Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SCA Concrete

Caricato da

tonydisoja0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

34 visualizzazioni9 pagineSCA concrete

Titolo originale

SCA concrete

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSCA concrete

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

34 visualizzazioni9 pagineSCA Concrete

Caricato da

tonydisojaSCA concrete

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 9

Research Journal of Applied Sciences, Engineering and Technology 7(12): 2569-2577, 2014

ISSN: 2040-7459; e-ISSN: 2040-7467

Maxwell Scientific Organization, 2014

Submitted: August 30, 2013

Accepted: September 16, 2013

Published: March 29, 2014

Compressive Strength and Microstructure of Sugar Cane Bagasse Ash Concrete

Asma Abd Elhameed Hussein, Nasir Shafiq, Muhd Fadhil Nuruddin and Fareed Ahmed Memon

Civil Engineering Department, Universiti Teknologi PETRONAS, Bandar Seri Iskandar,

31750, Tronoh, Perak, Malaysia

Abstract: This study presents the results of an experimental research study on the effectiveness of Sugar Cane

Bagasse Ash (SCBA) as a cement replacement material in concrete production. The ordinary Portland cement was

replaced with 0, 5, 10, 15, 20, 25 and 30%, respectively bagasse ash, the effect of Sugar cane Bagasse Ash on

workability, compressive strength and microstructure of Interfacial Transition Zone (ITZ) of concrete was

examined. The results showed that inclusion of Sugar cane Bagasse Ash in concrete up to 20% level significantly

enhanced the compressive strength of concrete at all ages; the highest compressive strength was obtained at 5%

SCBA replacement level. The ITZ thickness was greatly reduced with increasing the bagasse ash replacement level

up to 15%, beyond that the ITZ thickness was slightly increased, however the thickness was still narrower than the

normal concrete, it was observed that at 15% bagasse ash replacement level, the interfacial transition zone was

homogeneous and there was no gap between the coarse aggregate and the paste matrix.

Keywords: Compressive strength, interfacial transition zone, microstructure, sugar cane bagasse ash, workability

INTRODUCTION

Utilization of agricultural, industrial and agroindustrial by-products in the form of processed ash

attracting researchers to explore their potential as

cement replacement material or mineral admixture to

the properties of concrete at multiple levels. Utilization

of established materials such as silica fume, fly ash and

ground granulated blast furnace slag has proved as the

high performance concrete ingredients. The benefits

were mainly derived from presence of high SiO 2

content and amorphous mineralogical character, which

caused high strength and stability of the end product

(Shafiq et al., 2007; Shafiq, 2004). It happens due to

utilization of calcium hydroxide (free lime forms during

cement hydration) reacts with the silica content present

in the pozzolans and water that forms additional

calcium silicate hydrate, which is called secondary gel,

hence the compressive strength is enhanced

(Janjaturaphan and Wansom, 2010). Since last few

years tremendous efforts have been made to increase

the use of cement replacement materials in concrete

production because the cement production consumes

high energy and is responsible for 5% of global

anthropogenic CO 2 emission (each ton of cement

produces about one ton of CO 2 ) and their use can also

improve the properties of concrete (Fairbairn et al.,

2010).

Bagasse is an abundant waste produced in sugar

factories after extraction of juice from Sugarcane. The

huge supply of bagasse needs meaningful disposal. In

many countries this type of bulky waste usually used as

the boiler fuel in the sugar mills. Increasing cost of

natural gas and fuel oil resulting high prices of

electricity, due to calorific properties of bagasse waste;

since last decade it is being used as the principal fuel in

cogeneration plants to produce electric power (Fras

et al., 2011; Aigbodion et al., 2010). The burning of

bagasse as fuel leaves bulk quantity of ash called sugar

cane bagasse ash or SCBA. Sugar cane bagasse ash is

recently accepted as a pozzolanic material; however,

there is limited research data available on the effects of

SCBA on the properties of concrete. Therefore, due to

lack of research most of the bagasse ash is disposed in

the landfills (Chusilp et al., 2009) and only a few

studies reported the use of bagasse ash as partial

replacement of cement in concrete (Ganesan et al.,

2007). Since, there is a continuous increase in the

production of sugar worldwide and approximately 1500

Million tons of sugar cane are annually produced all

over the world, which leaves about 40-45% bagasse

after juice extraction. Therefore, an average annual

production bagasse is estimated as 600 Million tons,

which is a bulky waste from sugar industry (Goyal and

Anwar, 2007). Sugarcane plantations cover one-fifth of

the arable land in Sudan, according to WADE report

2004: Sudan has the highest potential among the

countries of eastern and southern Africa of producing

electricity from bagasse and over 40% of its electricity

can be produced from bagasse cogeneration (Morand,

2004).

Corresponding Author: Asma Abd Elhameed Hussein, Civil Engineering Department, Universiti Teknologi PETRONAS,

Bandar Seri Iskandar, 31750, Tronoh, Perak, Malaysia

2569

Res. J. Appl. Sci. Eng. Technol., 7(12): 2569-2577, 2014

As mentioned above there is limited research

available on the utilization of SCBA as cement

replacement material, CRM in concrete as compared to

other well-known pozzolans such as silica fume, fly

ash, ground granulated blast furnace slag and rice husk

ash. In order to establish SCBA as an alternative

cement replacement material for high performance

concrete, many properties of concrete containing

SCBA, such as microstructure of Interfacial Transition

Zone (ITZ), long term durability and structural

properties including bond strength need to be

investigated. The principal aim of this research study is

to present the results of an experimental study

performed to investigate the effect of SCBA on the

mechanical properties of concrete as well as

microstructure characteristics of ITZ.

MATERIALS

The materials used in this study are: The Ordinary

Portland Cement (OPC) type 1 was used in this study it

was complying with the requirements of BS 12 (1996)

and MS 522: Part 4 (1989). The chemical composition

of cement is shown in Table 1. Crushed Granite rocks

with a maximum particle size of 20 mm that was

employed as coarse aggregate in this study and mining

sand with a maximum particle size of 4.75 mm was

used as fine aggregate according to BS 812-103.2:

1989. A naphthalene formaldehyde sulphonate

superplasticizer in the form of aqueous solution was

used as Water Reducing Admixture (WRA) for all

concrete mixes.

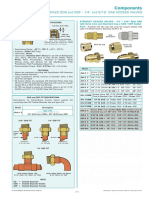

Sugar Cane Bagasse Ash (SCBA): The SCBA was

obtained from Guneid Sugar factory, located in Gezira

Province, Sudan. The obtained ash was further ground

in a Los Angeles abrasion machine until the particles

retained on 45 m-sieve were less than 5%. The

chemical composition of SCBA was determined using

X-Ray fluorescence technique, XRF, the results are

given in Table 1. The major oxide observed in SCBA is

silica (SiO 2 ), which is about 77.25%, the total

summation of SiO 2 + Al 2 O 3 + Fe 2 O 3 is 87.83%, the

calcium oxide, CaO is 4.05%, hence this ash classifies

as class F pozzolan according to ASTM C 618 (2009).

The X-Ray Diffraction (XRD) analysis of the SCBA

shows the amorphous silica formation with traces of

low quartz as shown in Fig. 1. The image of ground

SCBA is shown in Fig. 2.

Experimental program:

Concrete mixing and casting: A total of 7 concrete

mixes were prepared, one of the mixes was made of

100% cement (no SCBA content), denoted by NC and

called the reference mix. The remaining 6 mixes were

Table 1: Chemical composition of OPC and SCBA

Weight (%)

---------------------------------------------OPC

SCBA

Oxide

SiO 2

20.44

77.25

Al 2 O 3

2.84

6.37

Fe 2 O 3

4.64

4.21

CaO

67.73

4.05

K2O

0.26

2.34

MgO

1.43

2.61

Na 2 O

0.02

1.38

P2O5

0.10

0.59

TiO 2

0.17

0.58

MnO

0.16

0.27

SO 3

2.20

0.11

LOI

1.40

SiO 2 +Al 2 O 3 +Fe 2 O

87.83

Table 2: Concrete mix proportions

Mix description OPC

SCBA

NC

500

0

5% SCBA

475

25

10% SCBA

450

50

15% SCBA

425

75

20% SCBA

400

100

25% SCBA

375

125

30% SCBA

350

150

CA

945

945

945

945

945

945

945

Sand

745

745

745

745

745

745

745

Water

190

190

190

190

190

190

190

SP

3

3

3

3

3

3

3

Fig. 1: XRD pattern of SCBA

Fig. 2: Ground SCBA

prepared by adding SCBA content as partial

replacement to cement i.e., 5, 10, 15, 20, 25 and 30%,

respectively; these mixes are denoted by SCBA content,

e.g., 5% SCBA. Details of all mixes are given in

Table 2. All concrete ingredients were mixed according

to the procedure given in BS 1881-125 (1986), the

2570

Res. J. Appl. Sci. Eng. Technol., 7(12): 2569-2577, 2014

superplasticizer dosage was kept constant as 0.6% by

weight of cement.

Workability: The workability of the freshly mixed

concrete was determined using slump test that was

performed according to BS 1881: Part 102 (1983).

Compressive strength: The compressive strength was

determined using 100 mm cubes at the age of 7, 28, 90

and 180 days, respectively curing. During compression

test, the load on the cube was applied at a constant rate

of 3.0 KN/s according to BS 1881: Part 111 (1983).

Interfacial

Transition

Zone

(ITZ):

The

microstructure of interfacial transition zone of all 7

mixes was investigated using Field Emission Scanning

Electron Microscopy (FESEM) technique. For

performing this test, a cylindrical core was taken from

concrete cube and then a thin slice of about 2-3 mm

was cut by the diamond cutter and polished by the

electrical polisher for investing FESEM imaging. The

ITZ was imaged and its thickness was measured at the

same magnification.

RESULTS AND DISCUSSION

Effects of SCBA on workability: Figure 3 shows the

slump values for all the concrete mixes. Since the water

content and super plasticizer dosage was constant in all

seven mixes, therefore, the effect of SCBA on

workability of concrete can be better understood. As

shown in Fig. 3, the workability of concrete was

linearly increased with the increment in the SCBA

content. For reference concrete, NC the slump value

was obtained as 160 mm, whereas for 30%, the slump

was about 215 mm. It means the addition of SCBA

content reduces the water demand in concrete for

achieving a desired workability, which is good news for

high performance concrete. Although, the particle size

of SCBA is much finer than the cement particle but its

texture is more glassy similar to that of the fly ash

particles, improved workability can be attributed to the

low value of LOI 1.4% which indicates the SCBA is

completely burned and there is no carbon content in the

ash, similar observation was also reported in the

available research by others (Cordeiro et al., 2010;

Srinivasan and Sathiya, 2010).

Compressive strength: Figure 4 shows the

compressive strength of all 7 mixes determined at the

age of 7, 28, 90 and 180 days, respectively. At all ages,

four mixes containing 5, 10, 15 and 20%, respectively

SCBA showed higher compressive strength than the

reference mix, NC, whereas mixes 25 and 30% SCBA

showed further improvement in strength at the age of

90 and 180 days, which means SCBA has shown good

pozzolanic reactivity. At the age of 28 days mixes 5, 10

and 15% SCBA showed 91, 88 and 84 MPa

compressive strength, respectively in comparison to 62

MPa, the compressive strength of the reference mix,

NC. It is to be noted that reference mix NC has higher

slump, while all mixes were having constant water

content and dosage of super plasticizer. In case where

Fig. 3: Effect of SCBA on the workability of concrete

Fig. 4: Effect of SCBA on the compressive strength of concrete

2571

Res. J. Appl. Sci. Eng. Technol., 7(12): 2569-2577, 2014

Fig. 5: ITZ thickness measurements

Fig. 6: FESEM image of NC

the workability (slump value) of all mixes to be kept

constant, SCBA mixes will require lower water content,

hence the compressive strength will be further

improved. Twenty five percent SCBA showed similar

compressive strength at 28 days as the reference mix

achieved, therefore it can be concluded that 25% SCBA

mix is equivalent to the reference mix, NC, whereas 5

to 15% SCBA content is determined as optimum

replacement for producing high strength concrete.

In general SCBA showed an excellent performance

when included in concrete as partial replacement for

cement this can be attributed to:

2572

The high silica content present SCBA that enables

pozzolanic reactivity

Ultra-fine particle sizes in SCBA significantly

improve the microstructure that causes high early

strength

Res. J. Appl. Sci. Eng. Technol., 7(12): 2569-2577, 2014

Fig. 7: FESEM image of 5% SCBA

Fig. 8: FESEM image of 10% SCBA

2573

Res. J. Appl. Sci. Eng. Technol., 7(12): 2569-2577, 2014

Fig. 9: FESEM image of 15% SCBA

Fig. 10: FESEM image of 20% SCBA

2574

Res. J. Appl. Sci. Eng. Technol., 7(12): 2569-2577, 2014

Fig. 11: FESEM image of 25% SCBA

Fig. 12: FESEM image of 30% SCBA

2575

Res. J. Appl. Sci. Eng. Technol., 7(12): 2569-2577, 2014

Fig. 13: Effect of SCBA on ITZ thickness

The findings of this study are in agreement with other

available researches (Chusilp et al., 2009; Ganesan

et al., 2007; Srinivasan and Sathiya, 2010; Suvimol and

Daungruedee, 2008)

Interfacial transition zone: Interfacial transition zone,

ITZ thickness is defined as the gap length between the

aggregate and cement paste in concrete. ITZ thickness

was determined to investigate the microstructure

characteristics as well as to support the effects of SCBA

on compressive and tensile strength. Narrow ITZ

thickness results in higher compressive because the

bond between aggregate and cement paste become

stronger, three ITZ thickness measurements were taken

as shown in Fig. 5 and the average ITZ thickness is

reported. The FESEM images for all mixes are shown

in Fig. 6 to 12. The ITZ thickness in Micrometer is

plotted in Fig. 13. It can be observed that the SCBA

significantly reduced the ITZ thickness at all

replacement levels which strongly confirmed the

compressive strength results. The percentage of

reduction in ITZ thickness for 5, 10, 15, 20, 25 an 30%

SCBA was about 31, 37, 100, 70, 57 and 50%,

respectively as compared to the reference normal

concrete NC, it is also worthy to notice that at 15%

SCBA, Fig. 9, there was no gap to be measured

between the aggregate and mortar and the

microstructure was very homogeneous, this can be

attributed to the pore refinement which led to an

improved microstructure at interfacial zone. In general

and as it can be observed from, all the SCBA concrete

mixes investigated in this study showed a better

performance than the normal concrete and increasing

the SCBA replacement level in concrete led to increase

in the densification of interfacial zone as expected due

to its fineness and pozzolanic reactivity.

It was reported by Suvimol and Daungruedee

(2008), that the higher the bagasse ash quantity in

concrete, the lower the porosity of concrete, this

observation can support the improvement of

microstructure of ITZ in SCBA concrete mixes in this

study as there is no study on the ITZ encountered in the

literature.

CONCLUSION

From this experimental study the following

conclusions can be drawn.

Addition of SCBA as partial replacement to cement:

Linearly increase the workability of concrete

Up to 20% replacement enhanced both the

compressive strength at all ages

Highest 28-day compressive strength was obtained

using 5% SCBA replacement which was about

48% higher than the reference mix

Up to 20% SCBA in concrete is considered as the

optimum replacement level

Twenty five and thirty percent SCBA improved the

compressive strength after 28 days

Inclusion of SCBA in concrete up to 30%

significantly improved the microstructure of

concrete by reducing the ITZ thickness which

indicates better refinement of pore structure and

dense matrix compared to the reference mix

At 15% SCBA level the microstructure of ITZ was

totally homogeneous without the presence of wall

effect between the aggregate and the paste matrix

The microstructural properties are strongly related

to the compressive strength of concrete

Further studies on microstructure of ITZ for SCBA

concrete are needed as there is no available

literature and it is first introduced in this study

ACKNOWLEDGMENT

The authors would like to extend their

acknowledgement to the University Teknologi

PETRONAS for providing the facilities and financial

support to accomplish this research. It is further

extended to Technologist at civil engineering

department and centralized analytical laboratory at,

University Teknologi PETRONAS for their great

contribution and assistance to complete this study.

2576

Res. J. Appl. Sci. Eng. Technol., 7(12): 2569-2577, 2014

REFERENCES

Aigbodion, V.S., S.B. Hassan, T. Ause and G.B. Nyior,

2010. Potential utilization of solid waste (Bagasse

Ash ). J. Miner. Mater. Charact. Eng., 9(1): 67-77.

ASTM C 618, 2009. Standard Specification for Coal

Fly Ash and Raw or Calcined Natural Pozzolan for

Use as a Mineral Admixture in Concrete. Annual

Book of ASTM Standards. Retrieved from:

http://www. astm.org/Standards/C618.htm.

BS 12, 1996. Specifications for Portland Cement.

British Standards Institute, London.

BS 1881: Part 102, 1983. Testing Fresh Concrete:

Method for determination of Slump. British

Standards Institute, London.

BS 1881: Part 111, 1983. Method for Determination of

Compressive Strength of Concrete. British

Standards Institute, London.

BS 1881-125, 1986. Testing Concrete: Methods of

Mixing and Sampling Fresh Concrete in the

Laboratory. British Standards Institute, London.

Chusilp, N., C. Jaturapitakkul and K. Kiattikomol,

2009. Effects of LOI of ground bagasse ash on the

compressive strength and sulfate resistance of

mortars. Constr. Build. Mater., 23(12): 3523-3531.

Cordeiro, G.C., R.D.T. Filho and E.M.R. Fairbairn,

2010. Ultrafine sugar cane bagasse ash: High

potential pozzolanic material for tropical countries.

Ibracon Struct. Mater. J., 3(1): 50-58.

Fairbairn, E.M.R., B.B. Americano, G.C. Cordeiro,

T.P. Paula, R.D.T. Filho and M.M. Silvoso, 2010.

Cement replacement by sugar cane bagasse ash:

CO2 emissions reduction and potential for carbon

credits. J. Environ. Manage., 91(9): 1864-1871.

Fras, M., E. Villar and H. Savastano, 2011. Brazilian

sugar cane bagasse ashes from the cogeneration

industry as active pozzolans for cement

manufacture. Cement Concrete Compos., 33(4):

490-496.

Ganesan, K., K. Rajagopal and K. Thangavel, 2007.

Evaluation of bagasse ash as corrosion resisting

admixture for carbon steel in concrete. Anti-Corr.

Methods Mater., 54(4): 230-236.

Goyal, A. and A.M. Anwar, 2007. Properties of

Sugarcane BagasseAsh and its potential as cementpozzolana binder. Proceeding of the 12th

International Colloquium on Structural and

Geotechnical Engineering. Cairo, Egypt, December

10-12.

Janjaturaphan, S. and S. Wansom, 2010. Pozzolanic

activity of industrial sugar cane Bagasse Ash.

Suranaree J. Sci. Technol., 17(4): 349-357.

Morand, A., 2004. Bagasse Cogeneration-global

Review and Potential. World Alliance for

Decentralized Energy, pp: 1-56. Retrieved

from:http://www.energymanagertraining.com/CHP

Material/01-report_bagasse_cogeneration.pdf.

MS 522: Part 4, 1989. Specification for Portland

Cement (Ordinary and Rapid Hardening).

Malaysian Standards.

Shafiq, N., 2004. Effects of fly Ash on chloride

migration in concrete and calculation of cover

depth required against the corrosion of embedded

reinforcement. Struct. Concrete, 5(1): 5-9.

Shafiq, N., M.F. Nuruddin and I. Kamaruddin, 2007.

Comparison of engineering and durability

properties of fly ash blended cement concrete made

in UK and Malaysia. J. Adv. Appl. Ceramics Inst.

Mater. Miner. Mining, 106(6): 314-318.

Srinivasan, R. and K. Sathiya, 2010. Experimental

study on bagasse ash in concrete. Int. J. Serv.

Learn. Eng., 5(2): 60-66.

Suvimol, S. and C. Daungruedee, 2008. Bagasse ash:

Effect of pozzolanic activity and application in

cement use aspect. Proceeding of the 3rd ACF

International Conference-ACF/VCA, pp: 165-173.

2577

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Steel Sketch With ProblemDocumento59 pagineSteel Sketch With Problemmaniram7Nessuna valutazione finora

- Spherification How ToDocumento7 pagineSpherification How ToElfiNessuna valutazione finora

- Advanced Concrete Technology - 10cv81 - ACE NotesDocumento185 pagineAdvanced Concrete Technology - 10cv81 - ACE Notessaqeeb33% (3)

- Quiz 1 - MacromoleculesDocumento3 pagineQuiz 1 - MacromoleculesMariano Valiente Jr.Nessuna valutazione finora

- Physical Science Grade 11 - St. Lorenzo Module 2 - : Saint Louis School of Pacdal, IncDocumento10 paginePhysical Science Grade 11 - St. Lorenzo Module 2 - : Saint Louis School of Pacdal, IncNo nameNessuna valutazione finora

- Refining Processes 2004 PDFDocumento293 pagineRefining Processes 2004 PDFramachandran_chem100% (1)

- Guidelines For The Preparation of 8Th Sem B.E./B. Tech. Project ReportsDocumento4 pagineGuidelines For The Preparation of 8Th Sem B.E./B. Tech. Project ReportstonydisojaNessuna valutazione finora

- GRC - Mechanical Properties For Structural ApplicationsDocumento20 pagineGRC - Mechanical Properties For Structural ApplicationsaminjolesNessuna valutazione finora

- RHA Effectiveness in Cement and Concrete As A Fuction of Reactive Silica and Fineness PDFDocumento8 pagineRHA Effectiveness in Cement and Concrete As A Fuction of Reactive Silica and Fineness PDFTran Huynh NamNessuna valutazione finora

- Coir Fibre Reinforcement and Application in Polymer Composites: A ReviewDocumento14 pagineCoir Fibre Reinforcement and Application in Polymer Composites: A ReviewAshokan Keloth100% (1)

- CCCCCCCCCDocumento7 pagineCCCCCCCCCBIBINNessuna valutazione finora

- V5i402 Civil EngineeringDocumento6 pagineV5i402 Civil EngineeringtonydisojaNessuna valutazione finora

- High Strength Glass Fibers-TechnicalDocumento12 pagineHigh Strength Glass Fibers-TechnicalMayra ZezattiNessuna valutazione finora

- SCA ConcreteDocumento9 pagineSCA ConcretetonydisojaNessuna valutazione finora

- Bagasse Ash Replaced Cement Concrete StrengthDocumento8 pagineBagasse Ash Replaced Cement Concrete StrengthtonydisojaNessuna valutazione finora

- Sugar Can Ash 7 PDFDocumento6 pagineSugar Can Ash 7 PDFtonydisojaNessuna valutazione finora

- SCA ConreteeDocumento4 pagineSCA ConreteetonydisojaNessuna valutazione finora

- Acta 2014 3 11 PDFDocumento6 pagineActa 2014 3 11 PDFtonydisojaNessuna valutazione finora

- Srinivasan Estudio Experimental Bagasse AshDocumento7 pagineSrinivasan Estudio Experimental Bagasse Ashrobertsj21Nessuna valutazione finora

- SCA ConcreteDocumento9 pagineSCA ConcretetonydisojaNessuna valutazione finora

- Ijsrdv3i110384 PDFDocumento5 pagineIjsrdv3i110384 PDFtonydisojaNessuna valutazione finora

- 10 Vol16 And17 The Use of Sugarcane Eljack SulimanDocumento6 pagine10 Vol16 And17 The Use of Sugarcane Eljack SulimantonydisojaNessuna valutazione finora

- GrausacotothesisDocumento83 pagineGrausacotothesistonydisojaNessuna valutazione finora

- Bagasse Ash Utilization As Viscosity Modifying Agent To Produce An Economical Self Compacting ConcreteDocumento7 pagineBagasse Ash Utilization As Viscosity Modifying Agent To Produce An Economical Self Compacting ConcretetonydisojaNessuna valutazione finora

- Materials 06 03108 v2 PDFDocumento20 pagineMaterials 06 03108 v2 PDFtonydisojaNessuna valutazione finora

- Acta 2014 3 11 PDFDocumento6 pagineActa 2014 3 11 PDFtonydisojaNessuna valutazione finora

- 109 JMES 289 2012 VermaDocumento14 pagine109 JMES 289 2012 VermaNagwa MansyNessuna valutazione finora

- Ijaiem 2015 05 15 30 PDFDocumento10 pagineIjaiem 2015 05 15 30 PDFInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Studies On Mechanical Properties of Concrete Using Sugarcane Bagasse Ash (Scba)Documento5 pagineStudies On Mechanical Properties of Concrete Using Sugarcane Bagasse Ash (Scba)tonydisojaNessuna valutazione finora

- Utilization of Sugarcane Ash in ConcreteDocumento8 pagineUtilization of Sugarcane Ash in ConcretetonydisojaNessuna valutazione finora

- Bagasse Ash Replaced Cement Concrete StrengthDocumento8 pagineBagasse Ash Replaced Cement Concrete StrengthtonydisojaNessuna valutazione finora

- Ijsrdv3i110384 PDFDocumento5 pagineIjsrdv3i110384 PDFtonydisojaNessuna valutazione finora

- Bagasse Ash Potential in Concrete and as Cement ReplacementDocumento16 pagineBagasse Ash Potential in Concrete and as Cement ReplacementtonydisojaNessuna valutazione finora

- Materials 06 03108 v2 PDFDocumento20 pagineMaterials 06 03108 v2 PDFtonydisojaNessuna valutazione finora

- PGDIRI Syllabus PDFDocumento11 paginePGDIRI Syllabus PDFVinod KumarNessuna valutazione finora

- Return To TOC: Dowty Propellers Standard Practices ManualDocumento11 pagineReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNessuna valutazione finora

- Experiment 4Documento12 pagineExperiment 4Doğukan Aybars ÖztürkNessuna valutazione finora

- Mass Balance DescriptionDocumento10 pagineMass Balance DescriptionhazimraadNessuna valutazione finora

- Materials Compatibility List: Chemicals For Processing Endoscopes and Endoscopic InstrumentsDocumento24 pagineMaterials Compatibility List: Chemicals For Processing Endoscopes and Endoscopic InstrumentsAlina AlinaNessuna valutazione finora

- Odic Table Periodicity NeetDocumento59 pagineOdic Table Periodicity NeetAnubhav KohliNessuna valutazione finora

- Nitrogen ChemistryDocumento3 pagineNitrogen ChemistryjammyjammersNessuna valutazione finora

- UnfinishedDocumento8 pagineUnfinishedDaniel TorralbaNessuna valutazione finora

- Activity 4 - Flame Test For Metal - CRUZ ARJAYDocumento5 pagineActivity 4 - Flame Test For Metal - CRUZ ARJAYArjay Francisco CruzNessuna valutazione finora

- Henderson Hasslebach PDFDocumento21 pagineHenderson Hasslebach PDFJesseca Calaunan QuintoNessuna valutazione finora

- Chemistry Data BookletDocumento22 pagineChemistry Data BookletIsaline GurneNessuna valutazione finora

- Soap and Syndets: Differences and Analogies, Sources of Great ConfusionDocumento8 pagineSoap and Syndets: Differences and Analogies, Sources of Great Confusionيحي عامرNessuna valutazione finora

- The Preparation of Acetic Acid For Use in Otic Drops and Its Effect On Endocochlear Potential and PH in Inner Ear FluidDocumento4 pagineThe Preparation of Acetic Acid For Use in Otic Drops and Its Effect On Endocochlear Potential and PH in Inner Ear Fluidronahaniifah11Nessuna valutazione finora

- Questions For Well Life Cycle SessionDocumento17 pagineQuestions For Well Life Cycle SessionShubham PatelNessuna valutazione finora

- Ceridust TP 5091 For UV-curable Coatings With A Silk Finish: Exactly Your ChemistryDocumento2 pagineCeridust TP 5091 For UV-curable Coatings With A Silk Finish: Exactly Your ChemistryMaximiliano MackeviciusNessuna valutazione finora

- So Lucio Nario Bailey Chapter 2Documento37 pagineSo Lucio Nario Bailey Chapter 2Miguel Angel Rozo ArangoNessuna valutazione finora

- HCT590X+Z (HCT600XD / HC340XD / CR330Y590T-DP ) : Dual-Phase Steel For Cold FormingDocumento2 pagineHCT590X+Z (HCT600XD / HC340XD / CR330Y590T-DP ) : Dual-Phase Steel For Cold FormingGustavo figueiredoNessuna valutazione finora

- Ni-284-1 Lot#6 036108-10 - WDocumento1 paginaNi-284-1 Lot#6 036108-10 - WboroumandNessuna valutazione finora

- Why Is Stainless Steel Corrosion ResistantDocumento4 pagineWhy Is Stainless Steel Corrosion ResistantMELVIN MAGBANUANessuna valutazione finora

- Utilization of Distillery Slops and Gelatin to Produce Slow-Release FertilizerDocumento38 pagineUtilization of Distillery Slops and Gelatin to Produce Slow-Release FertilizerDizNessuna valutazione finora

- PPTDocumento41 paginePPTOkta KurniawanNessuna valutazione finora

- Lecture 1 Cement - AmanDocumento25 pagineLecture 1 Cement - AmanAdharsh SelvarajNessuna valutazione finora

- Olin - EPoxy Resin CatalogDocumento12 pagineOlin - EPoxy Resin CatalogkamalnandreNessuna valutazione finora

- 5 Centrifuge Tubes Evaporating Dish Test Tube Holder Crucible Tongs Two Droppers Latex Gloves LabelsDocumento16 pagine5 Centrifuge Tubes Evaporating Dish Test Tube Holder Crucible Tongs Two Droppers Latex Gloves LabelsMatti MendozaNessuna valutazione finora

- Groundwater Quality Status Using Water Quality Index in Amalner Town MaharashtraDocumento5 pagineGroundwater Quality Status Using Water Quality Index in Amalner Town Maharashtrasunaina agarwalNessuna valutazione finora

- SOLDER or BRAZE ODS & ODFDocumento4 pagineSOLDER or BRAZE ODS & ODFP.SELVAKUMARNessuna valutazione finora