Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

High Efficiency Boilers: Con X Us

Caricato da

Anonymous 7xHNgoKE6eTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

High Efficiency Boilers: Con X Us

Caricato da

Anonymous 7xHNgoKE6eCopyright:

Formati disponibili

HIGH EFFICIENCY BOILERS

CONXUS REMOTE CONNECT CAPABLE

CASCADING SEQUENCER

LOCH-N-LINK USB DRIVE SETUP

5 INPUTS FROM 399,999 TO 850,000 BTU/HR

10:1 TURNDOWN RATIO

COMMON VENT AND PVC DIRECT-VENTING

FLOW RATES FROM 10 TO 150 GPM

SMALL 6.2 SQ. FT. FOOTPRINT

4 PUMP CONTROL

WIRELESS OUTDOOR SENSOR CAPABLE

98%

Thermal Efficiency *

*See back page for efficiency by model

THE NEW 98% STANDARD

Lochinvar re-defined the fire-tube boiler category with its KNIGHT Wall-Mount and

CREST lines. For residential and light commercial applications, the FTXL adds models

from 399,999 to 850,000 Btu/hr, and takes Lochinvars fire-tube technology to the next

INTRODUCING

BOILER PLANT CONTROL,

FROM ANYWHERE.

level. FTXL offers best-in-class AHRI Thermal Efficiency and footprints, plus remote

FTXL features the next generation of Lochinvars all-in-one

connectivity that puts the SMART SYSTEM control at your fingertips, anywhere!

SMARTSYSTEM operating control with a re-designed multi-color LCD

REDUCE INSTALLATION COST WITH

VARIABLE FLOW TECHNOLOGY

FTXL can operate over a wide range of flow rates* with very low pressure drop.

$12,000

condensing boilers, the FTXL fire-tube

$10,000

three comparisons, based on building

year, at a cost of $1.09 per therm of

$2,000

$0

EFFICIENCY

85%

87%

94%

FTXL 98%

and other communications protocols. And now, the CONXUS mobile

communication platform allows SMART SYSTEM to go where no other

boiler has gone before.

ENHANCED MULTI-COLOR

LCD INTERFACE

lockout

maintain flow in a water-tube boiler. Variable flow also makes FTXL more flexible

boiler plants without ever stepping into the mechanical room. CONXUS

SMOOTH-RUNNING, MODULATING COMBUSTION

and anytime, from anywhere, a user can check system status and

FTXL boilers have a top-mounted, micrometal fiber burner, with a blower/gas

mobile application allows for remote access to all SMART SYSTEM

valve assembly that drives heat energy downward, through stainless steel fire

functions using any Internet-capable device..

re-program any boiler function. Once downloaded, the free CONXUS

maintenance

LOCH-N-LINK EASY USB

FLASH PROGRAMMING

easily manage multiple existing

building heat loads vary. An FTX500 fires at its maximum 500,000 Btu/hr rate

proven parameter sets. Quickly upload

when heat load is highest, then gradually turns down to as low as 10%

them via the front panel port into the

(50,000 Btu/hr) as load decreases. A modulating system runs smoothly and

FTXL boiler, reducing installation and

efficiently, without frequent on/off cycling.

programming time by up to 30

minutes per boiler.

MINIMUM SUPPLY PRESSURE, INSTALLER-FRIENDLY

FTXL operates with supply gas pressure as low as 4 inches water column.

Negative Regulation draws gas into a pre-mix combustion system, instead of

relying on utility pressure through the gas valve. The result is steady operation

in low gas pressure systems or when peak demand occurs on gas supply.

Automatic fan speed control fine-tunes the correct fuel/air ratio entering the

burner, providing superior combustion throughout the entire operating range.

CONXUS control board sold separately.

See back cover for a complete list of

SMART SYSTEM features.

and materials cost for running

sensor wire from standard outdoor

temperature sensor to boiler

normal

Use a USB drive to name, store and

modulation turndown, the burner automatically changes its firing rate as

WIRELESS

OUTDOOR SENSOR

Easy to install, greatly reduces time

CONXUS provides the ability to monitor and manage multiple FTXL

will send alerts via text or e-mail notifying of changes in system status,

tubes, with exhaust venting through the bottom of the unit. With up to 10:1

$6,000

$4,000

Fuel savings is based on a heating load of

19,000 therms per year being supplied by

an 82% efficient boiler at the DOE National

average for natural gas of $1.09.

be integrated directly into a Building Automation System via ModBus

SAVES $12,400

$8,000

load of approximately 19,000 therms/

natural gas.

time and materials cost of primary/secondary piping, and pumps needed to

*See back page for minimum and maximum flow rates by model.

Even when compared to other

significant fuel cost savings. Here are

This permits installation of a full flow (variable primary) system eliminating the

at handling frequent fluctuations in the system flow rate.

$14,000

combustion system will produce

interface. SMART SYSTEM provides outstanding functionality, and can

3 - Year Fuel Savings

HOW 98% TRANSLATES

INTO FTXL SAVINGS

control. Approximate range 2,000

feet line-of-sight.

PEACE OF MIND, WHEN

IT MATTERS MOST

THE NEW 98% STANDARD

Lochinvar re-defined the fire-tube boiler category with its KNIGHT Wall-Mount and

CREST lines. For residential and light commercial applications, the FTXL adds models

from 399,999 to 850,000 Btu/hr, and takes Lochinvars fire-tube technology to the next

level. FTXL offers best-in-class AHRI Thermal Efficiency and footprints, plus remote

connectivity that puts the SMART SYSTEM control at your fingertips, anywhere!

REDUCE INSTALLATION COST WITH

VARIABLE FLOW TECHNOLOGY

1 2 3 4 5 6

Up to eight FTXL boilers can be sequenced using a

In an Efficiency Optimized system, all boilers fire

2-wire daisy-chain connection. Cascade

and modulate simultaneously at the same BTU/hr

sequencing can be programmed for Lead-Lag or

input rates, maximizing thermal efficiency.

Efficiency Optimized operation.

If the lead boiler is turned off for maintenance,

With Lead-Lag operation, one lead boiler

Cascade Redundancy automatically shifts the lead

modulates to capacity on demand. As load

role to the second sequenced boiler. Peace of mind

increases, the system then cascades to additional

comes from knowing the system will still function

lag boilers in sequence. The first-on role shifts

with no downtime until the original lead boiler is

daily, distributing equal runtimes to each unit.

back online.

FTXL can operate over a wide range of flow rates* with very low pressure drop.

This permits installation of a full flow (variable primary) system eliminating the

time and materials cost of primary/secondary piping, and pumps needed to

maintain flow in a water-tube boiler. Variable flow also makes FTXL more flexible

at handling frequent fluctuations in the system flow rate.

*See back page for minimum and maximum flow rates by model.

THE SMALLEST FOOTPRINT,

EASY TO INSTALL & SERVICE

FTXL can be installed with zero clearance on the left and

SMOOTH-RUNNING, MODULATING COMBUSTION

right, and the boilers installed footprint is just 6.2 sq. ft.

All water, gas and vent connections are in the back of the

FTXL boilers have a top-mounted, micrometal fiber burner, with a blower/gas

unit. A hinged top opens for easy access to components

valve assembly that drives heat energy downward, through stainless steel fire

and the front panel is easily removed using no tools.

tubes, with exhaust venting through the bottom of the unit. With up to 10:1

modulation turndown, the burner automatically changes its firing rate as

building heat loads vary. An FTX500 fires at its maximum 500,000 Btu/hr rate

when heat load is highest, then gradually turns down to as low as 10%

(50,000 Btu/hr) as load decreases. A modulating system runs smoothly and

efficiently, without frequent on/off cycling.

FLEXIBLE VENTING

OPTIONS

FTXL offers 6 venting options, and

permits direct-vent air intake and

MINIMUM SUPPLY PRESSURE, INSTALLER-FRIENDLY

FTXL operates with supply gas pressure as low as 4 inches water column.

Negative Regulation draws gas into a pre-mix combustion system, instead of

relying on utility pressure through the gas valve. The result is steady operation

in low gas pressure systems or when peak demand occurs on gas supply.

exhaust runs up to 100 equivalent

feet, using PVC, CPVC, polypropylene

Room Air Vertical

Room Air Sidewall

Common Vent

Direct-Vent Vertical

Direct Vent

or stainless steel pipe. Plus multiple

units can be common-vented to

reduce time and materials costs.

Automatic fan speed control fine-tunes the correct fuel/air ratio entering the

burner, providing superior combustion throughout the entire operating range.

Vertical w/Sidewall Air

TO LEARN MORE, LOG ON TO WWW.FTXLBOILER.COM TODAY!

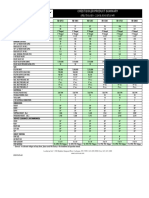

FTXL Boiler Dimensions and Specifications*

Air Inlet

Electrical Connections

2-1/2"

A

Gas Connection

F

53-1/2"

65-1/2"

Water Outlet

40"

Water Inlet

Flue Connection

26-1/4"

26-1/4"

9-3/4"

2-1/2"

Condensate Connection

22-1/2"

Input

NET AHRI

HEX

Model Min Max Thermal Output Rating Turn Flow (GPM) Water

Water

Vent

Air

Gas

Shipping

Number MBH MBH Efficiency MBH MBH down Min Max Volume A B C D E F G H Conn. Size Intake Conn. Wt. (lbs.)

FTX400(N,L) 40.0 399.9 98.0% 392

341

10:1 10

105 13

30-1/2" 27-1/2" 10-1/4" 17" 23-1/4" 46-1/4" 39-1/2" 10-3/4 2"

4 4 1 435

FTX500(N,L) 50.0 500.0 97.7% 489

425

10:1 15

105 12

30-1/2" 27-1/2" 10-1/4 17" 23-1/4" 46-1/4" 39-1/2 10-3/4 2"

4 4 1 460

FTX600(N,L) 85.0 600.0 97.5% 585

509

7:1 15

105 12

30-1/2" 27-1/2" 10-1/4 17" 23-1/4" 46-1/4" 39-1/2 10-3/4 2"

4 4 1 470

FTX725(N,L) 103.5 725.0 97.2% 705

613

7:1 20

150 17

33

28-1/2" 10-1/2 17-1/2" 23-1/2" 48-1/2" 41-1/4 11"

2-1/2" 6

4 1

510

FTX850(N,L) 121.5 850.0 97.0% 825

717

7:1 25

150 16

33" 28-1/2" 10-1/2 17-1/2" 23-1/2" 48-1/2" 41-1/4" 11" 2-1/2" 6 4 1 535

*Information subject to change without notice

Dimensions are in inches. Select N or L for Natural or LP gas

Smart System Features

> Smart System Digital Operating Control

Multi-Color Graphic LCD Display w/Navigation Dial

> Loch-N-Link USB Thumb Drive Port for Easy

Programming

> Cascading Sequencer with Built-in Redundancy

Selectable Cascade Type:

Lead Lag/Efficiency Optimization

Multiple Size Boilers

Front-End Loading

> 3 Reset Temperatures Inputs w/Independent Outdoor

Reset Curves for Each

Outdoor Sensor

> Four-Pump Control

System Pump with Parameter for Continuous Operation

Boiler Pump with Variable-Speed Control

Domestic Hot Water Boiler Pump

Domestic Hot Water Recirculation Pump Control

with Sensor

> Building Management System Integration

0-10 VDC Input to Control Modulation or Setpoint

0-10 VDC Input from Variable-Speed System Pump

0-10 VDC Modulation Rate Output Signal

0-10 VDC Enable/Disable Signal

> Programmable System Efficiency Optimizers

Space Heating Night Setback

DHW Night Setback

Anti-Cycling

Ramp Delay

Boost Time and Temperature

> High-Voltage Terminal Strip

120 VAC/60 Hertz/1 Phase

Pump Contacts for 3 Pumps

> Low-Voltage Terminal Strip

Building Recirculation Pump Start/Stop

Proving Switch Contacts

Flow Switch Contacts

Alarm Contacts

Runtime Contacts

3 Space Heat Thermostat Contacts

Tank Thermostat Contacts

System Sensor Contacts

Tank Sensor Contacts

Cascade Contacts

0-10 VDC BMS Contacts

0-10 VDC Boiler Rate Output Contacts

0-10 VDC Boiler Pump Speed Contacts

0-10 VDC System Pump Speed Contacts

ModBus Contacts

> Time Clock

> Data Logging

Ignition Attempts

Last 10 Lockouts

Space Heat Run Hours

Domestic Hot Water Run Hours

Standard Features

> 97%-98% Thermal Efficiency

> Modulating Burner with up to 10:1 Turndown

Direct Spark Ignition

Low NOx Operation

Sealed Combustion

Low Gas Pressure Operation

> Stainless Steel Fire-Tube Heat Exchanger

ASME-Certified, H Stamped

160 psi Working Pressure

50 psi Relief Valve

Combustion Analyzer Test Port

Fully Welded Design

> Vertical and Horizontal Direct Vent

Direct Vent up to 100 feet

PVC, CPVC, Polypropylene or AL29-4C

Factory Supplied Sidewall Vent Termination

> Smart System Control

> Other Features

On/Off Switch

Adjustable High Limit with Manual Reset

Automatic Reset High Limit

Manual Reset Low Water Cutoff

Flue Temperature Sensor

Low Air Pressure Switch

Temperature and Pressure Gauge

Condensate Trap

Zero Service Clearances

10-Year Limited Warranty (See Warranty)

Custom Maintenance Reminder with Contact Info

Password Security

Customizable Freeze Protection Parameters

Optional Equipment

CONXUS Remote Connectivity

Motorized Isolation Valve

Wireless Outdoor Temperature Sensor

Multi-Temperature Loop Control

Variable-Speed Boiler Circulator

Constant-Speed Boiler Circulator

ModBus Communication

Alarm Bell

Condensate Neutralization Kit

Concentric Vent Kit (FTX400-FTX600)

BMS Gateway to BACnet or LonWorks

High and Low Gas Pressure Switches w/Manual Reset

(FTX500-FTX850)

> Firing Controls

M9-Standard Construction

M13-CSD-1/FM/GE Gap (FTX500-FTX850)

Lochinvar, LLC

300 Maddox Simpson Parkway

Lebanon, Tennessee 37090

P: 615.889.8900 / F: 615.547.1000

Lochinvar.com

FTXE-01 (Reprint 4/15)

5M - PDP - Lochinvar, LLC - 8/15 - Printed in U.S.A.

iPhone and iPod touch are trademarks of Apple Inc., registered in the U.S. and other countries.

Android and Google are trademarks of Google Inc., registered in the U.S. and other countries.

App Store is a service mark of Apple Inc. Google Play is a service mark of Google Inc.

Potrebbero piacerti anche

- Ethical Conflicts in Psychology PDF DownloadDocumento2 pagineEthical Conflicts in Psychology PDF DownloadAvory0% (2)

- Current Trends and Issues in Nursing ManagementDocumento8 pagineCurrent Trends and Issues in Nursing ManagementMadhu Bala81% (21)

- Kinemax Gas or Oil Burners: Bulletin 4200Documento26 pagineKinemax Gas or Oil Burners: Bulletin 4200agua1829Nessuna valutazione finora

- SMMSi Cataluge e 2011Documento56 pagineSMMSi Cataluge e 2011Cong VietNessuna valutazione finora

- Lochinvar Water HeatersDocumento52 pagineLochinvar Water HeatersJohn MoreNessuna valutazione finora

- Skymark VAC - 8-25T Engineering GuideDocumento16 pagineSkymark VAC - 8-25T Engineering Guideastrowiz88Nessuna valutazione finora

- A Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyDocumento11 pagineA Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyNova Ariston100% (2)

- Lochinvar FTXL Fire Tube BoilerDocumento6 pagineLochinvar FTXL Fire Tube BoilerAnonymous buZ5kwNessuna valutazione finora

- Crest Boiler LiteratureDocumento6 pagineCrest Boiler LiteratureJohn MoreNessuna valutazione finora

- DeltaChill & DeltaChill FreeCool Chiller 110-1080kW SB UKDocumento16 pagineDeltaChill & DeltaChill FreeCool Chiller 110-1080kW SB UKNay Myo OoNessuna valutazione finora

- Steam & Combustion Technology Inc. - Boiler Room Air SupplyDocumento3 pagineSteam & Combustion Technology Inc. - Boiler Room Air SupplyAstri NgentNessuna valutazione finora

- Wallmount - JCIDocumento12 pagineWallmount - JCIALEXNessuna valutazione finora

- Plaquette Innov 2012 GB PDFDocumento12 paginePlaquette Innov 2012 GB PDFNico NicoNessuna valutazione finora

- 000-All MHI Folleto #HB91-06P003E-1-A-0 - VRF KX4-60hz #ABR2007-2BRDocumento58 pagine000-All MHI Folleto #HB91-06P003E-1-A-0 - VRF KX4-60hz #ABR2007-2BRJC FinNessuna valutazione finora

- CPac (Mr. Slim) R410a CatalogDocumento15 pagineCPac (Mr. Slim) R410a CataloghivnNessuna valutazione finora

- Multi Split - Catalogue Mitsubishi ElectricDocumento27 pagineMulti Split - Catalogue Mitsubishi ElectricHung Tran67% (3)

- Aquadry La-Rla EngDocumento2 pagineAquadry La-Rla EngtamanogNessuna valutazione finora

- HIP C60 Air Conditioner: Standard FeaturesDocumento3 pagineHIP C60 Air Conditioner: Standard Featuresgenas7265Nessuna valutazione finora

- FCU McQUAYDocumento12 pagineFCU McQUAYben_splNessuna valutazione finora

- Cbx26uh 060Documento12 pagineCbx26uh 060Alberto Nava RodriguezNessuna valutazione finora

- Design Control Document-MVACDocumento48 pagineDesign Control Document-MVACRudivic LumainNessuna valutazione finora

- Technical - Sales Catalogue - 0001101120 - 1.0Documento44 pagineTechnical - Sales Catalogue - 0001101120 - 1.0alejovelNessuna valutazione finora

- h11-515 - Rev - 6 Ruud Wiring PicDocumento12 pagineh11-515 - Rev - 6 Ruud Wiring PicElvis FariasNessuna valutazione finora

- P Serie R410a Eurovent Tecnair 2011Documento28 pagineP Serie R410a Eurovent Tecnair 2011sciurescuNessuna valutazione finora

- Duplex r4 en 2013 03Documento8 pagineDuplex r4 en 2013 03chaesar1Nessuna valutazione finora

- MitsubishiDocumento92 pagineMitsubishidorukbakir0% (1)

- Chiller - CarrierDocumento27 pagineChiller - CarrierJose Francisco Varela CruzNessuna valutazione finora

- ACMV ServicesDocumento22 pagineACMV ServicesRachel IngramNessuna valutazione finora

- KX6Documento70 pagineKX6phibaodalatNessuna valutazione finora

- Gas Heat Pump Catalogue27May14Documento35 pagineGas Heat Pump Catalogue27May14Raphael LopesNessuna valutazione finora

- Delivering Precision Air Conditioning For Critical ApplicationsDocumento26 pagineDelivering Precision Air Conditioning For Critical ApplicationsKarthikeyan SankarrajanNessuna valutazione finora

- Dynaforce Hot Water 300 5000Documento3 pagineDynaforce Hot Water 300 5000Oscar Dario Villada LopezNessuna valutazione finora

- Amana Amvc95Documento12 pagineAmana Amvc95Veljko MilasinovicNessuna valutazione finora

- 58TUA Furnace ManualDocumento8 pagine58TUA Furnace ManualwankerldNessuna valutazione finora

- Boge FLEX PET SystemsDocumento4 pagineBoge FLEX PET SystemsAir Repair, LLCNessuna valutazione finora

- Aqualogic Toplotne PumpeDocumento28 pagineAqualogic Toplotne PumpeAnonymous WNKDboSFlNessuna valutazione finora

- Каталог McQuay чиллеры ATS 2013Documento6 pagineКаталог McQuay чиллеры ATS 2013SBD AtkinsNessuna valutazione finora

- Daikin AlthermaDocumento48 pagineDaikin AlthermaDaniel MilosevskiNessuna valutazione finora

- Edm Aq410 2 S.1GB02.12 40-75Documento52 pagineEdm Aq410 2 S.1GB02.12 40-75Advokat HadziTonicNessuna valutazione finora

- Trane Rtwa 217Documento10 pagineTrane Rtwa 217Dalila AmmarNessuna valutazione finora

- ChillerDocumento3 pagineChillermaburaNessuna valutazione finora

- Nuaire Commercial Useful InfoDocumento10 pagineNuaire Commercial Useful InfoYaser AkarNessuna valutazione finora

- Midco-DB Duct BurnerDocumento2 pagineMidco-DB Duct BurnerTot GaNessuna valutazione finora

- Models: ELP-110 /199 Btu / HR: Typical Elite Plus Boiler ®Documento2 pagineModels: ELP-110 /199 Btu / HR: Typical Elite Plus Boiler ®shreyanshNessuna valutazione finora

- NAMV PaperDocumento8 pagineNAMV PaperenginvservNessuna valutazione finora

- Industrial Combustion System Riello PDFDocumento8 pagineIndustrial Combustion System Riello PDFAnonymous QY7Iu8fBNessuna valutazione finora

- E3CO CrownDocumento13 pagineE3CO CrownPekka ToivanenNessuna valutazione finora

- 1-3 Hybrid Cooling FlyerDocumento2 pagine1-3 Hybrid Cooling FlyersdiamanNessuna valutazione finora

- EEL - LIEBERT - Environmental Control SystemDocumento15 pagineEEL - LIEBERT - Environmental Control SystemJairo FlechasNessuna valutazione finora

- Ferroli Hot Oil HTR (GB)Documento30 pagineFerroli Hot Oil HTR (GB)RodNessuna valutazione finora

- Preheater Lores PDFDocumento8 paginePreheater Lores PDFamjed_de_enimNessuna valutazione finora

- 1.0 Chiller UnitDocumento12 pagine1.0 Chiller UnitfebousNessuna valutazione finora

- XII.6 Cost Comparison Between The Various Types of Cooling TowersDocumento3 pagineXII.6 Cost Comparison Between The Various Types of Cooling Towerssmartleo_waloNessuna valutazione finora

- LG MultiV III - CatalogueDocumento13 pagineLG MultiV III - CatalogueMuhidin KozicaNessuna valutazione finora

- I-Focs GBDocumento8 pagineI-Focs GBncourtneyNessuna valutazione finora

- Azanechiller Series 2010 (3) Final VersionDocumento12 pagineAzanechiller Series 2010 (3) Final VersionRajkumar GulatiNessuna valutazione finora

- Flyer - FXMQ - MFVJU Outside Air Processing - Daikin ACDocumento2 pagineFlyer - FXMQ - MFVJU Outside Air Processing - Daikin ACjohnking5555100% (1)

- 215 AllDocumento90 pagine215 Allriz333Nessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesDa EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNessuna valutazione finora

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDa EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNessuna valutazione finora

- Series 100Documento1 paginaSeries 100Anonymous 7xHNgoKE6eNessuna valutazione finora

- Troubleshooting E00669 PDFDocumento20 pagineTroubleshooting E00669 PDFCarlosNessuna valutazione finora

- Airtrol IOM 599 PDFDocumento6 pagineAirtrol IOM 599 PDFAnonymous 7xHNgoKE6eNessuna valutazione finora

- A Mobile Application That Provides Boiler Control, From AnywhereDocumento1 paginaA Mobile Application That Provides Boiler Control, From AnywhereAnonymous 7xHNgoKE6eNessuna valutazione finora

- 2001 - B&G Centrifugal PumpsDocumento6 pagine2001 - B&G Centrifugal PumpsAnonymous 7xHNgoKE6eNessuna valutazione finora

- Power System Dynamics and Control, 1a. Ed. - Harry G. Kwatny, Karen Miu-MillerDocumento274 paginePower System Dynamics and Control, 1a. Ed. - Harry G. Kwatny, Karen Miu-MillerAnonymous CqddyPpb100% (1)

- Bell & Gossett 1531 Pump Manual Circa 2007Documento8 pagineBell & Gossett 1531 Pump Manual Circa 2007Anonymous 7xHNgoKE6eNessuna valutazione finora

- 1536 Subm 277Documento2 pagine1536 Subm 277Anonymous 7xHNgoKE6eNessuna valutazione finora

- E-60 ECM - Subm-B-144-2-weaDocumento4 pagineE-60 ECM - Subm-B-144-2-weaAnonymous 7xHNgoKE6eNessuna valutazione finora

- Guide Specification Index: DomesticDocumento6 pagineGuide Specification Index: DomesticAnonymous 7xHNgoKE6eNessuna valutazione finora

- Domestic Pump: Series CM Boiler Feed UnitsDocumento4 pagineDomestic Pump: Series CM Boiler Feed UnitsAnonymous 7xHNgoKE6eNessuna valutazione finora

- 751-2001-FBII-I-O - Rev T - 100208043 - 2000004587 (6 INCH VENT) PDFDocumento68 pagine751-2001-FBII-I-O - Rev T - 100208043 - 2000004587 (6 INCH VENT) PDFAnonymous 7xHNgoKE6eNessuna valutazione finora

- Series 60 Inline Pump With Electronically Commutated Motor (ECM)Documento3 pagineSeries 60 Inline Pump With Electronically Commutated Motor (ECM)Anonymous 7xHNgoKE6eNessuna valutazione finora

- Bell & Gossett: Submittal B-341BDocumento2 pagineBell & Gossett: Submittal B-341BAnonymous 7xHNgoKE6eNessuna valutazione finora

- AWX2-I-O Rev G - High Altitude PDFDocumento68 pagineAWX2-I-O Rev G - High Altitude PDFAnonymous 7xHNgoKE6eNessuna valutazione finora

- B&G E1510 Pump Technical InformationDocumento8 pagineB&G E1510 Pump Technical InformationAnonymous 7xHNgoKE6eNessuna valutazione finora

- B&G E1510 Pump Technical InformationDocumento8 pagineB&G E1510 Pump Technical InformationAnonymous 7xHNgoKE6eNessuna valutazione finora

- SYNC-PCP Rev BDocumento20 pagineSYNC-PCP Rev BAnonymous 7xHNgoKE6eNessuna valutazione finora

- 60ECM Lit B 107D PDFDocumento4 pagine60ECM Lit B 107D PDFAnonymous 7xHNgoKE6eNessuna valutazione finora

- Series 60 Inline Pump With Electronically Commutated Motor (ECM)Documento3 pagineSeries 60 Inline Pump With Electronically Commutated Motor (ECM)Anonymous 7xHNgoKE6eNessuna valutazione finora

- Electric Iom PDFDocumento68 pagineElectric Iom PDFAnonymous 7xHNgoKE6eNessuna valutazione finora

- Usg Iom PDFDocumento56 pagineUsg Iom PDFAnonymous 7xHNgoKE6eNessuna valutazione finora

- 751-2001-FBII-I-O - Rev T - 100208043 - 2000004587 (6 INCH VENT)Documento4 pagine751-2001-FBII-I-O - Rev T - 100208043 - 2000004587 (6 INCH VENT)Anonymous 7xHNgoKE6eNessuna valutazione finora

- E-90 ECM - Subm-142Documento3 pagineE-90 ECM - Subm-142Anonymous 7xHNgoKE6eNessuna valutazione finora

- Modbus Communication Instructions: Models: 1.0 - 1.3 - 1.5Documento24 pagineModbus Communication Instructions: Models: 1.0 - 1.3 - 1.5Anonymous 7xHNgoKE6eNessuna valutazione finora

- Condensing Commercial Gas Water HeatersDocumento4 pagineCondensing Commercial Gas Water HeatersAnonymous 7xHNgoKE6eNessuna valutazione finora

- Crest Boiler Product Summary: (FB) 750,000 - 2,000,000 BTU/HRDocumento1 paginaCrest Boiler Product Summary: (FB) 750,000 - 2,000,000 BTU/HRAnonymous 7xHNgoKE6eNessuna valutazione finora

- Usg Iom PDFDocumento56 pagineUsg Iom PDFAnonymous 7xHNgoKE6eNessuna valutazione finora

- Alstrom Series ASTEG Steam Generator BrochureDocumento2 pagineAlstrom Series ASTEG Steam Generator BrochureAnonymous 7xHNgoKE6eNessuna valutazione finora

- Check-Trol: Isolation Flow Control FlangeDocumento2 pagineCheck-Trol: Isolation Flow Control FlangeAnonymous 7xHNgoKE6eNessuna valutazione finora

- Muscles of The Dog 2: 2012 Martin Cake, Murdoch UniversityDocumento11 pagineMuscles of The Dog 2: 2012 Martin Cake, Murdoch UniversityPiereNessuna valutazione finora

- Eapp Melc 12Documento31 pagineEapp Melc 12Christian Joseph HerreraNessuna valutazione finora

- Acetylcysteine 200mg (Siran, Reolin)Documento5 pagineAcetylcysteine 200mg (Siran, Reolin)ddandan_2Nessuna valutazione finora

- First - Second and Third Class Levers in The Body - Movement Analysis in Sport - Eduqas - Gcse Physical Education Revision - Eduqas - BBC BitesizeDocumento2 pagineFirst - Second and Third Class Levers in The Body - Movement Analysis in Sport - Eduqas - Gcse Physical Education Revision - Eduqas - BBC BitesizeyoyoyoNessuna valutazione finora

- Liquitex Soft Body BookletDocumento12 pagineLiquitex Soft Body Booklethello belloNessuna valutazione finora

- DN102-R0-GPJ-Design of Substructure & Foundation 28m+28m Span, 19.6m Width, 22m Height PDFDocumento64 pagineDN102-R0-GPJ-Design of Substructure & Foundation 28m+28m Span, 19.6m Width, 22m Height PDFravichandraNessuna valutazione finora

- Principles of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions ManualDocumento36 paginePrinciples of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions Manualoutlying.pedantry.85yc100% (28)

- Hw10 SolutionsDocumento4 pagineHw10 Solutionsbernandaz123Nessuna valutazione finora

- RSC Article Template-Mss - DaltonDocumento15 pagineRSC Article Template-Mss - DaltonIon BadeaNessuna valutazione finora

- Green Dot ExtractDocumento25 pagineGreen Dot ExtractAllen & UnwinNessuna valutazione finora

- Extract The .Msi FilesDocumento2 pagineExtract The .Msi FilesvladimirNessuna valutazione finora

- Past Simple Vs Past ContinuousDocumento3 paginePast Simple Vs Past ContinuousNatalia SalinasNessuna valutazione finora

- 21 Tara Mantra-Wps OfficeDocumento25 pagine21 Tara Mantra-Wps OfficeAlteo FallaNessuna valutazione finora

- Latest ResumeDocumento2 pagineLatest Resumesamy1234567Nessuna valutazione finora

- LFF MGDocumento260 pagineLFF MGRivo RoberalimananaNessuna valutazione finora

- MolnarDocumento8 pagineMolnarMaDzik MaDzikowskaNessuna valutazione finora

- Loop Types and ExamplesDocumento19 pagineLoop Types and ExamplesSurendran K SurendranNessuna valutazione finora

- CLA Brochure - 2022-3Documento10 pagineCLA Brochure - 2022-3Streamer AccountNessuna valutazione finora

- SecurityFund PPT 1.1Documento13 pagineSecurityFund PPT 1.1Fmunoz MunozNessuna valutazione finora

- Manual de Operacion y MantenimientoDocumento236 pagineManual de Operacion y MantenimientoalexNessuna valutazione finora

- Artificial Intelligence Practical 1Documento5 pagineArtificial Intelligence Practical 1sadani1989Nessuna valutazione finora

- Newsletter 1-2021 Nordic-Baltic RegionDocumento30 pagineNewsletter 1-2021 Nordic-Baltic Regionapi-206643591100% (1)

- Fire Prevention Plan Template - FINAL 5-30-08Documento5 pagineFire Prevention Plan Template - FINAL 5-30-08Peter GeorgeNessuna valutazione finora

- Digital Electronics Chapter 5Documento30 pagineDigital Electronics Chapter 5Pious TraderNessuna valutazione finora

- Unit 2 - Industrial Engineering & Ergonomics - WWW - Rgpvnotes.inDocumento15 pagineUnit 2 - Industrial Engineering & Ergonomics - WWW - Rgpvnotes.inSACHIN HANAGALNessuna valutazione finora

- Gujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalDocumento18 pagineGujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalABCDNessuna valutazione finora

- Galman V PamaranDocumento7 pagineGalman V PamaranChow Momville EstimoNessuna valutazione finora