Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Steam Vent

Caricato da

Shameer MajeedCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Steam Vent

Caricato da

Shameer MajeedCopyright:

Formati disponibili

310382499.

xls

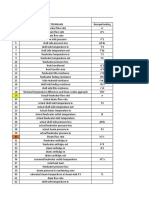

Estimateofsteamexitratefroma3"ventpipe

http://www.cheresources.com/invision/topic/6513-how-to-calculate-steam-vent-flow/

No

Description

units

values

Notes

A.

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

Note:

Exit steam rate to atmosphere, considering it as ideal gas, vent pipe length = 0

Exit steam rate to atmosphere, considering it as real gas, vent pipe length = 0

B1

B'2

B'3

B'4

B'5

B'6

B''2

B''3

B''4

B''5

B''6

Note

B2

B3

B4

B5

Note:

C

C1

C2

C3

C4

C5

C6

C7

Water temperature in deaerator

oC

Steam pressure in deaerator p

bara

Steam k=Cp/Cv

Steam density in deaerator

kg/m3

Critical pressure ratio p*/p

Corresponding p*

bara

Corresponding t*

oC

Corresponding *

kg/m3

Exit velocity at choke conditions u*

m/s

Steam pressure in deaerator p

Pa

Universal gas constant, R

J/kmol

Internal pipe diameter (3" Sch40)

mm

Internal pipe section

m2

Mass velocity

kg/m2/s

Steam exit rate

kg/h

Steam exit rate

kg/h

* means sonic conditions

118

Err:511

Err:511

Err:511

Err:511

Err:511

Err:511

Err:511

Err:511

Err:511

8314

77.9

4.77E-03

Err:511

Err:511

Err:511

Actually p=1.013 bar a at exit, flow can be choked

steam at t* and p* would be liquid

due to choked flow

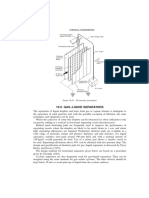

Perry's formula 6-122 (7th ed, 1997)

pipe section* mass velocity

pipe section*(u*)*(*)

Formula for steam PSV, Cl. Matthews, "pressure relief valves - a quick guide", PP 2004, p. 18, Table 2.4

Check of the formula for a steam condition (choked flow)

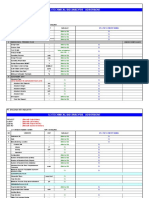

Pressure

bara

40

Exit pressure = 1.013 bar a

Temperature

oC

Err:511 saturated steam

Relieving rate from a 3" orifice

kg/h

97625 Kn=1 assumed. Orif size=int dia of 3" Sch40 pipe

Critical mass flow from steam tables kg/cm2/s/bara 1.42E-02 UK steam tables (SI), Ed Arnold 1970, p. 129

97183 So formula by Matthews seems right

Relieving rate, 3" orifice as above

Pressure

bara

10

Exit pressure = 1.013 bar a

Temperature

oC

Err:511 saturated steam

Relieving rate from a 3" orifice

kg/h

24406 Kn=1 assumed. Orif size=int dia of 3" Sch40 pipe

Critical mass flow from steam tables kg/cm2/s/bara 1.45E-02 UK steam tables (SI), Ed Arnold 1970, p. 129

24879 So formula by Matthews seems right

Relieving rate, 3" orifice as above

Formula of PSV discharge (choked flow) by Matthews agrees well with Ed Arnold steam rable diagram

Case of deaerator

Pressure

bara

Err:511 Exit pressure = 1.013 bar a

Temperature

oC

118

saturated steam

Relieving rate from a 3" orifice

kg/h

Err:511 Kn=1 assumed. Orif size=int dia of 3" Sch40 pipe

Formula by Cl. Mathews is applied for relieving rate

Steam rate to atmosphere, considering vent pipe length enough to avoid choked flow

Exit pressure

Pressure just upstream vent

Enthalpy of exit steam H

Average steam pressure

Steam temperature

Entalpy at steam temperature - H

Average steam density

bara

bara

kJ/kg

bar a

oC

kJ/kg

kg/m3

1.01

Err:511

Err:511

Err:511

115.0

Err:511

Err:511

atmospheric

just below limit of critical pressure ratio

Same as of sat steam of 118 oC

Upstream exit- downstream exit

Assumed, then verified through enthalpies

Steam properties at "average" conditions

of 1.30 bara and 115 oC

310382499.xls

C8

C9

C10

C11

Exit pressure loss

Exit pressure loss

Steam exit velocity

Steam exit rate

bar

m of fluid

m/s

kg/h

Err:511

Err:511

Err:511

Err:511

D

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

Note:

Steam rate to atmosphere, considering vent pipe length enough to avoid choked flow

Exit pressure

bara

1.01

atmospheric

Pressure just upstream vent

bara

Err:511 just below limit of critical pressure ratio

Enthalpy of steam at D2 H

kJ/kg

Err:511 Same as of sat steam of 118 oC

Steam temperature at D2

oC

116

Assumed, then verified through enthalpies

Entalpy at steam temperature - H

kJ/kg

Err:511

Steam density at D2

kg/m3

Err:511 At conditions of D2, 1.58 bar a and 116 oC

Exit pressure loss

bar

Err:511

Exit pressure loss

m of fluid

Err:511 based on density = 0.89 kg/m3

Steam exit velocity

m/s

Err:511

Steam exit rate

kg/h

Err:511 based on density = 0.89 kg/m3

Present result is considered more precise than C , but advise would be welcomed

Note: About 1 m of 3" dia vent pipe is adequate to cause P=1.86-1.58=0.28 bar. Then flow is not choked.

Ref

Cl Matthews, "Pressure Relief Valves - A quick guide", Professional Engineering, UK 2004

17-1-2012

ow can be choked

" conditions

310382499.xls

310382499.xls

Potrebbero piacerti anche

- P&ID Cooling System (PHE 1 Set)Documento1 paginaP&ID Cooling System (PHE 1 Set)Moon JaehyunNessuna valutazione finora

- Denox DesoxDocumento20 pagineDenox DesoxArzu AkarNessuna valutazione finora

- Cálculo de Eficiencia de Un HornoDocumento29 pagineCálculo de Eficiencia de Un HornoFranklin Santiago Suclla PodestaNessuna valutazione finora

- N2 Purging Demand Calculation Shutdown - Flare SystemDocumento54 pagineN2 Purging Demand Calculation Shutdown - Flare SystemMoch FaridNessuna valutazione finora

- Calculate the Heat Transfer Area (HTA) Required for a Steam CondenserDocumento6 pagineCalculate the Heat Transfer Area (HTA) Required for a Steam CondensersakalidhasavasanNessuna valutazione finora

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDocumento12 pagineSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoNessuna valutazione finora

- Data Sheet EjectorDocumento4 pagineData Sheet EjectorGunturMudaAliAkbarNessuna valutazione finora

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocumento9 pagineL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariNessuna valutazione finora

- Specification For Air Compressors and Air Dryer PackagesDocumento21 pagineSpecification For Air Compressors and Air Dryer PackagesSudjono BroNessuna valutazione finora

- Kaybob Gas Plant Piping and Instrumentation DiagramDocumento7 pagineKaybob Gas Plant Piping and Instrumentation DiagrampavanNessuna valutazione finora

- Section 7 - Separation EquipmentDocumento9 pagineSection 7 - Separation Equipmentlulis171Nessuna valutazione finora

- Reduce TDS in Cooling Water to 390 ppmDocumento6 pagineReduce TDS in Cooling Water to 390 ppmzamijakaNessuna valutazione finora

- Antoine Equation Curve FittingDocumento2 pagineAntoine Equation Curve FittingJM Flores De SilvaNessuna valutazione finora

- Shell K.O.drum SeparatorDocumento11 pagineShell K.O.drum SeparatorChitu Ionut LaurentiuNessuna valutazione finora

- Excel As Me P T CDocumento6 pagineExcel As Me P T CNurdinHasanantoNessuna valutazione finora

- 10.9. Gas Liquid Separators: Chemical EngineeringDocumento6 pagine10.9. Gas Liquid Separators: Chemical EngineeringsterlingNessuna valutazione finora

- 14 ACC Air Side PerformanceDocumento24 pagine14 ACC Air Side PerformanceShivakumarNessuna valutazione finora

- Technical Specification - LT (DP Based)Documento4 pagineTechnical Specification - LT (DP Based)ManodipPatilNessuna valutazione finora

- Blowdown TankDocumento1 paginaBlowdown TankShameer Majeed0% (1)

- Volume of Water for Test SectionDocumento2 pagineVolume of Water for Test SectionFerinoviardi100% (1)

- Damper System For Gas Turbine Exhaust Gas SystemDocumento2 pagineDamper System For Gas Turbine Exhaust Gas Systemjkhan_724384Nessuna valutazione finora

- Ammonia Plant Simulation 25.08.2016Documento81 pagineAmmonia Plant Simulation 25.08.2016Manish Gautam100% (1)

- RideDocumento8 pagineRidewahyuNessuna valutazione finora

- Section 19Documento97 pagineSection 19rahmat mamuriNessuna valutazione finora

- Flare Stack Calculation Sheet by Erwin ADocumento8 pagineFlare Stack Calculation Sheet by Erwin AaltruismNessuna valutazione finora

- Disturbance FactorDocumento46 pagineDisturbance FactorBossNessuna valutazione finora

- Thermophysical PropertiesDocumento14 pagineThermophysical PropertiesKalinga BalNessuna valutazione finora

- IPA HeaterDocumento14 pagineIPA HeaterNitin KurupNessuna valutazione finora

- Pumping TrapsDocumento36 paginePumping TrapsjonathanyflorenciaNessuna valutazione finora

- Ogpe OGPE Oil Fields: Calculation SheetDocumento4 pagineOgpe OGPE Oil Fields: Calculation SheetFaber TrujilloNessuna valutazione finora

- Steam DumpingDocumento9 pagineSteam DumpingsrinivasanNessuna valutazione finora

- Understanding LEL, UEL and PPMDocumento8 pagineUnderstanding LEL, UEL and PPMSherwin Delfin CincoNessuna valutazione finora

- Vent Line Pressure Drop CalculationDocumento4 pagineVent Line Pressure Drop CalculationRubensBoerngenNessuna valutazione finora

- Ta 0 °C Pa 0.98 Bar Xa 9260 % Ha 2435 KJ/KG: EvaporatorDocumento8 pagineTa 0 °C Pa 0.98 Bar Xa 9260 % Ha 2435 KJ/KG: EvaporatorShella Theresya PandianganNessuna valutazione finora

- Simulation of Distillation For ACETONE-BENZENE-CHLOROFORMDocumento8 pagineSimulation of Distillation For ACETONE-BENZENE-CHLOROFORMfjcgNessuna valutazione finora

- QIPP MPN018 J00 2304 (1) Instr ListDocumento9 pagineQIPP MPN018 J00 2304 (1) Instr Listsivasri999Nessuna valutazione finora

- Desuperheater Boiler Feed Water RequirementDocumento2 pagineDesuperheater Boiler Feed Water RequirementmayurjannuNessuna valutazione finora

- CondenserDocumento4 pagineCondenseratulbhogare7100% (1)

- DP Calc 1Documento3 pagineDP Calc 1Manjunath HardcheeseNessuna valutazione finora

- FTDocumento1 paginaFTmanodipNessuna valutazione finora

- TEP03 Part4 AbsorptionDocumento28 pagineTEP03 Part4 AbsorptionEK63Nessuna valutazione finora

- Calculate control valve CvDocumento3 pagineCalculate control valve CvRio SamudraNessuna valutazione finora

- TBA - AdsorbentDocumento4 pagineTBA - AdsorbentTifano KhristiyantoNessuna valutazione finora

- Two Phase Flow RegimeDocumento8 pagineTwo Phase Flow RegimeNoman Abu-FarhaNessuna valutazione finora

- This Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncDocumento3 pagineThis Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncJKKNessuna valutazione finora

- 13-391 Strainers Datasheet - GrottoDocumento3 pagine13-391 Strainers Datasheet - GrottoAniket GaikwadNessuna valutazione finora

- Coal Gasifier ProcessesDocumento28 pagineCoal Gasifier ProcessesH Janardan PrabhuNessuna valutazione finora

- Tank Venting Capacity-Fire CaseDocumento1 paginaTank Venting Capacity-Fire CaseAjay TiwariNessuna valutazione finora

- Tank FixturesDocumento21 pagineTank FixturesASSSSSSSSSSSSNessuna valutazione finora

- Air Separation Plants History and Technological Progress 2019 Tcm19 457349Documento28 pagineAir Separation Plants History and Technological Progress 2019 Tcm19 457349Jambanlaya JasdNessuna valutazione finora

- FV Flash Steam and Flash Vessel CalculationDocumento2 pagineFV Flash Steam and Flash Vessel Calculationbeymar_5631Nessuna valutazione finora

- Vent Dispersion CalcDocumento9 pagineVent Dispersion CalcPeddy Nesa0% (1)

- Recip Compressor Calculations For GCP-3Documento4 pagineRecip Compressor Calculations For GCP-3Greg GolushkoNessuna valutazione finora

- NKGSB Prs Ds 006 A4 A Water Spray NozzleDocumento52 pagineNKGSB Prs Ds 006 A4 A Water Spray Nozzleahmad santosoNessuna valutazione finora

- Calculation For Restriction OrificeDocumento4 pagineCalculation For Restriction OrificeAshish PawarNessuna valutazione finora

- Howden Netherlands air condenser performance analysisDocumento24 pagineHowden Netherlands air condenser performance analysisDSGNessuna valutazione finora

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Documento26 pagineSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801Nessuna valutazione finora

- Chapter 24: Energy Conservation Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocumento18 pagineChapter 24: Energy Conservation Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallRafael ReyesNessuna valutazione finora

- Flaresim case studyDocumento14 pagineFlaresim case studygiangvspNessuna valutazione finora

- Statistics for Process Control Engineers: A Practical ApproachDa EverandStatistics for Process Control Engineers: A Practical ApproachNessuna valutazione finora

- Proposal No: Contract No: Plant Item No: Document No: PRP/POP/2011/002/B221/DS/30000/X./1202 Data Sheet For Burner SketchDocumento1 paginaProposal No: Contract No: Plant Item No: Document No: PRP/POP/2011/002/B221/DS/30000/X./1202 Data Sheet For Burner SketchShameer MajeedNessuna valutazione finora

- Fuel Cells Could Be A "Game-Changer" For Carbon Capture PDFDocumento6 pagineFuel Cells Could Be A "Game-Changer" For Carbon Capture PDFShameer MajeedNessuna valutazione finora

- Annexure A (R1)Documento1 paginaAnnexure A (R1)Shameer MajeedNessuna valutazione finora

- Annexure ADocumento1 paginaAnnexure AShameer MajeedNessuna valutazione finora

- Repowering South Mississippi Electric Power Association's J.T PDFDocumento9 pagineRepowering South Mississippi Electric Power Association's J.T PDFShameer MajeedNessuna valutazione finora

- 20042413Documento32 pagine20042413Shameer MajeedNessuna valutazione finora

- Turbine Startup ProcedureDocumento3 pagineTurbine Startup ProcedureShameer Majeed100% (1)

- Az - Zour R&M Furnace Dimensions - ADocumento1 paginaAz - Zour R&M Furnace Dimensions - AShameer MajeedNessuna valutazione finora

- Az Zour R&M Fuel Data ADocumento4 pagineAz Zour R&M Fuel Data AShameer MajeedNessuna valutazione finora

- WWW - Power-Eng - PDF - GTCC Fast StartDocumento18 pagineWWW - Power-Eng - PDF - GTCC Fast StartShameer MajeedNessuna valutazione finora

- 20042403Documento54 pagine20042403Shameer MajeedNessuna valutazione finora

- 20040304Documento7 pagine20040304Shameer MajeedNessuna valutazione finora

- VFDDocumento30 pagineVFDShameer MajeedNessuna valutazione finora

- SaskPower Carbon Capture Facility Operating More ReliablyDocumento6 pagineSaskPower Carbon Capture Facility Operating More ReliablyShameer MajeedNessuna valutazione finora

- Southern Co. Kemper IGCC Delays, Cost Surges Are Under SEC Scru PDFDocumento6 pagineSouthern Co. Kemper IGCC Delays, Cost Surges Are Under SEC Scru PDFShameer MajeedNessuna valutazione finora

- 20040300Documento3 pagine20040300Shameer MajeedNessuna valutazione finora

- Fuel Cells Could Be A "Game-Changer" For Carbon Capture PDFDocumento6 pagineFuel Cells Could Be A "Game-Changer" For Carbon Capture PDFShameer MajeedNessuna valutazione finora

- Practical Consideration For Pump Baseplates, Grouting and FoundationDocumento6 paginePractical Consideration For Pump Baseplates, Grouting and FoundationВладимир СмирновNessuna valutazione finora

- SND Spray Nozzle Desuperheater-Installation Maintenance ManualDocumento16 pagineSND Spray Nozzle Desuperheater-Installation Maintenance ManualShameer Majeed100% (1)

- 20043200Documento287 pagine20043200Shameer MajeedNessuna valutazione finora

- Film Lubrication: Hydrodyn - IcDocumento16 pagineFilm Lubrication: Hydrodyn - IcShameer MajeedNessuna valutazione finora

- Nuclear Training CourseDocumento2 pagineNuclear Training CourseShameer MajeedNessuna valutazione finora

- Problems encountered in boiler feed pump operationDocumento10 pagineProblems encountered in boiler feed pump operationShameer Majeed100% (2)

- Combined-Cycle HRSG Shutdown, Layup, and Startup Chemistry Control - POWERDocumento15 pagineCombined-Cycle HRSG Shutdown, Layup, and Startup Chemistry Control - POWERShameer MajeedNessuna valutazione finora

- Blowdown ValvesDocumento13 pagineBlowdown ValvesShameer MajeedNessuna valutazione finora

- N2 Blanketing (Power)Documento7 pagineN2 Blanketing (Power)Shameer MajeedNessuna valutazione finora

- ACC PerformanceDocumento2 pagineACC PerformanceShameer MajeedNessuna valutazione finora

- Blowdown TankDocumento1 paginaBlowdown TankShameer Majeed0% (1)

- FAC ChemistryDocumento6 pagineFAC ChemistrymarydaughterNessuna valutazione finora

- HowTo Work With CR 90Documento87 pagineHowTo Work With CR 90WagBezerraNessuna valutazione finora

- Excel 2007 Lesson 7 QuizDocumento5 pagineExcel 2007 Lesson 7 Quizdeep72Nessuna valutazione finora

- 1.11 CHEM FINAL Chapter 11 Sulfuric AcidDocumento21 pagine1.11 CHEM FINAL Chapter 11 Sulfuric AcidSudhanshuNessuna valutazione finora

- XS Power Batteries D Series InstructionsDocumento2 pagineXS Power Batteries D Series InstructionsAutopiezas PanaNessuna valutazione finora

- USB GPW CB03 MT02 - EngDocumento21 pagineUSB GPW CB03 MT02 - EngRafael BispoNessuna valutazione finora

- Lsantos - Reflecting Writing For Optimization ProjectDocumento2 pagineLsantos - Reflecting Writing For Optimization Projectapi-341418797Nessuna valutazione finora

- QT140 500 KG Per Hr. Fish Feed Pelleting PlantDocumento11 pagineQT140 500 KG Per Hr. Fish Feed Pelleting PlantShekhar MitraNessuna valutazione finora

- PTP - Level MethodsDocumento23 paginePTP - Level Methodssasikiran mNessuna valutazione finora

- A320 CBT Test 1 PDFDocumento107 pagineA320 CBT Test 1 PDFCesarNessuna valutazione finora

- PDS - GulfSea Hydraulic AW Series-1Documento2 paginePDS - GulfSea Hydraulic AW Series-1Zaini YaakubNessuna valutazione finora

- Example 3 - S-Beam CrashDocumento13 pagineExample 3 - S-Beam CrashSanthosh LingappaNessuna valutazione finora

- AND Optimization OF Three Existing Ethylbenzene Dehydrogenation Reactors in SeriesDocumento5 pagineAND Optimization OF Three Existing Ethylbenzene Dehydrogenation Reactors in SeriesMuhammad Ridwan TanjungNessuna valutazione finora

- Tech Note 14Documento2 pagineTech Note 14meteohrNessuna valutazione finora

- Biology - Physics Chemistry MCQS: Gyanm'S General Awareness - November 2014Documento13 pagineBiology - Physics Chemistry MCQS: Gyanm'S General Awareness - November 2014santosh.manojNessuna valutazione finora

- LTE and SchedulingDocumento25 pagineLTE and SchedulingKrunoslav IvesicNessuna valutazione finora

- Nso User Guide-5.3 PDFDocumento178 pagineNso User Guide-5.3 PDFAla JebnounNessuna valutazione finora

- 8086 Instruction SetDocumento66 pagine8086 Instruction SetRaj KumarNessuna valutazione finora

- VCTDS 00543 enDocumento62 pagineVCTDS 00543 enguido algaranazNessuna valutazione finora

- DSD - Assignment 1 2018Documento3 pagineDSD - Assignment 1 2018Naveen KumarNessuna valutazione finora

- OracleDocumento23 pagineOracleriza arifNessuna valutazione finora

- M6 2020 Binomial Distribution Lecture NotesDocumento27 pagineM6 2020 Binomial Distribution Lecture Notescoyite8695Nessuna valutazione finora

- Winegard Sensar AntennasDocumento8 pagineWinegard Sensar AntennasMichael ColeNessuna valutazione finora

- Crystal Chem Crystallography: - Chemistry Behind Minerals and How They Are AssembledDocumento33 pagineCrystal Chem Crystallography: - Chemistry Behind Minerals and How They Are AssembledArkodip MandalNessuna valutazione finora

- Delta VFD E Series User ManualDocumento399 pagineDelta VFD E Series User ManualTendai AlfaceNessuna valutazione finora

- Eurotech IoT Gateway Reliagate 10 12 ManualDocumento88 pagineEurotech IoT Gateway Reliagate 10 12 Manualfelix olguinNessuna valutazione finora

- Steam Drive Correlation and Prediction PDFDocumento10 pagineSteam Drive Correlation and Prediction PDFEmre CengizNessuna valutazione finora

- PresiometroDocumento25 paginePresiometrojoseprepaNessuna valutazione finora

- Line and Circle Drawing AlgorithmsDocumento57 pagineLine and Circle Drawing AlgorithmsMILAN K JAIN B.Tech CSE B 2018-2022Nessuna valutazione finora

- 98 99 Anti Lock BrakesDocumento101 pagine98 99 Anti Lock BrakestrialnaqueraNessuna valutazione finora

- Bab 8Documento29 pagineBab 8Nurul AmirahNessuna valutazione finora