Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Design and Development of Caged Ball Heart Valve Using Solid Works

Caricato da

Ana NedeljkovicTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Design and Development of Caged Ball Heart Valve Using Solid Works

Caricato da

Ana NedeljkovicCopyright:

Formati disponibili

Proceedings of the 2013 International Conference on Biology and Biomedicine

Design and development of caged ball heart

valve using solid works

K.E.Ch. Vidyasagar

Ravi Varma N

Department of Biomedical engineering,

D.B.N.C.O.E.T, Yavatmal, India

vidyasagar_itsme@yahoo.co.in

Department of Biomedical engineering,

D.B.N.C.O.E.T, Yavatmal, India

ravivarma.nmp@gmail.com

Abstract--Currently, over 2, 90,000 heart valve surgeries

are performed worldwide annually and that number is

estimated to triple by 2050. Even though patients with

prosthetic valves lead a life relatively free from

symptoms, problems like physiological complications

and valve failure are significant. To date, all mechanical

heart valves are plagued with complications associated

with hemolysis and coagulation. These complications are

believed to be associated with non-physiological blood

flow patterns in the vicinity of the artificial heart valves.

The geometry of the valve prosthesis with respect to the

mitral valve annulus may significantly affect the flow

dynamics in the human heart. It is thus essential to

assess the hemodynamics of mitral prosthetic caged ball

valve to improve the design of the device.

This research work presents a 3D model of the left

human heart with optimized mitral caged ball valve

engineered by a computational tool (SolidWorks 2009).

The performance of the valve like hemodynamics across

the valve, stress analysis and physical properties like

mass, surface area, etc. is assessed virtually. This limits

the need to perform extensive, costly and timeconsuming in-vitro and animal tests. Thus optimization

of the caged ball heart valve design facilitates reduction

of flow-induced thrombogenicity and reduces the need

for post-implant anticoagulants.

Since 1962, the StarrEdwards valve has

undergone many modifications to improve its

performance; however, the changes have focused on

materials and construction techniques and have not

altered the overall concept of the valve design. Caged

ball valve implants generate flow patterns that are

significantly different from those present in normal

cardio vascular system (CVS). These flow patterns

include regions of high velocity and high shear stress

that potentially damage the blood cells [2]. Therefore,

thromboembolic complications are being measured by

turbulence shear stress experienced by blood cells.

The threshold for haemolysis is at 800 N/m2 [3].

II. PROBLEM DEFINITION

Patients who receive prosthetic heart valve (PHV)

implants

require

mandatory

anticoagulation

medication after implantation due to the thrombogenic

potential of the valve [1]. Optimization of the caged

ball heart valve design facilitates reduction of flowinduced thrombogenicity and thus reduces the need

for post-implant anticoagulants.

III. METHODOLOGY

Index Terms: Mitral valve, left ventricle, modeling,

turbulence, hemolysis, stress

A. Designing

I. INTRODUCTION

Solid Works is a 3D mechanical Computer Aided

Design (CAD) tool useful for modeling and analysis

of various structural elements. This tool has been

employed in human physiology to model and analyze

the various human organs. The left human heart is

modeled according to human anatomy [4]. It is semielliptical in shape with major and minor axes as 80

mm and 58 mm respectively (Fig.1). The volume of

modeled left ventricle is 126 ml and surface area is

28598.71 mm2. The conventional caged ball valve is

designed in accordance with standard values using

SolidWorks. The mitral annulus diameter is 30mm,

orifice diameter is 19mm and ball diameter 23.75mm

(Fig.2). SolidWorks enables to specify the materials the ball is of silicone rubber, cage is of titanium alloy

and the sewing ring is of Teflon (PTFE).

The heart has four chambers. Blood is pumped

through the chambers, aided by four heart valvesmitral, tricuspid, aortic and pulmonary. The valves

open and close to let the blood flow in only one

direction. Each valve has a set of flaps. When working

properly, the heart valves open and close fully.

An artificial heart valve is a device implanted in

the heart of a patient with heart valvular disease.

Several different mechanical valves are currently

available. Many of them have good bulk forward flow

hemodynamics, lower transvalvular pressure drops,

larger effective orifice areas, and fewer regions of

forward flow stasis. The design of the first artificial

ball-and-cage valve consists of a ball within a metal

cage. The ball occludes the valve orifice and thus

passively prevents backflow. The movement of the

ball is pressure driven across the two chambers.

25

Proceedings of the 2013 International Conference on Biology and Biomedicine

Fig.1 3D model of left human heart

Fig.3- Hemodynamic analysis with FloXpress tool

The caged ball valve is then assembled in the

mitral valve position in the left ventricle to analyze the

hemodynamics across the prosthetic valve using

FloXpress tool in SolidWorks.

However velocity profile in mitral blood flow in

normal human heart is only 38.2 cm/sec - 123.9

cm/sec. High velocity of 4.89 m/sec across the

prosthetic valve reults in hemolysis. Hence this

research work deals with design optimization of caged

ball valve to obtain the hemodynamics within the

physiological limit.

The Boundary Conditions given as input in

SolidWorks to analyze hemodynamics are:Inlet

Mass flow rate

= 0.126126 kg/sec

Volume flow rate = 1.26126 e-04 m3/sec

Temperature

= 310K

Pressure

= 15996 Pascal

Outlet

Pressure

B. Optimization

The strut of the caged ball valve is optimized so

as to obtain the hemodynamics within the

physiological limit. Four different designs for cross

section of struts are considered (A) circle (B) square

(C) ellipse and (D) spline (Fig. 4)

= 799.80 Pascal

Hemodynamic analysis with FloXpress tool

shows a maximum velocity of 4.89 m/sec across the

conventional caged ball valve (Fig.3).

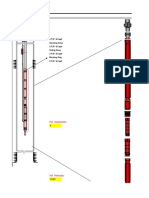

Fig. 2- 3D model of caged ball valve

Fig. 4 Strut design (A) circle (B) square (C) ellipse and (D) spline

26

Proceedings of the 2013 International Conference on Biology and Biomedicine

Table 2-Pressure Bearing Capacity

Caged ball valve with different dimensions of

each strut design ranging from 0.55 mm to 0.35 mm is

modeled. The design of the model is evaluated on 3

parameters(a) Hemodynamics within human physiological limit.

(b) Maximum pressure bearing capacity- i.e. least

stress over a range of pressure (10mmHg to 160

mmHg)

(c) Minimum surface area

IV. RESULT

The first parameter - hemodynamic analysis of

each design is evaluated using FloXpress tool of

SolidWorks. The second parameter - pressure bearing

capacity, is evaluated by performing Finite Element

Analysis (FEA) over a range of 10mmHg to 160

mmHg for each design of the valve. The third

parameter- surface area is measured for each design.

Pressure

(mmHg)

Circular

Strut

Stress

(N/m2)

Square

Strut

Stress

(N/m2)

Elliptical

Strut

Stress

(N/m2)

10

1324.2

1245.7

1112.7

40

5296.7

4982.6

4450.7

80

10593.4

9965.2

8901.4

120

15890.3

14947.9

13352.1

160

21186.9

19930.5

17802.8

Table1 Optimization Based on Above Parameters

Design

of strut

Dimension

(in mm)

Blood

Flow

Velocity

(m/sec)

Stress

(N/m2)

at

10

mmHg

Surface

Area

(mm2)

Circle

0.40

0.623

1324.2

1447.74

Square

0.45x0.45

0.625

1174

1363.21

Ellipse

0.45x0.35

0.624

1112.7

1455.43

Spline

0.40x0.40

0.622

4072

1398.82

Fig.5 Pressure Vs Stress

The graph indicates that the pressure bearing

capacity of the elliptical strut caged ball valve is

superior (least stress) than the circular strut caged ball

valve with almost similar blood flow velocity and

surface area.

Spline design of the strut is eliminated because of

maximum stress development at 10mmHg. This

indicates spline design of the strut has the least

pressure bearing capacity. The above optimized

dimensions of the three remaining strut designs, circle,

square and ellipse, are then evaluated for pressure

bearing capacity over a range of 10mmHg to

160mmHg

V. CONCLUSION

The result of hemodynamic analysis of the left

human heart with caged ball mitral valve and FEA of

the valve indicates that elliptical strut of the valve is a

superior design compared to conventional circular

strut. Hence this optimization of the structure of the

caged ball valve would greatly reduce flow induced

thrombogenicity.

27

Proceedings of the 2013 International Conference on Biology and Biomedicine

VI. FUTURE WORK

This model provides with a prospect to further

optimize the caged ball valve. The pressure-stress

analysis for different biomaterials can also be

performed to increase the durability of the valve.

REFERENCES

[1] Ajit P. Yoganathan, K.B. Chandran, and Fotis Sotiropoulos,

Flow in Prosthetic Heart Valves: State-of-the-Art and Future

Directions, Annals of Biomedical Engineering, December 2005,

Vol. 33. No. 12, pp. 16891694

[2] Lakshmi P Dasi, Helene A Simon, Philippe Sucosky, and Ajit P

Yoganathan, Fluid Mechanics of Artificial Heart Valves, Clin Exp

Pharmacol Physiol. February 2009, Vol. 36. No. 2, pp. 225237

[3] P.C. Lu, H.C. Lai and J.S. Liu, A reevaluation and discussion

on the threshold limit for hemolysis in a turbulent shear flow,

Journal of Biomechanics, 2001; Vol.34, pp. 13611364

[4] Richard T. Schoephoerster and Krishnan B. Chandran, Velocity

and turbulence measurements past mitral valve prostheses in a

model left ventricle, Journal of Biomechanics, 1991, Vol. 24. No. 7,

pp. 549-562

28

Potrebbero piacerti anche

- Steel - Equivalent GradesDocumento17 pagineSteel - Equivalent Gradessmsett100% (5)

- GTAG 1 IT Risk and Controls 2nd Edition MarchDocumento36 pagineGTAG 1 IT Risk and Controls 2nd Edition MarchCat ValentineNessuna valutazione finora

- Cat 772 Catálogo de Peças PDFDocumento937 pagineCat 772 Catálogo de Peças PDFTom Souza100% (1)

- 367 Final Fall 2013 AnswersDocumento18 pagine367 Final Fall 2013 AnswersMona Ali100% (1)

- Modelling and Numerical Simulation of Flow Through Artificial Heart ValvesDocumento10 pagineModelling and Numerical Simulation of Flow Through Artificial Heart ValvesJesus EmanuelNessuna valutazione finora

- IntraDocumento170 pagineIntraToufique KaziNessuna valutazione finora

- Prosthetic Cardiac ValvesDocumento5 pagineProsthetic Cardiac ValvessivaNessuna valutazione finora

- CFD Simulation of Blood Flow Through Artificial Heart ValvesDocumento4 pagineCFD Simulation of Blood Flow Through Artificial Heart ValvesMohmmed MahmoudNessuna valutazione finora

- 33Documento23 pagine33salaminiaNessuna valutazione finora

- Fluid Mechanics of Artificial Heart ValvesDocumento20 pagineFluid Mechanics of Artificial Heart ValvesYing WenNessuna valutazione finora

- Pages de 5Documento1 paginaPages de 5Anonymous g3MQl8Nessuna valutazione finora

- Research Essay: "Reliability of An Artificial Heart Valve" Alyona Ivanova V00722211 ENGR 110Documento7 pagineResearch Essay: "Reliability of An Artificial Heart Valve" Alyona Ivanova V00722211 ENGR 110i_alyonaNessuna valutazione finora

- Stress Analysis of The Aortic Valve Using Finite Element Modelling SoftwareDocumento9 pagineStress Analysis of The Aortic Valve Using Finite Element Modelling SoftwareMarco LaudisioNessuna valutazione finora

- Experimental Validation of The Fluid-Structure Interaction Simulation of A Bioprosthetic Aortic Heart ValveDocumento11 pagineExperimental Validation of The Fluid-Structure Interaction Simulation of A Bioprosthetic Aortic Heart Valvesiddharth GautamNessuna valutazione finora

- ANMCO POSITION PAPER Role of Intra-Aortic BalloonDocumento17 pagineANMCO POSITION PAPER Role of Intra-Aortic BalloonapipNessuna valutazione finora

- The Flow Patterns Within The Impeller Passages of A Centrifugal Blood Pump ModelDocumento13 pagineThe Flow Patterns Within The Impeller Passages of A Centrifugal Blood Pump ModelMohammed Al-AzawyNessuna valutazione finora

- Circulation 2007 Vlahakes 1759 60Documento3 pagineCirculation 2007 Vlahakes 1759 60Maggie LiNessuna valutazione finora

- ValvesDocumento6 pagineValvesMythily VedhagiriNessuna valutazione finora

- Journal of Biomedical Materials Research Part B 2009 KidaneDocumento14 pagineJournal of Biomedical Materials Research Part B 2009 KidaneNick ArmstrongNessuna valutazione finora

- Construction of A Vascularized Cardiopulmonary Resuscitation Mannequin With Hemodynamic Monitoring Including Peripheral VasculatureDocumento15 pagineConstruction of A Vascularized Cardiopulmonary Resuscitation Mannequin With Hemodynamic Monitoring Including Peripheral VasculatureDeng DaihaiNessuna valutazione finora

- Pulsatile Flow Pump Based On An Iterative Controlled Piston PumpDocumento7 paginePulsatile Flow Pump Based On An Iterative Controlled Piston Pumpyue jiangNessuna valutazione finora

- صمامات القلب باور بوينتDocumento28 pagineصمامات القلب باور بوينتAbeeesy AmrakeyNessuna valutazione finora

- Design and Control of A Peristaltic Pump To Simulate Left AtrialDocumento31 pagineDesign and Control of A Peristaltic Pump To Simulate Left Atrialhadeel fahimNessuna valutazione finora

- Effect of Cannulation Site On Emboli Travel During Cardiac SurgeryDocumento11 pagineEffect of Cannulation Site On Emboli Travel During Cardiac SurgeryAndi Tri SutrisnoNessuna valutazione finora

- Automation in Heart Lung MachineDocumento23 pagineAutomation in Heart Lung MachineKushal PatelNessuna valutazione finora

- Material Selection For Leaflet of Mechanical Heart ValveDocumento15 pagineMaterial Selection For Leaflet of Mechanical Heart ValveKushagra YadavNessuna valutazione finora

- Article On Heart ValvesDocumento16 pagineArticle On Heart Valvesrohit860Nessuna valutazione finora

- SDL 20 Prosthetic Heart Valves BMS16091064Documento6 pagineSDL 20 Prosthetic Heart Valves BMS16091064Jonathan YeohNessuna valutazione finora

- Cardiopulmonary Bypass: Learning ObjectivesDocumento5 pagineCardiopulmonary Bypass: Learning ObjectivesAnonymous zPwXqwNessuna valutazione finora

- European Journal of Mechanics B/Fluids: X. Zheng, J.H. Seo, V. Vedula, T. Abraham, R. MittalDocumento9 pagineEuropean Journal of Mechanics B/Fluids: X. Zheng, J.H. Seo, V. Vedula, T. Abraham, R. MittalHaider AliNessuna valutazione finora

- Abstract ChkhaidzeDocumento1 paginaAbstract ChkhaidzeZurab ChkhaidzeNessuna valutazione finora

- VoluteDocumento3 pagineVolutesamadonyNessuna valutazione finora

- Term Paper On Artificial Heart ValveDocumento5 pagineTerm Paper On Artificial Heart Valvebeemwvrfg100% (1)

- Heart ValveDocumento12 pagineHeart ValveNishanthini MohanNessuna valutazione finora

- Prosthetic Heart Valves - Part 1 - SelectionDocumento13 pagineProsthetic Heart Valves - Part 1 - SelectionwalltercesarNessuna valutazione finora

- Heart Valve SelectionDocumento16 pagineHeart Valve Selectionfelixsafar3243Nessuna valutazione finora

- Intra-Aortic Balloon Counterpulsation Therapy and Its Role in Optimizing Outcomes in Cardiac SurgeryDocumento31 pagineIntra-Aortic Balloon Counterpulsation Therapy and Its Role in Optimizing Outcomes in Cardiac SurgeryHendrik AbrahamNessuna valutazione finora

- Biomaterials Ppt-Part - 2 - CompressedDocumento176 pagineBiomaterials Ppt-Part - 2 - Compressedsparsh agarwalNessuna valutazione finora

- Aortic RegurgitationDa EverandAortic RegurgitationJan VojacekNessuna valutazione finora

- Positive Displacement PumpsDocumento11 paginePositive Displacement PumpsMohammed Al-AzawyNessuna valutazione finora

- Patient-Specific Neurovascular Simulator For Evaluating The Performance of Medical Robots and InstrumensDocumento6 paginePatient-Specific Neurovascular Simulator For Evaluating The Performance of Medical Robots and Instrumenspatogol278Nessuna valutazione finora

- Ec 5 C 3137685934 Bbef 5 eDocumento4 pagineEc 5 C 3137685934 Bbef 5 eapi-684047665Nessuna valutazione finora

- Regurgitation The Tricuspid Valve: Current Perspective and Evolving Management of TricuspidDocumento9 pagineRegurgitation The Tricuspid Valve: Current Perspective and Evolving Management of TricuspidAngga Maulana IbrahimNessuna valutazione finora

- Specialized Finite Element Analysis Computer Software For Modeling Hemodynamics in Abdominal Aortic and Carotid Artery Bifurcation AneurysmsDocumento8 pagineSpecialized Finite Element Analysis Computer Software For Modeling Hemodynamics in Abdominal Aortic and Carotid Artery Bifurcation AneurysmsKanesan MuthusamyNessuna valutazione finora

- Design of Tricuspid Polymeric Mechanical Heart Valve Replacements To Optimize Flow Pattern and Reduce Risk of ThrombosisDocumento6 pagineDesign of Tricuspid Polymeric Mechanical Heart Valve Replacements To Optimize Flow Pattern and Reduce Risk of Thrombosisapi-482373029Nessuna valutazione finora

- Daniel Timms ThesisDocumento274 pagineDaniel Timms ThesisIbrahim Basar AkaNessuna valutazione finora

- Medical Progress: Review ArticleDocumento10 pagineMedical Progress: Review Articleapi-90785308Nessuna valutazione finora

- Polymeric ValvesDocumento9 paginePolymeric ValvesDrăghici AlinaNessuna valutazione finora

- Axial Ow Artificial Heart Blood Pumps: A Brief Review: Trends in Biomaterials and Artificial Organs January 2013Documento8 pagineAxial Ow Artificial Heart Blood Pumps: A Brief Review: Trends in Biomaterials and Artificial Organs January 2013Saad BarnousNessuna valutazione finora

- Intellegent Systems For BiomechanicsDocumento5 pagineIntellegent Systems For BiomechanicsSrinivas RaghavanNessuna valutazione finora

- Applied Mathematical Modelling: A.C. Benim, A. Nahavandi, A. Assmann, D. Schubert, P. Feindt, S.H. SuhDocumento14 pagineApplied Mathematical Modelling: A.C. Benim, A. Nahavandi, A. Assmann, D. Schubert, P. Feindt, S.H. SuhMasterAlbus3dNessuna valutazione finora

- Cardiopulmonary Bypass - StatPearls - NCBI BookshelfDocumento11 pagineCardiopulmonary Bypass - StatPearls - NCBI Bookshelfhadeel fahimNessuna valutazione finora

- Abstract COBEM 2017Documento3 pagineAbstract COBEM 2017Diego CelisNessuna valutazione finora

- Spiral Blood PumpDocumento11 pagineSpiral Blood PumpMaryamNessuna valutazione finora

- Coanda Effect 1Documento7 pagineCoanda Effect 1Supriya PatilNessuna valutazione finora

- Polyurethane: Material For The Next Generation of Heart Valve Prostheses?Documento9 paginePolyurethane: Material For The Next Generation of Heart Valve Prostheses?pcnferreiraNessuna valutazione finora

- 1 IntroductionDocumento3 pagine1 IntroductionAnonymous hL4if1pTmNessuna valutazione finora

- Biofluid Assignment 3Documento6 pagineBiofluid Assignment 3Dina AssefaNessuna valutazione finora

- Flow Diverted Aneurysmal Hemodynamic Simulations and Validation With ExperimentsDocumento3 pagineFlow Diverted Aneurysmal Hemodynamic Simulations and Validation With ExperimentsJacob BarreraNessuna valutazione finora

- Simulation of The Cardiovascular Mechanical System Based On Pressure-Flow Model Rest ConditionDocumento12 pagineSimulation of The Cardiovascular Mechanical System Based On Pressure-Flow Model Rest ConditionInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Potri Hafisah B. Macadaya Group 2 BSN 3Documento26 paginePotri Hafisah B. Macadaya Group 2 BSN 3Marivic Diano100% (2)

- 102-Article Text-462-3-2-20200510Documento10 pagine102-Article Text-462-3-2-20200510Andre Boca Ribas FreitasNessuna valutazione finora

- Applsci 09 01216Documento11 pagineApplsci 09 01216ARABONessuna valutazione finora

- Surgery Valve Disease : For MultipleDocumento17 pagineSurgery Valve Disease : For MultipleShekhar Ricky SahaNessuna valutazione finora

- Parametri FrekventniDocumento2 pagineParametri FrekventniAna NedeljkovicNessuna valutazione finora

- Festo JastuciDocumento15 pagineFesto JastuciAna NedeljkovicNessuna valutazione finora

- Rotho BetonsteinDocumento15 pagineRotho BetonsteinAna NedeljkovicNessuna valutazione finora

- Edb - 6836591 - GBR - en ASP 1000Documento2 pagineEdb - 6836591 - GBR - en ASP 1000Ana NedeljkovicNessuna valutazione finora

- TECHMATIK MIESZARKI A4 12 Stron ENDocumento12 pagineTECHMATIK MIESZARKI A4 12 Stron ENAna NedeljkovicNessuna valutazione finora

- Sae3-Heavy DutyDocumento53 pagineSae3-Heavy DutyAna NedeljkovicNessuna valutazione finora

- 265id Transtecno Helical Parallel Gearmotors FT ATS ITS - 1017Documento99 pagine265id Transtecno Helical Parallel Gearmotors FT ATS ITS - 1017Ana NedeljkovicNessuna valutazione finora

- Air Actuators: For Pneumatic ApplicationsDocumento12 pagineAir Actuators: For Pneumatic ApplicationsAna NedeljkovicNessuna valutazione finora

- Cylindrical Roller Bearings Double Row Full complement-NNCL 4912 CVDocumento1 paginaCylindrical Roller Bearings Double Row Full complement-NNCL 4912 CVAna NedeljkovicNessuna valutazione finora

- The Wood-Mizer LT-15: Sawmill ReviewDocumento9 pagineThe Wood-Mizer LT-15: Sawmill ReviewAna Nedeljkovic100% (1)

- 01 Hydraulic Cylinders Iso60201Documento20 pagine01 Hydraulic Cylinders Iso60201Ana NedeljkovicNessuna valutazione finora

- Cylindrical Roller Bearings Double Row Full complement-NNCL 4912 CVDocumento1 paginaCylindrical Roller Bearings Double Row Full complement-NNCL 4912 CVAna NedeljkovicNessuna valutazione finora

- Concrete Vibrators 1003 HandbookDocumento8 pagineConcrete Vibrators 1003 HandbookMohammad Saleem ZahidiNessuna valutazione finora

- FeaDocumento168 pagineFeaAna NedeljkovicNessuna valutazione finora

- RecoVibTiny en Rev1p4Documento6 pagineRecoVibTiny en Rev1p4Ana NedeljkovicNessuna valutazione finora

- Mater I JaliDocumento25 pagineMater I JaliAna NedeljkovicNessuna valutazione finora

- 21 Artificial Heart Valve FinalDocumento11 pagine21 Artificial Heart Valve FinalAna NedeljkovicNessuna valutazione finora

- Pressure Volume CurvesDocumento22 paginePressure Volume CurvesRaghavendra PrasadNessuna valutazione finora

- Sivi LivDocumento15 pagineSivi LivAna NedeljkovicNessuna valutazione finora

- TrolisniDocumento7 pagineTrolisniAna NedeljkovicNessuna valutazione finora

- Brest CancerDocumento9 pagineBrest CancerAna NedeljkovicNessuna valutazione finora

- Mechanical Lung ModelDocumento4 pagineMechanical Lung ModelAna NedeljkovicNessuna valutazione finora

- Bartec Enclosure B201167 - 1EDocumento6 pagineBartec Enclosure B201167 - 1EsilvioNessuna valutazione finora

- Soil Test Report KolhapurDocumento35 pagineSoil Test Report Kolhapuryedida viswanadhNessuna valutazione finora

- Solvent Extraction: Please Submit Question 4 For MarkingDocumento3 pagineSolvent Extraction: Please Submit Question 4 For MarkingThembi Matebula100% (1)

- GLR EstimateDocumento2 pagineGLR EstimateanbujeNessuna valutazione finora

- Std-Insp-0002 (Incoming Material Inspection Procedure)Documento3 pagineStd-Insp-0002 (Incoming Material Inspection Procedure)airbroomNessuna valutazione finora

- DSE7410 MKII DSE7420 MKII Installation Instructions PDFDocumento2 pagineDSE7410 MKII DSE7420 MKII Installation Instructions PDFyao nestorNessuna valutazione finora

- Instruction ManualDocumento462 pagineInstruction ManualCaraluaNessuna valutazione finora

- 117position Monitor PDFDocumento2 pagine117position Monitor PDFJacob KalloorNessuna valutazione finora

- Robotic CafeDocumento13 pagineRobotic CafeRana SaqlainNessuna valutazione finora

- INFA3227 Esquema 01-MAR-2021Documento9 pagineINFA3227 Esquema 01-MAR-2021sasgarisNessuna valutazione finora

- Alfonso, Michael John Agaser 202005047MN0 Bachelor of Science in Electrical Engineering Enrolled SubjectsDocumento1 paginaAlfonso, Michael John Agaser 202005047MN0 Bachelor of Science in Electrical Engineering Enrolled SubjectsMJA.AlfonsoNessuna valutazione finora

- Broadcast BillDocumento22 pagineBroadcast BillLidwin SoundariaNessuna valutazione finora

- S.No. Test No. Test Completed Excavation Completed No - of Days For Manual Excavation & Arrangement of Soil BagsDocumento8 pagineS.No. Test No. Test Completed Excavation Completed No - of Days For Manual Excavation & Arrangement of Soil BagsKarthikeyan SnNessuna valutazione finora

- Timestamp Surname: First Name and Middle Initial: Email Address (Personal) : Course: Student Number: Payment Transaction Method: Transaction Number: Transaction DateDocumento26 pagineTimestamp Surname: First Name and Middle Initial: Email Address (Personal) : Course: Student Number: Payment Transaction Method: Transaction Number: Transaction DateJean ZyrelleNessuna valutazione finora

- Zones of Protection and Dead or Blind Zone in Power SystemDocumento4 pagineZones of Protection and Dead or Blind Zone in Power SystemkarthikNessuna valutazione finora

- DefluoridationDocumento13 pagineDefluoridationSuha Yechwad100% (1)

- Science 10 BowDocumento10 pagineScience 10 BowGERRY CHEL LAURENTENessuna valutazione finora

- The VI Editor PDFDocumento7 pagineThe VI Editor PDFPurandhar TataraoNessuna valutazione finora

- A TCP TutorialDocumento11 pagineA TCP Tutorialpfck4589Nessuna valutazione finora

- Chemistry Laboratory EquipmentsDocumento11 pagineChemistry Laboratory EquipmentsEliutario IgnacioNessuna valutazione finora

- Class 10 Science (Physics) MCQs Chapter 11 QuestionsDocumento28 pagineClass 10 Science (Physics) MCQs Chapter 11 QuestionsKSA TEXTILENessuna valutazione finora

- Emergency Off and Rescue From Helicopter: Ground Rescue Booklet Ec130T2Documento20 pagineEmergency Off and Rescue From Helicopter: Ground Rescue Booklet Ec130T2robbertmd100% (1)

- TyresDocumento9 pagineTyresNitesh KotianNessuna valutazione finora

- ZipGrade User Guide JPDocumento6 pagineZipGrade User Guide JPJinsen Paul MartinNessuna valutazione finora

- Sintech Pumps For Sugar Processing PlantDocumento18 pagineSintech Pumps For Sugar Processing Plantsahildhingra100% (2)

- Fruit Recognition Deep LearningDocumento53 pagineFruit Recognition Deep Learningsaran20099Nessuna valutazione finora

- Cloud Infrastructure and ServicesDocumento3 pagineCloud Infrastructure and ServicesShobha RaniNessuna valutazione finora