Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

KBR Phenol

Caricato da

stavros7Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

KBR Phenol

Caricato da

stavros7Copyright:

Formati disponibili

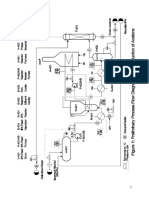

MONONITROBENZENE

HYDROGEN

TARS

Phenol

KBR has been involved in leading-edge phenol technology for over 50

years and has completed more than 50 phenol projects worldwide. KBRs

phenol technology team provides services to clients including technology

licensing and support in the initial planning phase of projects, through

process design, engineering and construction of phenol plants. Once the

plant is onstream, KBR provides technical services to continually optimize

production and meet client goals. KBRs phenol process:

ACETONE PRODUCT

SPENT AIR

Is highly efficient and well integrated

Offers reduced capital and operating costs

CONCENTRATION

Maximizes plant safety and operability

PHENOL FRACTIONATION

PHENOL PRODUCT

CATALYST

Produces highest yields and lowest emissions

CLEAVAGE

AIR

The Process

Cumene is oxidized with air at high efficiency to produce cumene hydroperoxide (CHP). CHP is then concentrated

and cleaved to phenol and acetone in the presence of an acid catalyst using KBRs Advanced Cleavage System. The

reaction conditions have been optimized to provide high selectivity and safety. The catalyst is removed, and the

CUMENE

HYDROCARBON

cleavage mixture is fractioned toRECOVERY

produce high-purity products.

The process produces extremely high-quality phenol

PHENOL RECOVERY

and acetone suitable for all applications. The fractionation train can be designed to either

separate

WASTE OIL

TO FUEL alpha methyl styrene

(AMS) as a pure co-product or hydrogenate the AMS to cumene for recycle to oxidation.

Phenol and, optionally,

WASTEWATER

EFFLUENT TREATMENT

co-product acetophenone (AP) are recovered from a heavies stream, which is a useful fuel. The aqueous effluent is

pretreated to allow efficient biotreatment of plant wastewater.

Air

Light Ends

Cumene

Spent Air

AMS

Hydrogenation

Oxidation

Acetone

Fractionation

Hydrogen

Recycle

Cumene

Organics

Salt Solution

Fresh

Cumene

Concentration

Cumene

Hydroperoxide

Acid

Acetone

Cleavage

Neutralization

Wastewater to

Dephenolation

Phenol

Fractionation

Phenol

Heavies

Removal

Heavy

Ends

Optimized Oxidation System

KBRs phenol technology employs a highly efficient dry oxidation system which results in an oxidation yield of more

than 95 percent by lowering the formation of by-products. The operating conditions in the oxidation system are

optimized weighing all factors such as reaction kinetics and selectivity, air compression and vent gas treatment cost

requirements, and process safety by minimizing the inventory of CHP.

Highly Efficient Purification Technology

KBR Phenol technology produces the highest purity phenol in the industry. Total cresols are typically less than 100

ppm, and total organic impurities less than 30 ppm. The highly efficient dry oxidation and advanced cleavage systems

employed in KBRs phenol technology result in very high yields of phenol and acetone, thus eliminating the need for

a heavy-end cracking system found in some phenol plants. This not only reduces the capital and operating costs, but

also improves the product quality.

Integrated Pollution Prevention System

KBR pioneered the development of many environmental control features used in phenol plants, including the integrated

vent scrubbing system, catalytic oxidation of off-gas and efficient dephenolation systems. KBR phenol plants achieve

lowest emissions, operate at forefront of pollution prevention and meet the most stringent standards in the industry.

KBR phenol plants use state-of-the-art safety protection systems to ensure safe operating conditions at all times. These

plants are safe, reliable and easy to operate.

KBR Phenol Product Quality

Property

Appearance

Purity (dry basis)

Total Organic Impurities

Water

Color (APHA)

Solidification Point (dry material)

Total Carbonyls

2-Methylbenzofuran (2-MBF)

Sulfuric Acid Discoloration (SAD) test

Iron

Specification

Clear

99.99 wt% min.

< 30 wt ppm

< 200 wt ppm

<5

40.85 C min.

< 10 wt ppm

< 2 wt ppm

95% min.

< 0.2 wt ppm

Potrebbero piacerti anche

- Malaysia Airlines Schedule End 2007Documento114 pagineMalaysia Airlines Schedule End 2007stavros7Nessuna valutazione finora

- LNG Terminal DesignDocumento76 pagineLNG Terminal Designsatishchemeng93% (14)

- New Olefin Production Technologies in SINOPECDocumento10 pagineNew Olefin Production Technologies in SINOPECTrevor J. HutleyNessuna valutazione finora

- AnilineDocumento2 pagineAnilineKPAC333100% (2)

- Phenol From Cuemen and TolueneDocumento9 paginePhenol From Cuemen and TolueneAnonymous RJkpep7D0rNessuna valutazione finora

- Engineers Guide - Cumene Peroxidation Process For Phenol ProductionDocumento2 pagineEngineers Guide - Cumene Peroxidation Process For Phenol ProductionEdrian A. Mañalong100% (1)

- Design of Phenol PlantDocumento1 paginaDesign of Phenol Plantapi-292667997Nessuna valutazione finora

- CaprolactamDocumento4 pagineCaprolactamArchie HisolerNessuna valutazione finora

- AnilineDocumento1 paginaAnilineCherry Pearl MiparanumNessuna valutazione finora

- AcetoneDocumento7 pagineAcetoneGeorgiana AndreeaNessuna valutazione finora

- ButadineDocumento68 pagineButadineraihonaNessuna valutazione finora

- Cve 240-Assignment 5 - Chapter 4Documento3 pagineCve 240-Assignment 5 - Chapter 4Ehab Wilson0% (1)

- Cybersecurity Essentials 1.0 Release Notes: PurposeDocumento5 pagineCybersecurity Essentials 1.0 Release Notes: PurposeRonny Kimer Fiestas VargasNessuna valutazione finora

- Aluminium Composite PanelsDocumento46 pagineAluminium Composite PanelsSashwat GhaiNessuna valutazione finora

- Types of Phenol Manufacturing ProcessDocumento4 pagineTypes of Phenol Manufacturing ProcessIsma AzraNessuna valutazione finora

- Side ReactionsDocumento22 pagineSide ReactionsAna Mariel VenturaNessuna valutazione finora

- Presentation CumeneDocumento39 paginePresentation Cumeneممدوح الرويليNessuna valutazione finora

- Production of IsopropanolDocumento9 pagineProduction of IsopropanolJohanNessuna valutazione finora

- Presentation CumeneDocumento39 paginePresentation CumeneBis ChemNessuna valutazione finora

- Manfacture OF: Cyclo HexaneDocumento91 pagineManfacture OF: Cyclo HexaneNikhil Kumar Chennuri100% (4)

- Chemical Kinetics On Thermal Decompositions of CumeneDocumento8 pagineChemical Kinetics On Thermal Decompositions of CumeneMario Alonso Velasquez FlorezNessuna valutazione finora

- Cumene A PDFDocumento4 pagineCumene A PDFdanena88Nessuna valutazione finora

- Report BTPDocumento47 pagineReport BTPvpsrpuchNessuna valutazione finora

- Formic Acid Plant: A Brief OverviewDocumento17 pagineFormic Acid Plant: A Brief OverviewMuzzamilNessuna valutazione finora

- Project ReportDocumento12 pagineProject ReportRabia SabirNessuna valutazione finora

- 0910 4 AbsDocumento9 pagine0910 4 AbsEngr Muhammad AqibNessuna valutazione finora

- CumeneDocumento5 pagineCumeneNasmiyeth Rodriguez VittaNessuna valutazione finora

- For Hysys UsersDocumento5 pagineFor Hysys UsersZohaib RanaNessuna valutazione finora

- Ethyl Benzene Plant DesignDocumento45 pagineEthyl Benzene Plant DesignfaridzawiNessuna valutazione finora

- MEK in School SecondDocumento13 pagineMEK in School Secondifiok100% (1)

- Physical Properties of Cumene Property ValueDocumento4 paginePhysical Properties of Cumene Property ValueC.Çağrı Yekeler50% (2)

- CUMENEDocumento24 pagineCUMENEhiteshNessuna valutazione finora

- PropeneDocumento2 paginePropenemow007100% (1)

- Mek From N Butene PDFDocumento111 pagineMek From N Butene PDFAlexis PulhinNessuna valutazione finora

- Butene-1: Trans-2-Butene, Isobutylene, and ButadieneDocumento1 paginaButene-1: Trans-2-Butene, Isobutylene, and ButadieneYESIKBMARTIN100% (1)

- Cumene To PhenolDocumento73 pagineCumene To Phenolvpsrpuch67% (3)

- Project: Design of A Reactor For The Aniline ProductionDocumento19 pagineProject: Design of A Reactor For The Aniline ProductionLUIS ESTEBAN VÁSQUEZ CASTANEDANessuna valutazione finora

- Styrene From Ethane and BenzeneDocumento6 pagineStyrene From Ethane and BenzeneAmy Puah100% (2)

- Phthalic AnhydrideDocumento1 paginaPhthalic AnhydrideShashikant PanchalNessuna valutazione finora

- 352,, - 9Lq/O&Korulgh 0Rqrphu9&03Odqw &dvherrnv: SimsciDocumento33 pagine352,, - 9Lq/O&Korulgh 0Rqrphu9&03Odqw &dvherrnv: Simscimfruge7Nessuna valutazione finora

- C4 DerivativesDocumento2 pagineC4 DerivativesdaabgchiNessuna valutazione finora

- Designandcontrolofthecumeneprocess PDFDocumento24 pagineDesignandcontrolofthecumeneprocess PDFTobias De Somer100% (1)

- Cumene Production Process DescriptionDocumento1 paginaCumene Production Process DescriptionAudrey Patrick KallaNessuna valutazione finora

- Manufacture of Phenol From CumeneDocumento8 pagineManufacture of Phenol From CumeneFabi OneNessuna valutazione finora

- Cumene ProductionDocumento26 pagineCumene ProductionAMOGH JHANWARNessuna valutazione finora

- PDDocumento2 paginePDnur_ika_1Nessuna valutazione finora

- Vinyl AcetateDocumento5 pagineVinyl AcetateroxetteNessuna valutazione finora

- Nhóm (Đ.Anh+ Hiếu + Ý) Syngas to MethanolDocumento40 pagineNhóm (Đ.Anh+ Hiếu + Ý) Syngas to MethanolStrong NguyenNessuna valutazione finora

- Wasteless Economic Method of Production of Phenol and AcetoneDocumento14 pagineWasteless Economic Method of Production of Phenol and AcetoneSiswand BIn Mohd AliNessuna valutazione finora

- Viewcontent11 PDFDocumento54 pagineViewcontent11 PDFEr Mayur PatilNessuna valutazione finora

- Glycol PlantDocumento8 pagineGlycol PlantDian Risti PurwantiNessuna valutazione finora

- Group Acetic Acid PresentationDocumento24 pagineGroup Acetic Acid PresentationNatko47Nessuna valutazione finora

- UOP Olefin Production Solutions BrochureDocumento2 pagineUOP Olefin Production Solutions BrochureJonas FloresNessuna valutazione finora

- First Review Report On Production of Phenol: Done by GuideDocumento27 pagineFirst Review Report On Production of Phenol: Done by GuideRuban RkNessuna valutazione finora

- Benzene: Chemical Economics HandbookDocumento3 pagineBenzene: Chemical Economics HandbookMaría VásquezNessuna valutazione finora

- Cumene To Phenol 2Documento73 pagineCumene To Phenol 2vpsrpuch0% (1)

- Ullmann's Enc. of Industrial Chemistry PLANTA.Documento12 pagineUllmann's Enc. of Industrial Chemistry PLANTA.yoelarismendi100% (1)

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsDa EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsNessuna valutazione finora

- Ion Exchange TechnologyDa EverandIon Exchange TechnologyF.C. NachodNessuna valutazione finora

- Ionic Liquids in Lipid Processing and Analysis: Opportunities and ChallengesDa EverandIonic Liquids in Lipid Processing and Analysis: Opportunities and ChallengesXuebing XuNessuna valutazione finora

- Single-Atom Catalysis: A Forthcoming Revolution in ChemistryDa EverandSingle-Atom Catalysis: A Forthcoming Revolution in ChemistryNessuna valutazione finora

- Experimental Methods in Catalytic Research: Physical Chemistry: A Series of MonographsDa EverandExperimental Methods in Catalytic Research: Physical Chemistry: A Series of MonographsRobert B. AndersonNessuna valutazione finora

- Adiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringDa EverandAdiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringNessuna valutazione finora

- 2016-07-21 IOC Presentation - ExxonMobil Acquisition of InterOilDocumento10 pagine2016-07-21 IOC Presentation - ExxonMobil Acquisition of InterOilampatNessuna valutazione finora

- Philippine Airlines Codeshare Winter 27dec2007Documento1 paginaPhilippine Airlines Codeshare Winter 27dec2007stavros7Nessuna valutazione finora

- Business Corporations Act - YukonDocumento243 pagineBusiness Corporations Act - Yukonstavros7Nessuna valutazione finora

- Investor Presentation US RoadshowDocumento29 pagineInvestor Presentation US Roadshowstavros7Nessuna valutazione finora

- Results of PAC + OSH Certification 15 July 2016Documento4 pagineResults of PAC + OSH Certification 15 July 2016stavros7Nessuna valutazione finora

- OSH Announcement - No New BidDocumento2 pagineOSH Announcement - No New Bidstavros7Nessuna valutazione finora

- CarbonblackuserguideDocumento28 pagineCarbonblackuserguideJose NinNessuna valutazione finora

- Oil Search Commencement of PRL 15 CertificationDocumento1 paginaOil Search Commencement of PRL 15 Certificationstavros7Nessuna valutazione finora

- 1604 Credit Suisse Asian Investment Conference, HK - OIL SEARCHDocumento29 pagine1604 Credit Suisse Asian Investment Conference, HK - OIL SEARCHstavros7Nessuna valutazione finora

- Golar FLNG PresentationDocumento19 pagineGolar FLNG Presentationstavros7100% (1)

- Carbon BlackDocumento10 pagineCarbon BlackEugene CollinsNessuna valutazione finora

- Oil Search Drilling Report For March 2015Documento4 pagineOil Search Drilling Report For March 2015stavros7Nessuna valutazione finora

- Belgian Consulting IndustryDocumento18 pagineBelgian Consulting Industrystavros7Nessuna valutazione finora

- NJ Nexmtbe and Nexetbe BrochureDocumento2 pagineNJ Nexmtbe and Nexetbe Brochurestavros7Nessuna valutazione finora

- TRA Melbourne Ballarat Airport Infrastructure Upgrade Web Project Review1Documento1 paginaTRA Melbourne Ballarat Airport Infrastructure Upgrade Web Project Review1stavros7Nessuna valutazione finora

- Tankfarm Brochure SiemensDocumento10 pagineTankfarm Brochure Siemensstavros7Nessuna valutazione finora

- Final CrudeOil and Petroleum Product TerminalsDocumento14 pagineFinal CrudeOil and Petroleum Product Terminalsbalavengu100% (1)

- Infrastructure: RATE SummaryDocumento26 pagineInfrastructure: RATE Summarystavros7Nessuna valutazione finora

- Session 5 Keynote Address NNPC David Ige Samue LndukweDocumento34 pagineSession 5 Keynote Address NNPC David Ige Samue Lndukwestavros7Nessuna valutazione finora

- Air Niugini Schedule Dec - March 2016Documento51 pagineAir Niugini Schedule Dec - March 2016stavros7Nessuna valutazione finora

- ICIS Olefins OutlookDocumento3 pagineICIS Olefins Outlookstavros7100% (1)

- Refinery - Petrochemicals Master Plan Article - KBRDocumento7 pagineRefinery - Petrochemicals Master Plan Article - KBRstavros7Nessuna valutazione finora

- Infrastructure Master Plan Section 2Documento2.494 pagineInfrastructure Master Plan Section 2stavros7Nessuna valutazione finora

- 2014 Infrastructure PlanDocumento96 pagine2014 Infrastructure Planstavros7Nessuna valutazione finora

- National Integrated InfrastructureDocumento29 pagineNational Integrated Infrastructurestavros7Nessuna valutazione finora

- YLNG March 2011 WebDocumento6 pagineYLNG March 2011 Webstavros7Nessuna valutazione finora

- TP Apac Feb2013 WebDocumento20 pagineTP Apac Feb2013 Webstavros7Nessuna valutazione finora

- YALE (C878) GDP135VX LIFT TRUCK Service Repair Manual PDFDocumento20 pagineYALE (C878) GDP135VX LIFT TRUCK Service Repair Manual PDFfjskekdmmemNessuna valutazione finora

- Intel® Desktop Board DP35DPDocumento84 pagineIntel® Desktop Board DP35DPAnticristo69Nessuna valutazione finora

- MGT 162Documento2 pagineMGT 162Myra Choyy100% (1)

- Lesson 3 Solid Pressure Osunero, Kim John S. BSED 2D SCIE 4Documento6 pagineLesson 3 Solid Pressure Osunero, Kim John S. BSED 2D SCIE 4Kim John OsuneroNessuna valutazione finora

- Zombie RPGDocumento30 pagineZombie RPGBo100% (3)

- List of All Entrance Exams A Student Can Appear After Passing 12th in IndiaDocumento2 pagineList of All Entrance Exams A Student Can Appear After Passing 12th in IndiaDeepak Gupta100% (1)

- RoundingDocumento65 pagineRoundingSourav Kumar100% (1)

- ListaDocumento1 paginaListaRonaldhinoFrankoNessuna valutazione finora

- Analog Servo Drive: Description Power RangeDocumento9 pagineAnalog Servo Drive: Description Power RangeElectromateNessuna valutazione finora

- PDH DFE1000 BrochureDocumento2 paginePDH DFE1000 Brochuremajdi1985Nessuna valutazione finora

- The Work of Frei Otto By. Ludwig GlaeserDocumento137 pagineThe Work of Frei Otto By. Ludwig GlaeserUntal Aparicio100% (1)

- Test AND Measurement: Eagle PhotonicsDocumento90 pagineTest AND Measurement: Eagle PhotonicsPankaj SharmaNessuna valutazione finora

- Related Learning Experience Journal: Lipa City, BatangasDocumento7 pagineRelated Learning Experience Journal: Lipa City, BatangasushenNessuna valutazione finora

- Litografia Soft LithographyDocumento33 pagineLitografia Soft Lithographyrfm147Nessuna valutazione finora

- Iris - International Railway Industry StandardDocumento17 pagineIris - International Railway Industry StandardDavid P MNessuna valutazione finora

- 2018 Index of Military Strength Air Domain EssayDocumento15 pagine2018 Index of Military Strength Air Domain EssayThe Heritage FoundationNessuna valutazione finora

- Peach TreeDocumento36 paginePeach TreeSana MeerNessuna valutazione finora

- Sharp BP30C25 - Installation ManualDocumento58 pagineSharp BP30C25 - Installation ManualSathish SukumaranNessuna valutazione finora

- Item # Ae102-8, Aeroquip Fire Sleeve - Ae102-8: List PriceDocumento3 pagineItem # Ae102-8, Aeroquip Fire Sleeve - Ae102-8: List PriceWalid HannaNessuna valutazione finora

- What Is Marketing MixDocumento12 pagineWhat Is Marketing Mixmansi mehtaNessuna valutazione finora

- ComE 223-Computer Fundamentals & Programming IIDocumento2 pagineComE 223-Computer Fundamentals & Programming IIDinah Fe Tabaranza-OlitanNessuna valutazione finora

- Inter Rat Handover GSM UmtsDocumento4 pagineInter Rat Handover GSM UmtsadanakebapNessuna valutazione finora

- Creating Your Online CSSD Student Profile - MA Acting ProgrammesDocumento7 pagineCreating Your Online CSSD Student Profile - MA Acting ProgrammesEleanor ShawNessuna valutazione finora

- RRP NoticeDocumento6 pagineRRP NoticeLucky TraderNessuna valutazione finora

- The Effectiveness of Acceptance and Commitment-BasDocumento18 pagineThe Effectiveness of Acceptance and Commitment-BasRaphaele ColferaiNessuna valutazione finora

- The Power Behind.: Rectifier DPR 2900B-48 (ESR48/56C F)Documento2 pagineThe Power Behind.: Rectifier DPR 2900B-48 (ESR48/56C F)Charmer JiaNessuna valutazione finora

- On API 650Documento52 pagineOn API 650ferdad79% (19)