Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

55 Nicrmov 7

Caricato da

Mogos PaulDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

55 Nicrmov 7

Caricato da

Mogos PaulCopyright:

Formati disponibili

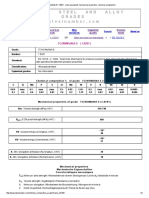

55NiCrMoV7 Steel

55NiCrMoV7 steel suppliers, delivering throughout the UK. West Yorkshire Steel are suppliers of this grade in diameters. As a nickel

chromium tool and die steel it has good hardening properties and combines very good high temperature toughness with shock and fatigue

strength characteristics.

We welcome export enquiries for 55NiCrMoV7 steel. Contact our sales office and consult our shipping policy for further details.

Analysis

Carbon

Manganese

Sulphur

Phosphorous

Form of Supply

West Yorkshire Steel are stockholders and suppliers of diameter bar which can be cut to your requirements .

Rounds can be cut as one offs or multiple cut pieces to your required lengths.

0.50-0.60%

0.60-0.90%

0.03% max

0.03% max

Chromium

Molybdenum

Silicon

Nickel

Vanadium

0.80-1.20%

0.35-0.55%

0.10-0.40%

1.50-1.80%

0.05-0.15%

Contact our experienced sales team who will assist you with your 55NiCrMoV7 steel enquiry.

Diameter

Applications

Typical applications include hot shear knives, backing plates, embossing tools, forming dies and punches.

Forging

Preheat the steel slowly to 700C then increase temperature more rapidly to 1050C. Do not forge below 800C.

Cool slowly after forging, either in a furnace or in vermiculite.

Annealing

Soak the 55NiCrMoV7 thoroughly at 740-760C before furnace cooling at a maximum rate of 10C per hour

down to 600C followed by air cooling.

Stress Relieving

When tools made from 55NiCrMoV7 are heavily machined or ground, the relief of internal strains is advisable

before hardening to minimise the possibility of any distortion. Stress relieving of this grade should be done after

rough machining. To stress relieve, heat the steel carefully to 600 to 650C, allow a generous soaking period

(two hours per 25mm of ruling section). Cool in the furnace to 500C then freely in air.

Hardening

Preheat to 600 to 700C. Soak thoroughly, then increase rapidly to the hardening temperature of 850 to 880C.

Air or oil quench. Tools should be tempered once they become hand-warm.

Tempering

Heat uniformly to the required temperature allowing a soaking time of about two hours per 25mm of ruling

section. Withdraw the steel from the furnace and allow to cool in air. Double tempering is highly recommended,

the tool being allowed to cool to room temperature between each temper.

Temperature [C] 200 250 300 400 500

Hardness [HRc]

55

54

53

49

45

Nitriding

55NiCrMoV7 can be nitrided to give a hard surface case. This steel grade is then very resistant to wear and

erosion. Nitriding also improves the steels resistance to corrosion. Before nitriding the steel should be hardened

and tempered at approximately 50C above the nitriding temperature.

Temperature

Time

Approx. Depth of Case

525C

20 hours

0.250mm

525C

30 hours

0.300mm

525C

60 hours

0.400mm

Heat Treatment

Heat treatment temperatures, such as the rate of heating, cooling and soaking times will vary due to factors

such as the shape and size of each component. Considerations during the heat treatment process include the

type of furnace, quenching medium and work piece transfer facilities. Please consult your heat treatment

provider for full guidance on heat treatment 55NiCrMoV7.

Final Grinding

Select the correct grade of wheel in consultation with the grinding wheel manufacturer. Ensure that the grinding

wheel is in good condition by means of a suitable dressing tool. Wet grinding is a preferable option using a

copious supply of coolant. If dry grinding is necessary then use a very soft wheel.

Quality Assured

Supply

55NiCrMoV7 steel is supplied in accordance with our ISO 9001:2008 registration.

Contact West Yorkshire Steel with your enquiries for round bar, diameters, sawn plate and flat bar

in 55NiCrMoV7 steel.

Contact Us

Tel:

01937 584440

Fax:

01937 580128

Email:

sales@westyorkssteel.com

Address:

West Yorkshire Steel Ltd,

Sandbeck Industrial Estate,

Wetherby, Leeds.

LS22 7DN. UK

Website:

http://www.westyorkssteel.com/

Potrebbero piacerti anche

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- X40Cr13 Steel: Shipping PolicyDocumento2 pagineX40Cr13 Steel: Shipping PolicyWassim MannaiNessuna valutazione finora

- D2 Tool Steel: Shipping PolicyDocumento2 pagineD2 Tool Steel: Shipping Policyالسيد ابراهيم عبدالعزيز عبداللهNessuna valutazione finora

- EN45 Spring Steel Stockholders and Suppliers, Delivering To The Whole of The UK. WestDocumento2 pagineEN45 Spring Steel Stockholders and Suppliers, Delivering To The Whole of The UK. WestMukund2288Nessuna valutazione finora

- 605m36 SteelDocumento2 pagine605m36 Steelhimanshudhol25Nessuna valutazione finora

- Otel de Scule - GBDocumento37 pagineOtel de Scule - GBColta VictorNessuna valutazione finora

- D3 Tool Steel Properties ApplicationsDocumento3 pagineD3 Tool Steel Properties ApplicationsEdilson Sarmiento AlonsoNessuna valutazione finora

- Pressure Vessel ComponentsDocumento24 paginePressure Vessel Componentsrpr013279100% (1)

- S 275Documento3 pagineS 275tnchsgNessuna valutazione finora

- EN36 Case Hardening Steel: Shipping PolicyDocumento2 pagineEN36 Case Hardening Steel: Shipping PolicyMohit YadavNessuna valutazione finora

- Sten A Aluminium Alloys 2008 EnglishDocumento8 pagineSten A Aluminium Alloys 2008 EnglishAnshuman RoyNessuna valutazione finora

- 16Mncr5: Quality 16Mncr5 Case Hardening SteelDocumento2 pagine16Mncr5: Quality 16Mncr5 Case Hardening SteelShubhangi ShindeNessuna valutazione finora

- S355 Steel Stockholders & SuppliersDocumento2 pagineS355 Steel Stockholders & SuppliersNagendra KumarNessuna valutazione finora

- Tool Steels: Prepared byDocumento35 pagineTool Steels: Prepared byabdsu75Nessuna valutazione finora

- Steels For Oil - Gas - ExplorationDocumento16 pagineSteels For Oil - Gas - Explorationدكتور مهندس جمال الشربينىNessuna valutazione finora

- Tool Steel Grade and Standard DesignationDocumento7 pagineTool Steel Grade and Standard DesignationMustafa SevimliNessuna valutazione finora

- Wear Resistant Chrome IronDocumento1 paginaWear Resistant Chrome IronUlises Quintana CarhuanchoNessuna valutazione finora

- Engineering Materials Assignment SummaryDocumento14 pagineEngineering Materials Assignment SummaryJoseph JoelNessuna valutazione finora

- 708M40 Alloy Steel: Form of SupplyDocumento3 pagine708M40 Alloy Steel: Form of SupplyLUCIA MAÑAYNessuna valutazione finora

- Weldability of Cr-Mo SteelsDocumento20 pagineWeldability of Cr-Mo SteelsNitin Bajpai100% (2)

- Metallurgy Project Done By: Mohammed Al-Jaloudi Abdallah Al-Majali Qusai Al-Kharabsheh Mohammed Al-Ananza Mahmood Al-KhateebDocumento6 pagineMetallurgy Project Done By: Mohammed Al-Jaloudi Abdallah Al-Majali Qusai Al-Kharabsheh Mohammed Al-Ananza Mahmood Al-KhateebAbdallah M Al-MajaliNessuna valutazione finora

- En 47Documento3 pagineEn 47Ankit SinghNessuna valutazione finora

- Steel MaterialsDocumento10 pagineSteel Materialsmanideep219Nessuna valutazione finora

- Optimized Die Steel Reference GuideDocumento16 pagineOptimized Die Steel Reference GuideKeattikhun ChaichanaNessuna valutazione finora

- Nitriding SteelDocumento2 pagineNitriding Steelyraju88Nessuna valutazione finora

- 070M20 Carbon Steel: Shipping PolicyDocumento2 pagine070M20 Carbon Steel: Shipping Policyrajvijay_99Nessuna valutazione finora

- Sandvik Steel Hardening GuideDocumento25 pagineSandvik Steel Hardening GuidejasonsivertsenNessuna valutazione finora

- Nitrodur steel: High-performance nitriding steel for demanding applicationsDocumento20 pagineNitrodur steel: High-performance nitriding steel for demanding applicationsABDELKADERNessuna valutazione finora

- Balancing Wear, StrengthDocumento4 pagineBalancing Wear, StrengthStephen MontelepreNessuna valutazione finora

- AISI 4130 Alloy SteelDocumento2 pagineAISI 4130 Alloy SteelKandeepanNessuna valutazione finora

- AISI 4130 Alloy SteelDocumento2 pagineAISI 4130 Alloy SteelSantosh IngaleNessuna valutazione finora

- Gear Selection ThesisDocumento13 pagineGear Selection ThesismastermechNessuna valutazione finora

- Nitriding SteelDocumento40 pagineNitriding SteelkaoblekstenaNessuna valutazione finora

- Tooling Materials&Heat TreatmentDocumento13 pagineTooling Materials&Heat TreatmentVinod MadireddyNessuna valutazione finora

- BRM2Documento3 pagineBRM2王向荣Nessuna valutazione finora

- Yss Tool Steels BDocumento77 pagineYss Tool Steels BneramjanNessuna valutazione finora

- ToolSteel AISIH13Documento2 pagineToolSteel AISIH13Hirmanto SuibNessuna valutazione finora

- En 19 TDocumento3 pagineEn 19 TchaitanyaNessuna valutazione finora

- Brochure PSMDocumento19 pagineBrochure PSMsirajuddin khowajaNessuna valutazione finora

- YSS Cold Working Die PDFDocumento11 pagineYSS Cold Working Die PDFHoang Le VuNessuna valutazione finora

- Cryogenic Steel Properties and ApplicationsDocumento0 pagineCryogenic Steel Properties and ApplicationsidienNessuna valutazione finora

- S6900QLDocumento4 pagineS6900QLmechkashanNessuna valutazione finora

- Special Steel Sheet: Cat - No.B1E-005-04Documento16 pagineSpecial Steel Sheet: Cat - No.B1E-005-04Arnaldo Macchi MillanNessuna valutazione finora

- Shielded Metal Arc Welding: by L D PoyyaraDocumento65 pagineShielded Metal Arc Welding: by L D PoyyaraAshish PatelNessuna valutazione finora

- 002 DEW Warmarbeitsstahl GB PDFDocumento76 pagine002 DEW Warmarbeitsstahl GB PDFSinan Yıldız100% (1)

- EN24T Alloy Steel: High Strength, Shock & Wear ResistantDocumento4 pagineEN24T Alloy Steel: High Strength, Shock & Wear ResistantDalibor CetojevicNessuna valutazione finora

- Welding Metallurgy 2Documento37 pagineWelding Metallurgy 2Asad Bin Ala QatariNessuna valutazione finora

- Standards R M Salem - UserguideDocumento49 pagineStandards R M Salem - Userguidearunas1081Nessuna valutazione finora

- 13 - Q+T Steels & Welding Q+T SteelsDocumento22 pagine13 - Q+T Steels & Welding Q+T SteelsbbqarNessuna valutazione finora

- 1020 Carbon Steel Bar GuideDocumento3 pagine1020 Carbon Steel Bar GuidethyskieNessuna valutazione finora

- 17 Weldability of SteelsDocumento54 pagine17 Weldability of SteelsPraviBeetlesNessuna valutazione finora

- Cold Rolled Steel SheetDocumento0 pagineCold Rolled Steel SheetJajat Derajat MutaqinNessuna valutazione finora

- Ruukki Hot Rolled Steels Processing of Material Thermal Cutting and Flame StraighteningDocumento6 pagineRuukki Hot Rolled Steels Processing of Material Thermal Cutting and Flame StraighteningtechspawNessuna valutazione finora

- Carbon Steel s45cDocumento4 pagineCarbon Steel s45ctam200Nessuna valutazione finora

- AISI 1024 Steel, 1024 Stainless Steel, 1024 Alloy Structural SteelDocumento2 pagineAISI 1024 Steel, 1024 Stainless Steel, 1024 Alloy Structural SteelDhileepan Kumarasamy67% (3)

- Tool Steels: Prepared byDocumento35 pagineTool Steels: Prepared bySWAPNIL NIGAMNessuna valutazione finora

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantDa EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantValutazione: 3.5 su 5 stelle3.5/5 (3)

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkDa EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNessuna valutazione finora

- Material Data Sheet: Material Number Country DesignationsDocumento2 pagineMaterial Data Sheet: Material Number Country DesignationsMogos PaulNessuna valutazione finora

- BS en 10089 2002 Hot Rolled Steels For Quenched and Tempered SpringsDocumento37 pagineBS en 10089 2002 Hot Rolled Steels For Quenched and Tempered SpringsDarkedgeNessuna valutazione finora

- Model Mania 2009 PDFDocumento1 paginaModel Mania 2009 PDFMogos PaulNessuna valutazione finora

- Ejercicios Solidworks PDFDocumento50 pagineEjercicios Solidworks PDFRic Frs80% (5)

- Din 332 PDFDocumento5 pagineDin 332 PDFMogos Paul100% (2)

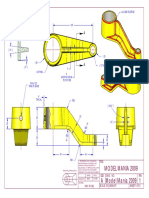

- Produced by An Autodesk Educational ProductDocumento1 paginaProduced by An Autodesk Educational ProductMogos PaulNessuna valutazione finora

- SAE ProjectDocumento200 pagineSAE ProjectKhai Huynh100% (3)

- Outokumpu Steel Grades Properties Global StandardsDocumento20 pagineOutokumpu Steel Grades Properties Global StandardsLance BlackstarNessuna valutazione finora

- Produced by An Autodesk Educational ProductDocumento1 paginaProduced by An Autodesk Educational ProductMogos PaulNessuna valutazione finora

- Astm A29Documento16 pagineAstm A29Mogos PaulNessuna valutazione finora

- Pad Eye, Solidwork - TutorialDocumento28 paginePad Eye, Solidwork - TutorialJogi Oscar SinagaNessuna valutazione finora

- Journal of Asian Ceramic Societies: Pardeep Sharma, Satpal Sharma, Dinesh KhandujaDocumento5 pagineJournal of Asian Ceramic Societies: Pardeep Sharma, Satpal Sharma, Dinesh KhandujaMogos PaulNessuna valutazione finora

- Model Mania 2009Documento1 paginaModel Mania 2009Mogos PaulNessuna valutazione finora

- Contribution To Improving The Durability of The Refractory Lining of The Steel LadlesDocumento20 pagineContribution To Improving The Durability of The Refractory Lining of The Steel LadlesMogos PaulNessuna valutazione finora

- Autodesk Educational Product DocumentDocumento1 paginaAutodesk Educational Product DocumentMogos PaulNessuna valutazione finora

- En 10263-1Documento30 pagineEn 10263-1Mogos PaulNessuna valutazione finora

- Aluminum AlloyDocumento1 paginaAluminum AlloyMehmet SoysalNessuna valutazione finora

- BS en 10250-3 2000Documento16 pagineBS en 10250-3 2000denys7Nessuna valutazione finora

- Produced by An Autodesk Educational Product: Tabla 3 MMDocumento1 paginaProduced by An Autodesk Educational Product: Tabla 3 MMMogos PaulNessuna valutazione finora

- Produced by An Autodesk Educational Product: Pozitia 7 - 1 Bucati Desen: 24399851Documento1 paginaProduced by An Autodesk Educational Product: Pozitia 7 - 1 Bucati Desen: 24399851Mogos PaulNessuna valutazione finora

- BS en 10002-2-1992Documento15 pagineBS en 10002-2-1992Unes JrdNessuna valutazione finora

- BS en 10002-2-1992Documento15 pagineBS en 10002-2-1992Unes JrdNessuna valutazione finora

- 6 PDFDocumento1 pagina6 PDFMogos PaulNessuna valutazione finora

- Produced by An Autodesk Educational Product: Pozitia 4 - 1 Bucati Desen: 24399851Documento1 paginaProduced by An Autodesk Educational Product: Pozitia 4 - 1 Bucati Desen: 24399851Mogos PaulNessuna valutazione finora

- Produced by An Autodesk Educational Product: Pozitia 3 - 2 Bucati Desen: 24399851Documento1 paginaProduced by An Autodesk Educational Product: Pozitia 3 - 2 Bucati Desen: 24399851Mogos PaulNessuna valutazione finora

- Pozitia 3 - 2 bucati Desen 24399851 Tabla 6 mmDocumento1 paginaPozitia 3 - 2 bucati Desen 24399851 Tabla 6 mmMogos PaulNessuna valutazione finora

- Art de Lucrat2Documento13 pagineArt de Lucrat2Mogos PaulNessuna valutazione finora

- 6 PDFDocumento1 pagina6 PDFMogos PaulNessuna valutazione finora

- Produced by An Autodesk Educational ProductDocumento1 paginaProduced by An Autodesk Educational ProductMogos PaulNessuna valutazione finora

- 27 PDFDocumento1 pagina27 PDFMogos PaulNessuna valutazione finora

- SKD61-Die Steel Round BarDocumento2 pagineSKD61-Die Steel Round BarAgustine SetiawanNessuna valutazione finora

- 8.1375E Wire Rod and BarDocumento40 pagine8.1375E Wire Rod and BarandreilocNessuna valutazione finora

- Everything about case hardening steelDocumento2 pagineEverything about case hardening steelFrancisco Botelho Carlos100% (1)

- Discussion: Ferrous Alloys Specimen 1 (X17)Documento5 pagineDiscussion: Ferrous Alloys Specimen 1 (X17)Syahirzabidi100% (1)

- Alloy Steel: Quik GuideDocumento8 pagineAlloy Steel: Quik GuidechamaljsNessuna valutazione finora

- Wire Rope and Material Properties GuideDocumento100 pagineWire Rope and Material Properties GuideReynald de VeraNessuna valutazione finora

- 316 LSDocumento5 pagine316 LSRouse ToxquiNessuna valutazione finora

- Shop Practice Number 8Documento5 pagineShop Practice Number 8JantzenCaliwliwNessuna valutazione finora

- AB Die Casting EngDocumento24 pagineAB Die Casting Engkaniappan sakthivelNessuna valutazione finora

- ASTM A194 2010a CS and Alloy Steel Nuts For The Bolts - HighPress OR HighTempServDocumento11 pagineASTM A194 2010a CS and Alloy Steel Nuts For The Bolts - HighPress OR HighTempServnse mcxNessuna valutazione finora

- 6.1 - Heat Treatment of SteelDocumento69 pagine6.1 - Heat Treatment of Steelsuhas110Nessuna valutazione finora

- Aisi 4150 Alloy Steel (Uns g41500)Documento5 pagineAisi 4150 Alloy Steel (Uns g41500)Jim GregsonNessuna valutazione finora

- High Strength FastenersDocumento9 pagineHigh Strength Fastenerssudhiruday31Nessuna valutazione finora

- Strengthening The Mechanical Properties of 20MnCr5 Steel by Developing Martensite Structure Through Deep Cryogenic TreatmentDocumento3 pagineStrengthening The Mechanical Properties of 20MnCr5 Steel by Developing Martensite Structure Through Deep Cryogenic TreatmentInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- European Steel and Alloy Grades: 7crwvmonb9-6 (1.8201)Documento2 pagineEuropean Steel and Alloy Grades: 7crwvmonb9-6 (1.8201)farshid KarpasandNessuna valutazione finora

- 06 VD Mee-Welding of Super Duplex Stainless SteelsDocumento12 pagine06 VD Mee-Welding of Super Duplex Stainless SteelsKareem AbdelazizNessuna valutazione finora

- p355n NH Nl1 Nl2 TubesDocumento4 paginep355n NH Nl1 Nl2 Tubesado31Nessuna valutazione finora

- Spring CalculationsDocumento1 paginaSpring CalculationswarhamniNessuna valutazione finora

- Sae Ams 5554F-2011Documento5 pagineSae Ams 5554F-2011Mehdi MokhtariNessuna valutazione finora

- Chapetr 5 - Phase Equilibria and Phase TransformationDocumento74 pagineChapetr 5 - Phase Equilibria and Phase TransformationAsh DenemNessuna valutazione finora

- Production: Unit 1 Operations ManagementDocumento26 pagineProduction: Unit 1 Operations ManagementRajat PawanNessuna valutazione finora

- EN24T Alloy Steel: High Strength, Shock & Wear ResistantDocumento4 pagineEN24T Alloy Steel: High Strength, Shock & Wear ResistantDalibor CetojevicNessuna valutazione finora

- SWRCH18A Steel DatasheetDocumento2 pagineSWRCH18A Steel DatasheetHari SuthanNessuna valutazione finora

- Materials Science of Steel, Wolfgang Bleck (Ed.) RWTHDocumento391 pagineMaterials Science of Steel, Wolfgang Bleck (Ed.) RWTHDawitt Badillo100% (2)

- Saarstahl 54SiCr6 material specification sheetDocumento1 paginaSaarstahl 54SiCr6 material specification sheetRichard RodriguezNessuna valutazione finora

- ATC 115 Preliminary CoverDocumento188 pagineATC 115 Preliminary Covertecanasio100% (1)

- Project ExtensionDocumento27 pagineProject Extensionrajith rajeevNessuna valutazione finora

- Plastic Mould Steel: M238 Böhler M238 BöhlerDocumento16 paginePlastic Mould Steel: M238 Böhler M238 BöhlerandresspatooNessuna valutazione finora

- Failure Analysis of An Oil Tanker MV Kurdistan: Presented By: MD - Irfan Khan - Student ID: 201311032Documento21 pagineFailure Analysis of An Oil Tanker MV Kurdistan: Presented By: MD - Irfan Khan - Student ID: 201311032Saquib Bin HabibNessuna valutazione finora

- Technical Data Sheet Jindal Stainless Steel Grade JSL AUS (J1)Documento5 pagineTechnical Data Sheet Jindal Stainless Steel Grade JSL AUS (J1)Dudung SNessuna valutazione finora