BMC has also contributed significantly towards

sports development in Lobatse and at national

level.

Key persons had specific concerns such as

potential and past impacts on groundwater, lack

of past consultation and attention to complaints.

SAIEA 2009

David Parry, Ecosurv

Client:

Botswana Meat Commission

RETROSPECTIVE EIA OF THE LOBATSE ABATTOIR, BOTSWANA

EIA process followed

Negative

Emissions

Air emissions from the abattoir site are flue gases

from the boiler, rendering plant and incinerator,

and odours and water vapour from the cooling

plant. From the waste water treatment works there

are odorous gases from the effluent, as well as

carbon dioxide (CO 2 ) and methane (CH 4 ) from

anaerobic ponds.

Liquid Waste

Maintenance and upkeep of treatment units and

the property was neglected in the past, resulting

in clogging up of the works with screenings and

sludge. Pollution occurred in Peleng River due to

overflow and seepage of raw and partially treated

effluent from the screens, fuels, oil and grease

(FOG) and sludge pits. Pollution of groundwater

(Woodland Aquifers) has probably occurred in

the past due to operation of the water treatment

works. The lack of monitoring of effluent flows

and absence of groundwater monitoring points

between the ponds and the river makes it difficult

to pinpoint problems and identify solutions.

Chemicals at the abattoir are used for analysing

meat and meat products for quality assurance.

SAIEA 2009

Once used, they are poured into empty containers

and stored at ambient temperature. There is no

exclusive place for storage. Sometimes used

chemicals are neutralised and disposed down the

drains.

Solid waste

Most of the solid waste generated by the abattoir

is conveyed off-site by wastewater, with the

exception of fly ash from the boilers. Other types

of solid wastes include lairage (faecal matter) and

wastes produced during carcass processing and

offal handling. Solid waste from the abattoir is

transported to the LTC landfill site for disposal.

It was noticed during the EIA that there are no

licences for waste carriers that transport solid

waste. Solid waste at the WWTW is made up of

screenings, sludge and FOG scraped from the

anaerobic ponds. Sludge disposal from the primary

anaerobic ponds was observed to be disposed of

in pits adjacent to the primary ponds and the

Peleng River.

The environmental impacts of the WWTW relate

mainly to the lack of monitoring by the individual

operational sections of resource use and

discharges/waste production. Although the

WWTW is located in the middle of town, it is

surrounded by undeveloped land and riverine

habitats. As a result the social impacts/concerns

are low. Social concerns relate to ease of public

access and the potential health problems associated

with biological material disposal.

Past management of the works effluent, prior to

discharge to the LTC treatment works, probably

is the cause of the saline pollution of the

Woodlands Aquifer. The salinity probably came

from salt drying of hides prior to the tannery

establishing its own evaporation ponds.

Indications are that this aquifer is now slowly

recovering.

There was concern for the survival of a small

(subsistence) brick making industry which was

reliant on the availability of fly ash produced by

the abattoir boilers.

David Parry, Ecosurv

Client:

Botswana Meat Commission

RETROSPECTIVE EIA OF THE LOBATSE ABATTOIR, BOTSWANA

Environmental setting

Polluted wastewater is however still entering the

Peleng River through seepage coming from three

main sources:

(1) P u m p i n g o f w a s t e w a t e r a n d s l u d g e

and disposal of fats, oils and grease into

the sludge pits which are unlined pits in

the river alluvium.

(2) S p i l l a g e f r o m c l o g g e d c o m p o n e n t s o f

the treatment works such as the screen

and clarifiers.

(3) Surface wash and percolation of rainfall

through the screening waste material,

which then enters the Peleng River.

Since all local aquifers are now polluted, Lobatse

is now supplied water from the North-South Water

Carrier. Any further pollution into the Woodlands

Aquifer will limit recovery of this important

resource.

Figure 4: Computer-simulated view of Lobatse town showing important features of the abattoir

and waste management systems.

SAIEA 2009

David Parry, Ecosurv

Client:

Botswana Meat Commission

RETROSPECTIVE EIA OF THE LOBATSE ABATTOIR, BOTSWANA

Environmental setting

Decision-making process

Cumulative

During the EIA public review period, the Draft

EIA was placed on the website of the

environmental authority and hard copies were

available at the town council and BMC facilities.

One appeal was made by an affected party located

downsteam along the Peleng River and downslope

of the LTC waste water treatment facility which

houses the tannery evaporation ponds.

Pollution of the groundwater is a result of

cumulative impacts from town development, pit

latrines, tannery and abattoir operations. Similarly

high odour levels in Lobase are a combination of

the abattoir rendering plant, abattoir waste water

treatment works, tannery pre-treatment and

tannery ponds and the council water works, all of

which are either within the urban environment or

immediately upwind of the town.

The appeal, which was the result of a review of

the EIA findings, related to potential pollution

from the tannery evaporation ponds into the

aquifer used by the affected party. This concern

was shown to be unfounded as monitoring

boreholes surrounding the ponds indicated no

pollution of groundwater and the ponds were

checked for integrity of the liner. No further

appeals were registered.

Implementation of the EMP

& compliance auditing

The retrospective EIA was used to prepare a

detailed EMP. The plan has been steadily

implemented and the following carried out:

Within a short period the corporation hired an

Environmental Health and Safety officer, began

registration of facilities requiring emission or

discharge permits, and began upgrading the

management and facilities of the waste water

treatment works. Monitoring of these efforts will

be important to ensure that the momentum is

maintained.

The abattoir management accepted the findings

of the EIA and moved immediately to address the

concerns and EMP requirements.

SAIEA 2009

David Parry, Ecosurv

Client:

Botswana Meat Commission

RETROSPECTIVE EIA OF THE LOBATSE ABATTOIR, BOTSWANA

Main elements of excellence

in this EIA

The main elements that contributed to the success

of the EIA were:

Commitment of BMC to the EIA process

Structure of the EIA team, which included

social and stakeholder engagement specialists,

hydrogeology, hydrology and environmental

specialists, an environmental engineer and a

waste water specialist.

The preparation of an EMP to guide

implementation of the suggested mitigations

was crucial to successful implementation

of the findings.

Lessons learnt

The EIA clearly shows that there is an important

role for retrospective EIAs. Such assessments do

not have to be confrontational, rather they should

be a guide to getting a facility on track to

compliance, as in an audit. The difference in using

a retrospective EIA rather than an audit is the

opportunity to identify and investigate impacts

arising from failure to comply with legal

requirements. A second major advantage of

retrospective EIA is the legal requirement for

public consultation, which is critical to identifying

issues and impacts already experienced by the

public and key stakeholders.

As the situation changed and proportionally fewer

persons benefited from the abattoir, public

tolerance to negative impacts dropped. The public,

though, acknowledged the social contribution of

the abattoir to football development within

Lobatse, which indicates how effective corporate

social responsibility programmes are.

It was also found that the physical surroundings

of industrial sites change over time, and often

unsuitable or conflicting land use developments

are established. This emphasises the need for

industrial processes to adapt and comply to new

constraints.

A good understanding of the history of

development of the facility was critical to

understanding the impacts and the socio-political

climate of the interested and affected parties. How

the facility interacted with the public in the past,

how it addressed their concerns, and its social

SAIEA 2009

programmes, all greatly influenced how the pubic

were prepared to tolerate impacts. When the

abattoir was the main industry in Lobatse, public

tolerance was high and few public representatives

raised concerns.

www.saiea.com

Potrebbero piacerti anche

- Practical Design of Water Distribution Systems PDFDocumento29 paginePractical Design of Water Distribution Systems PDFmcsfuvNessuna valutazione finora

- Rain Water Harvesting Seminar Report PDFDocumento16 pagineRain Water Harvesting Seminar Report PDFHarveen Sai75% (8)

- ERA Ethiopia 2011 LVR+Design+Manual+A+FDraft ERA v110610Documento45 pagineERA Ethiopia 2011 LVR+Design+Manual+A+FDraft ERA v110610mcsfuv100% (2)

- Sewage Treatment Plant Design ProjectDocumento53 pagineSewage Treatment Plant Design ProjectShreyas Panchal82% (17)

- Bacolod Chicken Inasal: Engineer'S ReportDocumento4 pagineBacolod Chicken Inasal: Engineer'S Reportadrian bustamanteNessuna valutazione finora

- Principles of Geotechnical Engineering 9th Edition Das Solutions Manual PDFDocumento18 paginePrinciples of Geotechnical Engineering 9th Edition Das Solutions Manual PDFFarouk100% (3)

- EIA - Terms of ReferenceDocumento2 pagineEIA - Terms of ReferencemcsfuvNessuna valutazione finora

- 01 - Algae Biofuel Talk 6 October Peer SchenkDocumento37 pagine01 - Algae Biofuel Talk 6 October Peer SchenkGeorgina Alejandra RomanoNessuna valutazione finora

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationDa EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationNessuna valutazione finora

- Decentralized Wastewater Treatment System (DEWATS) For The Sta. Cruz Class AA Municipal AbattoirDocumento5 pagineDecentralized Wastewater Treatment System (DEWATS) For The Sta. Cruz Class AA Municipal AbattoirOswar MungkasaNessuna valutazione finora

- Water PollutionDocumento5 pagineWater PollutionFahiem ChaucerNessuna valutazione finora

- WOM Project Wastewater Management ProposalDocumento25 pagineWOM Project Wastewater Management ProposalJeffrey JamesNessuna valutazione finora

- Treatment of Soap and Detergent Industry WastesDocumento76 pagineTreatment of Soap and Detergent Industry Wastessumit kumar0% (1)

- Wastewater Management in The PhilippinesDocumento69 pagineWastewater Management in The PhilippinesRed Hair0% (1)

- T1 PageDocumento8 pagineT1 PageMinos SoftNessuna valutazione finora

- Project@SynopsisDocumento7 pagineProject@SynopsissareqaderiNessuna valutazione finora

- Organic Inggris EditDocumento13 pagineOrganic Inggris EditSarah AyundaNessuna valutazione finora

- Water Pollution: (Stream and Marine)Documento16 pagineWater Pollution: (Stream and Marine)RahulNessuna valutazione finora

- Biological Treatment of WastewaterDocumento66 pagineBiological Treatment of WastewaterHasnul WafaNessuna valutazione finora

- Characterization of Abattoir WastewaterDocumento12 pagineCharacterization of Abattoir WastewaterAG-Metal /Tretman Otpadnih Voda/Wastewater Treatment40% (5)

- Intensive Fish CultureDocumento10 pagineIntensive Fish CultureGrowel Agrovet Private Limited.Nessuna valutazione finora

- Subic WaterDocumento7 pagineSubic WaterBEA GEDELYN GARCIANessuna valutazione finora

- Ebt Assignment 1Documento7 pagineEbt Assignment 1surabhiNessuna valutazione finora

- Industrial Training Report (Tsholo)Documento19 pagineIndustrial Training Report (Tsholo)Promise T Muzenda50% (2)

- Mustapha 2009Documento4 pagineMustapha 2009adsvgnmNessuna valutazione finora

- Water Management in CambodiaDocumento6 pagineWater Management in CambodiaPheap ChanchealinNessuna valutazione finora

- Bayawan City Adopts The Ecosan ApproachDocumento4 pagineBayawan City Adopts The Ecosan ApproachAlan LimkaiNessuna valutazione finora

- Training Lecture Notes - Water Pollution and Industrial - Urban Wastewater Treatent-Dr AKBDocumento19 pagineTraining Lecture Notes - Water Pollution and Industrial - Urban Wastewater Treatent-Dr AKBsweatha palaniNessuna valutazione finora

- RayterDocumento4 pagineRayterLTE002Nessuna valutazione finora

- Field Assignment On Feacal Sludge ManagementDocumento10 pagineField Assignment On Feacal Sludge ManagementSarah NamyaloNessuna valutazione finora

- (PNQ) Prem Koonjoo: No Presence of Sharks in The Vicinity of Floating Cages of Aquaculture FarmsDocumento7 pagine(PNQ) Prem Koonjoo: No Presence of Sharks in The Vicinity of Floating Cages of Aquaculture FarmsION NewsNessuna valutazione finora

- 0702204037MBP On Composite Fish Farming - Update Final - EDocumento14 pagine0702204037MBP On Composite Fish Farming - Update Final - EBalakrishna GopinathNessuna valutazione finora

- Kuwait Evaluating The Kuwaiti Wastewater Development StrategyDocumento56 pagineKuwait Evaluating The Kuwaiti Wastewater Development StrategyNoman SyedNessuna valutazione finora

- Assignment 5Documento20 pagineAssignment 5Kumar NihalNessuna valutazione finora

- Waste Management Is The CollectionDocumento14 pagineWaste Management Is The CollectionAMIN BUHARI ABDUL KHADERNessuna valutazione finora

- Bayawan City Waste Management and Ecology Center ReportDocumento6 pagineBayawan City Waste Management and Ecology Center ReportIan Dalisay0% (1)

- Strategies de Gestion Des Cadres Et Conditions de Vie Des Populations A AboboDocumento16 pagineStrategies de Gestion Des Cadres Et Conditions de Vie Des Populations A AboboDauriac Jérôme brunoNessuna valutazione finora

- Safewater Org Wastewater TreatmentDocumento14 pagineSafewater Org Wastewater TreatmentFaizan NazirNessuna valutazione finora

- Mining Pollution: The Case of The Baguio Mining District, The PhilippinesDocumento10 pagineMining Pollution: The Case of The Baguio Mining District, The PhilippinesFritz GuevarraNessuna valutazione finora

- Jon Gibb (River Lochy Association) The Lochy Smolt ProgrammeDocumento27 pagineJon Gibb (River Lochy Association) The Lochy Smolt ProgrammeIntegrated Aquatic Resources Management Between Ireland, Northern Ireland & ScotlandNessuna valutazione finora

- Water PollutionDocumento8 pagineWater PollutionLata PardeshiNessuna valutazione finora

- Waste Water Management Unit: Updated: Tuesday, 26/09/2017Documento2 pagineWaste Water Management Unit: Updated: Tuesday, 26/09/2017Shavin ChandNessuna valutazione finora

- Deepor Beel PresentationDocumento22 pagineDeepor Beel PresentationBleh Bleh BlehNessuna valutazione finora

- Exercise 2 Second Sem 1415Documento2 pagineExercise 2 Second Sem 1415Yani ZoiloNessuna valutazione finora

- FF 7.30.10Documento4 pagineFF 7.30.10Strong Team REALTORSNessuna valutazione finora

- Waste Management SystemDocumento7 pagineWaste Management SystemMarrielle BalagotNessuna valutazione finora

- Dairy Waste Water Treatment by BiofilterDocumento29 pagineDairy Waste Water Treatment by BiofilterShah Rajendra100% (1)

- 2011 10 28 MinutesDocumento6 pagine2011 10 28 MinutesmassieguyNessuna valutazione finora

- Solid Waste AssignmentDocumento19 pagineSolid Waste AssignmentAlfatah muhumed0% (1)

- DDDDDDocumento2 pagineDDDDDABHISHEK SINGHNessuna valutazione finora

- SPR Kapkules BH DRSLP II Baringo September 2021Documento34 pagineSPR Kapkules BH DRSLP II Baringo September 2021simonpeternekesaNessuna valutazione finora

- Artikel Akira Agus DwiyantoDocumento8 pagineArtikel Akira Agus DwiyantoAgusDwiyantoNessuna valutazione finora

- Impact of RO FiltrationDocumento5 pagineImpact of RO Filtrationnggjgt5zmfNessuna valutazione finora

- Local CouncilDocumento1 paginaLocal CouncilmonacraywoodNessuna valutazione finora

- Reporte.06.Cargill English PDFDocumento22 pagineReporte.06.Cargill English PDFRaymond OjedaNessuna valutazione finora

- A Study of Industrial Anaerobic Treatment of Opaque Beer BreweryDocumento7 pagineA Study of Industrial Anaerobic Treatment of Opaque Beer BreweryasvsmsNessuna valutazione finora

- Decentralized WTF For Liloan Cebu Public MarketDocumento7 pagineDecentralized WTF For Liloan Cebu Public MarketN.a. M. TandayagNessuna valutazione finora

- Government of The Libyan Arab JamahiriyaDocumento15 pagineGovernment of The Libyan Arab JamahiriyaMohamed AliNessuna valutazione finora

- Watson Letter To Bradly Waste MGMT EADocumento35 pagineWatson Letter To Bradly Waste MGMT EAJon WillingNessuna valutazione finora

- Environmental Case Study Analysis: Preserving The Water Quality of Iloilo CityDocumento20 pagineEnvironmental Case Study Analysis: Preserving The Water Quality of Iloilo Citypaolo.canejaNessuna valutazione finora

- EcotourismDocumento19 pagineEcotourismAnindita RoyNessuna valutazione finora

- Intensive Fish Culture PDFDocumento10 pagineIntensive Fish Culture PDFRajNessuna valutazione finora

- Sewagepollution PDFDocumento42 pagineSewagepollution PDFKharisma NataliaNessuna valutazione finora

- Lecture 1Documento19 pagineLecture 1Omar DoskyNessuna valutazione finora

- Assessment of The Levels of Phosphate in Detergents SamplesDocumento15 pagineAssessment of The Levels of Phosphate in Detergents SamplesMridul BhadulaNessuna valutazione finora

- Aquacultural Engineering: John Davidson, Neil Helwig, Steven T. SummerfeltDocumento10 pagineAquacultural Engineering: John Davidson, Neil Helwig, Steven T. SummerfeltPoseidonNessuna valutazione finora

- EIA - Purpose and AimsDocumento3 pagineEIA - Purpose and AimsmcsfuvNessuna valutazione finora

- MST 006 Repair To Existing Road Patching and PotholesDocumento14 pagineMST 006 Repair To Existing Road Patching and PotholesmcsfuvNessuna valutazione finora

- D 791Documento15 pagineD 791mcsfuvNessuna valutazione finora

- CavitationDocumento1 paginaCavitationmcsfuvNessuna valutazione finora

- Bases & Columns ScheduleDocumento4 pagineBases & Columns SchedulemcsfuvNessuna valutazione finora

- Dissolved Air FlotationDocumento2 pagineDissolved Air FlotationmcsfuvNessuna valutazione finora

- List of Figure StablesDocumento2 pagineList of Figure StablesmcsfuvNessuna valutazione finora

- Fact 2014Documento41 pagineFact 2014mcsfuvNessuna valutazione finora

- 2014 ConstitutionDocumento13 pagine2014 ConstitutionmcsfuvNessuna valutazione finora

- Site InvestigationDocumento11 pagineSite InvestigationmcsfuvNessuna valutazione finora

- Consolidation Settlement - Endra Susila PHDDocumento85 pagineConsolidation Settlement - Endra Susila PHDAlifya SalsadilaNessuna valutazione finora

- Forests: Deforestation and DesertificationDocumento15 pagineForests: Deforestation and DesertificationFaiza NoorNessuna valutazione finora

- 50 Plus Customers and Total India CountDocumento32 pagine50 Plus Customers and Total India Countrupesh417Nessuna valutazione finora

- JohnsonDiversey Global Headquarters Case StudyDocumento1 paginaJohnsonDiversey Global Headquarters Case StudyPranav RawatNessuna valutazione finora

- Geological Conditions Necessry For Construction of DamsDocumento2 pagineGeological Conditions Necessry For Construction of Damspaul machariaNessuna valutazione finora

- Water Resource EnggDocumento9 pagineWater Resource EnggShaik Jhoir100% (1)

- Mock Exam 9Documento42 pagineMock Exam 9Jay Escalera BahulayNessuna valutazione finora

- Class-Ix Geography Assignment-3 TOPIC-DrainageDocumento2 pagineClass-Ix Geography Assignment-3 TOPIC-DrainageSoumitraBagNessuna valutazione finora

- Facts About Phosphorus and LawnsDocumento5 pagineFacts About Phosphorus and LawnsboomissyNessuna valutazione finora

- Review of The Main Factors Affecting The Flotation of Phosphate OresDocumento23 pagineReview of The Main Factors Affecting The Flotation of Phosphate Oreskhodjetelfehm oussamaNessuna valutazione finora

- Food, Soil and Pest Management1Documento16 pagineFood, Soil and Pest Management1Shie ShieNessuna valutazione finora

- Rate Analysis Based On MSR 2017 Name of Work:-Maintenance of Road Connecting Heikrumakhong Bazar To Umang Connecting Keirang RoadDocumento3 pagineRate Analysis Based On MSR 2017 Name of Work:-Maintenance of Road Connecting Heikrumakhong Bazar To Umang Connecting Keirang RoadHemam PrasantaNessuna valutazione finora

- Water ResourcesDocumento32 pagineWater ResourcesAidenPearceNessuna valutazione finora

- 02 Design Based Report - 20140130Documento133 pagine02 Design Based Report - 20140130vinaygvm0% (1)

- ГОСТ Р 52911-2013Documento13 pagineГОСТ Р 52911-2013ИринаNessuna valutazione finora

- E5 01A ThemeContentsDocumento24 pagineE5 01A ThemeContentsmohammadNessuna valutazione finora

- Truckee Meadows Public Lands Management Map 2023Documento1 paginaTruckee Meadows Public Lands Management Map 2023Ben MargiottNessuna valutazione finora

- The Gorgon LNG ProjectDocumento10 pagineThe Gorgon LNG ProjectthawdarNessuna valutazione finora

- Bo Tro Success Anh 10 FullDocumento8 pagineBo Tro Success Anh 10 FullsjskimNessuna valutazione finora

- Soil Conservation MeasuresDocumento16 pagineSoil Conservation MeasuresPradeep YadavNessuna valutazione finora

- Difference Between Lifestyle of Farmers in India and USADocumento1 paginaDifference Between Lifestyle of Farmers in India and USABlue Heart50% (6)

- AgricultureDocumento193 pagineAgriculturekupakwasheNessuna valutazione finora

- Londax® - A New Herbicide For Aerial Sown Rice: W.S. NSW &Documento1 paginaLondax® - A New Herbicide For Aerial Sown Rice: W.S. NSW &shabaeeshNessuna valutazione finora

- The Importance of Agriculture in Present WorldDocumento8 pagineThe Importance of Agriculture in Present WorldAllen Nanqui DadizonNessuna valutazione finora

- Karakteristik Bahan GalianDocumento11 pagineKarakteristik Bahan GalianZul KifliNessuna valutazione finora

- Chapter 1 - Resources and Development: CBSE Notes Class 10 Social Science GeographyDocumento38 pagineChapter 1 - Resources and Development: CBSE Notes Class 10 Social Science GeographyscedhuNessuna valutazione finora

- List of Schemes Odisha GovtDocumento3 pagineList of Schemes Odisha GovtAnsuman PattanaikNessuna valutazione finora