Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Coring Operation

Caricato da

Anonymous I5fzg8uc100%(2)Il 100% ha trovato utile questo documento (2 voti)

294 visualizzazioni11 paginereservoir engineering field

Titolo originale

1. Coring Operation

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoreservoir engineering field

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(2)Il 100% ha trovato utile questo documento (2 voti)

294 visualizzazioni11 pagineCoring Operation

Caricato da

Anonymous I5fzg8ucreservoir engineering field

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 11

CORING OPERATIONS

Definition

Obtain undisturbed samples of solid, fractured, or weathered rock

formations

Primary Importance, quantitative measurements of following :

Porosity - The volume of voids within a unit volume of rock.

Permeability - The quality of the connections between the voids.

Saturation - The composition of the fluids filling the voids.

Secondary importance is the additional information relating to:

Formation boundaries, large scale sedimentary structures,

undisturbed paleontological data, and the opportunity for

uncontaminated geochemical sampling.

Core Point Selection

Correlation with known marker in databases including seismic

data, correlation wireline/LWD , mudlogs with offset wells or any

other petro-physics related data.

Two types of coring operations

1. Conventional coring (at the time of drilling)

Use a core barrel attached to the end of a drill rod string

Rod string and core barrel assembly are removed after each

cutting run to recover the sample

The core barrel is emptied and returned to the borehole for the

next run

Two types of coring operation(contd)

2. Wireline coring

More efficient that Conventional Coring Systems

Use an outer barrel and a core casing

An inner barrel can be lifted through the drill string to the

surface

The inner barrel is lifted to the surface with a wire-line device,

then lowered back in

Coring Operations sequence

- Drilling pilot hole to determined starting coring point at

prognosis depth ( watch for drilling break or any gas show or

cutting if core start depth might come shallower than prognosis)

- Core point is reached the usual routine is to stop drilling, flow

check, circulate bottoms up and evaluate all the data available

(cuttings for lithology, porosity, oil shows, gas shows, drilling

exponents, ROP, torque, LWD logs -etc.) prior to making the

decision to trip out of hole to change with Coring Assembly.

Coring Operations Sequence (contd)

- Run in hole with Coring Assembly to core start depth circulate hole

and make sure inner barrels is clean start cut the core pull out of

hole with core. At this stage the trip out of hole speed is one of

considerations to make sure core is safe until it recovered.

- Some problems regardless of the sophistication of the coring

equipment, is hole problems, typical hole problems are :

Lost Circulation --- Kicks --- Sloughing Formations --- Doglegs /

well shape --- Stuck Pipe --- Unconsolidated Formations --- Junk -- H2S

Coring Operations Sequence (contd)

Example of real time problems that may occurs :

Rock mass surrounding borehole not self-supporting

(unconsolidated formations)

Protruding material in borehole (junk)

Small diameter, vertical boreholes are generally more stable

(doglegs and well shape)

Friable sandstone and solution channeled limestone or

dolomite are more susceptible to wall failure (formation

factors)

Coring Operations sequence (contd)

To avoid those several problems, some consideration should be

have been decided upon prior to coring :

1. All drilling-related items in the prognosis are satisfactory,

including the rig equipment, gauges and indicators

2. The correct drilling fluid properties have been obtained

3. The borehole is cleaned

4. The core barrel has been assembled correctly

5. The type of core bit being used

Coring Operations sequence (contd)

Various core bit

6. The coring parameters

7. Positioning the core catcher for the best recovery

8. The length of the core to be cut

9. Coring BHA (Bottom Hole Assembly) design

Core Handling Procedures

Properly label and identify all samples (Top and Bottom

marker with depth and direction)

Marking

Cutting

Core Handling Procedures (contd)

After cutting a core barrels

into certain length ( every

1m for example), take core

chip from bottom-top depth

for quick sample description

including oil/gas shows

under microscope

Core chipping

Core Handling Procedures (contd)

Packaging and Shipping Core Barrels

Potrebbero piacerti anche

- Lecture 4 - Coring TechniquesDocumento31 pagineLecture 4 - Coring Techniqueshasan sabahNessuna valutazione finora

- Dipmeter Surveys in Petroleum ExplorationDa EverandDipmeter Surveys in Petroleum ExplorationValutazione: 5 su 5 stelle5/5 (1)

- CoringDocumento14 pagineCoringfaisal muhamamdNessuna valutazione finora

- PETE 220 RESERVOIR ROCK PROPERTIESDocumento64 paginePETE 220 RESERVOIR ROCK PROPERTIESrestofficalNessuna valutazione finora

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementDa EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementValutazione: 4.5 su 5 stelle4.5/5 (2)

- Basic Well Logging - CHAPTER 1 PDFDocumento34 pagineBasic Well Logging - CHAPTER 1 PDFLiliana Maria Plata Sarmiento100% (1)

- Drilling Fluids Processing HandbookDa EverandDrilling Fluids Processing HandbookValutazione: 4.5 su 5 stelle4.5/5 (4)

- Lithology Reconstruction from LogsDocumento32 pagineLithology Reconstruction from LogsSyed ShaiqNessuna valutazione finora

- Drillability of FormationsDocumento7 pagineDrillability of Formationsdrilling moneytreeNessuna valutazione finora

- Cuttings Analysis During Mud LoggingDocumento6 pagineCuttings Analysis During Mud LoggingMuhammad MufarridNessuna valutazione finora

- Coring Oprations Alun Whittaker PDFDocumento184 pagineCoring Oprations Alun Whittaker PDFalvaro_massimoNessuna valutazione finora

- Coring ProgramsDocumento52 pagineCoring ProgramsNamwangala Rashid NatinduNessuna valutazione finora

- Chap 2 Coring and Core Analysis Processes PDFDocumento43 pagineChap 2 Coring and Core Analysis Processes PDFDaniel Viloria100% (12)

- Introduction to Petroleum Production and Reservoir GeologyDocumento48 pagineIntroduction to Petroleum Production and Reservoir GeologyPotten NickNessuna valutazione finora

- GBP-2 - Cuttings PDFDocumento32 pagineGBP-2 - Cuttings PDFisfanNessuna valutazione finora

- Drilling Fluids (Mud) : Habiburrohman AbdullahDocumento18 pagineDrilling Fluids (Mud) : Habiburrohman AbdullahrickyngsNessuna valutazione finora

- Drill Cuttings Description Reference GuideDocumento9 pagineDrill Cuttings Description Reference Guide066709100% (2)

- Open Hole Well Logging: Tools, Utility and How To Interpret The ChartDocumento36 pagineOpen Hole Well Logging: Tools, Utility and How To Interpret The Chartaistop0% (1)

- GBP-2 - Cuttings PDFDocumento32 pagineGBP-2 - Cuttings PDFisfanNessuna valutazione finora

- Basic Mud LoggingDocumento241 pagineBasic Mud Logginghasan sabahNessuna valutazione finora

- Mud Logging Theory, Lag CalculationsDocumento17 pagineMud Logging Theory, Lag CalculationsMuhammad NaumanNessuna valutazione finora

- Reservoir Rock Properties Lab Report SummaryDocumento97 pagineReservoir Rock Properties Lab Report SummaryMarshal betaNessuna valutazione finora

- Drilling Lab BackgroundDocumento34 pagineDrilling Lab Backgroundahmed1adnan-10Nessuna valutazione finora

- Drillability and Mechanical Specific Energy AnalysDocumento11 pagineDrillability and Mechanical Specific Energy AnalysSohaib RashidNessuna valutazione finora

- Rock Identification TablesDocumento2 pagineRock Identification TablesKevin JohnNessuna valutazione finora

- IX. Geoscience Information From Wells: University of Georgia Department of Geology GEOL 4320/6320 Petroleum GeologyDocumento36 pagineIX. Geoscience Information From Wells: University of Georgia Department of Geology GEOL 4320/6320 Petroleum GeologyRoger PeñaherreraNessuna valutazione finora

- Subsurface Geology Lecture Notes - DR - Mohamed Farouk - 2011-2012 - GEO PEDIADocumento82 pagineSubsurface Geology Lecture Notes - DR - Mohamed Farouk - 2011-2012 - GEO PEDIAStephen FortisNessuna valutazione finora

- GeosteeringDocumento4 pagineGeosteeringDwaipayan ChakrabortyNessuna valutazione finora

- Question-1: Answer:: Convergent, Divergent and Transform Continental Margins Can Provide Oil & Gas?Documento6 pagineQuestion-1: Answer:: Convergent, Divergent and Transform Continental Margins Can Provide Oil & Gas?Shaker Ullah ChowdhuryNessuna valutazione finora

- When Rock Mechanics Met DrillingDocumento13 pagineWhen Rock Mechanics Met Drillingxvacilo100% (2)

- The Evolution of Real-Time Torque & Drag Analysis From Manual Local Usage To Automated Cloud-Based AnalyticsDocumento22 pagineThe Evolution of Real-Time Torque & Drag Analysis From Manual Local Usage To Automated Cloud-Based AnalyticshamayunNessuna valutazione finora

- Understanding Source and Reservoir RocksDocumento13 pagineUnderstanding Source and Reservoir RocksKhagen DoleyNessuna valutazione finora

- Drilling PresentationDocumento354 pagineDrilling Presentationمصطفى عصام شيت حمديNessuna valutazione finora

- Conventional Coring - AAPG WikiDocumento9 pagineConventional Coring - AAPG WikiAbhinav SharmaNessuna valutazione finora

- NickNelson Mudlogging Oct 2013 ClassDocumento14 pagineNickNelson Mudlogging Oct 2013 ClassAbhik MazumderNessuna valutazione finora

- Oh DSTDocumento30 pagineOh DSTWanderererNessuna valutazione finora

- 2015 ROP Enhancement in Shales Through Osmotic Processes SPE IADC 173138 MSDocumento19 pagine2015 ROP Enhancement in Shales Through Osmotic Processes SPE IADC 173138 MSSteven MarinoffNessuna valutazione finora

- Formation Fluid Prediction Through Gas While Drilling AnalysisDocumento89 pagineFormation Fluid Prediction Through Gas While Drilling AnalysisIcan100% (1)

- Geochemical Methods of Petroleum ExplorationDocumento5 pagineGeochemical Methods of Petroleum ExplorationNilesh SinghalNessuna valutazione finora

- Well Prognosis Planning and MonitoringDocumento35 pagineWell Prognosis Planning and MonitoringKiryaki FrancisNessuna valutazione finora

- Wellbore Stability Analysis with PSI SoftwareDocumento2 pagineWellbore Stability Analysis with PSI SoftwareNagaLangit69Nessuna valutazione finora

- Overview of Drilling Operations MAY 2011 SEMDocumento48 pagineOverview of Drilling Operations MAY 2011 SEMdatug100% (1)

- PDC Bit Running Procedures DDIDocumento39 paginePDC Bit Running Procedures DDImaicrv100% (1)

- Mud Logging and Wireline Logging GuideDocumento23 pagineMud Logging and Wireline Logging GuideHaritsari DewiNessuna valutazione finora

- Geomechanics: Wellbore Stability, Casing Drilling, Conclusions and Way ForwardDocumento7 pagineGeomechanics: Wellbore Stability, Casing Drilling, Conclusions and Way ForwardAnca SesermanNessuna valutazione finora

- Gas Cut MudDocumento53 pagineGas Cut Mudabnou_223943920Nessuna valutazione finora

- Geostatic (Overburden) Gradient.: Psi/ftDocumento9 pagineGeostatic (Overburden) Gradient.: Psi/ftAHMED BAKR100% (1)

- Classification of Lost Circulation MaterialsDocumento4 pagineClassification of Lost Circulation MaterialspididiwNessuna valutazione finora

- Rock Mechanics in Wellbore ConstructionDocumento65 pagineRock Mechanics in Wellbore ConstructionAnonymous rey6aU3ZNessuna valutazione finora

- Chapter 1 - Formation Evaluation - Dr. Adel SalemDocumento26 pagineChapter 1 - Formation Evaluation - Dr. Adel Salemnaefmubarak100% (1)

- Defining Mud LoggingDocumento2 pagineDefining Mud LoggingYash GurjarNessuna valutazione finora

- Wellsite Geologist Training Report 3Documento7 pagineWellsite Geologist Training Report 3tonyxcrime100% (3)

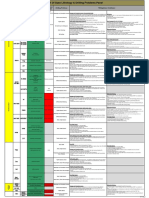

- GOS Lithology and Drilling Problems PanelDocumento1 paginaGOS Lithology and Drilling Problems PanelMohamed Mokhtar100% (1)

- About DrillingDocumento20 pagineAbout DrillingKri Kri100% (1)

- Mudloggers BibleDocumento61 pagineMudloggers BibleTudor MarcusNessuna valutazione finora

- SPE Stavanger - Introduction To GeosteeringDocumento7 pagineSPE Stavanger - Introduction To Geosteeringtrinhtu7Nessuna valutazione finora

- Technical Publications: Direction 2190775 100Documento21 pagineTechnical Publications: Direction 2190775 100zakaria alhosinyNessuna valutazione finora

- Staircase Preliminary Design Based On NBC and IS CodeDocumento10 pagineStaircase Preliminary Design Based On NBC and IS CodeEducation. HubNessuna valutazione finora

- IEC CsODESDocumento2 pagineIEC CsODESArun KumarNessuna valutazione finora

- Hit-Re 500 With Hit-V Has RodsDocumento3 pagineHit-Re 500 With Hit-V Has RodsMKNessuna valutazione finora

- 06-Fc428mar Water-in-Fuel Indicator Sensor Circuit - Voltage Above Normal or Shorted To High SourceDocumento3 pagine06-Fc428mar Water-in-Fuel Indicator Sensor Circuit - Voltage Above Normal or Shorted To High SourceSuryadiNessuna valutazione finora

- SHB 2503-3703 en 1000081433Documento192 pagineSHB 2503-3703 en 1000081433Alberto100% (1)

- W 7570 enDocumento276 pagineW 7570 enthedoors89Nessuna valutazione finora

- Strength of Pressure Vessels With Ellipsoidal HeadsDocumento8 pagineStrength of Pressure Vessels With Ellipsoidal Headsنصرالدين ادريسNessuna valutazione finora

- V8fr-Ii V8r7-IiDocumento1 paginaV8fr-Ii V8r7-Iiaeroseb1Nessuna valutazione finora

- DR System ConciseDocumento37 pagineDR System ConciseJiten KarmakarNessuna valutazione finora

- Technical Presentation - Arik Ethan Kinajil (25231)Documento5 pagineTechnical Presentation - Arik Ethan Kinajil (25231)Arik EthanNessuna valutazione finora

- Coco Press KitDocumento55 pagineCoco Press KitPaula RiddenNessuna valutazione finora

- Easygen-3000 Series (Package P1) Genset Control: InterfaceDocumento102 pagineEasygen-3000 Series (Package P1) Genset Control: InterfacejinameNessuna valutazione finora

- Vinay Quality ResumeDocumento3 pagineVinay Quality Resumevinay kumarNessuna valutazione finora

- Physics Lab ReportDocumento2 paginePhysics Lab ReportFelix SonsunNessuna valutazione finora

- Aso Airfield Standards Quick ReferenceDocumento66 pagineAso Airfield Standards Quick ReferenceRahul RanaNessuna valutazione finora

- 5TH Week EnergyDocumento6 pagine5TH Week EnergyMira VeranoNessuna valutazione finora

- Studio4 - LEED - Green - Associate - Study - Guide - Master 2nd Edition PDFDocumento310 pagineStudio4 - LEED - Green - Associate - Study - Guide - Master 2nd Edition PDFyu zhangNessuna valutazione finora

- Experion Scada PinDocumento7 pagineExperion Scada PinKhalid AliNessuna valutazione finora

- Ali Haider ResumeDocumento3 pagineAli Haider ResumeHasnain ShakirNessuna valutazione finora

- A Study of The Spectral Properties of Rhodamine (6G&B) Dyes Mixture Dissolved in ChloroformDocumento14 pagineA Study of The Spectral Properties of Rhodamine (6G&B) Dyes Mixture Dissolved in ChloroformNoureddine BarkaNessuna valutazione finora

- Dacnewppt p4Documento21 pagineDacnewppt p4vmspraneethNessuna valutazione finora

- Epc of Well Pad D For Sorik Marapi Geothermal Project Recovery ScheduleDocumento1 paginaEpc of Well Pad D For Sorik Marapi Geothermal Project Recovery ScheduleGema SuryaNessuna valutazione finora

- Asme B36.10M-2018Documento36 pagineAsme B36.10M-2018امينNessuna valutazione finora

- Motion ReportDocumento2 pagineMotion Reportmikeb-erau100% (2)

- Calgon Tech SpecDocumento4 pagineCalgon Tech SpecDanStratoNessuna valutazione finora

- Applied Fluid Mechanics: Viscosity of FluidsDocumento22 pagineApplied Fluid Mechanics: Viscosity of FluidsMaggie HepditchNessuna valutazione finora

- Wrangling Logs With Logstash and ElasticSearch PresentationDocumento38 pagineWrangling Logs With Logstash and ElasticSearch PresentationMohammad Syafiq Bin HussainNessuna valutazione finora

- GD&T Training Levels and ServicesDocumento1 paginaGD&T Training Levels and ServicesdramiltNessuna valutazione finora

- Biogas Calculator TemplateDocumento27 pagineBiogas Calculator TemplateAlex Julian-CooperNessuna valutazione finora