Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Reserves

Caricato da

Mohanad Hussien0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni3 pagine'Docslide.us Wireline Logsdocx

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documento'Docslide.us Wireline Logsdocx

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni3 pagineReserves

Caricato da

Mohanad Hussien'Docslide.us Wireline Logsdocx

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

AS D-1 August 05, 2014

RIG AS D.1 Reserves to do before SPUD next Location

.Rig is very well equiped, some shortage of simple items

The major part of the NPT is due to the shortage of spear Parts,

.requested since but without Feed back

:Below some remarques

:Rig Floor

:Stand Pipe Must be equiped by

. Gauge 5 000 Psi .HP Fill up Line ''2 Pressure Sensors well functioning ( Lot NPT) The Hose used is for TDS, not adapted for the Kelly ( So

.long, encombrement, difficulte to store Kelly)

The second Hose is not in place, if any probleme, we haven't

.another way to circulate

,TDS Down, electric cable problem

Kelly Without Kelly Spiner ( 45 mn are the average

.connection time)

.Kelly Saver Sub Without Well Head Protector

,Power tong to be repaired or changed (No Spare parts)

,Back up Manual tong on Rig Side not available

DP Slips to repair ( no Dies ??)

Cat Head '' Easy Torque'' Wire Line to replace.- Done

: Rotary Table

High Torque, While drilling, no Difference

between off botom and on botom

Last test gave a High Torque and Less RPM (Probleme to

.Fixe)

Can be due to non Conventioaal DP 5 1/2 used

.Kelly Bushing to open and verify the roulements

:Mast

.Must to be well centralised/ Rotary table & Well head

,Derrickman Escape to install

Stop chute to instal

:Mud Pumps

Impossible for the Driller to change the selection without

Electrician intervention on SCR ( need to be

checked by

.a specialist)

:Must be equiped by

.Right pressure relief valve easy to check and reset *

Gage 5 000 Psi well functonning, ( MP 2 & 3 actually out *

of service)

Gage for the Azote pre charge '' Pulsation Dampener'' (MP *

,1 not Exist, MP 2& 3 to verify)

.Fixe Mud Pump HP lines corectly to the substructure *

:Mud Tanks

Mud System: Not Working

Rig is equiped by complete solid control system,

:unfortunatly

Mud Cleaner not well functionning Vibration Motor &

Cones

,Desilter no Cones to replace

.Centrifuge High Speed Functioning to check

.Sand Trap has to be easy Open/ Close valve

:General

Flare line to be extented

Fixed cementing line/ Walk Way

.Mud line for Cementing Unit

.Need more Light Around the Location

Coordination/ Communication between the differents service

:companies

.Driller/Mud Engineer & Mud Logging

,Shortage of the Personnal

.Personnel some time stay more than 2 Months

Accomodation to be performed, many claims from the

.personnel

Supervisor Office: Desk and Chairs to replace Need Waching

machine

:HSE

Chock Panel not connected Flexible

Chock Manifold Valves & Manual Chock difficulties to

manipulate (Bloqued)

,Location need to be cleaned, avoid oil in cellars

,Safety equipments to be used

,Cars without Speed Limit & Radio

.Walky Talk & batteries chargers Out

Stop to use the Mobils in Rig Floor/ an Habit used also by

.Drillers

.Ajust the Pressures on Koomey & control Panel

.All valves HP & LP has to be tested befor next Spud

.''DP 5 1/2 to avoid in 8 1/2 section- to replace by 5

Potrebbero piacerti anche

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- U6OHREPORT2008Documento89 pagineU6OHREPORT2008Anonymous pKsr5vNessuna valutazione finora

- Troubleshooting Boiler OperationDocumento5 pagineTroubleshooting Boiler OperationRahul ChandrawarNessuna valutazione finora

- 2nd TA Modification Work List Rev1Documento71 pagine2nd TA Modification Work List Rev1Vy NguyenNessuna valutazione finora

- Ahmed A'Nasser Handover 22 November PDFDocumento3 pagineAhmed A'Nasser Handover 22 November PDFmohamed hamedNessuna valutazione finora

- Ahmed A'nasser Hitch ReportDocumento3 pagineAhmed A'nasser Hitch Reportmohamed hamedNessuna valutazione finora

- Monthly Report: OOS Gretha: OR Oskar Savo October 2016Documento11 pagineMonthly Report: OOS Gretha: OR Oskar Savo October 2016Legend AnbuNessuna valutazione finora

- Delay in Opening of LP Bypass ValveDocumento94 pagineDelay in Opening of LP Bypass ValveCharu ChhabraNessuna valutazione finora

- CPP Equipment HistoryDocumento97 pagineCPP Equipment HistorychuminhNessuna valutazione finora

- Eng - Report 10.04.2013Documento41 pagineEng - Report 10.04.2013Shivraj GurjarNessuna valutazione finora

- Handover Notes: Site / Place of Handover Department / Service From Date / Time To CCDocumento3 pagineHandover Notes: Site / Place of Handover Department / Service From Date / Time To CCandi dipayadnyaNessuna valutazione finora

- HP Breech Nut OpeiningDocumento10 pagineHP Breech Nut OpeiningG G K MURTHY100% (1)

- Steam Turbine OutageDocumento18 pagineSteam Turbine OutageNida AliNessuna valutazione finora

- Design Challenge: External Pipe Climbing DeviceDocumento4 pagineDesign Challenge: External Pipe Climbing Deviceazeem sheikhNessuna valutazione finora

- Aug 2011Documento31 pagineAug 2011Basudev PatraNessuna valutazione finora

- Presentation On NSTPS VISITDocumento46 paginePresentation On NSTPS VISITACHAL AGRAWALNessuna valutazione finora

- Pradeepthi Enviro Engineers: WORKS: B-1, Block-B, Industrial Estate, Auto Nagar, Visakhapatnam-530018Documento4 paginePradeepthi Enviro Engineers: WORKS: B-1, Block-B, Industrial Estate, Auto Nagar, Visakhapatnam-530018Raju KandivalasaNessuna valutazione finora

- Date, MAR: Event Analysis ReportDocumento2 pagineDate, MAR: Event Analysis ReportSE ESTNessuna valutazione finora

- Time Management Optimization For Senior TechniciansDocumento21 pagineTime Management Optimization For Senior TechniciansVinod KumarNessuna valutazione finora

- Parco Maintenance ProcessDocumento12 pagineParco Maintenance ProcessSohaib Ur-rehmanNessuna valutazione finora

- May 12Documento33 pagineMay 12dillipsh123Nessuna valutazione finora

- Jun12 PDFDocumento30 pagineJun12 PDFSreekanthMylavarapuNessuna valutazione finora

- MMD Monthly Report November 2019Documento5 pagineMMD Monthly Report November 2019biranchi satapathyNessuna valutazione finora

- Unit withdrawn due to BTL in ReheaterDocumento2 pagineUnit withdrawn due to BTL in ReheaterSE ESTNessuna valutazione finora

- Morning MeetingDocumento5 pagineMorning MeetingFazalur Rehman BabarNessuna valutazione finora

- 300E Airflow Sensor ReplacementDocumento2 pagine300E Airflow Sensor ReplacementDharmin DslrNessuna valutazione finora

- Final AOH Report - TMD 060818Documento15 pagineFinal AOH Report - TMD 060818sanmukhaNessuna valutazione finora

- AG-101 Frac Design Proposal V2Documento30 pagineAG-101 Frac Design Proposal V2ayman morsyNessuna valutazione finora

- Delphi HP Pump DiagnosisDocumento38 pagineDelphi HP Pump DiagnosisИгорь Ясюк100% (1)

- Drill String Stuck HF121-M121D2Documento17 pagineDrill String Stuck HF121-M121D2ahmedNessuna valutazione finora

- Transformer FailureDocumento66 pagineTransformer FailureLammie Sing Yew Lam100% (1)

- Fluid Machinery - Eng - Pump - Part2 (Compatibility Mode)Documento65 pagineFluid Machinery - Eng - Pump - Part2 (Compatibility Mode)ณัฐวัศ มั่นบุญสมNessuna valutazione finora

- How To Start Combined Cycle Power PlantDocumento37 pagineHow To Start Combined Cycle Power PlantBv Rao100% (1)

- QAP For Flow MeterDocumento7 pagineQAP For Flow MeterhiyogsNessuna valutazione finora

- Coil TubingDocumento2 pagineCoil TubingMeghesh SamadhiyaNessuna valutazione finora

- 38000Documento2 pagine38000dinesh_mishra111yahoNessuna valutazione finora

- PRL-4 20.11.2013Documento2 paginePRL-4 20.11.2013SE ESTNessuna valutazione finora

- Event Analysis Report for 210 MW Unit at Parli-V StationDocumento2 pagineEvent Analysis Report for 210 MW Unit at Parli-V StationSE ESTNessuna valutazione finora

- 1 - Hand Over A.Scarpete SurvilleDocumento9 pagine1 - Hand Over A.Scarpete Survillealex.verdzadze98Nessuna valutazione finora

- O Ffis:Chandrapursuperthermalpowerstationunitcapacity:500Mw: SuoolvDocumento2 pagineO Ffis:Chandrapursuperthermalpowerstationunitcapacity:500Mw: SuoolvSE ESTNessuna valutazione finora

- Ele. Daily ReportDocumento57 pagineEle. Daily ReportDhilip AnNessuna valutazione finora

- CHD-6 12.02.2015Documento2 pagineCHD-6 12.02.2015SE ESTNessuna valutazione finora

- # AhpDocumento21 pagine# AhprahulNessuna valutazione finora

- Downhole Blowout PreventerDocumento8 pagineDownhole Blowout Preventernjava78Nessuna valutazione finora

- SL Short Term Action Plan Responsibility: Eps (Iron)Documento10 pagineSL Short Term Action Plan Responsibility: Eps (Iron)Abhishek KukrejaNessuna valutazione finora

- 05 RDK 4Documento46 pagine05 RDK 4partha6789Nessuna valutazione finora

- Experiment No 1 Trial On Vane PumpDocumento9 pagineExperiment No 1 Trial On Vane PumpvishalNessuna valutazione finora

- Hand Over 4 22Documento2 pagineHand Over 4 22Ahmed AlwakeelNessuna valutazione finora

- BoilerDocumento6 pagineBoilersaravan1891Nessuna valutazione finora

- U#1 Aoh Major Jobs Planned: A Boiler MaintenanceDocumento7 pagineU#1 Aoh Major Jobs Planned: A Boiler Maintenanceanil peralaNessuna valutazione finora

- HANDOVER NOTESDocumento3 pagineHANDOVER NOTESandi dipayadnyaNessuna valutazione finora

- Weekly Maintenance Plan April 28 To May 4,2012Documento6 pagineWeekly Maintenance Plan April 28 To May 4,2012vgnapaNessuna valutazione finora

- 2 September ReportDocumento9 pagine2 September ReportAli AhmadNessuna valutazione finora

- Mechanical Punch ListDocumento30 pagineMechanical Punch Listramakrishna100% (2)

- States of Factory Equipment TodayDocumento3 pagineStates of Factory Equipment TodayUmar DarNessuna valutazione finora

- 727 904 Tech NotesDocumento0 pagine727 904 Tech NotesSerdar AsNessuna valutazione finora

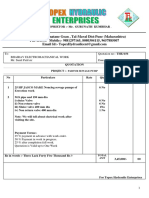

- Jalana Quotation QN-THE156Documento1 paginaJalana Quotation QN-THE156Rujuta kemkar MsebNessuna valutazione finora

- Game plan to complete well and perforate intervals in Meleiha areasDocumento3 pagineGame plan to complete well and perforate intervals in Meleiha areasMohammed Ali YoussefNessuna valutazione finora

- Work Over RigDocumento28 pagineWork Over RigbvkvijaiNessuna valutazione finora

- Oil 2014 105 120Documento16 pagineOil 2014 105 120raifelmbNessuna valutazione finora

- Ultra ISOPremium 9 RDocumento1 paginaUltra ISOPremium 9 RMohanad HussienNessuna valutazione finora

- Choose Between Long-Stroke Sucker Rod Pumping Systems.: September 2015Documento5 pagineChoose Between Long-Stroke Sucker Rod Pumping Systems.: September 2015Mohanad HussienNessuna valutazione finora

- KeysDocumento1 paginaKeysMohanad HussienNessuna valutazione finora

- PETE402 FinalDocumento2 paginePETE402 FinalMohanad HussienNessuna valutazione finora

- New Microsoft Excel WorksheetDocumento1 paginaNew Microsoft Excel WorksheetMohanad HussienNessuna valutazione finora

- Vision - Brain RulesDocumento1 paginaVision - Brain RulesMohanad HussienNessuna valutazione finora

- Basic SurveillanceDocumento20 pagineBasic SurveillanceMohanad HussienNessuna valutazione finora

- Basic Surveillance: Using Pressure-Transient Data To Monitor Well & Reservoir PerformanceDocumento25 pagineBasic Surveillance: Using Pressure-Transient Data To Monitor Well & Reservoir PerformanceEkpenyong OkpoNessuna valutazione finora

- Hts LogDocumento1 paginaHts LogMohanad HussienNessuna valutazione finora

- Impact 1Documento1 paginaImpact 1Mohanad HussienNessuna valutazione finora

- ApplyDocumento1 paginaApplyMohanad HussienNessuna valutazione finora

- What Is Fluid Intelligence? Can It Be Improved?Documento24 pagineWhat Is Fluid Intelligence? Can It Be Improved?Mohanad HussienNessuna valutazione finora

- Sec Booklet 2018Documento77 pagineSec Booklet 2018Mohanad HussienNessuna valutazione finora

- Dokumen - Tips - Petrel 20112 Release Notes PDFDocumento17 pagineDokumen - Tips - Petrel 20112 Release Notes PDFMohanad HussienNessuna valutazione finora

- Tips For Performance Schlumberger Petrel 2010-2011: Processor MemoryDocumento4 pagineTips For Performance Schlumberger Petrel 2010-2011: Processor MemoryMohanad HussienNessuna valutazione finora

- Ds 0174 Form BlankDocumento6 pagineDs 0174 Form BlankCristobal PerdomoNessuna valutazione finora

- Tips For Performance Schlumberger Petrel 2010-2011: Processor MemoryDocumento4 pagineTips For Performance Schlumberger Petrel 2010-2011: Processor MemoryMohanad HussienNessuna valutazione finora

- Basic Reservoir EngineeringDocumento26 pagineBasic Reservoir EngineeringMohanad HussienNessuna valutazione finora

- IRP 20 2015 FinalDocumento76 pagineIRP 20 2015 FinalMohanad HussienNessuna valutazione finora

- Canadian International Comparing Venezuelan and Canadian Heavy OilDocumento0 pagineCanadian International Comparing Venezuelan and Canadian Heavy Oilmartin_montana55_479Nessuna valutazione finora

- Tubular Make Up TorqueDocumento1 paginaTubular Make Up TorqueMohanad HussienNessuna valutazione finora

- ObamaDocumento10 pagineObamaMohanad HussienNessuna valutazione finora

- O o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o oDocumento6 pagineO o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o oMohanad HussienNessuna valutazione finora

- Europass MoazDocumento3 pagineEuropass MoazMohanad HussienNessuna valutazione finora

- Clarification of Rig D3 Desilter and Desander Spare Parts Request (MR No. 103)Documento4 pagineClarification of Rig D3 Desilter and Desander Spare Parts Request (MR No. 103)Mohanad HussienNessuna valutazione finora

- Oil Sands and Heavy Oil: Origin and Exploitation: Stephen R. Larter and Ian M. HeadDocumento7 pagineOil Sands and Heavy Oil: Origin and Exploitation: Stephen R. Larter and Ian M. HeadMohanad HussienNessuna valutazione finora

- Charles DickensDocumento9 pagineCharles DickensMohanad HussienNessuna valutazione finora

- Obama's Speech in CairoDocumento10 pagineObama's Speech in CairoMohanad HussienNessuna valutazione finora

- S1-S6 Recompletion & Repair ProgramsDocumento1 paginaS1-S6 Recompletion & Repair ProgramsMohanad HussienNessuna valutazione finora

- Using Electricity SafelyDocumento1 paginaUsing Electricity SafelymariaNessuna valutazione finora

- FG - BDER-78 Technical Catalogue - Technical - UNDocumento8 pagineFG - BDER-78 Technical Catalogue - Technical - UNAnh Le NgocNessuna valutazione finora

- As 4123.4-2008 Mobile Waste Containers Containers With Four Wheels With A Capacity From 750 L To 1700 L WithDocumento7 pagineAs 4123.4-2008 Mobile Waste Containers Containers With Four Wheels With A Capacity From 750 L To 1700 L WithSAI Global - APACNessuna valutazione finora

- Classification of FluidDocumento29 pagineClassification of FluidAbdur RehmanNessuna valutazione finora

- PHP AngularJS CRUD with Search and PaginationDocumento18 paginePHP AngularJS CRUD with Search and PaginationZaiful BahriNessuna valutazione finora

- Previews AGA XQ9902 PreDocumento6 paginePreviews AGA XQ9902 PreAldrin HernandezNessuna valutazione finora

- Establishing OPC UA Connectivity With Rockwell Automation® Integrated ArchitectureDocumento3 pagineEstablishing OPC UA Connectivity With Rockwell Automation® Integrated ArchitecturehuiyitNessuna valutazione finora

- Foxpro For O LevelDocumento3 pagineFoxpro For O LevelShiv PathakNessuna valutazione finora

- ApaveMare Training 2013Documento41 pagineApaveMare Training 2013fbarakaNessuna valutazione finora

- Revision of Bs 8002, 8004, AND 8081Documento34 pagineRevision of Bs 8002, 8004, AND 8081Rupesh Kaushik100% (1)

- 06-Fc428mar Water-in-Fuel Indicator Sensor Circuit - Voltage Above Normal or Shorted To High SourceDocumento3 pagine06-Fc428mar Water-in-Fuel Indicator Sensor Circuit - Voltage Above Normal or Shorted To High SourceSuryadiNessuna valutazione finora

- Hit-Re 500 With Hit-V Has RodsDocumento3 pagineHit-Re 500 With Hit-V Has RodsMKNessuna valutazione finora

- Microcontrolled Electromagnetic Engine: Atul Kumar Singh, Prabhat Ranjan TripathiDocumento4 pagineMicrocontrolled Electromagnetic Engine: Atul Kumar Singh, Prabhat Ranjan TripathiTarun SinghNessuna valutazione finora

- Leica 307 ManualDocumento4 pagineLeica 307 ManualRaluca Sandu100% (2)

- Achievements Under EpiraDocumento6 pagineAchievements Under EpiraLyn Dela Cruz DumoNessuna valutazione finora

- Que Dice Ese Gesto Descargar GratisDocumento2 pagineQue Dice Ese Gesto Descargar GratisjavierNessuna valutazione finora

- Method Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksDocumento16 pagineMethod Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksAn-an ChanNessuna valutazione finora

- 2022 Manufacture AnswerDocumento8 pagine2022 Manufacture AnswerChampika V SamarasighaNessuna valutazione finora

- Calgon Tech SpecDocumento4 pagineCalgon Tech SpecDanStratoNessuna valutazione finora

- Wire Rope Maintenance enDocumento12 pagineWire Rope Maintenance ensriabolfazlNessuna valutazione finora

- Technical Specifications: 12 V 18ah AGM 5 YearsDocumento2 pagineTechnical Specifications: 12 V 18ah AGM 5 YearsDaniel EspinozaNessuna valutazione finora

- WATCHDocumento9 pagineWATCHGANTORONessuna valutazione finora

- Heat Exchanger Systems en PPL 2015-03-01Documento59 pagineHeat Exchanger Systems en PPL 2015-03-01corneltincuNessuna valutazione finora

- LV12 - Drive Shafts - Issue 1Documento19 pagineLV12 - Drive Shafts - Issue 1Đức HòangNessuna valutazione finora

- Symfony 2 The BookDocumento354 pagineSymfony 2 The BookYamuna ChowdaryNessuna valutazione finora

- Assessment Clo1 Clo2 Clo3 Clo4 Clo5 Plo1 Plo2 Plo2 Plo1Documento12 pagineAssessment Clo1 Clo2 Clo3 Clo4 Clo5 Plo1 Plo2 Plo2 Plo1Ma Liu Hun VuiNessuna valutazione finora

- Estimating/ Construction Planning/ Scheduling and Programming/ Feasibility Project StudiesDocumento4 pagineEstimating/ Construction Planning/ Scheduling and Programming/ Feasibility Project StudiesVholts Villa VitugNessuna valutazione finora

- DEA R ScriptsDocumento3 pagineDEA R ScriptsFrancisco SilvaNessuna valutazione finora

- NPTEL Science and Technology of PolymersDocumento2 pagineNPTEL Science and Technology of PolymersAzhagiri PonNessuna valutazione finora