Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Electrical Installation Certificate - Red

Caricato da

Mark CottenCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Electrical Installation Certificate - Red

Caricato da

Mark CottenCopyright:

Formati disponibili

Original Certificate

Certificate reference:

ELECTRICAL INSTALLATION

CERTIFICATE

(Requirements for Electrical Installations BS 7671

IEE Wiring Regulations)

DETAILS OF THECLIENT

Client/

Address:

DETAILS OF THE INSTALLATION

Address:

New

Extent of the

installation covered

by this Certificate:

An

Addition

An

Alteration

DESIGN

I/We, being the person(s) responsible for the design of the electrical installation (as indicated by my/our signature(s) below, particulars of

which are described above, having exercised reasonable skill and care when carrying out the design, hereby Certify that the design work

for which I/We have been responsible is, to the best of my/our knowledge and belief, in accordance with BS 7671:2008 amended to Amend

ment 3:2015 except for the departures, if any, detailed as follows:

Details of departures from BS 7671, as amended (Regulations 120.3.120.4)

The extent of liability of the signatory/signatories is limited to the work described above as the subject of this certificate. For the DESIGN

of the installation:

** (Where there is divided responsibility for the design)

Name

Signature

Date

Designer 1

(CAPITALS)

Signature

Date

Name

(CAPITALS)

Designer 2 **

CONSTRUCTION

I/We, being the person(s) responsible for the construction of the electrical installation (as indicated by my/our signature(s) below,

particulars of which are described above, having exercised reasonable skill and care when carrying out the construction, hereby Certify

that the construction work for which I/We have been responsible is, to the best of my/our knowledge and belief, in accordance with BS

7671:2008 amended to Amendment 3:2015 except for the departures, if any, detailed as follows:

Details of departures from BS 7671, as amended (Regulations 120.3.120.4)

The extent of liability of the signatory is limited to the work described above as the subject of this certificate.

For the CONSTRUCTION of the installation:

Signature

Date

Name

(CAPITALS)

Constructor

INSPECTION AND TESTING

I/We, being the person(s) responsible for the inspection and testing of the electrical installation (as indicated by my/our signature(s)

below, particulars of which are described above, having exercised reasonable skill and care when carrying out the inspection and testing,

hereby Certify that the inspection and testing work for which I/We have been responsible is, to the best of my/our knowledge and belief, in

accordance with BS 7671:2008 amended to Amendment 3:2015 except for the departures, if any, detailed as follows:

Details of departures from BS 7671, as amended (Regulations 120.3.120.4)

The extent of liability of the signatory is limited to the work described above as the subject of this certificate.

For the INSPECTION AND TESTING of the installation:

Signature

Date

Name

(CAPITALS)

INSPECTOR

Date

Name

(CAPITALS)

Qualified

Supervisor

Reviewed by

Signature

Report reference: 310528380.odt

Report pages including inspection and test schedules 1 of 7

DESIGN, CONSTRUCTION, INSPECTION AND TESTING

* This box is to be completed only where the design, construction,

inspection and testing have been the responsibility of one person.

I, being the person responsible for the design, construction, inspection and testing of the electrical installation (as indicated by my

signature below), particulars of which are described above, having exercised reasonable skill and care when carrying out the design,

construction, inspection and testing, hereby CERTIFY that the inspection and testing work for which I have been responsible is, to the

best of my knowledge and belief, in accordance with BS 7671:2008 amended to Amendment 3:2015 except for the departures, if any,

detailed as follows:

Details of departures from BS 7671, as amended (Regulations 120.3.120.4)

The extent of liability of the signatory is limited to the work described above as the subject of this certificate.

For the DESIGN, CONSTRUCTION, and the INSPECTION AND TESTING of the installation.

Signature

Date

Name

(CAPITALS)

INSPECTOR

Date

Name

(CAPITALS)

Qualified

Supervisor

Reviewed by

Signature

PATICULARS OF THE ORGANISATION(S) RESPONSIBLE FOR THE ELECTRICAL INSTALLATION

DESIGN (1)

Organisation

Address:

Registration No.

(Where appropriate)

Branch number

(If applicable)

DESIGN (2)

Organisation

Address:

Registration No.

(Where appropriate)

Branch number

(If applicable)

CONSTRUCTION

Organisation

Address:

Registration No.

(Where appropriate)

Branch number

(If applicable)

INSPECTION & TESTING

Organisation

Address:

Registration No.

(Where appropriate)

Branch number

(If applicable)

SUPPLY CHARACTERISTICS AND EARTHING ARRANGEMENTS

System Types

Number and types of live conductors

TN-S

A.C.

TN-C-S

1-Phase

2 wire

TN-C

2-Phase

3 wire

TT

3-Phase

3 wire

IT

Nature of supply Parameters

D.C.

1-Phase

3 wire

3-Phase

4 wire

Nominal Voltage U/Uo

Volts

2 pole

Nominal Frequency

Hz

3 pole

Prospective fault current

kA

Other

External Ze

Other

Ohms

Number of supplies

CHARACTERISTICS OF THE SUPPLY OVERCURRENT PROTECTIVE DEVICE

Type BS/EN

Report reference: 310528380.odt

Nominal current rating

Amps

Short circuit capacity

KA

Report pages including inspection and test schedules 2 of 7

PARTICULARS OF INSTALLATION AT THE ORIGIN

Means of earthing

Details of installation Earth Electrode (where applicable)

Suppliers

facility

Type:

(e.g. rods, tape ect)

Installation earth

electrode

Electrode

resistance, RA

Maximum Demand

(Load) Per phase

Location

Ohms

Method of

measurement

Method of protection against indirect

contact

Amps

EEBADS

Main Switch or circuit-Breaker

Type

BSEN

No. Of

poles

Voltage

rating

Current

rating

RCD

In

mA

RCD

at In

mS

Supply conductors

Conductor material

mm2

Conductor csa

Earthing conductors

Conductor material

Conductor csa

mm2

Continuity check

() OK

Continuity check

() OK

Main equipotential bonding conductors

Conductor material

Conductor csa

mm2

Bonding of extraneous conductive parts ()

Water

service

Gas

service

Oil

service

Structural

steel

Lightning

protection

Other

services

List in report

notes

COMMENTS ON THE EXISTING INSTALLATION

Additional information and report notes

Note: Enter 'NONE' or, where appropriate, the page number(s) of additional page(s) of comments on the existing

installation.

NEXT INSPECTION

I/We the designer(s), recommend that this installation is further inspected and tested after an interval of not more than

Report reference: 310528380.odt

Report pages including inspection and test schedules 3 of 7

SCHEDULE OF ITEMS INSPECTED

PROTECTIVE MEASURES AGAINST ELECTRIC SHOCK

Prevention of mutual detrimental influences

Basic and fault protection

Proximity of non-electrical services and other

influences

SELV

Segregation of band I and band II circuits or band II

insulation used

PELV

Segregation of safety circuits

Basic protection

Identification

Insulation of live parts

Presence of diagrams, instructions, circuit charts and

similar information

Barriers and enclosures

Presence of danger notices and other warning signs

Obstacles

Labelling of protective devices, switches and terminals

Placing out of reach

Identification of conductors

Double or Reinforced insulation

Cables and conductors

Fault Protection (Automatic disconnection of supply)

Selection of conductors for current-carrying capacity and

volt drop

Presence of earthing conductors

Erection methods

Presence of circuit protection conductors

Routing of cables in prescribed zones

Presence of main equipotential conductors

Cables incorporating earthed armour or sheath or run in

an earthed wiring system or protected against nails,

screws and the like

Presence of earthing arrangements for combined

protective and functional purposes

Additional protection by a 30mA for cables concealed in

walls (where required in premises not under the

supervision of skilled or instructed persons

Presence of adequate arrangements for alternative

sources(s), where applicable

Connection of conductors

PELV

Choice and setting of protective and monitoring devices

Non-conducting location:

Absence of protective conductors

Earth free equipotential bonding:

Presence of earth free equipotential bonding conductors

Electrical separation

for one item of current using equipment

Electrical separation

for more than one item of current using equipment

Presence of fire barriers, suitable seals and protection

against thermal effects

General

Adequacy of access to switchgear and other equipment

Presence and correct location of appropriate devices for

isolation and switching

Particular protective measures for special installations and

locations

Connection of single pole devices for protection or

switching in phase conductors only

Correct connection of accessories and equipment

Additional protection

(For use in controlled supervised conditions only)

Presence of under voltage protective devices

Presence of residual current device(s)

Selection of equipment and protective measures

appropriate to external influences

Presence of supplementary bonding conductors

Selection of appropriate functional switching devices

To indicate that an inspection or test has been carried out and the result is satisfactory

To indicate that an inspection or test has been carried out and the result was unsatisfactory

LIM

To indicate that an inspection or test has not been carried out following agreed limitations of inspection or testing

N/A

To indicate the inspection or test is not applicable

N/V

To indicate that details could not be verified

Report reference: 310528380.odt

Report pages including inspection and test schedules 4 of 7

SCHEDULE OF ITEMS TESTED

External earth loop impedance, Ze

Basic protection against direct contact by barrier or

enclosure provided during erection

Installation earth electrode resistance, Ra

Insulation of non-conducting floors or walls

Continuity of protective conductors

Polarity

Continuity of ring circuit conductors

Earth fault loop impedance Zs

Insulation resistance between live conductors

Verification of phase sequence

Insulation resistance between live conductors and earth

Operation of residual current devices

Protection by separation of circuits

Functional testing of assemblies

Verification of voltage drop

SCHEDULE OF ADDITIONAL RECORDS

(See attached schedule)

Note: Additional page(s) must be identified by the Electrical Installation Certificate serial number and page number(s).

Page No(s) :

TEST INSTRUMENTS USED

Instrument Serial No(s)

Earth fault loop impedance

Insulation resistance

Continuity

RCD

Other

NOTES FOR RECIPIENT

THIS CERTIFICATE IS A VALUABLE DOCUMENT AND SHOULD BE RETAINED FOR FUTURE REFERENCE

This safety certificate has been issued to confirm that the electrical installation work to which it relates has been designed, constructed and

inspected and tested in accordance with British Standard 7671 (The IEE Wiring regulations).

You should have received an original Certificate and the contractor should have retained a duplicate Certificate. If you were the person

ordering the work, but not the owner of the installation, you should pass this Certificate, or a full copy of it including the schedules

immediately to the user.

The original certificate should be retained in a safe place and be shown to any person inspecting or undertaking further work on the

electrical installation in the future. If you later vacate the property, this Certificate will demonstrate to the new owner that the electrical

installation complied with the requirements of British Standard 7671 at the time the Certificate was issued was issued. The

Construction (Design and Management) Regulations require that for a project covered by those Regulations, a copy of this Certificate,

together with schedules is included in the health and safety documentations.

For safety reasons, the electrical installation will need to be inspected at appropriate intervals by a competent person. The maximum

time interval recommended before the next inspection is stated in the Certificate under Next Inspection.

This Certificate is intended to be issued only for a new electrical installation or for new work associated with an alteration or addition to

a existing installation. It should not have been issued for the inspection of an existing electrical installation. A Periodic Inspection

Report should be issued for such a periodic inspection.

The Certificate is only valid if a Schedule of Inspection of Test Results is appended.

Report reference: 310528380.odt

Report pages including inspection and test schedules 5 of 7

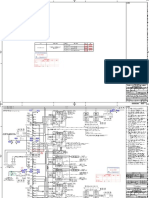

DISTRIBUTION BOARD DETAILS

Zs at this

board ():

Ipf at this

board (KA):

Main switch type

BSEN reference:

Distribution

board location:

Rating:

Supplied

from:

mm2

Rating:

Amps

R1 + R2

R2

At In ms

Polarity

Report pages including inspection and test schedules 6 of 7

At 5 x In ms

r2

RCD

Maximum Measured Zs

rn

Neutral /Earth M

r1

All circuits

(At least

one column

to be

completed)

Phase /Earth M

Maximum permitted Zs

In mA

Ring final circuits

only (Measured end

to end)

Insulation resistance

Phase /Neutral M

Circuit impedances

RCD

Short circuit capacity (KA)

Rating (A)

Overcurrent devices

Type BS EN

Max.Disconnection time permitted (s)

cpc (mm2)

Live (mm2)

Number of points served

Reference method

Type of wiring

Circuit Reference

Report reference: 310528380.odt

Earth:

TEST RESULTS

Circuit

conductors

Circuit designation

mm2

Supply protective

device type:

BSEN reference:

No. Of

phases:

CIRCUIT DETAILS

Supply

conductors:

Amps

Phase /Phase M

DB

ref.:

PVC/PVC

CABLES

PVC CABLES

IN METALLIC

CONDUIT

PVC CABLES IN

NON-METALIC

CONDUIT

PVC CABLES IN

METALIC

TRUNKING

Report reference: 310528380.odt

CODES FOR TYPES OF WIRING

E

F

PVC CABLES IN

NON-METALIC

TRUNKING

PVC/SWA

CABLES

XLPE/SWA

CABLES

MINERALINSULATED

CABLES

O (other please state)

Report pages including inspection and test schedules 7 of 7

Potrebbero piacerti anche

- Minor Electrical Installation Works CertificateDocumento1 paginaMinor Electrical Installation Works CertificatesiekhaiNessuna valutazione finora

- MCC Check ListDocumento6 pagineMCC Check ListAndres AguirreNessuna valutazione finora

- Original Electrical CertificateDocumento7 pagineOriginal Electrical CertificateAnas Kabar100% (2)

- Grounding and earthing system diagramDocumento1 paginaGrounding and earthing system diagramdharuNessuna valutazione finora

- ITP For Cable Tray - Rev BDocumento6 pagineITP For Cable Tray - Rev BDonny Subarja100% (1)

- Secondary Injection KitDocumento9 pagineSecondary Injection KitSamundar KhanNessuna valutazione finora

- Electrical Installation CertificateDocumento7 pagineElectrical Installation CertificateOneaL.Tavi50% (2)

- Minor Electrical Installation CertificateDocumento2 pagineMinor Electrical Installation Certificate1e7tejp027041100% (1)

- Insulation Test Report For Low Voltage Cables Free Ks4ibyDocumento1 paginaInsulation Test Report For Low Voltage Cables Free Ks4ibyJalal AlbadriNessuna valutazione finora

- Electrical Cable Tray Check SheetsDocumento5 pagineElectrical Cable Tray Check SheetsAldeline SungahidNessuna valutazione finora

- Engineering Encyclopedia Saudi AramcoDocumento83 pagineEngineering Encyclopedia Saudi AramcoMANUEL JESÚS GÓMEZ GARCÍA100% (2)

- Install, Operate and Maintain Low Voltage PanelDocumento72 pagineInstall, Operate and Maintain Low Voltage Panelgiau richkyNessuna valutazione finora

- Cable Laying ChecklistDocumento4 pagineCable Laying ChecklistKhalid AwanNessuna valutazione finora

- Check ListDocumento6 pagineCheck ListSikandar Khan0% (1)

- Job Plan: Lead Craft Condition For Work Crafts Department Craft QTYDocumento3 pagineJob Plan: Lead Craft Condition For Work Crafts Department Craft QTYMohsin YasinNessuna valutazione finora

- Rsae-Frm-216 Rev 00 Inspection Check List LV Bus DuctDocumento1 paginaRsae-Frm-216 Rev 00 Inspection Check List LV Bus DuctUtku Can Kılıç50% (2)

- Megger TestDocumento3 pagineMegger Testmagdi badranNessuna valutazione finora

- Checking of Electrical PanelDocumento7 pagineChecking of Electrical PanelReneboy LambarteNessuna valutazione finora

- Cable Tray SizingDocumento28 pagineCable Tray Sizingshrikanth5singhNessuna valutazione finora

- LV Panel ChecklistDocumento1 paginaLV Panel ChecklistvaradharajanNessuna valutazione finora

- HI-POT Setup and TestingDocumento10 pagineHI-POT Setup and Testingsaghaee.rezaNessuna valutazione finora

- Clas Ohlson ReadingDocumento22 pagineClas Ohlson ReadingJennifer BradyNessuna valutazione finora

- Inspection and Test Procedure of SwitchgearDocumento4 pagineInspection and Test Procedure of SwitchgearShahadat HossainNessuna valutazione finora

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Item Checklist Description Result RemarksDocumento1 paginaEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Item Checklist Description Result RemarksmeeNessuna valutazione finora

- Panelboard O&M ManualDocumento7 paginePanelboard O&M Manualchris100% (1)

- Electrical Inspection and Test PlanDocumento1 paginaElectrical Inspection and Test PlanJames Pol JumarangNessuna valutazione finora

- SS04 CH01 - 48V BDT Transducer SAT FormatDocumento74 pagineSS04 CH01 - 48V BDT Transducer SAT FormatshameemindiaNessuna valutazione finora

- ATS Test Report 34Documento3 pagineATS Test Report 34Rami Badran63% (8)

- Procedure For Cable Laying - 03Documento14 pagineProcedure For Cable Laying - 03RamaKrishna ANessuna valutazione finora

- JX NIPPON OIL & GAS LOW VOLTAGE SWITCHBOARD INSPECTIONDocumento2 pagineJX NIPPON OIL & GAS LOW VOLTAGE SWITCHBOARD INSPECTIONAmyNessuna valutazione finora

- Philippine Electrical Code History and PrinciplesDocumento18 paginePhilippine Electrical Code History and PrinciplesZen Marl GaorNessuna valutazione finora

- Rmu Visual Inspection ChecklistDocumento1 paginaRmu Visual Inspection ChecklistJoe_Average100% (2)

- Material Quality Inspection ReportDocumento1 paginaMaterial Quality Inspection Reportisaacwabbi100% (2)

- Electrical WIP Test FormDocumento28 pagineElectrical WIP Test FormDick Anthony Mabao100% (1)

- Sf6 Gas Circuit Breaker Test Report: CharacteristicsDocumento1 paginaSf6 Gas Circuit Breaker Test Report: CharacteristicsIlir R. DalipiNessuna valutazione finora

- Metal Clad vs Metal Enclosed Switchgear: Key DifferencesDocumento2 pagineMetal Clad vs Metal Enclosed Switchgear: Key DifferencesVictor HutahaeanNessuna valutazione finora

- Types of BondingDocumento5 pagineTypes of Bondingsaipavan999Nessuna valutazione finora

- 11 KV RMU-Tech. Spec PDFDocumento23 pagine11 KV RMU-Tech. Spec PDFMohsin ElgondiNessuna valutazione finora

- Cable Schedule Table Functions and TricksDocumento9 pagineCable Schedule Table Functions and TricksHamid KhanNessuna valutazione finora

- Electrical Installation Condition ReportDocumento9 pagineElectrical Installation Condition ReportSullam SyamsunNessuna valutazione finora

- Sample Electrical Installation CertificateDocumento6 pagineSample Electrical Installation CertificateDilanka Rathnayake100% (1)

- Electrical Technical SpecificationDocumento37 pagineElectrical Technical SpecificationKamal KhanNessuna valutazione finora

- Fault Current Calculation FormDocumento3 pagineFault Current Calculation Formrasim_m1146Nessuna valutazione finora

- 109 Substation Pre Energization Checklist Energization1Documento10 pagine109 Substation Pre Energization Checklist Energization1Adrian ReyesNessuna valutazione finora

- Boardmasters-2021 2195 1621443031 Pat-Testing-Certificate-TemplateDocumento4 pagineBoardmasters-2021 2195 1621443031 Pat-Testing-Certificate-Templatemessaoudmoussouni58Nessuna valutazione finora

- Electrical Test Report FormatDocumento1 paginaElectrical Test Report Formatzee159100% (3)

- Bs 76712018 Model Forms Minor Electrical Installation Works CertificateDocumento4 pagineBs 76712018 Model Forms Minor Electrical Installation Works Certificatehany mohamedNessuna valutazione finora

- Minor Electrical Installation Works - RedDocumento2 pagineMinor Electrical Installation Works - RedSeby SebastianNessuna valutazione finora

- Qatar Petroleum Construction Co. Ltd Inspection & Test PlanDocumento1 paginaQatar Petroleum Construction Co. Ltd Inspection & Test PlanmeeNessuna valutazione finora

- Street Light Pole Voltage Drop Calculation (1.1.19)Documento12 pagineStreet Light Pole Voltage Drop Calculation (1.1.19)jiguparmar1516Nessuna valutazione finora

- Order DMX3 breakers componentsDocumento3 pagineOrder DMX3 breakers componentsShan TanuNessuna valutazione finora

- Check List For The Commissioning of DTS SystemDocumento2 pagineCheck List For The Commissioning of DTS SystemmohammadNessuna valutazione finora

- Electrical Testing Report Format - SwyrdDocumento20 pagineElectrical Testing Report Format - SwyrdSakib Khan100% (1)

- Old LT Panel 400 AmpDocumento5 pagineOld LT Panel 400 AmpAbhinav TewariNessuna valutazione finora

- LV Switchgear Dielectric TestsDocumento2 pagineLV Switchgear Dielectric TestswaseemsamsodienNessuna valutazione finora

- Contractors Form Nigerian Electricity Management Service Agency (NEMSA)Documento5 pagineContractors Form Nigerian Electricity Management Service Agency (NEMSA)kol wole50% (2)

- Camlock Electrical Maintenance ServicesDocumento3 pagineCamlock Electrical Maintenance ServicesCamlock0% (1)

- Letter of approval for plant earthing layoutDocumento1 paginaLetter of approval for plant earthing layoutElectrical RadicalNessuna valutazione finora

- Estimate For Electrical Work at ESRDocumento16 pagineEstimate For Electrical Work at ESRparameshvkr0% (1)

- Busway InstallationDocumento20 pagineBusway InstallationSufiyan KhedekarNessuna valutazione finora

- 5 - SMDBDocumento4 pagine5 - SMDBKhyle Laurenz DuroNessuna valutazione finora

- Zappendix 2 Forms of Completion and Inspection RevisedDocumento5 pagineZappendix 2 Forms of Completion and Inspection Revisedtesa korNessuna valutazione finora

- IEE Electrical Installation Certificate - TemplateDocumento5 pagineIEE Electrical Installation Certificate - TemplateElvisNessuna valutazione finora

- SW-2.1 355 ManualDocumento2 pagineSW-2.1 355 Manuallaroca71Nessuna valutazione finora

- William SpecificationDocumento7 pagineWilliam SpecificationAnonymous ZlkRpwNessuna valutazione finora

- Current Ratings and Voltage Drop TablesDocumento1 paginaCurrent Ratings and Voltage Drop Tablesmpendleton100% (2)

- Insulating and Sheathing Materials of Electric Cables - Common Test MethodsDocumento20 pagineInsulating and Sheathing Materials of Electric Cables - Common Test Methodstotok.madriantolubisNessuna valutazione finora

- Map of The 110 and 220 KV Power Transmission Line and Substation Ulaanbaatar City " Ikh Toirog " ProjectDocumento10 pagineMap of The 110 and 220 KV Power Transmission Line and Substation Ulaanbaatar City " Ikh Toirog " ProjectAltanochir AagiiNessuna valutazione finora

- Saudi Arabian Oil Company: 521 P BA-169229 FS1 00Documento4 pagineSaudi Arabian Oil Company: 521 P BA-169229 FS1 00Sara thNessuna valutazione finora

- Cable DetailDocumento3 pagineCable Detailrajeshpalla4Nessuna valutazione finora

- Ground Floor Lighting Layout Second Floor Lighting Layout: Electrical LegendDocumento1 paginaGround Floor Lighting Layout Second Floor Lighting Layout: Electrical LegendJordan Cabuso Guevarra UapNessuna valutazione finora

- Ch2 MV Overcurrent ProtectionDocumento64 pagineCh2 MV Overcurrent Protectionharini deviNessuna valutazione finora

- English: 4-Way SwitchDocumento4 pagineEnglish: 4-Way SwitchShadi AbdelsalamNessuna valutazione finora

- Checklist Socket and Wires ConditionDocumento4 pagineChecklist Socket and Wires ConditionAmirul HafizNessuna valutazione finora

- Jadual Penentuan Ujian Peperiksaan AkhirDocumento2 pagineJadual Penentuan Ujian Peperiksaan AkhirfaizkuzaNessuna valutazione finora

- Philippine Electrical Code #5Documento116 paginePhilippine Electrical Code #5Jeffrey AlimarioNessuna valutazione finora

- Punch List Photos No.2 19sep 2016Documento12 paginePunch List Photos No.2 19sep 2016tuyen nguyen longNessuna valutazione finora

- ESTIMATING AND COSTING OF DOMESTIC INSTALLATIONDocumento31 pagineESTIMATING AND COSTING OF DOMESTIC INSTALLATIONkrishnareddy_chintalaNessuna valutazione finora

- Industrial Cable List Price - 17th August 2021Documento6 pagineIndustrial Cable List Price - 17th August 2021Mohan BabuNessuna valutazione finora

- Installation Instructions For BVT-250 and BVR-250: Introduction To The Series 250Documento3 pagineInstallation Instructions For BVT-250 and BVR-250: Introduction To The Series 250pawa100% (1)

- Table of Common Electrical Wire Sizes and Amps or Fuse Ratings - ResidentialDocumento1 paginaTable of Common Electrical Wire Sizes and Amps or Fuse Ratings - ResidentialHectorNessuna valutazione finora

- Bill of Quantity For G+4 (Residence) (For 140 Square Meter) : Electrical InstallationDocumento2 pagineBill of Quantity For G+4 (Residence) (For 140 Square Meter) : Electrical InstallationWelday GebremichaelNessuna valutazione finora

- RacewaysDocumento9 pagineRacewaysluh luhNessuna valutazione finora

- Op Exam 14-A - 001 - 2Documento4 pagineOp Exam 14-A - 001 - 2Joel JusayNessuna valutazione finora

- FS/DK drop key fireman switch technical specificationsDocumento1 paginaFS/DK drop key fireman switch technical specificationsTommy MuiNessuna valutazione finora

- Insulation Test ReportDocumento28 pagineInsulation Test ReportMARE MARENessuna valutazione finora

- What Is Pilot Wire in Electrical Engineering - QuoraDocumento3 pagineWhat Is Pilot Wire in Electrical Engineering - Quoramarkigldmm918Nessuna valutazione finora

- Calculate Circuit Breaker Amp and Wire Color Code GuideDocumento7 pagineCalculate Circuit Breaker Amp and Wire Color Code GuideGohdsNessuna valutazione finora

- ADC Part 1Documento1 paginaADC Part 1Maung PDDNessuna valutazione finora

- Eaton 16A & 125A OutletDocumento6 pagineEaton 16A & 125A OutletREALLY ?Nessuna valutazione finora