Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Orginal BP Tra

Caricato da

MuhammadIqbalMughalCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Orginal BP Tra

Caricato da

MuhammadIqbalMughalCopyright:

Formati disponibili

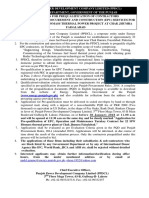

HAZARDOUS CONSTRUCTION ACTIVITIES

Sr. #

ACTIVITIES

Loading / Un-loading.

Bush cutting / Tree cutting. Bush transportation.

Erection of parda wall.

Erection of fence.

Water Bowzer.

Traffic control.

Road works. Heating of bitumen.

Electrical works (Lighting) outside.

Scaffolding.

10

Erection of masonry wall.

11

Steel works (Rebars)

12

Manual lifting (Cement, blocks, bags & pumps).

13

Shuttering.

14

Culverts & bridges.

15

Paint.

16

Dewatering.

17

Cellar pipe.

18

Water proofing.

19

Concrete pouring.

20

Sand blasting.

HAZARDOUS CONSTRUCTION ACTIVITIES

Sr. #

ACTIVITIES

21

Movement through populated area.

22

Parking.

23

Driving and working in rain / fog condition. (Bed weather)

24

Night working.

25

Underground utilities identification (In and outside).

26

Hydrotesting.

27

Gas cylinder handling / storage / transportation (Propane)

28

Fabrication.

29

Jack hammering.

30

Dismantling of equipment / manual or mechanical.

31

Material storage on site.

32

Mechanical Excavation.

33

Pipeline activities.

34

Thrust boring.

35

Survey.

36

Temporary ladder / handrail.

37

Job related to working at height.

38

Energy isolation (outside fence)

39

Identification of un-recognized confined space.

40

Pigging of pipelines.

HAZARDOUS CONSTRUCTION ACTIVITIES

Sr. #

ACTIVITIES

41

Shoring of deep trench.

42

Drilling / grinding / cutting on site.

43

Workover jobs.

44

Pulling of stuck equipment.

45

Mobilization / demobilization.

46

Working in extreme weather.

47

Control of working hours.

48

Contractor's living conditions in camps / on site.

49

Route & risk identification with journey management.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

01

1a

. Improper handling of

material.

Loading and Off. Improper use of Lifting

loading of material

Equipments

. Over loading

Transportation of

Loaded Material

. Slippery / narrow

paths

. Blind Turnings

. Poor vision

. Crowded / populated

places

. Remote areas

. Under Construction

Road

. Pedestrians /

Animals access /

crossing.

. Collision with the

protrude portion, over

speeding.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment .

Controls

Action to be taken

Describe Action.

. Proper tightening with chain or belts after loading.

. Equipment Check List (Verified).

. Area cordon off.

. Proper indication marked on the extrude portion

before the movement.

. Load the material as per the designed loading

capacity of the vehicle.

. Loading material will not protrude more than 2 feet

from the transporting vehicle.

. Loading capacity indication on the vehicle.

. Weight of load clearly marked / Known.

. In case of critical loading no person stand near

lifting Equipment.

12

. Secure the

load.

. Prohibited.

. Procedure.

. GCMs

. GCMs

. Driving

policy.

Date: 20-Mar-2004

Residual Risk.

Resources

. Certified persons /

Equipments.

. Certified lifting

gears.

. Tightening chain /

belts.

. Vehicle Checklist.

. Fasten the seat belts.

. Proper indication marked on the protrude portion before

the movement.

. Speed limits / DRU's.

. Control the Speed limit of transporting vehicle as per

Bp's driving policy.

. Drive right.

. Conduct Route survey before transportation.

. Designate lookouts in all critical places like blind turnings, . Seat Belts.

crowded places, under construction roads.

. Physical condition of driver.

. Special care will be taken near Public buses, Sugarcane

Loaded vehicles, animal driven carts and villages.

. Defensive driving courses to contractor's drivers.

. No movement in the adverse wheather conditions.

HE

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

02

03

04

. Improper use of tools

. Snake Bite / Poisonous

insects.

. Climbing on the trees.

. Improper stacking of

Crop, Bush and Trees

cut trees & bushes.

cutting and than

. Blind turning.

Transportation

. Crowded places.

. Narrow path.

. Over loading.

. Ground Condition

. Condition of Trees

Erection of Parda

Wall

Erection of Fence.

. Improper handling of

material.

. Fire / ignition source.

. Weather condition.

. Working at height.

. Cables / shock.

. Local Issues.

. Change in SOW.

. Snake bite.

. Hit.

. Spark / Fire.

. Improper handling of

bitumen drum.

. Exposure to hot surface

(High skin temperature).

. Working at height.

. Application of hot

bitumen.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Environment .

. People.

. Equipment.

. Facility.

. Environment .

Controls

Action to be taken

Describe Action.

. GCMs

. ERP

. Procedure.

. Prohibited.

. Equipment Check List

. Trained persons

. Ensure no person stand under the tree to be cut.

. Visit of the working area with local community persons for

awareness of hazard (like presence of snakes, ponds and

transportation of vegetation waste)

. Proper awareness about the nature / size of trees and

bushes

. Before cutting of trees area to be barricade.

. Trim / Cut to size for adequate handling

. Adequate equipment for trimming.

. Standby Vehicle

Date: 20-Mar-2004

Residual Risk.

Resources

HE

. Snake Bite Kit.

. First Aid Box.

. Drive right.

. Seat Belts.

. GCMs.

. Pohibited.

. Procedure.

. Emergency

rescue plan.

. Equipment checklist.

. Area cordon-off.

. Conduct the GCM with nearby community people.

. Proper Scaffolding must be installed if working at height 6' and

above.

. Fire proof Tarpaulin sheet must be used.

. Extreme vigilance to restrict unauthorized entry.

. Display of warning sign board.

. Better planning & clarity of SOW .

. Close liaison of PR department.

. Stand by vehicle.

. FAB.

. Snake bite kit.

. Fire proof

Tarpaulin sheet.

. Scaffolding.

. GCM.

. ERP

. Procedure.

. Prohibited.

. Proper Scaffolding must be installed if working at height

6' and above, Stable plateform to be provided when

working at height less than 6 feet.

. Area cordon off.

. Proper Material storage place.

. Equipment check list.

. Skilled manpower.

. Use certified chain block for tightening of fence.

. Heating perform at safe place.

. Use proper fuel.

. Proper house keeping on daily basis.

. Empty cement bags to be proper disposed off.

. Conduct GCM related to the Environment hazard.

. Awareness about the Emergency rescue plan.

. Fire watchman.

. Fire extinguisher.

. Medic man.

. Safety watch.

. First Aid Box.

. Stand by vehicle.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

05

Water Bowser for

Sprinkling /

Transportation at

designated place

. Fast movement

. Changing Route

. Over turning

. Blind Turnings

. Poor vision

. Crowded places

. Remote areas

. Access/ crossing.

. Pedestrians/

animals.

. Change in condition.

. Excessive Sprinkling

. Pedestrians.

. Animal Carts.

. Narrow path.

. Blind turning.

. Over speeding.

. Equipment failure.

. Road condition.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment .

06

Traffic Control

7a

. Adverse wheather

condition.

. Temporary heating

. People.

Road works.(Bitumen place near straw, bushes

. Equipment.

Heating)

etc.

. Environment.

. Improper handling of

bitumen drum.

. Fire / ignition source.

Controls

Action to be taken

Describe Action.

. GCM.

. ERP

. Procedure.

. Prohibited.

Residual Risk.

Resources

HE

. Drive right.

. Seat Belts.

. Look outs

. Competent driver.

. Route awareness.

. Competency of driver.

. Followed speed limit.

. Equipment check list.

. No movement in bad weather/high wind/ fog/ night

condition.

. Installed traffic sign board.

. Refresher course should be done time to time.

. Conduct road safety awareness program with local

community.

. Driver's eye sight / vision test.

. Deputed skilled lookout near by populated area/

village/narrow path/ blind turning.

. Lookout.

. Drive right.

. Certified Drivers.

. Cordon off heating place.

. Appropriate PPE

. Check wind direction.

. Use of thermometer / apparatus for carefully watching

temperature of bitumen.

. Avoid to over filling bitumen in Dope kettle.

. Use of proper fuel.

. Heating place must not exist on shoulder.

. Presence of sand to avoid spreading of fire from the

heating place.

. Equipment for proper melting ( Dope kettle)

. Fire watch man.

. Fire extinguisher.

. Dope kettle.

. PPE.

. Bowser Checklist.

. Conduct Route analysis before transportation.

. Designate lookouts in all critical places like blind

turnings, near villages roads.

. Control the Speed limit of transporting vehicle as

. GCMs

per Bp's driving policy.

. Procedure.

. Conduct the GCM with nearby community people.

. Special care will be taken near Sugarcane Loaded

vehicles, animal driven carts and villages.

. Periodic inspection of Bowser.

. Physical condition of driver.

. GCM.

. Procedure.

Date: 20-Mar-2004

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

7b

7C

Road Works.

(Spraying of Hot

bitumen)

. spill of bitumen from

dope kettle.

. People.

. Safe distance b/w work

. Equipment.

place and heating place.

. Environment.

. Cutting of bitumen

drum.

Road Works.

(Compaction of rock

with road roller.)

. Failure of equipment.

. Other vehiclular

movement.

. personal injury.

. property damage.

. Narrow road.

. Labor working on that

section.

. Crowded place.

. People.

. Equipment.

. Environment .

Controls

Action to be taken

Describe Action.

R

. Prohibited.

. Procedure.

. Emergency

response

plan.

. GCM with

Workers /

local

community.

. Prohibited.

. Procedure.

. Emergency

response

plan.

. GCM with

Workers /

local

community.

. Driving

policy.

Date: 20-Mar-2004

Residual Risk.

Resources

HE

. Leather Gloves for the person for handling hot bitumen.

. Heating place will be at safe place.

. Sufficient distance b/w heating and work place.

. Use of additional safety cover area over all.

. Display of sign board.

. Proper storage of material.

.Traffic control.

. Fire watch man.

. Fire extinguisher.

. Dope kettle.

. PPE.

. Equipment check list

. Safety Talk

. safe distance b/w two tractor.

. keep sufficient distance b/w roller and labor.

. Valid license.

. Competency of operator.

. Safety awareness meeting with local community.

. Driving policy.

. Medic.

Stand by vehicle.

. Safety watchman.

. First aid box.

. Fire watchman.

. Fire extinguisher.

. Look out.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

7d

7e

Road Works (Dirt

filling by trolley-in

material.)

Road Works

(Mobilization/

Demobilization)

. Narrow roads.

. loading of material at

borrow site.

. crop adjacent to dirt

road/track

. populated areas.

. stucking of equipment.

. sugar cane trolleys.

. over loading of trolleys.

. Simops of equipment.

. Snake bite

. Pedestrians.

. Animal Carts.

. Poor Vision.

. Slippery road.

. Narrow path.

. Blind turning.

. Over speeding.

. Equipment failure.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment .

Controls

Date: 20-Mar-2004

Action to be taken

Residual Risk.

Describe Action.

Resources

HE

12

. No person traveling with tractor trolley.

. Equipment check list.

. During the loading of material, tractor driver to keep away

from the equipment.

. No movement in bad weather condition.

. Valid HTV license holder in case of filling to be done by

dumper.

. Preferably use of Dumper where possible.

. only hydraulic trolleys where dumper movement is not

possible.

. No movement of hydraulic trolleys on dirt track having

width less then 12'

. Designate look out in all critical points e.g sharp turning,

near Goths and under construction work.

. Community awareness meetings.

. Route map from borrow area to site.

. Try to Select borrow area nearest to rig road.

. Avoid excessive use of Pressure horn.

. Follow vehicle policy.

. Look out.

. Snake bite kit.

. Safety watchman.

. Medic man.

. F.A.B.

. Certified medic

man.

. Stand by vehicle.

. Dust mask.

. Lookout.

. Fire extinguisher.

. Competent driver.

. Prohibited.

. Procedure.

. Emergency

response

plan.

. GCM with

Workers /

local

community.

. Driving

policy.

. GCMs

. Driving

policy.

. Route Awareness.

. No movement in bad weather/high wind/ fog/ night

condition.

. Followed speed limit.

. Equipment check list.

. Installed traffic sign board.

. Conduct road safety awareness program with local

community.

. No passenger is allowed to sit In Cargo Cabin & it must

be strictly Prohibited.

. Physical fitness of driver.

. Deputed skilled lookout near by populated area/

village/narrow path/ blind turning.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

. Improper use of tools

. Snake Bite / Poisonous

insects

. Snake Bite / Poisonous

insects

. Climbing on the trees

. People.

. Improper stacking of

. Equipment.

cut trees & bushes

. Environment .

. Blind turning.

. Crowded places.

. Narrow path.

. Over loading.

. Ground Condition

. Condition of Trees

7f

Road Work s(Bush

and tree cutting)

7g

. Improper handling of

material.

. Improper use of Lifting

Equipments

Road Works

. Over loading

(Offloading of

. Hit by rolling rock

construction material

. Slip from heap of rock

e.g Rock, Morum,

. confined space

Crush Etc.)

condition

. Dust

. Hit by Flat bar installed

on truck

. People.

. Equipment.

. Facility.

. Environment .

Controls

Action to be taken

Describe Action.

. Prohibited.

. Procedure.

. Emergency

response

plan.

. GCM with

Workers /

local

community.

. Prohibited.

. Procedure.

. Emergency

response

plan.

. GCM.

Date: 20-Mar-2004

. Equipment Check List

. Ensure no person stand under the tree to be cut.

. Visit of the working area with local community persons for

awareness of hazard (like presence of snakes, ponds and

transportation of vegetation waste)

. Proper awareness about the nature / size of trees and

bushes

. Before cutting of trees area to be barricade.

. Trim / Cut to size for the ease of handling.

. Appropiate equipment for trimming.

Residual Risk.

Resources

. Trained persons.

. Snake Bite Kit.

. First Aid Box

. Standby Vehicle.

. Proper tightening with chain and belts after loading.

. Equipment Check List.

. Area cordon off.

. Load the material as per the designed loading capacity of

. Certified persons.

the vehicle.

. Loading capacity indication on the vehicle.

. Certified

. Weight of load clearly marked / Known.

Equipments.

. Use dumper instead of truck.

. Use such trucks having sliding sides / adjustable frames.

. Use such truck having low height body.

HE

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

7h

7i

Road Work (Pushing

by Tractor &

Ploughing, Leveling

and Grading by

Tractor Blade.)

. Simops of tractor.

. Failure of tractor.

. Reversing maneuver.

. Snake bite.

. Live equipment.

. People.

. Equipment.

. Environment .

Road Work

(Survey)

. Improper handling /

placement of instrument.

. Carelessness about

vehicular traffic.

. Slip from slopes.

. Stuck in soft soil.

. Harsh weather ( hot,

sunshine)

. Marshy/ wet area.

. Thick bushes.

. Snake/ poisonous

insect bite.

. Local cultural

sensitivities.

. Getting stranded.

. People.

. Equipment.

. Facility.

. Environment .

Controls

Date: 20-Mar-2004

Action to be taken

Residual Risk.

Describe Action.

Resources

HE

. Prohibited.

. Procedure.

. Emergency

response

plan.

. GCM.

. Equipment check list

. PTW.

. Safety Talk

. Keep Safe distance 15 to 20 ' b/w tractors.

. Special precaution/ care have been taken during the

working near well head and other live lines and equipment.

. Tractor movement will be in such a way that the face of

tractor will not be direct towards equipment/ well head.

. Monitor change of condition.

. Coordination with the production.

. Well head area must be cordon off/ temporary fenced.

. Proper supervision.

. First Aid Box

. Look out.

. Snake bite Kit.

. Safety watchman.

. Fire extinguisher.

. Certified Medic

man.

. Competent driver.

. Procedure.

. Emergency

response

plan.

. GCM.

. Check ground condition.

. Proper placement of instrument.

. Signal man to guide traffic.

. Try to minimize exposure.

. Communication.

. Proper rest to avoid dehydration.

. Umbrella for surveyor if survey to be done by equipment.

. F.A.Box.

. Snake bite kit.

. Medic Man.

. Ample water /

food reserves.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

Electrical Works

(Lighting outside)

08

. Shock,

{Power arrangement (Gen . Burn,

. Fire,

set , Power outlet )

Material arrangement for . Explosion,

Installation of lighta and

. Injury,

Termination of electric

. Use of improper tools.

. People.

. Equipment.

. Facility.

. Environment .

09

Scaffolding

10

. Hit.

. Fall.

Erection of masonary

. Environmental.

wall.

. Working at height.

. Cement / Chemical.

11

Steel works (Rebar)

. Improper use of tools.

. Working at height.

. People.

. Equipment.

. Facility.

. Environment.

. People.

. Equipment.

. Facility.

. Environment .

. People.

Action to be taken

Describe Action.

Residual Risk.

Resources

HE

. Generator's checklist,

. Isolated Distribution Box with ELCB,

. Classified Equipments for specified area,

. Use of Explosion proof light & proper handling of lights,

. Proper Connection,

. Proper instruments and tools.

. No work on live lines.

. Certified

Electrician,

. Specific Gloves.

. PPE.

. Testing

Equipments.

. Distribution box.

. Procedure.

. PTW.

. GCM.

.

Segregation /

Barricade.

. ERP.

. Elevated ground condition.

. Proper anchoring. (preferably over head).

Scaffolding material must be used as per procedure.

Unavailability of competent person for design erection

and inspect as well.

Tag system.

Use of prefabricated ladder.

PPE (Full body

harness with shock

absorber.)

Emergency stand

by vehicle.

. FAB.

. Certified safety

supervisor.

. Scaffolding check

list.

Certified

Scaffolders.

. Procedure.

. PTW.

. GCM.

.

Segregation /

Barricade.

. ERP.

. Use of proper tools.

. Proper plate form.

. Cordon off.

. Proper Material storage place.

. Proper house keeping.

. Empty cement bags to be proper disposed off.

. Conduct GCM related to the Environment hazard.

. Availability of MSDS.

. Safety watch.

. First Aid Box.

. Skilled Mason.

. Rubber gloves

and dust mask.

. Stand by vehicle.

. Procedure.

. PTW.

. GCM.

. Barricade.

. ERP.

. Medic man.

. Safety Watch.

. Mechanical rebar

cutter.

cable}

Trip and fall

. Poor ground condition.

Fall of object from

height

Unbalance structure

Loose members and

planks.

Heavy wind

Inadequate design.

. Working at height.

Controls

Date: 20-Mar-2004

. Prohibited.

. Procedure.

. Emergency

response

plan.

. GCM.

. GCMs.

. Area to be barricade.

. Skilled Person.

. Display of sign board.

. Material to be properly stacked at job site on wooden

planks and also to be covered by polythene sheet..

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

12

13

Manual Lifting

(Cement, Blocks,

bags & pumps etc.)

Shuttering

Culvert & bridges.

14a (Excavation)

. Improper handling of

material.

. Fall.

. Hit.

. Slip.

. Lifting of excess load.

. Snake bite.

. Improper use of tools

. Exposed nails of wood

. Insufficient support

. Quality of shuttering.

. Protrude portion of

bracing/ horizontal

support.

. Working at height.

. Hit / Fall / Slip / Cut.

. Under ground Utilities

lines can get struck while

performing the

excavation.

. Fire

. Electric shock.

. High Water Table.

. Collapse.

. Working in depth.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment.

Controls

. Procedure.

. PTW.

. GCM.

. ERP.

. Procedure.

. PTW.

. GCM.

. ERP.

Action to be taken

Describe Action.

. Procedure.

. PTW.

. GCM.

. ERP.

Date: 20-Mar-2004

. Appropriate Supervision.

. Access from the storage to the Loading site must be

clear.

. Skilled manpower to shift the load.

. Proper procedure to be adopted during manual lifting.

. Sufficient break to rest.

. Material must be stacked in proper storage place.

. Area to be barricade

. Removing of nails from work site.

. Display of Sign board.

. House Keeping.

. Material to be properly stacked at work site.

. Follow the route marker.

. Area cordon off.

. Use of cable detector.

. Equipment Check List.

. Bell holes.

. Remove soil/ stock pile material maximum away from

edge.

. Steps , Slop , Shoring after 4' depth as per soil condition.

Residual Risk.

Resources

HE

. First aid box.

. Snake bite kit.

. Medic man.

. Safety

Watchman.

. Safety

Watchman.

. Stand by vehicle.

. Skilled persons .

. Safety supervisor.

. Medic man.

. Fire watch man.

. Safety watchman.

. Medic man with

F.A.Box.

. Fire extinguisher.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

Culvert & bridges.

14b (Shuttering)

Culvert & bridges.

14c (Steel Fixing)

Culvert & bridges.

14d (Concreting)

Culvert & bridges.

14e (Brick Masonry)

. Improper use of tools

. Exposed nails of wood

. Insufficient support

. Quality of shuttering.

. Protrude portion of

bracing/ horizontal

support.

. Working at height.

. Hit / Fall / Slip / Cut.

. Improper use of tools.

. Working at height.

. Improper use of tools/

Machinery.

. Improper access for the

placement of concrete.

. Cement & dust

inhalation.

. Enviromental hazard

. Unbalanced position of

mixer machine.

. Improper form work.

. Hit.

. Fall.

. Environmental.

. Working at height

. Cement.

. People.

. Equipment.

. Facility.

. Environment.

. People.

. Equipment.

. Facility.

. Environment.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment.

Controls

. Procedure.

. PTW.

. GCM.

. ERP.

. Procedure.

. PTW.

. GCM.

. ERP.

Action to be taken

Describe Action.

Date: 20-Mar-2004

. Skilled persons.

. Area to be barricade.

. Removing of nails from work site.

. Display of Sign board.

. House Keeping.

. Material to be properly stacked at work site.

Residual Risk.

Resources

. Safety supervisor.

. Medic man.

HE

. Area to be barricade.

. Skilled Person.

. Display of sign board.

. Material to be properly stacked at job site on wooden

planks and also to be covered by polythene sheet..

. Safety Watch.

. Mechanical rebar

cutter.

. Medic man

. Procedure.

. PTW.

. GCM.

. ERP.

. Skilled man power.

. Dust mask.

. Proper disposal of Empty cement bags.

. Use of gum boots by mason.

. Proper Passage for Wheel Barrow.

. Equipment Check lists.

. Area cordon off.

. Material to be properly stacked at job site.

. Use of proper/ safe way for crossing of Canal.

. Standby Vehicle

. Safety Watch.

. Medic man

. F.A.Box.

. Standby

Equipment (In

mass concrete)

. Dust mask.

. Procedure.

. PTW.

. GCM.

. ERP.

. Use of proper tools.

. Proper plate form.

. Cordon off.

. Skilled Mason.

. Proper Material storage place.

. Proper house keeping.

. Empty cement bags to be properly disposed off.

. Conduct GCM including the Environmental hazards.

. Safety watch.

. First Aid Box.

. Rubber gloves

and dust mask.

. Stand by vehicle.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

14f

15

16

. Lifting Operation.

. Welding.

. Inadequate crane base.

. Working at height.

. Improper Signals

. Failure of lifting gears.

. Misjudgment of load.

Culvert & bridges.

. Fire Ignition Source.

(Placement of Girder/

. Improper use of tools.

Fabrication /

. Inadequate working

Welding)

area for the welder.

. Insufficient working

space b/w crane and

trailer.

. High flow of drain

canal.

. Ground Condition.

Painting

Toxic fumes.

Environment hazard.

Skin swollen.

Expired paint.

Dewatering.

. Use of machinery

. Mis handling

. Inadequate ground

condition

. Trip and Fall

. Improper hose

connections

. Noisy area

. Snake bite.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment .

Controls

Date: 20-Mar-2004

Action to be taken

Residual Risk.

Describe Action.

Resources

HE

. Procedure.

. PTW.

. GCM.

. ERP.

. Equipment Check List

. Area cordon off.

. Certified Operators, Riggers and Equipments.

. No unauthorized / unconcerned persons allowed to enter

in the lifting operation area.

. Proper working platform provided for the welders and

helpers.

. Conduct meeting with near by villagers before critical and

time taken lifting operations.

. In case of single access provision of by-pass will be

made for local villagers.

. Physical condition of the crane operators.

. Installation of warning sign board.

. Safety watchman.

. Fire Watchman.

. Fire extinguisher.

. Medic man

. First aid box.

. Lookouts.

. GCM.

. PTW.

. ERP.

. Manpower competency.

. Proper disposal of empty cans / cotton rags / gloves /

roller etc.

. Skilled painting supervisor.

. Avoid keeping unused paint cans in open atmosphere.

. Paint should not be mixed on ground with out arranging

wooden ply or tarpaulin.

. Ensure availability of MSDS.

. Leather gloves.

. Splash glasses.

. PPE.

. Facemask.

. First aid box.

. Medic.

. PTW

. GCM

. ERP

. Procedure.

. Prohibited.

. Valid equipment check list

. Skilled Personal

. House keeping

. Proper barricade

. Warning sign board

. Proper hose connection (Jubilee clamps not permissible)

. Approved dewatering procedure

. Availability of quick set fitting and well points system.

. Snake bite kit.

. PPE

. First aid box

. Emergency stand

by vehicle

. Water bowser.

. Certified Safety

watch

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

17

18

19

Installation of Cellar

and Conductor Pipe

. Slipping of Tripod Legs.

. Machinery may fall and

can hit some one.

. Sling can be broken.

. Sliding of equipment

during unloading with

chain block.

. Ground condition.

. Sliding of equipment

during unloading with

chain block.

. Failure of equipment.

Water Proofing

. Improper material

Handling

. People.

. Cutting Tool

. Working at height

. Facility.

. Handling of hot bitumen . Environment .

unto roof.

. Enviromental

Concrete Pouring.

. Improper use of tools/

Machinery.

. Improper access for the

placement of concrete.

. Cement & dust

inhalation.

. Enviromental hazard

. Unbalance position of

mixer machine.

. Improper form work.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment .

Controls

Action to be taken

Describe Action.

Date: 20-Mar-2004

Residual Risk.

Resources

HE

. GCM

. ERP

. Procedure.

. Prohibited.

. Certified lifting gears.

. Trained & experienced person.

. Tripod legs stands on hard ground.

. Area cordon off.

. Equipment check list.

. House keeping.

. Coordination with associated work force

same location.

. GCM

. ERP

. Procedure.

. Prohibited.

. Leather gloves for the persons for handling hot bitumen.

. Proper scaffolding .

. Shifting of bitumen through rope and bucket safely.

. No one should stand during the pulling of bucket.

. Area should be barricade.

. Check Wind direction.

. House Keeping.

. Safety watch.

. Fire Watch.

. Fire Extinguisher.

. Medic Man.

. F.A. Box.

. Stand by Vehicle.

. GCM

. ERP

. Procedure.

. Prohibited.

. Skilled man power.

. Dust mask is mandatory.

. Proper disposal of Empty cement bags.

. Use of gum boots by mason.

. Proper Passage for Wheel Barrow.

. Standby Equipment (In mass concrete)

. Equipment Check list

. Area cordon off.

. Material to be properly stacked at job site.

. Use of proper/ safe way for crossing of Canal.

. Dust mask.

. Safety Watch.

. Medic man

. F.A.Box.

. Standby Vehicle.

. Safety watchman.

. Medic man.

. F.A.B.

. Certified operator.

. Certified rigger.

working at . Stand by vehicle.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

20

21

Sand blasting SA 2

Piping & Structure

Movement through

populated area

. High Pressure

. Rupture

. Fire

. Enviromental Damage

. Improper Connection

. Inhaling

. Abrasive

. Suffocation .

. Pedestrians.

. Poor Vision.

. Slippery road.

. Narrow path.

. Blind turning.

. Over speeding.

. Equipment failure.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment .

Controls

Date: 20-Mar-2004

Action to be taken

Residual Risk.

Describe Action.

. PTW.

. GCM

. ERP

. Procedure.

. Prohibited.

. Equipment Should be with Valid Check List

. All Connection Should Be with Chicago Coupling & With

Quick Open & Lock

. All PSVS . Should Calibrated With Tracebility Certificate.

. Operator & Sand Blaster Both Should See to Each Other

Easily

. Dead man Switch be Operational.

. Use Dust Mask.

. Use Breathing Apparatus With Regulator.

. Area Should Cordoned Off

. Depute Safety & fire Watch man.

. Use Approved Quality Silica Sand

. Separate air Breathing Connection Air Filter.

. Procedure for disposal of Grit / Silica.

. Pressure rating on hoses should be marked.

. Driving

policy.

. GCM.

. Follow speed limit.

. Equipment check list.

. No movement in bad weather/high wind/ fog/ night

condition.

. Route awareness.

. Drive right.

. Installed traffic sign board.

. Portable fire

. Conduct road safety awareness program with local

extinguishers.

community.

. Lookout.

. Refresher course should be done time to time.

. Competent driver.

. Physical fitness of driver.

. Deputed skilled lookout near by populated area/

village/narrow path/ blind turning.

. Arrange seminars to learn traffic rules.

. DDT for contractors.

Resources

. PPE

. Dust Mask.

. FAB.

. Compressor and

sand blating

accessories.

HE

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

22

Parking.

. Road condition.

. Narrow path.

. Animal sit beneath the

vehicle to rest.

. Blind turning.

. Over speeding.

. Equipment failure.

. Pedestrians.

. Animal carts.

. People.

. Equipment.

. Facility.

. Environment .

Driving in Rain or

Fog Weather

Condition

. Poor Vision.

. Slippery road.

. Narrow path.

. Blind turning.

. Over speeding.

. Equipment failure.

. Movement on

inspection path.

. Flow of electric current.

. People.

. Equipment.

. Facility.

. Environment .

24

Night Working

. Low visibility,

. Snake bite,

. Blind Spots.

. People.

. Equipment.

. Facility.

. Environment .

25

. under ground utility

lines can get struck while

Under ground

performing excavation

utilities identification either by manual/

(Inside & Outside the Mechanical.

Facility)

. Electric shock.

. Fire ignition.

. Environmental.

23

. People.

. Equipment.

. Facility.

. Environment .

Action to be taken

Controls

Describe Action.

Date: 20-Mar-2004

Residual Risk.

Resources

HE

. Parking Triangle.

. Driving

policy.

. GCM.

. Use of designated parking at location and all other

working places.

. Competency of driver.

. Use of triangles

. If parked at populated area it depends on driver

competency to judge the hazard.

. Park away from passing by Vehicle, animal carts etc.

. Inspection round the vehicle immediately before starting

and maneuvering has been declared a must.

. Vehicle must be parked in reverse direction.

. Driving

policy.

. GCM.

. Stop vehicle at safe place.

. Competent driver.

. In foggy weather if vision is slightly clear then reduce the

speed limit to half of design speed.

. Immediately report to Radio room.

. Use 4 x 4 vehicle.

. Use of head light in foggy / rainy condition.

. Heavy vehicle is not allowed to move during rain and

foggy weather.

. Vehicle check list

. Wait till the weather gets normal and avoid to rush.

. Professional driver should be used.

. Avoid un-necessary movement.

. PTW.

. GCM

. ERP

. Procedure.

. Prohibited.

. Lightning arrangement

. Permission CTL.

. Proper illumination.

. Lights.

. PTW.

. GCM

. ERP

. Procedure.

. Prohibited.

. Bell holes are made prior to excavation and reliance on

production / maintenance for information.

. Area cordon off.

. Follow Route marker.

. Cable detector used inside facility.

. Fire Drill.

. Ensured appropriate/ right kind of tools and equipment

are used for excavation.

. Stand by Vehicle.

. Safety Watch.

. First aid box.

. Fire watchman.

. Medic man.

. Fire extinguisher.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

26

27

Hydro Testing

Gas Cylinder

Handling &

Transportation

. Improper Anchoring

. High Pressure

. Rupture

. Environmental

Damage.

. Use of Machinery.

. Snake bite.

. High Pressure

. rupture

. Improper Storage

. Fire

. Enviromental Damage

. Unbranded cylinders.

. Leakage.

. Mis-Handling

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment .

Controls

Action to be taken

Describe Action.

Date: 20-Mar-2004

. PTW.

. GCM

. ERP

. Procedure.

. Prohibited.

. Area Cordoned Off.

. Proper Anchoring.

. Use appropriate rating assembly for Hydro-Testing .

. Approved Hydro Testing Procedure.

. No Entry for Unauthorized Persons.

. Make sure proper tightening.

. Testing Pressure As per Code & Piping Specification.

. Valid Equipment Check List.

. Approved hydro test package.

. All Inline Valve should be in open position.

. High Vent Point Air Removal.

. Approved Water.

. Joint Should be Exposed for inspection.

. Testing Recorder Should be Calibrated.

. Air Blowing Before & After Hydro Testing.

. Make Sure Filling Point Should Low Elevated.

. Use of rupture disc during Air blowing.

. Procedure implementation

. PTW.

. GCM

. Procedure.

. Prohibited.

. Keep Cylinders In Vertical Position.

. Dont Keep near any Flammable, Fire Catching

Substances.

. During transportation keep in vertical position and should

be Properly Tightened.

. Fix Cylinder Cap.

. Always Keep In Separate and safe distance & Dont mix

with each Other.

. Should be Properly Painted As per Color Coding.

. Always Keep In Shed.

. Make sure tightening with proper tool to avoid Leakage.

. Check All Threads and Nozzle for leakage..

. Install sign boards.

. Use Approved And As per Standard Cylinder.

Residual Risk.

Resources

HE

. PPE.

. Calibrated PSV &

PI.

. Safety Watch.

. FAB.

. Snake bite kit.

. Warning Sign.

. Stand by Vehicle.

. Skilled manpower.

. Medic.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

. Sparks

. Chipping

. Un trained persons

. Injuries.

. High temperature.

. Current.

. Shock.

. Abrasive wheel.

. Equipment damage

. People.

. Equipment.

. Facility.

. Environment .

28

Fabrication

29

. Under ground utility

lines can get struck while

performing

the

floor

demolishing job inside

the facility.

Jack Hammering.

. Use of machinery.

(Inside or outside the . Splash of concrete.

facility)

. Hit.

. Spark.

. Electric shock.

. Improper use of

equipment.

. Chisel breakage.

. People.

. Equipment.

. Facility.

. Environment .

30

. Falling of load,

. Damage to adjacent

equipment,

. Sparks,

. Fire Explosion,

Dismantling Of

. Mishandling,

Equipment/Manual/M

. Breaking,

ech

. Failure of Lifting Gears

or equipment

. Miscalculation of weight

or underestimation.

. Pressure.

. People.

. Equipment.

. Facility.

. Environment .

Controls

Action to be taken

Describe Action.

Date: 20-Mar-2004

Residual Risk.

Resources

HE

. PPE

Screen.

Fire extinguisher

Stand by vehicle

First aid box

. PTW.

. GCM

. Procedure.

. Prohibited.

. Follow the route markers.

. Area cordon off.

. Fire Drill.

. Awareness of muster point

. Equipment check list.

. Proper as built of all under ground utility lines.

. Required proper Check List format of jack hammer.

. Use of detector should be introduced.

. Ensure the Route marker availability out side the facility.

. Use of Fire Proof Tarpaulin Sheet / Fire Retarder (Inside

the facility)

. Physical fitness of equipment operator.

. Safety Watch.

. Stand by Vehicle.

. Fire watchman.

. Medic man & First

aid box.

. Fire extinguisher.

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

. Energy

Isolation.

. Area cordon off.

. Equipment check list.

. Certified Slings,

. Certified Crane,

. Brass Hammers,

. Proper Rigging Plan.

. Third Party certified persons,

. Standby- Vehicle.

. FAB.

. Medic.

. Slings.

. Crane.

. PTW.

. GCM

. Procedure.

. Prohibited.

. Certified and approved persons

. Equipment checklist

Gas test

Screening.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

31

32

Material storage at

site

. Improper placement.

. Fall

. Open ends

. Improper stacking

. Uncovered congestion

. Improper lifting gear

. MSDS

. Over stacking

. Dust .

Excavation

(Manually/

Mechanical)

. under ground Utilities

lines can get struck while

performing the

excavation inside facility.

. Fire

. Electric shock.

. High Water Table.

. Collapse

. Under ground Utilities.

. Deep excavation

. Oxygen deficiency.

condition.

. Working in depth.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment.

Controls

Action to be taken

Describe Action.

Date: 20-Mar-2004

Residual Risk.

Resources

HE

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

. Certified manpower.

. All pipes and fitting should be with stopper.

. Area should be cordoned off

. Hazards Material should be marked And Isolated

. Material should be covered from rain & dust

. Easy access of movement for loading off loading

. Material should be elevated from ground level.

. Racks.

. Fix end caps where its required

. Shelfs.

. Fitting ,Valves & instruments should be placed in side

. Tarpaulins.

the container or storeroom

. Flammable material, Chemical & high Pressure Material

should be placed at safe & specified area

. Sensitive items, polyken tape ,heat shrink sleeve, epoxy

coating , paint & electronic equipment should be placed in

cold storeroom

. Availability of MSDS.

12

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

. Follow the route marker.

. Area cordon off.

. Use of cable detector.

. Equipment Check List.

. Remove soil/ stock pile material maximum away from

edge.

. Steps , Slop , Shoring after 4' depth as per soil condition.

. Bell holes.

. Safety watchman.

. Cable detector.

. Medic.

. Bell holes.

. F.A.Box.

. Fire extinguisher.

. Fire watch man.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

PIPE LINE

33a (Mobilization)

Transportation of

personels.

. Transportation of

equipment.

. Haulage of line pipes.

Loading / off loading

Hit and fall

Use of machinery

Over speeding

. Over load / insecure

material

33b

. Equipment stucking.

. Handling of culvert

pipe.

. Roll over due to uneven

ground.

PIPE LINE

. Use of machinery.

(Preparation of ROW.) Environmental hazard.

Roll over due to un

even ground

. Snake and other

reptiles.

. Use of machine.

33c

PIPE LINE

(Stringing)

. Fall of pipe.

. Roll over.

. Hit.

. Lifting operation.

. People.

. Equipment.

. Facility.

. Environment.

. People.

. Equipment.

. Facility.

. Environment.

. People.

. Equipment.

. Facility.

. Environment .

Date: 20-Mar-2004

Action to be taken

Controls

Describe Action.

Residual Risk.

Resources

HE

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

Route survey

. Condition of road / ROW.

Verified equipment check list.

Certified equipments, lifting gears and manpower

. Speed limits.

. Proper securing of load.

. Certified eqpt.lifting gears and all M/P.

PPE.

. Drive right.

Safety supervisor

First aid box.

Look out.

Emergency stand

by vehicle.

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

Minimum removal of trees

Verified equipment check list

Certified M/P

. Area barricade.

. Speed limit.

. PPE

Snake bite kit

First aid box.

Look out

. Safety supervisor.

Emergency stand

by vehicle.

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

PPE

. Look Out.

. FAB.

. Safety supervisor.

Certified eqpt.lifting gears and all M/P

Use of tag line.

Proper rigging procedure

Verified check list.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

33d

Use of machine.

Welding light.

Spark.

Burn.

PIPE LINE (Welding)

Toxic gases.

Roll over welded.

segments.

. Hit / strike.

. People.

. Equipment.

. Facility.

. Environment.

Controls

Action to be taken

Describe Action.

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

Date: 20-Mar-2004

Residual Risk.

Resources

Emergency stand

. Valid check list.

by vehicle.

Proper welder's kit.

. First aid box.

Proper support to hold the welded segments.

PPE

Skill and certified manpower.

. Gas test in facility.

. Fire

. Avoid excessive exposure at high temperature.

extinguishers.

. Proper house keeping to be ensure after completion of . Fire watch.

job.

. Gas detector.

HE

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

PIPE LINE

33e (Radiography)

. Radiation exposure

. Over dose

. Property loss

. Ionizing radiation

. Vomiting

. Nausea

. Paleness

. Loss of hairs

. Loss of appetite

geneses

. Damage of

. People.

. Equipment.

. Facility.

. Environment.

Controls

Date: 20-Mar-2004

Action to be taken

Residual Risk.

Describe Action.

Resources

HE

. Source under lock and key.

. Personal Monitoring.

. Area monitoring / Cordon Off.

. Camera in lead box and lead box in the trunk of vehicle.

. Vehicle valid check list.

. Maintain daily and monthly dose record through film

badge.

. Personal monitoring through dosi meter.

. Cordoned off radiation zone through radiation warning

sign.

. Continuous radiation monitoring with the help of survey

meter.

. Reduce radiation exposure.

. Retract source back to container.

. Spare container.

. DDT qualified driver

. Handling and transportation to be performed as per BPP

standing instructions.

. Radiation dose records keeping.

. PPE

. Certified Personel

(level II ASNT)

. Dosi meter.

. Survey meter.

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

33f

33g

33h

PIPE LINE

(Installation of Heat

shrink sleeve)

. Fire due to mis

handling of methane gas

torch.

. Explosion due to miss

handling of methane gas

cylinder/ torch.

. High temperature.

. Body burning due to

contact to hot surface.

PIPE LINE

(Excavation of line

pipe trench)

. Excavation more than

4' deep

. Use of machine.

. Slip

. Critical soil condition

. Hand tools

. Collapse

. Cave in

. Sand boiling

. High water table.

. Snake bite.

PIPE LINE (Holiday

detector test)

. Electric shock

. Spark

. Fire

. Mishandling

. People.

. Equipment.

. Facility.

. Environment.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment .

Controls

Action to be taken

Describe Action.

Date: 20-Mar-2004

Residual Risk.

Resources

. Fire extinguisher

. Certified Sleeve

man

. certified fire watch

man

. First aid box

. Emergency stand

by vehicle.

. Pyro-meter.

HE

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

.Segregation.

. PPE (as per requirement)

. Valid check list

. Screening

. Installation Procedure.

. Propane gas for required temperature.

12

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

. Skilled and competent persons

. Equipment valid check list

. Benching / Slopping / Shoring

. Elevated ground condition

. Dewatering.

. Excavated soil should be placed at least 2' away from

edge of the trench.

. Look out with

whistle.

. First aid box.

. Emergency stand

by vehicle

. Snake bite kit.

. PPE.

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

. Segregation

. PPE (as per requirement).

. Experienced and competent equipment operator.

. Equipment calibration.

. Proper grounding as per procedure.

. Close monitoring of the segments.

. Ensure electrical insulation.

. Equipment check list.

. Fire extinguisher

. Certified fire

watch man

. First aid box

. Emergency stand

by vehicle

. Certified safety

watchman

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

33i

. Use of machinery

. Fall, hit and roll (pipe

segments)

PIPE LINE (Lowering

. Heavy wind

of Pipe line

. Invisibility

segments)

. Inadequate ground

condition.

. Lifting operation.

33j

PIPE LINE (Tie-In)

. Use of machine

. Spark

. Improper trench

. Heavy wind

. Invisibility

. Deficiency of oxygen

. Collapsing of side walls

. Cave in.

. Lifting operation.

33k

PIPE LINE (Back

Filling)

. Use of machine

. Slip

. Critical soil condition.

. Snake bite.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment.

. People.

. Equipment.

. Facility.

. Environment .

Controls

Date: 20-Mar-2004

Action to be taken

Describe Action.

Residual Risk.

Resources

HE

. Equipment certified documents.

. Certified lifting gears and manpower.

. Equipment valid check list..

. Implementation of lowering procedure.

. Look out

. First aid box

. Emergency stand

by vehicle

. certified safety

watchman.

. PPE

. Skilled and

certified personals

12

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

. Segregation

. Gas test

. Valid equipment check list

. Certified equipment and lifting gears

. Skilled and certified personals

. Shoring /stepping/slopping

. Tie in Procedure

. Emergency stand

by vehicle

. First aid box

. Certified Medic

. PPE

. Gas tester.

. Certified fire

watchman

. Certified safety

watch

. Look out

. Shoring plates.

. GCM

. Procedure.

. Prohibited.

. ERP.

. Valid equipment check list

. Certified and competent persons.

. Elevated ROW condition.

. Back filling procedure.

. Employment of proper equipment.

. Look out.

. Snake bite ket.

. PTW.

. GCM

. Procedure.

. Prohibited.

. ERP.

. Segregation

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

33l

PIPE LINE (Pigging)

. High Pressure

. Rupture / Fire

. Enviromental Damage

. Improper Connection.

. Stuck

. Improper anchoring

. Mishandling of

Temporary Pig receiver

and Launcher.

. Short bolting.

. Use of machine.

. People.

. Equipment.

. Facility.

. Environment.

Controls

Action to be taken

Describe Action.

. GCM

. Procedure.

. Prohibited.

. ERP.

Date: 20-Mar-2004

. Adequate piping class & fittings.

. Proper tightening & adequate gaskets.

. Adequate Stud bolt sizes.

. Equipment Should be with Valid Check List

. Proper Connections.

. During pigging communication source should be at both

end.

. Install certified pig receiver and launcher at both ends.

. Line should be properly anchored

. RT & PT should be clear before pigging

. Area should be cordoned off.

. Depute Safety & fire Watch man

. Un authorize personnel are not allowed in working area

. Receiving end vent valve should be in open position

. Warning sign board should be installed at both ends at

appropriate locations.

. Pig indicator should be mounted at Pig receiver &

launcher.

. Before pigging water filling as required.

. Water disposal arrangement.

Residual Risk.

Resources

. Emergency

Vehicle

. Warning sign

board.

. Stand by vehicle

at both end.

. PPE.

. Medic with first

aid kit at both

ends.

HE

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

PIPE LINE (Hydro

33m static testing)

34

Thrust Bore.

. Improper Anchoring

. High Pressure

. Rupture

. Environmental

Damage.

. Use of Machinery.

. Snake bite.

. Deep excavation of

thrust boring pits

. Oxygen defeciency.

. Collapse

. Cave in

. Placement of boring

machine, track, shoring

plate and pipes

. Use of machinery.

. Snake bite.

. Hit and Fall.

. Open ditch.

. Inadequate alignment

or leveling.

. High water table.

. Lifting operation.

. Critical soil condition.

. People.

. Equipment.

. Facility.

. Environment.

. People.

. Equipment.

. Facility.

. Environment.

Controls

12

Action to be taken

Describe Action.

. GCM

. Procedure.

. Prohibited.

. ERP.

. GCM

. Procedure.

. Prohibited.

. ERP.

Date: 20-Mar-2004

. Area Cordoned Off.

. Proper Anchoring.

. Proper Rating Hydro Testing Assembly.

. Approved Hydro Testing Procedure.

. Depute Safety Watch.

. No Entry for Unauthorized Persons.

. Make sure proper tightening of all the bolt.

. Skilled manpower.

. Testing Pressure As per Code & Piping Specification.

. Valid Equipment Check List.

. Approved hydro test package.

. All Inline Valve should be in open position.

. High Vent Point Air Removal.

. Approved Water.

. Testing Recorder Should be Calibrated.

. Ensure implementation of procedure.

. Air Blowing Before & After Hydro Testing.

Residual Risk.

Resources

HE

. PPE.

. Calibrated PSV &

PI.

. Stand by Vehicle.

. FAB.

. Snake bite kit.

. Medic.

. Warning Sign

boards.

. Approved profile of pit

. Slopping, benching and shoring

. Valid equipment check list

. Surveyor.

. Certified lifting equipment and lifting gears

. Leveling machine.

. Certified Personals

. Look out.

. Dewatering

. Warning sign

. House keeping

. Proper barricade

board.

. Tag line to avoid swing

. Snake bite kit.

. Certified Safety watch

. First aid box.

. Experienced and competent Thrust bore supervisor and . Night watchman.

workforce

. PPE.

. Approved rigging plan.

. Approved Thrust bore procedure.

. Gas / oxygen test.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

35

36

37

Survey Work

. Improper handling /

placement of instrument.

. Carelessness about

vehicular traffic.

. Slip from slopes.

. Stuck in soft soil.

. Harsh weather ( hot,

sunshine)

. Marshy/ wet area.

. Thick bushes.

. Snake/ poisonous

insect bite.

. Local cultural

sensitivities.

. Getting stranded.

. Snake bite.

. People.

. Equipment.

. Facility.

. Environment.

Temporary ladder /

Hand rail.

. Improper and

inadequate ground

condition.

. Slip and fall

. Failure of structure.

. People.

. Equipment.

. Facility.

. Environment .

Working at Height.

Trip and fall

Fall of object from

height

Unbalanced structure

Loose members and

planks.

Heavy wind.

. Over load on scaffold.

Inadequate design of

scaffold.

. People.

. Equipment.

. Facility.

. Environment.

Controls

Action to be taken

Describe Action.

Date: 20-Mar-2004

Residual Risk.

Resources

HE

. GCM

. Procedure.

. Prohibited.

. ERP.

. Check ground condition.

. Proper placement of instrument.

. F.A.Box.

. Signal man guiding traffic.

. Snake bite kit.

. Try to minimize exposure.

. Communication.

. Medic Man.

. Proper rest to avoid dehydration.

. Umbrella for surveyor if survey to be done by equipment.

. Awareness of local cultural sensitivities.

. GCM

. Procedure.

. Prohibited.

. ERP.

. Place ladder at proper ground

. Ladder should be place at approprite angle to avoid slip.

. Guard rail ( If required).

. Proper barricade

. House keeping.

. Inspection of Structure.

. PPE

. Certified Safety

watch

. First aid box

. Emergency stand

by vehicle

. GCM

. Procedure.

. Prohibited.

. ERP.

.Segregation

. Barricade the area..

. Anchoring point preferably at top ( For saafety harness).

. Scaffolding check list & tagging.

. Ensure implementation of procedure.

. Competent person to certify scaffolding.

Full body harness with shock absorber.

Proper anchoring.

Tool kit belt.

PPE (full body

harness)

Emergency stand

by vehicle.

. FAB.

. Certified safety

supervisor.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

38a

energy isolation

(outside) fence

{Repair of Pipe line

leakage }

energy isolation

38b (outside) fence

{Electrical work }

39

Identification of unrecognized confined

space (Chimney,

cellar pipe, Stack , Pit

, Basement , Unventilated room ,

Excavation more

than 4 feet where

Oxygen contents less

than 21%)

. Damage of property

. Injury

. Fire

. Environment

. Shock

. Burn

. Fire

. Explosion

. Property loss.

. Explosion

. Suffocation.

. Excess temperature.

. Slip.

. Poor Vision.

. Toxic Gases.

. People.

. Equipment.

. Facility.

. Environment.

. People.

. Equipment.

. Facility.

. Environment.

. People.

. Equipment.

. Facility.

. Environment .

Controls

Date: 20-Mar-2004

Action to be taken

Residual Risk.

Describe Action.

Resources

HE

. GCM

. Procedure.

. Prohibited.

. ERP.

. Double block & bleed system,

. Valves closed locked & tagged by authorized person.

. Gas test before starting of job.

. Area cordoned off.

. Stored energy released,

. Removal and disposal of contaminated soil.

. Ensure awareness for procedure implementation.

. Arrange double block and bleed system where not

available.

. Ensure application of environmental protection protocols.

PPE.

Emergency stand

by vehicle.

. FAB.

. Certified safety

supervisor.

. GCM

. Procedure.

. Prohibited.

. ERP.

. Specified circuit breakers should be off.

. Tagged and locked by authorized person.

. Certified electrician.

. Specific gloves.

. Communication.

PPE.

. Certifed

manpower.

Emergency stand

by vehicle.

. FAB.

. Safety supervisor.

. GCM

. Procedure.

. Prohibited.

. ERP.

. Oxygen test

. PTW issuance by authorized person

. Adequate lighting.

. Committed communication.

. Gas test.

. Use of gum boots (in case of sludge inside vessel).

. Maintaining of log book.

. Confined space

attendant

. Self breathing

apparatus

. Blower / Exhaust

fan

. Life line

. PPE

. Stand by vehicle.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

40

41

. High Pressure

. Rupture / Fire

. Enviromental Damage

. Improper Connection.

. Stuck

Pigging of pipe lines . Improper anchoring

. Mishandling of

Temporary Pig receiver

and Launcher

. Short bolting

. Use of machine

Shoring of Deep

Trenches

. Existence of Under

ground utility lines.

. Improper use of

equipment/ tool.

. Soil collapsing.

. High water table.

. Inadequate support.

. Working at depth.

. Confined space.

. Use of machinery.

. Hit / Fall / Slip.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment .

Controls

Date: 20-Mar-2004

Action to be taken

Residual Risk.

Describe Action.

Resources

HE

. GCM

. Procedure.

. Prohibited.

. ERP.

. Adequate piping class & fittings.

. Proper tightening & adequate gaskets.

. Adequate Stud bolt size.

. Equipment Should be with Valid Check List.

. Proper Connection.

. During pigging Communication Should be At both end.

. Stand by vehicle at both end.

. Install certified pig receiver and launcher at both ends.

. Line should be properly anchored.

. RT & PT should be clear before pigging.

. Area Should Cordoned Off.

. Depute Safety & fire Watch man.

. Un authorize personnel are not allowed in working area.

. Receiving end vent valve should be in open position.

. Warning sign board should be installed at both on

appropriate locations.

. Pig receiver & launcher should be pig indicator mounted.

. Before pigging water filling as required.

. Water disposal arrangement.

. Warning sign

board.

. PPE

. Medic with first

aid kit at both end.

. Stand by vehicle.

. GCM

. Procedure.

. Prohibited.

. ERP.

. Follow the route markers.

. Area cordon off.

. Equipment checklist

. Cable/ pipe detector used inside facility.

. Follow confined space entry procedure.

. Competent operator.

. Use of gas detector.

. Safety Watch.

. Stand by Vehicle.

. Fire watchman.

. Medic man & First

aid box.

. Fire extinguisher.

RISK ASSESSMENT

TASK RISK ASSESSMENT FORM

TASK TITLE: TRA for Defined activities.

Location : XXXXXXXXX

Risk Evaluation

Sr.#

Distinct Activity

Hazard

Hazard

Effect.

(Refer to Evaluation

Form)

HE

42

44

45

. Sparks

. Chipping

. Un trained persons

. Injuries.

Drilling /Grinding and

. High temperature.

cutting at site

. Current.

. Shock.

. Abrasive wheel.

. Equipment damage

Pulling of Stuck

Equipment.

Mobilization

demobilization.

. Improper signals during

operation.

.Breaking Or Damaging

& shackle and tow hook.

. Hit.

. Environmental

Hazards.

. Fire ignition.

. Pedestrians.

. Animal Carts.

. Poor Vision.

. Slippery road.

. Narrow path.

. Blind turning.

. Over speeding.

. Equipment failure.

. People.

. Equipment.

. Facility.

. Environment .

. People.

. Equipment.

. Facility.

. Environment.

. People.

. Equipment.

. Facility.

. Environment.

Controls

12

Action to be taken

Describe Action.

Date: 20-Mar-2004

Residual Risk.

Resources

HE

. GCM.

. PTW.

. Procedure.

. Prohibited.

. ERP.

. Certified and approved persons

. Equipment checklist

Gas test

Screening

Gas detector.

Screen.

Fire extinguisher.

Emergency stand

by vehicle.

First aid box.

. PPE.

. GCM

. Procedure.

. Prohibited.

. Certified Sling & shackles.

. Valid Check list.

. Slow operation during pulling.

. Proper handling of sling.

. Traffic control during operation.

. No person could stand near equipment during pulling.