Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Maxon EC90 Flat 90watt With Encoder

Caricato da

ElectromateDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Maxon EC90 Flat 90watt With Encoder

Caricato da

ElectromateCopyright:

Formati disponibili

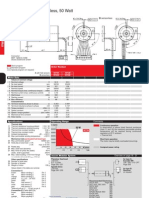

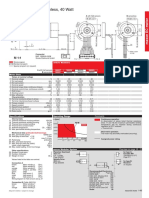

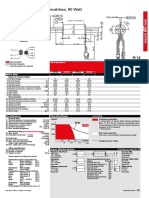

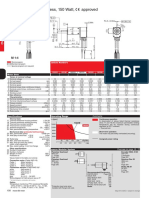

brushless, 60 Watt, with encoder

maxon flat motor

Connector:

1-828582-0

AMP

39-28-1083

MOLEX

M 1:2

Stock program

Standard program Order Number

Special program (on request)

with Hall sensors 353984 346970

Motor Data

Values at nominal voltage

1 Nominal voltage V 12.0 36.0

2 No load speed rpm 1600 1560

3 No load current mA 338 108

4 Nominal speed rpm 1260 1240

5 Nominal torque (max. continuous torque) mNm 327 405

6 Nominal current (max. continuous current) A 4.56 1.78

7 Stall torque mNm 2330 3400

8 Starting current A 33.1 15.6

9 Max. efficiency % 81.2 84.3

Characteristics

10 Terminal resistance phase to phase W 0.363 2.3

11 Terminal inductance phase to phase mH 0.264 2.5

12 Torque constant mNm / A 70.5 217

13 Speed constant rpm / V 135 44.0

14 Speed / torque gradient rpm / mNm 0.697 0.467

15 Mechanical time constant ms 22.3 15.0

16 Rotor inertia gcm2 3060 3060

Specifications Operating Range Comments

Thermal data n [rpm]

17 Thermal resistance housing-ambient 3.7 K / W Continuous operation

18 Thermal resistance winding-housing 3.4 K / W In observation of above listed thermal resistance

1800

60 (lines 17 and 18) the maximum permissible winding

19 Thermal time constant winding 60 s

346970 temperature will be reached during continuous

20 Thermal time constant motor 549 s 1500

operation at 25°C ambient.

21 Ambient temperature -20 ... +70°C

1200 = Thermal limit.

22 Max. permissible winding temperature +125°C

900

Short term operation

Mechanical data (preloaded ball bearings) 600 The motor may be briefly overloaded (recurring).

23 Max. permissible speed 1750 rpm

24 Axial play at axial load < 15 N 0 mm 300

> 15 N 0.14 mm

100 300 500 Assigned power rating

25 Radial play preloaded

26 Max. axial load (dynamic) 12 N 0.5 1.0 1.5 2.0 2.5

27 Max. force for press fits (static) 150 N

(static, shaft supported) 8000 N

28 Max. radial loading, 7.5 mm from flange 30 N maxon Modular System Overview on page 16 - 21

Connection Motor Planetary Gearhead

Other specifications

Pin 1 Hall sensor 1 Æ52 mm

29 Number of pole pairs 12 Pin 2 Hall sensor 2 4 - 30 Nm

30 Number of phases 3 Pin 3 4.5 ... 18 VDC Page 244

31 Weight of motor 713 g Pin 4 Motor winding 3

Values listed in the table are nominal. Pin 5 Hall sensor 3

Pin 6 GND

Technical Data Encoder Encoder Pin 7 Motor winding 1

Function principle optical Pin 8 Motor winding 2

Number of pulses per revolution 2048 Wiring diagram for Hall sensors see p. 29

Number of channels 2 Connection Encoder

Max. pulse frequency 60 kHz Pin 1 N.C.

Supply voltage VCC 5V ± 10% Pin 2 VCC

Output signal EIA Standard RS422 Pin 3 GND

Driver used DS26C31T Pin 4 N.C. Recommended Electronics:

Power per channel -20 ... +20 mA Pin 5 A\ EPOS2 24/5 Page 303

Signal rise and fall times 30 ns Pin 6 A EPOS2 50/5 303

Pin 7 B\ EPOS 70/10 303

(typically, at CL = 25pF, RL = 1kW EPOS P 24/5 306

Pin 8 B

Cable Pin 9 N.C. Notes 20

Pin 10 N.C. Sold & Serviced By:

Connection cable zu EPOS, L = 500 mm 354045

Connection cable Encoder, L = 500 mm 354046 ELECTROMATE

INDUSTRIAL SALES LIMITED

PRECISION TECHNOLOGY & QUALITY

200 Toll Free Phone (877) SERVO98 May 2009 edition / subject to change

Toll Free Fax (877) SERVO99

sales@electromate.com

www.electromate.com

Potrebbero piacerti anche

- Maxon EC-Powermax30 200wattDocumento1 paginaMaxon EC-Powermax30 200wattElectromateNessuna valutazione finora

- Maxon EC22 50wattDocumento1 paginaMaxon EC22 50wattElectromateNessuna valutazione finora

- Maxon EC90 Flat 90wattDocumento1 paginaMaxon EC90 Flat 90wattElectromateNessuna valutazione finora

- Maxon EC-Max40 70wattDocumento1 paginaMaxon EC-Max40 70wattElectromateNessuna valutazione finora

- 12 149 enDocumento1 pagina12 149 enLuka MadridNessuna valutazione finora

- Maxon EC60 400wattDocumento1 paginaMaxon EC60 400wattElectromateNessuna valutazione finora

- Maxon EC-Max22 25wattDocumento1 paginaMaxon EC-Max22 25wattElectromateNessuna valutazione finora

- Maxon EC-Max16 5wattDocumento1 paginaMaxon EC-Max16 5wattElectromateNessuna valutazione finora

- Maxon EC22 50watt SterilisableDocumento1 paginaMaxon EC22 50watt SterilisableElectromateNessuna valutazione finora

- En 21 251Documento1 paginaEn 21 251Froylan OchoaNessuna valutazione finora

- Maxon RE30 Graphite Brushes 60wattDocumento1 paginaMaxon RE30 Graphite Brushes 60wattElectromateNessuna valutazione finora

- Maxon EC6 1.2wattDocumento1 paginaMaxon EC6 1.2wattElectromateNessuna valutazione finora

- En 21 250Documento1 paginaEn 21 250compimagmaticNessuna valutazione finora

- EC 22 22 MM, Brushless, 50 Watt: Part NumbersDocumento1 paginaEC 22 22 MM, Brushless, 50 Watt: Part NumbersfurkanfurkanfurkanNessuna valutazione finora

- 12 156 enDocumento1 pagina12 156 enLuka MadridNessuna valutazione finora

- Maxon RE65 Graphite Brushes 250wattDocumento1 paginaMaxon RE65 Graphite Brushes 250wattElectromateNessuna valutazione finora

- Maxon Ec45 136210Documento1 paginaMaxon Ec45 136210compimagmaticNessuna valutazione finora

- EC 90 Flat: 90 MM, Brushless, 600 WattDocumento1 paginaEC 90 Flat: 90 MM, Brushless, 600 WattDiy DoeNessuna valutazione finora

- Motor Maxon 323772Documento1 paginaMotor Maxon 323772Henry Daniel VerdugoNessuna valutazione finora

- Maxon EC22 20watt Integrated ElectronicsDocumento2 pagineMaxon EC22 20watt Integrated ElectronicsElectromateNessuna valutazione finora

- EC 40 40 MM, Brushless, 170 Watt: Part NumbersDocumento1 paginaEC 40 40 MM, Brushless, 170 Watt: Part NumbersfurkanfurkanfurkanNessuna valutazione finora

- 90mm EC Brushless MotorDocumento1 pagina90mm EC Brushless MotorLucas SuplinoNessuna valutazione finora

- Maxon EC-Max30 40wattDocumento1 paginaMaxon EC-Max30 40wattElectromateNessuna valutazione finora

- RE50Documento1 paginaRE50Yhony Gamarra VargasNessuna valutazione finora

- RE 50 50mm Graphite Brushes 200W MotorDocumento1 paginaRE 50 50mm Graphite Brushes 200W MotorJorge Alejandro Barrutia BorbollaNessuna valutazione finora

- 12 171 enDocumento1 pagina12 171 enLuka MadridNessuna valutazione finora

- EC-max 30 ∅30 mm, brushless, 60 Watt motor specsDocumento1 paginaEC-max 30 ∅30 mm, brushless, 60 Watt motor specsfurkanfurkanfurkanNessuna valutazione finora

- Maxon Re40 DC Motor 148866 Datasheet PDFDocumento1 paginaMaxon Re40 DC Motor 148866 Datasheet PDFtoony reyesNessuna valutazione finora

- EC 20 MOTOR SPECSDocumento1 paginaEC 20 MOTOR SPECSivanlawms6745Nessuna valutazione finora

- Maxon RE40 Graphite Brushes 150wattDocumento1 paginaMaxon RE40 Graphite Brushes 150wattElectromateNessuna valutazione finora

- F2140 Eng DatasheetDocumento4 pagineF2140 Eng Datasheettngyew leeNessuna valutazione finora

- 17 en 170 Lstage DatasheetDocumento1 pagina17 en 170 Lstage DatasheetSana SyedNessuna valutazione finora

- Maxon EC20 Flat 5wattDocumento1 paginaMaxon EC20 Flat 5wattElectromateNessuna valutazione finora

- Maxon Re40Documento1 paginaMaxon Re40compimagmaticNessuna valutazione finora

- MAXON Brushed Motor A-Max 26, 4.5 WDocumento1 paginaMAXON Brushed Motor A-Max 26, 4.5 WRadu BabauNessuna valutazione finora

- Motores Maxon 2017Documento1 paginaMotores Maxon 2017--Nessuna valutazione finora

- Maxon RE50 Graphite Brushes 200wattDocumento1 paginaMaxon RE50 Graphite Brushes 200wattElectromateNessuna valutazione finora

- 12 158 enDocumento1 pagina12 158 enLuka MadridNessuna valutazione finora

- Maxon EC20 Flat 3wattDocumento1 paginaMaxon EC20 Flat 3wattElectromateNessuna valutazione finora

- Maxon RE25 Precious Metal Brushes 10wattDocumento1 paginaMaxon RE25 Precious Metal Brushes 10wattElectromateNessuna valutazione finora

- Maxon RE-Max17 Graphite Brushes 4.5wattDocumento2 pagineMaxon RE-Max17 Graphite Brushes 4.5wattElectromateNessuna valutazione finora

- 30 MM, Graphite Brushes, 60 Watt: Order NumberDocumento1 pagina30 MM, Graphite Brushes, 60 Watt: Order NumberRatanieriNessuna valutazione finora

- Graphite Brushes, 60 Watt Maxon DC MotorDocumento1 paginaGraphite Brushes, 60 Watt Maxon DC MotorRatanieriNessuna valutazione finora

- Maxon EC45 Flat 30wattDocumento1 paginaMaxon EC45 Flat 30wattElectromateNessuna valutazione finora

- EC 60mm 400W Brushless MotorDocumento1 paginaEC 60mm 400W Brushless MotorZoltán SoósNessuna valutazione finora

- RE-max17 GP16 MR RE-max17 GB 4.5W #216013Documento3 pagineRE-max17 GP16 MR RE-max17 GB 4.5W #216013Alexander MonteNessuna valutazione finora

- 16 275 enDocumento1 pagina16 275 enmawadNessuna valutazione finora

- Analog Circuit Techniques: With Digital InterfacingDa EverandAnalog Circuit Techniques: With Digital InterfacingNessuna valutazione finora

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDa EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsValutazione: 3.5 su 5 stelle3.5/5 (6)

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsDa EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsValutazione: 3 su 5 stelle3/5 (5)

- Analog Circuit Design Volume Three: Design Note CollectionDa EverandAnalog Circuit Design Volume Three: Design Note CollectionValutazione: 3 su 5 stelle3/5 (2)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDa EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Digital Power Electronics and ApplicationsDa EverandDigital Power Electronics and ApplicationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsDa EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNessuna valutazione finora

- Introducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionDocumento1 paginaIntroducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionElectromateNessuna valutazione finora

- Exor X5 Wireless Press ReleaseDocumento1 paginaExor X5 Wireless Press ReleaseElectromateNessuna valutazione finora

- Electromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseDocumento1 paginaElectromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseElectromateNessuna valutazione finora

- New High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesDocumento2 pagineNew High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesElectromateNessuna valutazione finora

- Electromate Recertified As A Great Place To Work' Press ReleaseDocumento1 paginaElectromate Recertified As A Great Place To Work' Press ReleaseElectromateNessuna valutazione finora

- Galil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesDocumento1 paginaGalil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesElectromateNessuna valutazione finora

- Electromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaDocumento1 paginaElectromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaElectromateNessuna valutazione finora

- Electromate Elated With Win at The 2022 Business Achievement AwardsDocumento2 pagineElectromate Elated With Win at The 2022 Business Achievement AwardsElectromateNessuna valutazione finora

- Meet The World's Most Precise Six-Axis RobotDocumento1 paginaMeet The World's Most Precise Six-Axis RobotElectromateNessuna valutazione finora

- New LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsDocumento1 paginaNew LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsElectromateNessuna valutazione finora

- Kollmorgen Debuts EKM Series Servo MotorsDocumento1 paginaKollmorgen Debuts EKM Series Servo MotorsElectromateNessuna valutazione finora

- ADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesDocumento2 pagineADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesElectromateNessuna valutazione finora

- Mecademic Robotics Releases New Firmware For Its Meca500 RobotDocumento2 pagineMecademic Robotics Releases New Firmware For Its Meca500 RobotElectromateNessuna valutazione finora

- AMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMDocumento2 pagineAMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMElectromateNessuna valutazione finora

- Electromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesDocumento2 pagineElectromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesElectromateNessuna valutazione finora

- POSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsDocumento1 paginaPOSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsElectromateNessuna valutazione finora

- Electromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardDocumento2 pagineElectromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardElectromateNessuna valutazione finora

- Electromate Extends Its Product Portfolio To Include Robots From MecademicDocumento1 paginaElectromate Extends Its Product Portfolio To Include Robots From MecademicElectromateNessuna valutazione finora

- Netzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsDocumento1 paginaNetzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsElectromateNessuna valutazione finora

- Electromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseDocumento2 pagineElectromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseElectromateNessuna valutazione finora

- New Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseDocumento1 paginaNew Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseElectromateNessuna valutazione finora

- ADVANCED Motion Controls Releases The FM060-25-CMDocumento1 paginaADVANCED Motion Controls Releases The FM060-25-CMElectromateNessuna valutazione finora

- Excellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesDocumento2 pagineExcellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesElectromateNessuna valutazione finora

- New Integrated Spindle Drives Available From JVLDocumento1 paginaNew Integrated Spindle Drives Available From JVLElectromateNessuna valutazione finora

- New 100 Amps Peak FlexPro Servo Drives Available From AMCDocumento1 paginaNew 100 Amps Peak FlexPro Servo Drives Available From AMCElectromateNessuna valutazione finora

- Electromate Recognized With 2021 AHTD Foundation AwardDocumento1 paginaElectromate Recognized With 2021 AHTD Foundation AwardElectromateNessuna valutazione finora

- Electromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsDocumento2 pagineElectromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsElectromateNessuna valutazione finora

- Electromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020Documento2 pagineElectromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020ElectromateNessuna valutazione finora

- New LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsDocumento1 paginaNew LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsElectromateNessuna valutazione finora

- Maxon's New IDX Integrated Motor - Power at The Press of A ButtonDocumento1 paginaMaxon's New IDX Integrated Motor - Power at The Press of A ButtonElectromateNessuna valutazione finora

- Smc2870w MNDocumento56 pagineSmc2870w MNDavide SestiNessuna valutazione finora

- McKesson Enterprise Intelligence - Quality Emeasures For Horizon ClinicalsDocumento2 pagineMcKesson Enterprise Intelligence - Quality Emeasures For Horizon ClinicalsMcKesson Surgical SolutionsNessuna valutazione finora

- Spark 35DSGDocumento1 paginaSpark 35DSGMoez JbeliNessuna valutazione finora

- Fs Nice Actimize Brochure - Watch List Filtering SolutionDocumento0 pagineFs Nice Actimize Brochure - Watch List Filtering Solutionapi-245482086Nessuna valutazione finora

- ElecEng4FJ4 Module03 PDFDocumento22 pagineElecEng4FJ4 Module03 PDFFrew FrewNessuna valutazione finora

- Introduction of Online BankingDocumento18 pagineIntroduction of Online BankingRavi Kashyap506Nessuna valutazione finora

- C++ Richard Halterman PDFDocumento634 pagineC++ Richard Halterman PDFUros1994Nessuna valutazione finora

- Monoprice Delta Mini Manual, Version 1Documento20 pagineMonoprice Delta Mini Manual, Version 1Ted ThompsonNessuna valutazione finora

- How To Extract .SAR File For Windows - My Code CommunityDocumento3 pagineHow To Extract .SAR File For Windows - My Code CommunityRangabashyamNessuna valutazione finora

- Cyber Security Guide to CASB, Threats & Best PracticesDocumento26 pagineCyber Security Guide to CASB, Threats & Best PracticesTharun RickyNessuna valutazione finora

- Hysys Dynamics PDFDocumento549 pagineHysys Dynamics PDFminh nguyenNessuna valutazione finora

- Globe Telecom SEC Form 17-A for Fiscal Year 2017Documento296 pagineGlobe Telecom SEC Form 17-A for Fiscal Year 2017Rexer AnthonyNessuna valutazione finora

- Hypercar Pollution PreventionDocumento32 pagineHypercar Pollution Preventionnagesh patilNessuna valutazione finora

- Chapter 3 PCM and TDMDocumento49 pagineChapter 3 PCM and TDMjudgelightNessuna valutazione finora

- Con BFM Connecting SleevesDocumento2 pagineCon BFM Connecting SleevesRhiieeNessuna valutazione finora

- 16 - Incident Response, Disaster Recovery & Business Continuity Section PDFDocumento10 pagine16 - Incident Response, Disaster Recovery & Business Continuity Section PDFnallamalli subramanyamNessuna valutazione finora

- PLL CircuitsDocumento20 paginePLL CircuitsNeeresh KumarNessuna valutazione finora

- Tarlac State University: Name: Sam C. Tolentino Section: Bsed Social Studies 3B Course Code: Sse 101Documento10 pagineTarlac State University: Name: Sam C. Tolentino Section: Bsed Social Studies 3B Course Code: Sse 101Sam TolentinoNessuna valutazione finora

- Dell EMC Unity Power Down Up ProcedureDocumento5 pagineDell EMC Unity Power Down Up ProcedureShahulNessuna valutazione finora

- Voyage Planning WorkbookDocumento5 pagineVoyage Planning WorkbookRobert M. Maluya100% (2)

- Edureka VM Readme PDFDocumento4 pagineEdureka VM Readme PDFagangapurNessuna valutazione finora

- Ccnav7 Srwe Skills Assessment: TopologyDocumento9 pagineCcnav7 Srwe Skills Assessment: TopologyPaul Andres Heredia FerrufinoNessuna valutazione finora

- Stereo DVD Tuner Deck Receiver ManualDocumento164 pagineStereo DVD Tuner Deck Receiver ManualMicael Cesar Mendoza PaccoNessuna valutazione finora

- Digitalization and Its Influence On Business Model InnovationDocumento18 pagineDigitalization and Its Influence On Business Model InnovationNegera AbetuNessuna valutazione finora

- 760GXK8MC Manual v1.0 TCH (91 181 760 M2 0T)Documento23 pagine760GXK8MC Manual v1.0 TCH (91 181 760 M2 0T)cesar marcanoNessuna valutazione finora

- A Study On Impact of Financial Technologies of UNB Bank's Service QualityDocumento104 pagineA Study On Impact of Financial Technologies of UNB Bank's Service QualityBhuvaneshwari .ANessuna valutazione finora

- Apc NetbotzDocumento2 pagineApc NetbotzAndre OccensteinNessuna valutazione finora

- SCHEDULINGDocumento29 pagineSCHEDULINGkishoreNessuna valutazione finora

- Iec Ieee 60780-323 - 2016Documento36 pagineIec Ieee 60780-323 - 2016Tamara Silvana Cárcamo100% (1)

- YZU Master Programs For International Students (2022)Documento2 pagineYZU Master Programs For International Students (2022)fatehNessuna valutazione finora