Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

120 1224 001 - F03 - 0010

Caricato da

musaismail8863Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

120 1224 001 - F03 - 0010

Caricato da

musaismail8863Copyright:

Formati disponibili

JOB No.

Doc. No.

S-120-1224-001

REV.

0-0698-00-0000

Owner No.

RGTSU-JGC-PRO-EQP-36-1224-001

F03

DATE

AIR-COOLED HEAT EXCHANGER

PROCESS DATA SHEET

PREP'D

23

SEP

2015

SHEET

OF

SHENDY GILANG

CHK'D

SANDY A / T. AKAMA

APP'D

GATONG CAHYONO

FOR INFORMATION

EPCIC FOR RGTSU MINIMUM SEND-OUT CAPABILITY IMPROVEMENT

PROJECT

REGAS TERMINAL (SG. UDANG) SDN. BHD.

CONTRACT NO. PGB/HO/19/2014/0073

REV.

DESCRIPTION

PREP'D

CHK'D

APP'D

ALL

FOR INFORMATION

THA

SA/TA

GC

FOR INFORMATION

THA

SA

GC

24-APR-15

ALL

FOR INFORMATION

SP

SA

GC

23-SEP-15

3,5,7

FOR INFORMATION

SP

SA

GC

DATE

PAGE

F00

6-MAR-15

F01

31-MAR-15

F02

F03

A

R

D

1

0

2

N

I 23-SEP 5

JOB No.

Doc. No.

S-120-1224-001

REV.

0-0698-00-0000

Owner No.

RGTSU-JGC-PRO-EQP-36-1224-001

F03

DATE

AIR-COOLED HEAT EXCHANGER

PROCESS DATA SHEET

23

SEP

PREP'D

CHK'D

SANDY A / T. AKAMA

APP'D

GATONG CAHYONO

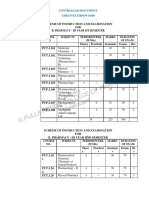

TABLE OF CONTENT

Service

Sheet

E-36301A/B

1st Stage RGTEC Cooler A/B

E-36302A/B

2nd Stage RGTEC Cooler A/B

E-36303A/B

3rd Stage RGTEC Cooler A/B

Tag No.

A

R

D

1

0

2

N

I 23-SEP 5

2015

SHENDY GILANG

SHEET

OF

JOB No.

Doc. No.

S-120-1224-001

REV.

0-0698-00-0000

Owner No.

RGTSU-JGC-PRO-EQP-36-1224-001

F03

DATE

AIR-COOLED HEAT EXCHANGER

PROCESS DATA SHEET

23

Type

2015

SHEET

OF

SANDY A / T. AKAMA

CHK'D

1st Stage RGTEC Cooler A/B

SHENDY GILANG

PREP'D

GATONG CAHYONO

APP'D

Service :

SEP

Item No. E-36301A/B (Note 3)

Qty: 2

Forced / Induced

Heat Exchanged Duty

By Vendor

MW

Operating Data

Fluid Circulated :

Inlet : at

Sp. Gr.

@Oper.

Condition

Flowing

Density

3

(kg/m )

Molecular

Weight

Viscosity

(cP)

Flow Rate

(kg/hr)

130 (Note 6) C Total

Note 1

Note 1

Note 1

Note 1

47 C Total

Note 1

Note 1

Note 1

Note 1

Outlet : at

Specific Heat

Vapor

Note 1

Liquid

Thermal Conductivity

Vapor

Note 1

Liquid

at

at

at

at

Note 1

Note 1

at

kJ/kg-C

at

kJ/kg-C

at

W/m-K

at

W/m-K

Pour Point

Steam Coil

Dew Point

Bubble Point

Yes

No

Condensing Data

14.65 / By Vendor

barG

Pressure Drop, Allowable

0.3

Max. Allowable Velocity

20

bar

m/s

Pressure, inlet / outlet

Fouling Resistance

0.000176 (Note 2), as per PTS 16.12.01

24

Design Pressure

m2-K/W

barG

170

Design Temperature

Ambient Conditions

Design Ambient Temperature

36

Min. Ambient Temp.

Design Atmospheric Pressure

1.01325

bar

Min. Atmos Press.

Noise

18.5

bar

85

dB at 1m beside Equip.,

Type of Temperature Controller

Louvers

Yes,

Automatic,

Manual,

Adjust.,

Fan Pitch

Yes,

Automatic,

Manual,

Adjust.,

Control Action on Air-Failure

- Fan pitch

Min./Max. : - Louver

No

No

Open / Close

Notes

1.) Case

Normal flow(**), kg/hr

(for each cooler A & B)

Lean

Rich

Alt.(*)

7071

7908

6669

Nitrogen

10

27

1.58

desired outlet temperature.

Methane

90

73

98.27

Ethane

0.13

(**) Vendor shall rating the AFC design with compressor

manufacturer's rated capacity (i.e. 103% of normal flow)

Propane

Mol. Weight

0.02

17.24

19.28

16.26

at 130 degC

2.35

2.00

2.55

shall also be considered.

at 47 degC

2.17

1.86

2.34

3.) E-36301A, E-36302A, and E-36303A shall be designed

at 130 degC

0.049

0.046

0.051

fan 2x50% operation. It is also applicable for cooler B.

at 47 degC

0.037

0.035

0.038

4.) Vendor shall study the maximum duty can be covered

at 130 degC

8.13

9.06

7.67

5.) Vendor shall consider the governing case (between

at 47 degC

10.52

11.41

9.69

lean and rich) for equipment design.

at 130 degC

0.015

0.016

0.015

design. Vendor shall rating and check the AFC design

at 47 degC

0.013

0.014

0.012

based on actual compressor data.

Composition, %mole

good ACHE performance (positive overdesign) and

Spec. Heat, kJ/kg-C

2.) In addition, fouling factor for air side 0.00035 m2-K/W

Therm. Cond., W/m-K

in 1 (one) common bay, 3 (three) bundle in parallel, and

Flow Density, kg/m3

when 1 (one) fan fail.

Viscosity, cP

A

R

D

1

0

2

N

I 23-SEP 5

(*) This is an optional case.

Based on ACHE design by lean or rich case, vendor

shall advise the maximum inlet temperature to keep

6.) Design inlet temperature has considered 10% over-

JOB No.

Doc. No.

S-120-1224-001

0-0698-00-0000

Owner No.

RGTSU-JGC-PRO-EQP-36-1224-001

DATE

AIR-COOLED HEAT EXCHANGER

PROCESS DATA SHEET

Service : 1st Stage RGTEC Cooler A/B

Code

Specifications

Tube Bundle

Bundle Frame

23

SEP

PREP'D

SHENDY GILANG

CHK'D

SANDY A / T. AKAMA

APP'D

GATONG CAHYONO

2015

SHEET

REV.

OF

Item No.

E-36301A/B

Design & Construction Code and Specification

Mechanical to advise

Mechanical to advise

Materials - Construction

Mechanical to advise

Mechanical to advise

Header

Type

Material

Plug Material

Gasket Material

Corrosion Allowance

Connection, Inlet

Outlet

Special Nozzle

Rating & Facing

Mechanical to advise

Carbon steel

Mechanical to advise

Mechanical to advise

3.0

6

6

Mechanical to advise

mm

in

in

Tube

Materials

ASTM / ASME / JIS

O.D. Min. Thickness

Max. Length

Carbon steel

Mechanical to advise

25.4 x 2.11

Mechanical to advise

Fin

Type

Material

Structure Mounting

Surface Preparation

Vibration Switch

Fan Material

Driver Type

Enclosure

Volt / Phase / Cycle

Speed Reducer Type

Note :

A

R

D

1

0

2

N

I 23-SEP 5

By Vendor

By Vendor

Miscellaneous

Mechanical to advise

Mechanical to advise

Yes,

No

Mechanical Equipment

Mechanical to advise

Mechanical to advise

Mechanical to advise

Mechanical to advise

Mechanical to advise

mm

mm

F03

8

JOB No.

Doc. No.

S-120-1224-001

REV.

0-0698-00-0000

Owner No.

RGTSU-JGC-PRO-EQP-36-1224-001

F03

DATE

AIR-COOLED HEAT EXCHANGER

PROCESS DATA SHEET

23

Type

SHEET

OF

GATONG CAHYONO

Item No. E-36302A/B (Note 3)

Qty: 2

Forced / Induced

Heat Exchanged Duty

2015

SANDY A / T. AKAMA

CHK'D

2nd Stage RGTEC Cooler A/B

SHENDY GILANG

PREP'D

APP'D

Service :

SEP

By Vendor

MW

Operating Data

Fluid Circulated :

Inlet : at

Sp. Gr.

@Oper.

Condition

Flowing

Density

(kg/m3)

Molecular

Weight

Viscosity

(cP)

Flow Rate

(kg/hr)

130 (Note 6) C Total

Note 1

Note 1

Note 1

Note 1

47 C Total

Note 1

Note 1

Note 1

Note 1

Outlet : at

Specific Heat

Vapor

Note 1

Liquid

Thermal Conductivity

Vapor

Note 1

Liquid

at

at

at

at

Note 1

Note 1

at

kJ/kg-C

at

kJ/kg-C

at

W/m-K

at

W/m-K

Pour Point

Steam Coil

Dew Point

Bubble Point

Condensing Data

Yes

No

32.2 / By Vendor

Pressure, inlet / outlet

Pressure Drop, Allowable

0.2

Max. Allowable Velocity

20

Fouling Resistance

barG

bar

m/s

0.000176 (Note 2), as per PTS 16.12.01

36

Design Pressure

m2-K/W

barG

170

Design Temperature

Ambient Conditions

Design Ambient Temperature

36

Min. Ambient Temp.

Design Atmospheric Pressure

1.01325

bar

Min. Atmos Press.

Noise

85

dB at 1m beside Equip.,

Type of Temperature Controller

Louvers

Yes,

Automatic,

Manual,

Adjust.,

Fan Pitch

Yes,

Automatic,

Manual,

Adjust.,

Control Action on Air-Failure

- Fan pitch

Min./Max. : - Louver

18.5

bar

No

No

Open / Close

Notes

1.) Case

Lean

Rich

Alt.(*)

(*) This is an optional case.

7071

7908

6669

Based on ACHE design by lean or rich case, vendor

shall advise the maximum inlet temperature to keep

Nitrogen

10

27

1.58

desired outlet temperature.

Methane

90

73

98.27

Ethane

Propane

Mol. Weight

17.24

19.28

0.13

0.02

16.26

(**) Vendor shall rating the AFC design with compressor

manufacturer's rated capacity (i.e. 103% of normal flow)

at 130 degC

2.39

2.03

2.60

shall also be considered.

at 47 degC

2.25

1.93

2.44

3.) E-36301A, E-36302A, and E-36303A shall be designed

at 130 degC

0.050

0.047

0.052

fan 2x50% operation. It is also applicable for cooler B.

at 47 degC

0.038

0.036

0.039

4.) Vendor shall study the maximum duty can be covered

at 130 degC

17.37

19.32

16.43

5.) Vendor shall consider the governing case (between

at 47 degC

22.43

24.82

21.27

lean and rich) for equipment design.

at 130 degC

0.015

0.017

0.015

design. Vendor shall rating and check the AFC design

at 47 degC

0.013

0.014

0.013

based on actual compressor data.

Normal flow(**), kg/hr

(for each cooler A & B)

Composition, %mole

good ACHE performance (positive overdesign) and

Spec. Heat, kJ/kg-C

2.) In addition, fouling factor for air side 0.00035 m2-K/W

Therm. Cond., W/m-K

in 1 (one) common bay, 3 (three) bundle in parallel, and

Flow Density, kg/m3

when 1 (one) fan fail.

Viscosity, cP

A

R

D

1

0

2

N

I 23-SEP 5

6.) Design inlet temperature has considered 10% over-

JOB No.

Doc. No.

S-120-1224-001

0-0698-00-0000

Owner No.

RGTSU-JGC-PRO-EQP-36-1224-001

DATE

AIR-COOLED HEAT EXCHANGER

PROCESS DATA SHEET

23

SEP

PREP'D

SHENDY GILANG

CHK'D

SANDY A / T. AKAMA

APP'D

GATONG CAHYONO

2015

SHEET

REV.

OF

Service : 2nd Stage RGTEC Cooler A/B

Item No.

E-36302A/B

Design & Construction Code and Specification

Mechanical to advise

Code

Mechanical to advise

Specifications

Tube Bundle

Bundle Frame

Materials - Construction

Mechanical to advise

Mechanical to advise

Header

Type

Material

Plug Material

Gasket Material

Corrosion Allowance

Connection, Inlet

Outlet

Special Nozzle

Rating & Facing

Mechanical to advise

Carbon steel

Mechanical to advise

Mechanical to advise

3.0

4

4

Mechanical to advise

mm

in

in

Tube

Materials

ASTM / ASME / JIS

O.D. Min. Thickness

Max. Length

Carbon steel

Mechanical to advise

25.4 x 2.11

Mechanical to advise

Fin

Type

Material

Structure Mounting

Surface Preparation

Vibration Switch

Fan Material

Driver Type

Enclosure

Volt / Phase / Cycle

Speed Reducer Type

Note :

A

R

D

1

0

2

N

I 23-SEP 5

By Vendor

By Vendor

Miscellaneous

Mechanical to advise

Mechanical to advise

Yes,

No

Mechanical Equipment

Mechanical to advise

Mechanical to advise

Mechanical to advise

Mechanical to advise

Mechanical to advise

mm

mm

F03

8

JOB No.

Doc. No.

S-120-1224-001

REV.

0-0698-00-0000

Owner No.

RGTSU-JGC-PRO-EQP-36-1224-001

F03

DATE

AIR-COOLED HEAT EXCHANGER

PROCESS DATA SHEET

23

Type

SHEET

OF

GATONG CAHYONO

Item No. E-36303A/B (Note 3)

Qty: 2

Forced / Induced

Heat Exchanged Duty

2015

SANDY A / T. AKAMA

CHK'D

3rd Stage RGTEC Cooler A/B

SHENDY GILANG

PREP'D

APP'D

Service :

SEP

By Vendor

MW

Operating Data

Fluid Circulated :

Inlet : at

Sp. Gr.

@Oper.

Condition

Flowing

Density

(kg/m3)

Molecular

Weight

Viscosity

(cP)

Flow Rate

(kg/hr)

130 (Note 6) C Total

Note 1

Note 1

Note 1

Note 1

50 C Total

Note 1

Note 1

Note 1

Note 1

Outlet : at

Specific Heat

Vapor

Note 1

Liquid

Thermal Conductivity

Vapor

Note 1

Liquid

at

at

at

at

Note 1

Note 1

at

kJ/kg-C

at

kJ/kg-C

at

W/m-K

at

W/m-K

Pour Point

Steam Coil

Dew Point

Bubble Point

Condensing Data

Yes

No

68.95 / By Vendor

Pressure, inlet / outlet

Pressure Drop, Allowable

0.2

Max. Allowable Velocity

20

Fouling Resistance

barG

bar

m/s

0.000176 (Note 2), as per PTS 16.12.01

76

Design Pressure

m2-K/W

barG

170

Design Temperature

Ambient Conditions

Design Ambient Temperature

36

Min. Ambient Temp.

Design Atmospheric Pressure

1.01325

bar

Min. Atmos Press.

Noise

85

dB at 1m beside Equip.,

Type of Temperature Controller

Louvers

Yes,

Automatic,

Manual,

Adjust.,

Fan Pitch

Yes,

Automatic,

Manual,

Adjust.,

Control Action on Air-Failure

- Fan pitch

Min./Max. : - Louver

18.5

bar

No

No

Open / Close

Notes

1.) Case

Normal flow(**), kg/hr

(for each cooler A & B)

Composition, %mole

Lean

Rich

Alt.(*)

7071

7908

6669

(*) This is an optional case.

Based on ACHE design by lean or rich case, vendor

shall advise the maximum inlet temperature to keep

good ACHE performance (positive overdesign) and

Nitrogen

10

27

1.58

desired outlet temperature.

Methane

90

73

98.27

Ethane

Propane

Mol. Weight

17.24

19.28

0.13

0.02

16.26

(**) Vendor shall rating the AFC design with compressor

manufacturer's rated capacity (i.e. 103% of normal flow)

at 130 degC

2.49

2.11

2.71

shall also be considered.

at 50 degC

2.44

2.07

2.66

3.) E-36301A, E-36302A, and E-36303A shall be designed

at 130 degC

0.052

0.049

0.054

fan 2x50% operation. It is also applicable for cooler B.

at 50 degC

0.042

0.039

0.043

4.) Vendor shall study the maximum duty can be covered

at 130 degC

37.06

40.97

35.17

5.) Vendor shall consider the governing case (between

at 50 degC

48.86

53.47

46.65

lean and rich) for equipment design.

at 130 degC

0.016

0.017

0.016

design. Vendor shall rating and check the AFC design

at 50 degC

0.014

0.015

0.014

based on actual compressor data.

Spec. Heat, kJ/kg-C

2.) In addition, fouling factor for air side 0.00035 m2-K/W

Therm. Cond., W/m-K

in 1 (one) common bay, 3 (three) bundle in parallel, and

Flow Density, kg/m3

when 1 (one) fan fail.

Viscosity, cP

A

R

D

1

0

2

N

I 23-SEP 5

6.) Design inlet temperature has considered 10% over-

JOB No.

Doc. No.

S-120-1224-001

0-0698-00-0000

Owner No.

RGTSU-JGC-PRO-EQP-36-1224-001

DATE

AIR-COOLED HEAT EXCHANGER

PROCESS DATA SHEET

Service : 3rd Stage RGTEC Cooler A/B

Code

Specifications

Tube Bundle

Bundle Frame

23

SEP

PREP'D

SHENDY GILANG

CHK'D

SANDY A / T. AKAMA

APP'D

GATONG CAHYONO

2015

SHEET

REV.

OF

Item No.

E-36303A/B

Design & Construction Code and Specification

Mechanical to advise

Mechanical to advise

Materials - Construction

Mechanical to advise

Mechanical to advise

Header

Type

Material

Plug Material

Gasket Material

Corrosion Allowance

Connection, Inlet

Outlet

Special Nozzle

Rating & Facing

Mechanical to advise

Carbon steel

Mechanical to advise

Mechanical to advise

3.0

3

3

Mechanical to advise

mm

in

in

Tube

Materials

ASTM / ASME / JIS

O.D. Min. Thickness

Max. Length

Carbon steel

Mechanical to advise

25.4 x 2.11

Mechanical to advise

Fin

Type

Material

Structure Mounting

Surface Preparation

Vibration Switch

Fan Material

Driver Type

Enclosure

Volt / Phase / Cycle

Speed Reducer Type

Note :

A

R

D

1

0

2

N

I 23-SEP 5

By Vendor

By Vendor

Miscellaneous

Mechanical to advise

Mechanical to advise

Yes,

No

Mechanical Equipment

Mechanical to advise

Mechanical to advise

Mechanical to advise

Mechanical to advise

Mechanical to advise

mm

mm

F03

8

Potrebbero piacerti anche

- Bristle BlasterDocumento6 pagineBristle Blastermusaismail8863Nessuna valutazione finora

- Ags 10 PDFDocumento33 pagineAgs 10 PDFmusaismail8863Nessuna valutazione finora

- API 570 Authorized Piping Inspector Preparatory Program Mock Exam QuestionsDocumento13 pagineAPI 570 Authorized Piping Inspector Preparatory Program Mock Exam QuestionsShanawas Abdul Razak80% (5)

- AWS PricelistDocumento1 paginaAWS Pricelistmusaismail8863Nessuna valutazione finora

- Part 1 eDocumento70 paginePart 1 emusaismail8863Nessuna valutazione finora

- 02 MechanicalDocumento44 pagine02 Mechanicalmusaismail8863Nessuna valutazione finora

- Material Specification Sheet Saarstahl - C40E (Ck40)Documento2 pagineMaterial Specification Sheet Saarstahl - C40E (Ck40)musaismail8863Nessuna valutazione finora

- API 570 Day 2 Book (1 To 51)Documento65 pagineAPI 570 Day 2 Book (1 To 51)AbdulQuddus100% (3)

- WPQ FormDocumento1 paginaWPQ Formudaysrp100% (1)

- C1 13jgfjdfgDocumento25 pagineC1 13jgfjdfgmusaismail8863Nessuna valutazione finora

- Steel Vessels 2008: Rules For Building and ClassingDocumento18 pagineSteel Vessels 2008: Rules For Building and Classingmusaismail8863Nessuna valutazione finora

- ABS Guide for FPSO Conversion RulesDocumento1 paginaABS Guide for FPSO Conversion Rulesmusaismail8863Nessuna valutazione finora

- FFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)Documento1 paginaFFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)musaismail8863100% (1)

- Guide To ColorsDocumento1 paginaGuide To ColorsMardiSantosoNessuna valutazione finora

- Shop Drawing Register for Seahorse III Central PlatformDocumento1 paginaShop Drawing Register for Seahorse III Central Platformmusaismail8863100% (1)

- APPEA Guidelines For Lliting EquipmentDocumento41 pagineAPPEA Guidelines For Lliting EquipmentJason RobertsNessuna valutazione finora

- Risks in Facility Build Quality and Project Handover: What Happened?Documento3 pagineRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863Nessuna valutazione finora

- AS 1100 Part 301 Architectural DrawingDocumento24 pagineAS 1100 Part 301 Architectural DrawingHao Much100% (2)

- D Internet Myiemorgmy Iemms Assets Doc Alldoc Document 5431 Brochure-RevisedDocumento2 pagineD Internet Myiemorgmy Iemms Assets Doc Alldoc Document 5431 Brochure-Revisedmusaismail8863Nessuna valutazione finora

- Anchor Bolt Chair Weld Map Cond N22Documento1 paginaAnchor Bolt Chair Weld Map Cond N22sharif339Nessuna valutazione finora

- 2009FDocumento26 pagine2009FdaimaheshNessuna valutazione finora

- 232 50Documento2 pagine232 50musaismail8863Nessuna valutazione finora

- ASTM A105 Flange Heat TreatmentDocumento16 pagineASTM A105 Flange Heat TreatmentpuffdNessuna valutazione finora

- Cidb Green CardDocumento1 paginaCidb Green CardMuhammad Adzim Azizi67% (3)

- Piping design basics seriesDocumento16 paginePiping design basics seriesManas KotruNessuna valutazione finora

- Instruction Manual - Dial Thickness Gauge Kit How Replica Tape WorksDocumento6 pagineInstruction Manual - Dial Thickness Gauge Kit How Replica Tape Worksmusaismail8863Nessuna valutazione finora

- YeldDocumento2 pagineYeldmusaismail8863Nessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5782)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Determination of Chloroparaffins in Foodstuffs by GC MS-MSDocumento74 pagineDetermination of Chloroparaffins in Foodstuffs by GC MS-MSThuy Ngo NgocNessuna valutazione finora

- ELSD IQ OQ ProtocolDocumento7 pagineELSD IQ OQ ProtocolRajan RamaswamiNessuna valutazione finora

- Catalogue V 7Documento212 pagineCatalogue V 7Keris TidarNessuna valutazione finora

- 11 Teasdale ICH Q3DDocumento28 pagine11 Teasdale ICH Q3DBlueSagaNessuna valutazione finora

- Shield Piping System Technical DataDocumento52 pagineShield Piping System Technical Datamyusuf_engineerNessuna valutazione finora

- rx087 PDFDocumento21 paginerx087 PDFYinna RuizNessuna valutazione finora

- MSDS LyseDocumento14 pagineMSDS LyseidaNessuna valutazione finora

- Indian Chemical IndustryDocumento16 pagineIndian Chemical Industryhemant KumarNessuna valutazione finora

- MaskaraDocumento15 pagineMaskarasreehas sreehasNessuna valutazione finora

- Proceedings IndexDocumento13 pagineProceedings Indexf2321125Nessuna valutazione finora

- I-P R10 Ch04Documento9 pagineI-P R10 Ch04Prajin KundoorNessuna valutazione finora

- Fire Phenomena Explained: Rollovers, Flashovers & BackdraftsDocumento4 pagineFire Phenomena Explained: Rollovers, Flashovers & BackdraftsAyodeji OyelamiNessuna valutazione finora

- Prueba de Tension para Bloques Comprimidos Reforzado Con FibrasDocumento6 paginePrueba de Tension para Bloques Comprimidos Reforzado Con Fibrasrafalejo9Nessuna valutazione finora

- DHS Explosives PDFDocumento43 pagineDHS Explosives PDFBangkit GotamaNessuna valutazione finora

- Lip Mud CC-FR-21-006-K12Documento2 pagineLip Mud CC-FR-21-006-K12Emilio HipolaNessuna valutazione finora

- Emergency Medicine - Approach To PoisoningDocumento35 pagineEmergency Medicine - Approach To PoisoningSuggula Vamsi KrishnaNessuna valutazione finora

- Comprehensive Organic Synthesis - Volume 4 (1991)Documento1.293 pagineComprehensive Organic Synthesis - Volume 4 (1991)Sam West88% (8)

- MSDS ACETIC ACID GLACIAL CASNO 64 19 00005 EN - AspxDocumento11 pagineMSDS ACETIC ACID GLACIAL CASNO 64 19 00005 EN - AspxNitika SinhaNessuna valutazione finora

- Physical Pharmaceutics Lab Manual PDFDocumento27 paginePhysical Pharmaceutics Lab Manual PDFNAGARANI0% (1)

- Laundry Detergent Trends and InnovationsDocumento24 pagineLaundry Detergent Trends and InnovationsRashmi GopalakrishnanNessuna valutazione finora

- Concrete Pavement RepairDocumento10 pagineConcrete Pavement Repairgorafd449Nessuna valutazione finora

- Vpci - 337 / GE / Winterized: FeaturesDocumento2 pagineVpci - 337 / GE / Winterized: Featuresabdul ahad loneNessuna valutazione finora

- Ship TankerDesignDocumento103 pagineShip TankerDesignmariodalNessuna valutazione finora

- Ultramedica - Company ProfileDocumento20 pagineUltramedica - Company ProfilewaelajlanyNessuna valutazione finora

- Session 4 - Environmental Impacts PDFDocumento9 pagineSession 4 - Environmental Impacts PDFjamil voraNessuna valutazione finora

- Howe 6000-RLDocumento2 pagineHowe 6000-RLPatricioLeónNessuna valutazione finora

- SDS CN en PDFDocumento8 pagineSDS CN en PDFKhanh Ly Nguyen ThiNessuna valutazione finora

- SL MC Test s2 Models of Bonding - Structure (Second Test)Documento7 pagineSL MC Test s2 Models of Bonding - Structure (Second Test)Amira Selpa KhairunnisaNessuna valutazione finora

- New Standard For FRP PipingDocumento37 pagineNew Standard For FRP PipingKamatchi NathanNessuna valutazione finora

- Bolts and ConnectionsDocumento11 pagineBolts and ConnectionsSafrul EfendiNessuna valutazione finora