Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Catalytic Synthesis of Sec Butyl Acetate On Sulfoacid Resin

Caricato da

Dea YusufTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Catalytic Synthesis of Sec Butyl Acetate On Sulfoacid Resin

Caricato da

Dea YusufCopyright:

Formati disponibili

International Journal of Advancements in Research & Technology, Volume 2, Issue 8, August-2013

ISSN 2278-7763

Catalytic Synthesis of Sec-butyl Acetate on

Sulfoacid Resin

NIE Xin1, LI Jian1, YANG Li-na1, WANG Lu-xun2 , XU Long1

1

Department of Petrochemistry, Liaoning Shihua University, Fushun, China;

Jinxi Petrochemical Company,

Petrochina, Huludao, China.

Email: niexin0317@163.com

ABSTRACT

In this experiment, acetic acid and sec-butanol are used as raw materials for the synthesis of sec-butyl

acetate with the sulfoacid resin D005 as the catalyst, the influences of operating parameters including

reaction temperature, reaction time, mole ratio and the amount of catalyst were investigated to

determine the proper process conditions. It is shown that the proper process conditions are:

temperature 120, tim e4h, mole ratio of sec-butanol to acetic acid is 1.2:1, the amount of catalyst 15%

weight, then acetic acid conversion rate is 64%. In optimal conditions, the catalyst was reused five

times; the acetic acid conversion rate is still more than 63%, so the catalyst has good stability.

IJOART

Key wordsEsterification;Sec-butyl acetate; Sulfoacid resin

1. INTRODUCTION

Sec-butyl acetate which is slightly yellow transparent oily liquid and possess unique aroma of ester

material belong to low carbon fatty acid. Sec-butyl acetate is insoluble in water, but it can dissolve with

alcohol, ether and other organic solvents. Sec-butyl acetate is acetic esters organic solvent. With the

unceasing enhancement worldwide environmental consciousness, people tend to use sec-butyl acetate

such oxygenated solvent gradually, thus sec-butyl acetate gradually replace toxic aromatic and ketone

solvents in coatings. The performance of sec-butyl acetate is similar to n-butyl acetate, and the price is

lower than n-butyl acetate. So sec-butyl acetate has good development potential.Sec-butyl acetate is

widely existing in the fruit such as apples, bananas, grapes, pears. Sec-butyl acetate is a kind of widely

used organic chemical products and mainly used for paint solvent, diluent, all kinds of vegetable oil

and resin solvent. It also used for medical and pharmaceutical [1]. The synthesis of sec-butyl acetate is

not so easy due to the side reaction for the dehydration of sec-butyl alcohol and the high steric

hindrance when the reaction occurs, therefore the selectivity of the catalyst is very crucial, and the

catalyst with high dehydration activity will decrease the objective products yield. The traditional

synthesis method is with acetic acid and sec-butyl alcohol as the feeds, with sulfuric acid or proton

acid for example benzene sulfonic acid as catalyst. Due to poor selectivity of concentrated sulfuric

acid, there are many effects, for example side effect occurring and the difficulty of separation and

purification of products, and severe environmental pollution and equipment corrosion which is

disadvantageous for industrial production. So people are actively looking for new environmentally

friendly catalyst [2], [3], [4].

Although the sulfonic acid resin is a kind of the commonly industrialized catalyst in some

reactions, it is seldom used in the esterification. As the heterogeneous catalyst, it not only can

overcome the disadvantages of concentrated sulfuric acid as the catalyst, but also simplify the process

of separation and purification of product, and reduce the energy consumption and the generation of

acid waste water [5].

2. EXPERIMENTAL

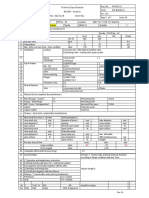

2.1 Experiment reagent and instrument

Copyright 2013 SciResPub.

IJOART

International Journal of Advancements in Research & Technology, Volume 2, Issue 8, August-2013

ISSN 2278-7763

Acetic acid(AR), 5% Phenolphthalein indicator were purchased from Baishi Co., Ltd Tianji,

China;sec-butanol(CP)was purchased from China National Medicines Co.,Ltd; NaOH(AR), 37% HCL

were purchased from chemical reagent factory, Shenyang; sulfoacid resin D005(AR)was purchased

from Mingzhu special resin co., Ltd Dandong, China.

2.2 The pretreatment of the catalyst

The sulfonic acid resin was treated with 4% HCl, deionized water, 4% NaOH and deionized water in

turn until the water is neutral, and then the resin was dried at 100 for more than 12h.

2.3 Esterification

A certain amount of sulfonic acid resin D005, acetic acid and sec-butyl alcohol are put into the round

bottom flask which is in DF - 101s collector-type constant temperature heating magnetic stirrer at some

temperature with stirring. Under a certain temperature, then the raw material is heated with reflux for

certain hours, then the acetic acid conversion rate is calculated.

the acid values before and after reaction were determined with a solution of 0.05mol sodium

hydroxide, and the acetic acid conversion rate is calculated as followings:

Acetic acid conversion rate=1-

V1

V0

100%

V1the volume that consumption of 1.5molL-1NaOH before reaction

IJOART

V0the volume that consumption of 1.5molL-1NaOH after reaction

3. RESULTS AND DISCUSSION

3.1 Catalytic Activity Contrast

At the reaction condition: temperature 120, tim e2h, mole ratio of sec-butanol to acetic acid is 1.1:1,

the amount of catalyst 10%weightH zeoliteFeCl 3 and sulfoacid resin were used as the catalysts

to compare the catalytic activity. The results are shown in table 1. The data from table 1 shows that

without catalyst the acetic acid conversion rate is only 38.0%. Using H zeolite as the catalyst, the

acetic acid conversion rate is 46.0%. However, this result is too low to sec-butyl acetate catalytic

Synthesis. The catalytic activity of FeCl 3 is the best, and the acetic acid conversion rate is 66.0%,

However, FeCl 3 dissolved in reaction liquid making product with deeper color, catalyst recycling is

difficult and not reused[6], [7]. So sulfoacid resin is the appropriate catalyst.

Table 1 Catalytic activity contrast

serial number

Catalyst

Acetic acid conversion rate%

None

38.0

H zeolite

46.0

FeCl 3

66.0

sulfoacid resin

64.0

Copyright 2013 SciResPub.

IJOART

International Journal of Advancements in Research & Technology, Volume 2, Issue 8, August-2013

ISSN 2278-7763

3.2 Reaction Time Effect on Acetic Acid Conversion Rate

At the reaction condition: temperature 120, m ole ratio of sec-butanol to acetic acid is 1.1:1, the

amount of sulfoacid resin 10%weightinfluence of reaction time was studied, and the results

are shown in figure 1. With the increasing of reaction time, the acetic acid conversion rate

increases. When the time is 4h, the acetic acid conversion rate is larger than other time. When

prolong the reaction time, the acetic acid conversion rate declined. The reasons for this

phenomenon are that the esterification reaction is reversible reaction and may due to the

adsorption effect of catalyst. Because in the longer reaction time, raw material be adsorbed more

acetic acid conversion rate/%

on the surface of the catalyst. So the appropriate time is 4h.

66.0

64.0

62.0

60.0

58.0

56.0

54.0

52.0

0

3

time/h

IJOART

Figure1 reaction time effect on acetic acid conversion rate

3.3 Reaction Temperature Effect on Acetic Acid Conversion Rate

At the reaction condition: time 2h, mole ratio of sec-butanol to acetic acid is 1.1:1, the amount of

sulfoacid resin 10%weightthe influences of reaction temperature were studied. The results are

shown in figure 2, it can be seen that at low temperature, the esterification are incomplete, the

acetic acid conversion rate increases with the increasing of reaction temperature. When the

temperature is 120, the acetic acid conversion rates no longer increase. Because the temperature

acetic acid conversion rate/%

is too high, the reaction can make more by-products. So the appropriate temperature is 120.

65

60

55

50

45

40

35

40

60

80

100

120

temperature/

140

160

Figure 2 reaction temperature effects on acetic acid conversion rate

Copyright 2013 SciResPub.

International Journal of Advancements in Research & Technology, Volume 2, Issue 8, August-2013

ISSN 2278-7763

3.4 The Amount of Catalyst Effect on Acetic Acid Conversion rate

At the reaction condition: time 2h, mole ratio of sec-butanol to acetic acid is 1.1:1, temperature 120,

the influences of the amount of sulfoacid resin were studied. The results are shown in figure 3. It can

be seen that the acetic acid conversion rate increases with the increasing of the amount of catalyst for

the increasing catalyst activity centers. But when the catalyst is more than 15%weight, acetic acid

conversion rate fall slightly. This is because the adsorption of feeds and products on the catalyst which

acetic acid conversion rate/%

reduces the mass transfer rate, so the appropriate the amount of catalyst is 15%weight.

64.0

62.0

60.0

58.0

56.0

54.0

52.0

50.0

48.0

46.0

44.0

0

10

15

the amount of catalyst/%

20

25

IJOART

Figure 3 the amount of catalyst effect on acetic acid conversion rate

3.5 mole ratio of sec-butanol to acetic acid is effect on acetic acid conversion rate

At the reaction condition: time 2h, temperature 120, the amount of sulfoacid resin 10%weight, the

influences of mole ratio of the feed(sec-butanol: acetic acid) were studied. The results are shown in

figure 4, It can be seen that appropriately increase of the amount of the sec-butanol, can help balance

move to generate sec-butyl acetate direction. But when the mole ratio of sec-butanol to acetic acid is

more than 1.2 :1, acetic acid concentration declines, which results in the decrease of the acetic acid

acetic acid conversion rate/%

conversion rate, so the appropriate mole ratio of sec-butanol to acetic acid is 1.2:1.

65.0

60.0

55.0

50.0

45.0

40.0

35.0

0.7

0.8

0.9

1

1.1

1.2

1.3

mole ratiosec-butanolacetic acid

1.4

Figure 4 mole ratio of sec-butanol to acetic acid is effect on acetic acid conversion rate

3.6 The performance of reused catalysts

At the reaction condition: time 2h, temperature 120, the amount of sulfoacid resin15%weight, mole

ratio of sec-butanol to acetic acid is 1.1:1 . The catalysts were used for several times in the reaction, and

the reaction results with the used catalyst are shown in figure 5. It can be seen that the sulfoacid resin

Copyright 2013 SciResPub.

IJOART

International Journal of Advancements in Research & Technology, Volume 2, Issue 8, August-2013

ISSN 2278-7763

acetic acid conversion rate/%

has good stability. The acetic acid conversion rate is still as high as 63% after 4 times of reactions.

70.0

68.0

66.0

64.0

62.0

60.0

58.0

56.0

54.0

52.0

50.0

0

2

3

4

repeated times of catalyst

Figure 5 the performance of reused catalyst effect on acetic acid conversion rate

4. CONCLUSIONS

With sulfoacid resin as the catalyst the appropriate reaction parameters are: temperature 120, tim e

4h, mole ratio of sec-butanol to acetic acid is 1.2:1, the amount of catalyst 15%weight, then acetic acid

conversion rate is 64%. The acetic acid conversion rate when the reaction has repeated 5 times is still as

high as 63%, and the catalyst which is not dissolved in the reactants can easily separate from the

IJOART

reaction completely.

5. REFERENCES

[1] Amornchai A. , Kittipong K., Worapon K., Piyasan P., Suttichai A., Production of n-butyl acetate from dilute acetic

acid and n-butanol using different reactive distillation systems: Economic analysis, Journal of the Taiwan Institute of

Chemical Engineers, 2009.40: 21~28

[2] Ramesh C.Mahender G., Ravindranath N., Biswanath D., A simplemild and efficient procedure for selective

cleavage of prenyl esters using silica supported sodium hydrogen sulphate as a heterogenous catalyst [J]

Tetrahedron letters , 2003, 44(7):1465~1467

[3] Pascale D., Jacques C. V., Eric P., Gthrd H., Frederic L., Heteropolyacids supported on activated carbonas catalysts

for the esterification of acrylic acid by butanol, Applied Catalysis A: General 129(1995): 217~227

[4] D.L. Trimm, The regeneration or disposal of deactivated heterogeneous catalysts, Applied Catalysis A, 2001,

212:153~160

[5] Sergej B., Sandra P., Oliver B., Peter M., David L., Rudolf We. ,Hans H., Influence of ion-exchange resin catalysts on

side reactions of the esterification of n-Butanol with acetic acid, Chemical Engineering Science 2006, 2(61):753~765

[6] Adharvana Chari M Syamasundar K Polymer( PVP) supported ferric chloride: an efficient and recyclable

heterogeneous catalyst for high yield synthesis of 15 benzodiazepine derivatives under solvent free conditions

and microwave irradiationJCatalysis communications20056( 1) :6770

[7] Ramesh CMahender GRavindranath NBiswanath DA simplemild and efficient procedure for selective

cleavage of prenyl esters using silica-supported sodium hydrogen sulphate as a heterogenous catalystJ

Tetrahedron letters200344( 7) :1465 1467.

Copyright 2013 SciResPub.

IJOART

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Unit 5.12 PrecipitationDocumento16 pagineUnit 5.12 PrecipitationMutale InongeNessuna valutazione finora

- Everyday Science PDFDocumento101 pagineEveryday Science PDFMahmood SyedNessuna valutazione finora

- Thermo Scientific Taq Dna Polymerase With KCL Buffer: DescriptionDocumento3 pagineThermo Scientific Taq Dna Polymerase With KCL Buffer: DescriptionCHIRANJEEVINessuna valutazione finora

- SLR Strainer Data SheetDocumento7 pagineSLR Strainer Data SheetKailas NimbalkarNessuna valutazione finora

- Eisco Industrial Catalogue - FinalDocumento276 pagineEisco Industrial Catalogue - FinalSOHAM AlhatNessuna valutazione finora

- Fibc Type A B C D Classification SafetyDocumento2 pagineFibc Type A B C D Classification Safetydhineshbabu rNessuna valutazione finora

- TWM 3178 PDSDocumento2 pagineTWM 3178 PDSsunnyooiNessuna valutazione finora

- Asme Sec V Art 6 2007 (Ingles)Documento8 pagineAsme Sec V Art 6 2007 (Ingles)fdvrevtrfvrtfNessuna valutazione finora

- CRC 2-26Documento2 pagineCRC 2-26saranNessuna valutazione finora

- Aws Cwi QuestionDocumento8 pagineAws Cwi Questionfrenskiran75% (4)

- TM 10-4930-220-13PDocumento133 pagineTM 10-4930-220-13PAdvocateNessuna valutazione finora

- The Motion of ColorDocumento6 pagineThe Motion of Colorapi-374832521Nessuna valutazione finora

- Test1 Goc & Poc Tough by S.K.sinha See Chemistry Animations atDocumento3 pagineTest1 Goc & Poc Tough by S.K.sinha See Chemistry Animations atmyiitchemistry100% (1)

- TECS-W IOM ManualDocumento60 pagineTECS-W IOM Manualxuyen tran100% (4)

- tmpA3C2 TMPDocumento11 paginetmpA3C2 TMPFrontiersNessuna valutazione finora

- What Pipeliners Need To Know About Induction Bends PDFDocumento20 pagineWhat Pipeliners Need To Know About Induction Bends PDFmarcos2dami2o2de2azeNessuna valutazione finora

- 01-0019-01 Flame Methods Manual For AADocumento117 pagine01-0019-01 Flame Methods Manual For AARobert Larry Cordova DiazNessuna valutazione finora

- Cell Wall: Presented by M. Vijaya LakshmiDocumento9 pagineCell Wall: Presented by M. Vijaya LakshmiATCHUNALA SAINessuna valutazione finora

- Materials and Design: Ehab A. El-Danaf, Magdy M. El-Rayes, Mahmoud S. SolimanDocumento6 pagineMaterials and Design: Ehab A. El-Danaf, Magdy M. El-Rayes, Mahmoud S. Solimankamal touilebNessuna valutazione finora

- Drugdistributionfinal 151003021801 Lva1 App6891Documento12 pagineDrugdistributionfinal 151003021801 Lva1 App6891Raju NiraulaNessuna valutazione finora

- Tds Chemical Resistant CoatingDocumento3 pagineTds Chemical Resistant CoatingUtilities2Nessuna valutazione finora

- Completions and WorkoverDocumento309 pagineCompletions and WorkoverFan Jack67% (3)

- Pharmacology Notes (Introduction To Pharmacology)Documento16 paginePharmacology Notes (Introduction To Pharmacology)BRYCE WILLIAM GONessuna valutazione finora

- Enviromental Toxicity and EvaluationDocumento25 pagineEnviromental Toxicity and EvaluationSalma ShadNessuna valutazione finora

- Carbon Fiber - CoursDocumento33 pagineCarbon Fiber - Courstrannhu1293599Nessuna valutazione finora

- Application of ESP For Gas Cleaning in Cement Industry - With Reference To IndiaDocumento24 pagineApplication of ESP For Gas Cleaning in Cement Industry - With Reference To IndiaSJ ChuaNessuna valutazione finora

- Waste-To-Energy Plant Process Safety ChallengesDocumento5 pagineWaste-To-Energy Plant Process Safety Challengessomesh sharmaNessuna valutazione finora

- 7 - Casing DesignDocumento36 pagine7 - Casing Designام فاطمة البطاط100% (1)

- Electrozincados en 10152 (2009)Documento18 pagineElectrozincados en 10152 (2009)joaopedrosousaNessuna valutazione finora

- Hydro Silk Fluid Englisch 06 2020Documento1 paginaHydro Silk Fluid Englisch 06 2020Saman KhalidNessuna valutazione finora