Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pneumatic Comparators (Metrology)

Caricato da

Larry SmithCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pneumatic Comparators (Metrology)

Caricato da

Larry SmithCopyright:

Formati disponibili

3/12/2016

PneumaticComparators(Metrology)

whatwhenhow

InDepthTutorialsandInformation

PneumaticComparators(Metrology)

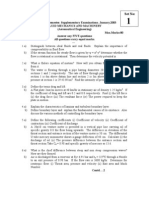

5.8.

Airgauginghasrapidlyincreasedduringsomepasttimeduetothefollowingimportant

characteristics:

(a)Veryhighamplificationsarepossible.Itcanbeusedtomeasurediameters,length,

squareness,parallelism,concentricity,taper,centredistancebetweenholesandother

geometricconditions.

(b)Asnophysicalcontactismadeeitherwiththesettinggaugeorthepartbeing

measured,thereisnolossofaccuracybecauseofgaugewear.Forthisreason,airspindleand

airsnapgaugeslastverylong.Alsoverysoftpartswhichareeasilyscratched,canbegauged.

(c)Internaldimensionscanbereadilymeasurednotonlywithrespecttotolerance

boundariesbutalsogeometricform.Inotherwords,whilemeasuringaboreitcanreveal

completestoryofsize,taper,straightness,camberandbellmouthetc.

(d)Itisindependentofoperatorskill.

(e)Highpressureairgaugingcanbedonewithcleansingofthepartswhichhelpsto

eliminateerrorsduetodirtandforeignmatter.

(f)Gaugingpressurescanbekeptsufficientlylowtopreventpartdeflection.

(Ingeneral,highpressuregaugesaresuitableforthosepartsinwhichtolerancesare

relativelylargeandlowpressureairgaugesarepreferableforhighlyprecisework.)

(g)Dimensionalvariationsthroughoutthelengthofshaftorcylinderborecanbe

exploredforoutofroundness,taperness,concertricity,regularityandsimilarconditions.

(h)Notonlyitmeasurestheactualsize,butitcanalsobeusedtosalvageoversized

piecesforreworkortosortoutforselectiveassembly,i.e.,itissuitablebothforvariable

inspection(measurementofsize)andattributeinspection(GOandNOGO)gaugingandlimits.

(i)Thetotallifecostofthegaugingheadsinmuchless.

(j)Itisaccurate,flexible,reliable,universalandspeedydeviceforinspectingpartsin

massproduction.

(k)Itisbestsuitedforcheckingmultipledimensionsandconditionsonapartsimul

taneouslyinleastpossibletime.Itcanbeusedforpartsfrom0.5mmto900mmdiameter

havingtoleranceof0.05mmorless.Itcanbeeasilyusedforonlinemeasurementofpartsas

theyarebeingmachinedandtakecorrectiveactions.

5.8.1.

SystemsofPneumaticGauges

.Basedonthephysicalphenomenaonwhich

theoperationofpneumaticgaugesisbased,thesemaybeclassifiedas:

(i)Floworvelocitytype,(ii)Backpressuretype.

Floworvelocitytypepneumaticgaugesoperatebysensingandindicatingthemomen

taryrateofairflow.Flowcouldbesensedbyaglasstubewithtaperedbore,mountedovera

graduatedscale.Insidetheboreafloatisliftedbytheairflow.

Velocityofairinvelocitytypepneumaticgaugescanalsobesensedbysensingthe

velocitydifferentiali.e.,differentialpressureacrossaventurichamber.Suchsystemshave

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

1/17

3/12/2016

PneumaticComparators(Metrology)

Fig.5.32.Freeflowairgauge.

quickresponse.Thesepermituseoflargeclearancebetweennozzleandobjectsurface,

resultinginreducedwearofthegaugingmembers.Thereislessairconsumption.Magnifica

tionoftheorderof500to5000timesispossible.

5.8.1.1.

FreeFlowAirGauges(Floworvelocitytype).

Inthiscasethecompressedair

afterthefilteringandpressurereducingunitflowsthroughataperedglasstubecontaininga

smallmetalfloatandthenthroughaplastictubetothegaugeheadhavingtwodiametrically

opposedorificesforairescapementintoatmosphere(ReferFig.5.32).Thepositionofthetube

isdependentupontheamountofairflowingthroughthegaugehead,whichinturnis

dependentupontheclearancebetweentheboretobemeasuredandthegaugehead.Fig.5.34

showsacurvebetweentheairflowandtheclearancebetweenthepartandtheorificeingauge

head.

Fig.5.33.Zeroandmagnificationadjustment

inflowtypepneumaticcomparator.

Fig.5.34.Characteristicofairflow

versusclearanceofflow.

Theflowvelocitytypepneumaticcomparatorwithzeroadjustmentandmagnification

adjustmentisshowninFig.5.33.Magnificationcanbechangedbypassingsomeoftheair

supply,usingascrewattheinlettothetaperedglasstube.Thefloatcanbezeroedbyableed

valveinstalledatthetopofthetube.Sizeismeasuredbythevelocityofairinataperedglass

tubewhichismeasuredbytheheightofthefloatintube.

Thestraightportionofthecurveisutilizedforthemeasuringrange.Itprovideshigh

amplification(10:1)andthuswithinthelinearrange,itispossibletoreadaccuratelyupto

micronsdependinguponscalelength,orclassifythesizesquicklyandaccurately.The

amplificationcanbechangedbyquickchangeoftube,floatandscale.Airgaugeamplification

andrangearebasedonthetoolingandinstrumentstandardsofmanufacturer.Theamplifica

tionandinstrumentareselectedbyconsideringthetotaltolerancespreadandchoosingthe

instrumentthatcoverstherange.About50to100mmofcolumnisusuallyallowedforthe

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

2/17

3/12/2016

PneumaticComparators(Metrology)

actualtolerancespread.

Inthegauginghead,theairescapementorificesarerecessedbelowitscylindrical

surfacesothattheorificesnevercontactthepartbeinggauged.Thusthesurfacewearwillnot

affecttheaccuracytillitisworndowntoorificelevel.Alsotheorientationofgaugeortheway

operatorholdsthegaugeisofnoconsequenceandsamereadingswillbeobtainedforgiven

diameter.Onthegauge,knobsarealsoprovidedforadjustingfloatpositionandcalibration.

Airgaugeissetbyplacingmastersformaximumandminimumtolerancesonspindle

alternativelyandadjustingthefloatpositionforeachmasterbyturningtheknurledknobsat

thebaseoftheinstrument.

Freeflowcolumntypegaugesareusuallyassembledtogethersidebysideandthus

multipleinterrelatedreadingscanbeseenataglance.Thisisthebigadvantageofairgauging

thatthemultipledimensionsandconditionscanbeinspectedwithgreatease,accuracyand

speed.

Pneumaticcircuitscanbearrangedtodeterminedimensionaldifferencesliketaper

(comprisingthediameterofboreatdifferentpointsalongapart),borecentredistanceandalso

toselectpartstoassembletopredeterminedclearancesorinterferencefits.

5.8.1.2.

BackPressureGauges.

Thebasicprincipleandthetheoryofpneumatic

gauginginthebackpressuregaugesisdescribedbelow.(ReferFig.5.35)

Airfromaconstantpressuresource

flowstotheatmospherethroughtwoorifices

OcandOminseries.

Pisthepressureupstreamofthefirst

orificeandpisthepressurebetweenthetwo

orifices,bothmeasuredwithreferenceto

theatmosphericpressureasdatum.

Fig.5.35.Theoryofpneumaticgauging.

TherelationshipbetweenpandPwilldependupontherelativesizesofthetwoorifices:

pbeingequaltoPwhenOmisblockedandtendstozeroasOmisincreasedindefinitely.LetC

bethegeometricalareaofOeandMthatofOm.

ThenifpandCarekeptconstantwhileMisvaried,therelationshipbetweenthe

dimensionlessquantitiesp/PandMICisofthetypeshowninFig.5.36.

(Thegeneralformofthiscurveisquitewellpredictedbyananalysisemploying

Bernoulisequationforflowofacompressiblefluid.)

Weareinterestedinlinearportionofthiscurve.

Fordesignpurposeswefollowanempiricalapproachwhichisbasedonanexperimental

studyatN.P.L.(London)oftherelationshipbetweenpressuresandorificesareas.

Thecharacteristicsofp/PandMICaredeterminedexperimentallyforpressureP

varyingfrom2to75poundspersq.inch(0.13to5kg/cm2)andinspectionofanyoneofthese

showsthatwithintherange0.6p/Pto0.8p/P,thecurveapproximatestoastraightline,the

equationforwhichmavbewrittenas

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

3/17

3/12/2016

PneumaticComparators(Metrology)

Fig.5.36.Characteristiccurveofpneumaticgauge.

ExaminationofthefamilyofcurvesshowsthatconstantA,theinterceptonthep/Paxisis

closelyconstantovertherangeofpressuresinvestigatedandforpracticalpurposes,thevalue

ofA=1.10canbeadoptedforanyvalueofPlikelytobeused.

TheslobebofstraightportioncharacteristicsishowevernotindependentofP,its

numericalvaluedecreasesasPincreasesandthelimitingvaluesfoundintheinvestigation

areasunder:

b=0.6whenP=0.13kg/cm2

b=0.4whenP=5kg/cm2.

5.8.1.3.

Areaofescapeorifice.

When

theclearancebetweenthesurfaceandthe

nozzlefaceiszero,noairescapesfromthe

nozzleandtheareaoftheescapeorificeiszero.

Whentheclearancebetweenthesur

faceandthenozzlefaceisverylarge,thearea

oftheescapeorificeis^d2,wheredisthe

diameterofthenozzle.

Betweentheseextremes,especially

wheretheclearanceissmallandwhereair

gaugingcanbeemployed,theareaofthe

escapeorificeisndl,thatis,theareaofthe

curvedsurfaceofthecylindershownin

Fig.5.38.

5.8.1.4.

Rangeoflinearmeasurement.

Thecondition0.6<p/P<0.8definesa

sectionofthecharacteristicswhichex

perimentalinvestigationhasshowntobe

lineartowithin1%.

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

4/17

3/12/2016

PneumaticComparators(Metrology)

Fig.5.37.Experimentallydetermined

characteristicsfordifferentoperatingpressures.

Fig.5.38.Areaoftheescapeorifice.

Fig.5.39.Rangeoflinearmeasurement.

5.8.1.5.PneumaticSensitivity,i.e.howpvariesbyvariationofM.

5.8.1.6.

Changingsensitivity(Magnification).

Aplotofpressureagainstescape

orificeareaforanumberofdifferentsizesofcontrolorificewillshowthatsensitivityincreases

asthediameterofthecontrolorificedecreases,i.e.,forsmallcontrolorificesthechangein

pressureisgreaterforagivenchangeinescapeorificearea.Utilisingthisproperty,itis

possibletosetpreciselythesensitivity(magnification)byincorporatingavariablecontrol

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

5/17

3/12/2016

PneumaticComparators(Metrology)

orifice.

5.8.1.7.

OverallMagnification.

Inapracticalpneumaticmeasuringapparatusthe

areaMwillbeassociatedwiththemeasuringheadandchangeinMwillbetheresultofa

changeinthedimensionwhichis

beingmeasurede.g.achangeinthe

separationLbetweennozzleand

surface(Fig.5.40).

Theoverallmagnificationof

theapparatus,i.e.theratioofthe

linearmovementofthepointeror

indexofthepressuremeasuringin

strumenttothechangeinthe

Fig.5.40.VariationofMw.r.t.L.

Thisconditionrequiresthemeasuringheadtobecorrectlydesigned.Thefinalescape

mentoftheairfromthenozzletotheatmosphereistakenasbeingthroughanareaofthe

curvedsurfaceofthecylinderoflengthLanddiameterD,whereListheseparationbetween

thenozzlesurfaceandthesurfacetobegaugedandDistheinternaldiameterofthenozzle.

5.8.1.8.

ResponseSpeed.

Forabackpressuresystemthespeedofresponseisnotas

fastasforfreeflowtype,becausesometimeisrequiredforthepressuretobuildup.Thespeed

ofresponsebecomesofconcernwhenthegaugingheadisseparatedfromindicatinginstrument

bylongdistance.

Apneumaticmeasuringsystemwillnotcorrectlymeasuredisplacementsoffrequency

greaterthanabout2cycles/second,becauseofitsslowspeedofresponse.Theresponseis

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

6/17

3/12/2016

PneumaticComparators(Metrology)

considerablyslowercomparedtotheelectricalsystembecauseofthefollowingreasons.

Betweenthecontrolorificeandthemeasuringhead,thereexistsaclosedvolumeassociated

withthemeasuringinstrumentusedtomeasurethepressurep.Adimensionalchange,e.g.,a

displacementofthesurfacealterstheflowsochangingthepressurep.Thetimeneededto

establishthenewvalueofpdependsonthetotalvolumeandontherateofairflowintoand

outofit.ThelatterinturndependsupontheoperatingpressurePandthesizeofthecontrol

orificeandorificeinthemeasuringhead.Theseorificesarerelatedinsizeanddeterminethe

pneumaticsensitivity,thesmallerorifices(correspondingtothehighermagnification),having

amorerestrictiveeffectontheairflowandsoslowingtheresponse.

Ithasbeenexaminedtheoreticallyandexperimentallythatresponseisslowedbyusing

alargeoperatingpressurePandalargevolume,butbythesehighsensitivity(magnification)

isobtained.Inanypracticalpneumaticmeasuringsystem,theoverallresponsewillbe

influencedbydynamiccharacteristicsofthepressuremeasuringdevice.Thusitfollowsthat

theuseofalowoperatingpressurewillnotimprovetheoverallresponseifalowpressure

measuringdeviceofslowresponseisusedtomeasurethepressurechanges.Highsensitivity

willinevitablybeassociatedwithslowresponseandtheonlyfactorlefttothedesigneristhe

volume,whichshouldbemadeassmallaspossibleforquickresponse.

Sincegaugeisalwayslocatedatsomedistancefromthecontrolunit,theeffectof

variationsinthegaugingpositiondoesnotreachthecontrolunitinstantaneously,thoughthe

sizevariationsoftheobjectwillpromptlyaffecttheairflowatnozzles.Thetimegapbetween

thesensingandindicationisknownasresponsetimewhichdependsupon:Lengthofairline

betweenthenozzlesandindicator,(ii)typeofgaugesystem,and(Hi)thedesignofcontrolunit.

Responseincaseofflowtypepneumaticgaugesisrelativelyquick.Responseincaseofback

pressuregaugesisslow,thecompressibilityofairalsocontributingtothedelayedtransmission

ofthevariationssensedatthenozzles.

Responsetimeofbackpressuretypepneumaticgaugescanbeimprovedbyutilising

followingdevices:

(i)Usingfilledsystempressuregauge,therebyreducingvolumeofair.

(ii)Restrictingtheunimpededescapeofairthroughtheorificeswhenthegauginghead

isnotinoperation,byusingaspringchargedcoversleevearoundthegaugehead.

(iii)Counteractingtheunrestrictedairescapebyanauxiliaryairsupplyrelaywhose

operationautomaticallydiscontinuesassoonasaspecificbackpressuredevelopsduringthe

actualgaugingprocess.

(iv)Usingahighspeedrelaytocompensateforadditionstothevolumeoftheinstrument

system.

5.8.1.9.

ZeroSetting.

Itisaccomplishedbymeansofableedvalveandconsistsin

adjustingtheindicatingelementofthegaugetothatmarkingonthescalewhichwasselected

tosignalcoincidentwiththenominallimitsizerepresentedbyasettingmaster.

5.8.1.10.

DatumControl.

Ifmeansbeprovidedtochangethepressureinthecavity

(betweencontrolorificeandmeasuringorifice)usingavariablebleedtoatmosphere,adatum

orzerocanbeprovidedwhichvariesthepressurepwhentheescapeorificearearemains

fixed.Thisadditiontoacircuitprovidesmeansofaccommodatingsmalldifferenceswhich

inevitablyoccurinthemanufactureofgaugeheads.Limiteduseofadatumcontrolintheform

ofableedtoatmospherehasaninsignificanteffectonlinearity.

However,thissystemdependshighlyuponthepressureregulatortomaintainthe

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

7/17

3/12/2016

PneumaticComparators(Metrology)

supplypressurewithinveryclosepressurelimits.Thusthepressureregulatorisacritical

componentinthiscircuit.Thisproblemisovercomeindifferentialbackpressurecircuitin

Fig.5.41.Practicalbackpressurecircuit.

whichaccuracyismaintainedregardlessofsomevariationintheregulatorperformancewhich

controlssupplypressure.Fig.5.42showsapracticalflowresponsivesystemwhichisin

commonuse.Thissystememploysvariableorificesforsensitivityanddatumcontrol.

Fig.5.42.Practicalflowresponsivesystem.

Fig.5.43.Plugforpneumaticcomparator.

5.8.1.11.Am

plificationAdjustment.

Thispermitsdifferentrangeofgaugeindica

tionsonsamescalelengthandiscarriedoutwithaprecisionvalveofthecontrolunit.Both

zerosettingandamplificationadjustmentshouldbecheckedfromtimetotimedependingupon

experience.

5.8.1.12.

JetRecession.

Ithasalreadybeenseenthatwhenthesurfacebeingmeasured

isveryclosetothenozzleface,equalincrementsofchangeinclearancedonotproduceequal

incrementsofpressurechange.Thesystemisnotlinearundertheseconditions.

Becauseofthisthefacesofthejetsonairpluggaugesaregroundbelowthebody

diameteroftheplugasshownFig.5.43.Thisgrindingbackiscalledjetrecessionanditisthe

meansbywhichthenonlinearportionatthehighpressure(lowflow),endofthepres

sure/clearancecurvesisavoided.

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

8/17

3/12/2016

PneumaticComparators(Metrology)

5.8.1.13.

MeasurementofBore.[ReferFig.5.44(a)and(6)]

Intheabovediscussionwehaveas

sumedajetseparationofthenozzlefromthe

flatsurface.Thisisalsoapplicabletomeasure

mentofbore,whereLismodifiedas:

L=Lx+L2,LxRadialgapforonejet

andL2=Radialgapforotherjet.

TheoreticallyLishouldbeequaltoL2,

butevenifL\*L2thebackpressurewouldbe

closelyequaltothatcorrespondingtothecon

ditionL1=L2=L/2.Thisisabigadvantageas

operatorneednotbeverymeticulousabout

orientationofthemeasuringheadinthebore,

andthusthereadingsfromoperatorto

operatorwillbeuniformastheydonotdepend

uponahighdegreeofoperatorskillorsenseof

feel.

5.8.1.14.

MeasuringHeadsMeasuringheadsfallundertwocategories,

viz.directhead[Fig.5.45(a)and

(6)1,andindirectorcontacthead[Fig.5.45(c)

and(d)].Taperednosetypedirecthead[Fig.

5.45(a)]isquitepopularasitpermitseasy

accessinconstrictedmeasuringconditions.

Theratiooflanddiameter(overalldiameterat

taperedsmallend)comparedtojetdiameteris

twiceinsize.Biggerratiowouldaffecttheescapementofairandthecharacteristicsofthe

system.

HeadatFig.5.45(b)providesgoodprotectiontothenozzleduetoincorporationofguard

ringandescapementholes.Inthecaseofindirectmeasuringheads,thejetisprotectedfrom

accidentaldamage.Thesizeofairescapementiscontrolledbyaneedlevalveorflatplate[Fig.

5.45(c)and(d)respectively]whichmoveduetomovementofmeasuringplunger.Bychanging

thetaperofneedlevalve,therangeofmeasurementcanbechanged.Parabolicneedleprovides

linearresponse.Fig.5.45(e)showsthepluggaugeusedformeasurementofdiameter,lobing,

taperetc.Themeasuringsideismadesomewhatsmallerthantheboresothatitentersmuch

moreconveniently.

5.8.2.

SolexPneumaticGauge.(Fig.5.46).

Thisinstrumentisproducedcommercially

bySolexAirGaugesLtd.Thisisgenerallydesignedforinternalmeasurement,butwith

suitablemeasuringheaditcanbeusedforexternalgaugingalso.

Itisobviousfromtheequationforsensitivitythatinorderthatsensitivity(magnifica

tion)remainsconstant,thesupplypressurePmustbeconstant.

Thusitisnecessarytohaveasimplepressureregulatorwhichmaycontrolthepressure

ofairfromthenormalsupplyline,andifnecessarythepressuremightbereducedalso.The

arrangementusedinSolexgaugeistopassthehighpressureairafterfiltering,throughaflow

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

9/17

3/12/2016

PneumaticComparators(Metrology)

valve.Thereisatankinwhichwaterisfilleduptoacertainlevelandadiptubeisimmersed

intoituptoadepthcorrespondingtoairpressurerequired.InFig.5.46,itisrepresentedby

H.Sinceairissentathigherpressurethanrequiredone,someairwillleakoutfromthedig

tubeandbubbleoutofwaterandtheair

movingtowardscontrolorificewillbeat

desiredconstantpressureH.

Nowadaysdiaphragmtype

pressureregulatorsarereadilyavail

ableinthemarketandtheyarebetter

forregulatingthepressurethanthe

abovedevice.Theairatreducedpres

surethenpassesthroughthecontrol

orificeandescapesfromthemeasuring

jets.Thebackpressureinthecircuitis

indicatedbytheheadofwaterdisplaced

inthemanometertube.Thetubeis

graduatedlinearlytoshowchangesin

pressureresultingfromchangesinin

ternaldiameteroftheworkmeasured.

Thisinstrumentiscapableofmeasur

ingtotheaccuracyofmicrons.

ItisveryobviousfromFig.5.46

thatthediameterbeingmeasuredat

anyinstantiscorrespondingtothepor

tionagainsttwojets.Nowtofindthe

concentricity(roundnessofanyjobat

anysection),theworkpiecemaybe

revolvedaroundmeasuringgauge.Ifno

changeinreadingisthere,thenitis

perfectlyroundhole.Similarlythe

diametercanbenoteddownatseveral

placesalongthelengthofboreandthus

taperingofholeisdetermined.This

methodis,therefore,bestsuitedfor

measuringroundnessandtapernessof

cylinderboresandgunbarrelbores.

Byhavingsuitablemeasuring

headthiscanbeusedforexternalgaug

ing,andheadinthiscasewillbeas

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

10/17

3/12/2016

PneumaticComparators(Metrology)

(a),(6)Directheads(c)Forwardhead

(d)Reversehead(e)Pluggauge.

Fig.5.45.Measuringheads.

Fig.5.46.SolexAirGauge.

showninFig.5.47.Thiscanbestrevealanylobingeffect

also.Itisalsopossibletohavearrangementtomeasure

thelengthofslipgaugebyhavingtheflattableandone

jetatthetop.

5.8.2.1.

OverallMagnificationandRange.

FromequationdpIdM=0.40P/Mc,thepneumaticsen

sitivityofapneumaticmeasuringapparatuscanbe

increasedbyincreasingtheoperatingpressureP,but

controlledbythelengthofscaleofpressuremeasuring

instrumentcorrespondingtopressurechangesfrom0to

P.Ifthisscalelengthistoremainofconvenientmag

nitude,increasingtheoperatingpressureisnota

suitablemethodforimprovingtheoverallmagnification.Theonlyeffectivemethodfor

obtainingthehighermagnificationis,therefore,toreduceaverageseparationbetweennozzle

andsurface,whichatthesametime,ofcourse,reducestherangeoflinearmeasurement.

5.8.2.2.

Limitationsofempiricalapproach.

Fromtheviewpointofairflow,the

effectiveareaofanorificeisnotusuallyidenticalwithitsgeometricalarea.Iftwoorificesare

madebyproducingholesofidenticalgeometricalareaintwothindiscs,theireffectiveareas

maybeappreciablydifferentasaresultofedgeeffectsontheairflowarisingattheperipheries

oftheorifices.Againtherelationshipbetweeneffectiveareaandgeometricalareaisunlikely

tobethesameforairflowthroughanorificeandthejetofairfromanozzle.Intheexperimental

determinationofthep/P,MICcharacteristicsthevalueofMandCusedwerethegeometrical

areasoforificesOmandOc.Thereforeduetoeffectiveareabeingdifferentfromthegeometrical

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

11/17

3/12/2016

PneumaticComparators(Metrology)

area,theempiricalequationobtainedbyanalysingthesecharacteristicswouldnotbeexpected

toprovideacompletelyaccuratenumericalforecastofperformance.

Nevertheless,experiencehasshownthattheydogiveafirstapproximationsufficiently

reliabletopermittherequiredperformancetobeobtainedbyasinglestepcorrectiveadjust

mentofthecontrolorifice.

5.8.3.

DifferentialComparators.

Alaterdevelopmentbroughtoutthebalanced

circuittypeofairgauge.Inthisequipmentadifferentialpressureindicatingmechanism,

connectedacrossthetwoairpathsandabuiltingaugezeroingvalveisprovided.Sucha

balancedcircuitisshownschematicallyinFig.5.48.Anairgaugebasedonthisbalancedcircuit

iscalledDifferentialComparator.

Threeequallyspacedmeasuringorifices

(jets)revealanylobbingeffectalso.

Fig.5.47

Fig.5.48.DifferentialCircuit.

Compressedairfromasuitablesource,afterpassingthroughairdrierandfilteris

regulatedforconstantpressurebyapressureregulator.Nowtheairflowsintotwochannels,

eachofwhichhasacontrolorificeOclandOc2(controlorificesarealsocalledmasterjets).

FromthecontrolorificeOcl,airflowstothemeasuringheadwhereitmeetsfurtherrestriction

oftheworkpieceorthemastersettings.Therestrictionoftheworkpiecebuildsupback

pressureasexplainedearlier.Atthesametime,otherhalfoftheairisflowingthroughthe

othercontrolorificeOc2tothereferencejetOm.Byclosingoropeningthevalveofreferencejet

Om,thepressureinthespacebetweenOc2andOmisregulated(adjusted)tomatchtheback

pressurefromthemeasuringjets,whichissensedbythepressureindicatingdevicefitted

acrossthetwochannelsasshown.Atthisadjustmentofthereferencejet,thepressureindicator

wouldindicateequalpressureinthetwochannelsandhencereadzeroonthescale.Thiszero

setting(adjustingofreferencejetOm)isdonewithmasterworkpiecewhosedimensionisexact

nominalsize.

Nowthevariationofthedimensionatthemeasuringheadwouldcausechangeof

backpressureinchannelA.Thispressurewouldbedifferentfromthemeanpressurewhich

hasbeenalreadysetinthechannelB(byreferencejet).Nowthedifferenceofpressureofthe

twochannelswouldbeindicatedbythepressureindicatingdevicewhichcanbedirectly

calibratedintermsofvariationofdimensionfromthemeandimensions.Hencetheinstrument

basedonthemeasurementofdifferentialpressureiscalledDifferentialComparator.

IfthedimensioncausesadecreaseingapLascomparedtoLa,thisinturndecreases

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

12/17

3/12/2016

PneumaticComparators(Metrology)

MandhenceincreasingbackpressureinchannelAandviceversa.Inthesecasesthepressure

indicatorwouldshowreadingsonbothsidesofzerocorrespondingtodeviationfrommaster

setting.

5.8.3.1.

AdvantagesofDifferentialCircuitoverSingleChannelCircuit,

(i)Effect

ofchangeofoperatingpressureP.Theoperatingpressuremayvaryslightlyfromthedesigned

value.Itcanbeshownthaterrorduetochangeofpressurewouldbe0.6to0.8timesthechange

inpressureinsinglechannelincaseofdifferentialcircuittheerrorwouldbe0.1timesthe

changeinpressure.

(ii)Zerosettingofmastergaugeisanextraadvantage.

(iii)Rectificationforcontrolorifice.Inasinglechannelsystem,thepracticallimitations

maynotgivetheperfectlycorrectandaccuratedimensionofthecontrolorificeasdesigned.

Sometimesitmaygooutoftheusefulrangeofthedesignanditmayhavetobediscarded.

Therefore,inordertoavoidtheerrorofmanufactureandalsototakeintoaccountthe

factthatthegeometricalareaisdifferentfromtheeffectivearea,weneedaneedlevalveso

thatareamaybeadjustedaccordingly.

Butinthedifferentialcircuitwhichincorporatesaneedlezeroadjustingvalve,the

offsetoftheactualsizeofthecontrolorificefromthedesignedvaluecanbenullifiedby

adjustingthisvalve.

5.8.4.

NoncontactandContactTypePneumaticGaugingElements.

Noncontact

toolingisbestsuitedforautomaticgaugingapplicationsbecauseoftheadvantagesofno

contact,clearingofoilorforeignparticlesfromgaugingarea,etc.

Inthecaseofnoncontactairgaugetooling,onlytheaircomingoutoftheairescapement

orificetouchestheparttobemeasured,theairflowratedependingonthecrosssectionalarea

ofthejetandtheclearancebetweenthejetandtheparttobemeasured.Itmayhaveasingle

jet,twodiametricallyoppositejetsormoreevenlyspacedjets.Singleopenjettoolingcanbe

usedforcheckingoutsidediameter,height,depth,straightness,squareness,etc.andFig.5.49

showsafewofsuchapplications.Dualjettechniquescanbeappliedfordeterminingtrue

diameter,outorround,bellmouth,thick

ness,etc.Thevariousgaugesmaybe

designedeitherforpresentingthegauges

topartorviceversa.

Manymodernmechanicalas

sembliesdemandthatholesshouldbe

closelycontrolledforstraightnessaswell

asdiameter.Anairpluggaugefor

gaugingholestraightnessisshownin

Fig.5.50.

Inthecontacttooling,amechani

calmemberisincorporatedbetweenthe

airescapementorificeandtheparttobe

measured.Theairflowfromthejetchan

gesduetodisplacementofthismechani

calmemberwhenitcontactsthepart.

Themechanicalmembercouldbeaball,

lever,plungerorblade.Abigadvantage

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

13/17

3/12/2016

PneumaticComparators(Metrology)

ofcontacttypeairgaugeisthatamuch

biggermeasuringrange(upto2.5mm)is

possiblei.e.itissuitableforwiderange

ofgauging.Anotheradvantageisthatit

eliminatessurfaceroughnessfrom

size.Itmaybementionedthatopen

jettypemethodwouldbesubjectto

errorforroughsurfacesbecauseit

measuresacombinationofsizeand

surfacefinishfurtheritsrangeof

measurementislimited.Balljet

spindlegivesapointreadingrather

thantheaverageoverasmallarea

andisbestsuitedforgauginginside

diameterofsoftorporouspartsand

forroughbores.Leafjetspindlecan

beusedforcheckinglaminatedbores,blindholesinwhichkeywaysetc.donotpermittheuse

ofopenjetspindlesatextremebottomofblindholesetc.Bladejetspindlesareusedfor

inspectinggunboresinwhichoilgrooves,orslotsdonotpermittheuseofballjetorleafjet

spindles.

Fig.5.51showsasmallplungertypeairgaugingcartridgewhichishighlyefficient

sizesensingelementforwiderangeofgauging,tooling,fixturing,andmachinecontrol

applications.Itessentiallyconsistsofaspringloadedplunger.Thespringtriestokeepthe

Fig.5.49.Applicationsofsingleopenjettooling.

Fig.5.50.Straightnessmeasuringgauge.

Fig.5.51.AirCartridge.

plungeroutwardsandwhentheparttobemeasuredcomesincontactwithitoritcomesin

contactwiththepartitmovesinandattheendrestrictstheorifice,therebyincreasingthe

backpressure.Themaximumandminimumlimitsoftheplungermovementcanbesetwith

thehelpofmasters.Suchcartridgescanbesecuredingaugingpositiononvarioustypesof

fixturesandusedformeasurementslikeheight,depth,flatness,concentricity,squareness,

inside/outsidediameter,etc.

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

14/17

3/12/2016

PneumaticComparators(Metrology)

inside/outsidediameter,etc.

Fig.5.52showsthesameprincipleusedinatestindicatorwhichisveryefficientfor

severalapplications.Ithasatinystyluscapableofenteringintosmallholes,keyways,slots

Fig.5.52.Pneumatictestindicator.

etc.anditsmovementcausesthetaperedendtoactasaprecisionvalvestemtoregulatethe

amountofairflowingthroughanorifice.Itisfreeofhysteresisorlagordraginindications

whenthestylusismovedinanydirectionacrosstheworkpiece.

Thecontacttypeadjustablespindlekitsandadjustableairsnapgaugesavailablein

marketarefoundtobeverysuitableforhandlingnewdesigns,altereddimensionsandvarious

othervariedapplications.

5.8.5.

IndirectPneumaticGaugingDevices.

Theopenjethasthedisadvantageof

smallmeasuringrange.Itcanbeovercomebyusingindirectpneumaticgaugingdevicesby

usingagaugingcartridge.Suchcartridgeemploysacontactingstylus,theinnerendofwhich

istaperedandformstherestrictioninanescapeorifice.Thepositionofthestylusand

consequentlythepositionofthetaperintheorificecauseschangesintheareaoftheorifice.

Changesintherateoftaperchangethemeasuringrangeofthecartridge.Measuringranges

upto3mmcanbeobtainedwiththistypeofcartridge.

5.8.6.

Airgaugingwithelectronicsensors.

Airgaugingsystemoperateoneither

loworhighairpressure.Whilelowpressuresystemshavegreatersensitivity,quickerresponse

timeandminimaldistortionwhenmeasuringflexiblecomponents,thehighpressuresystems

areselfcleaningtypeandhavealargemeasuringrange.Basicallyairgaugingcomprisesair

jetgaugessuchasringorplug,andairoperatedliquidcolumnsformultidimensional

measurement.

Nowadayselectronicflowmetersareusedinplaceofairoperatedliquidcolumns.They

havetheadvantageofmeasuringflowofairwiththeaddedbenefitofelectronicdisplay.Such

instrumentscaneasilyhave2or3rangeselectiontogiveanextramagnificationfactor.

Tolerancelimitlightscanbeincorporatedtoindicatewhetherpartsareinsideoroutside

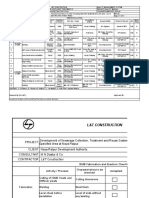

manufacturingtolerances.Responsetimeincreasesmanyfolds.

Theversatilityofairgaugingisenhancedbythewiderangeofmeasuringtoolslike2

and3jetnoncontactairpluggauges,settingringsandairjetringgauges.

5.8.7.

MultigaugingSystems.

Multigaugingsystemsareusedtomeasureanumber

ofdimensionssimultaneously.Partstobegaugedarecomparedwithasettingmasterwhich

simulatesthecomponent.Thefeaturesgaugedcouldbeexternal/internaldiameters,lengths,

straightness,squareness,ovality,runoutoffaces,etc.Themeasuringheadgaugingfixtureis

specificallydesignedtosuitthecomponenttobemeasuredandmaybecompletelyspecialor

itmaybebuiltusingaseriesofmodularelements.Itcontainsthemeansforsensingthe

dimensionaldifferencebetweenthecomponentsandthemasterwhichmaytaketheformof

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

15/17

3/12/2016

PneumaticComparators(Metrology)

mechanicalorelectronicprobesorairjetsconnectedtothemeansforamplifyingthedifference.

Theamplifyinganddisplayofreadingsmaytaketheformofdialgaugesorsomeform

ofelectronicorair/electronicsystem.

Displaymaybeanalogue,digitalorgraphicandmaybeaugmentedbyoutoftolerance

indication.

Usingelectronicdifferentialmethods,therelationshipbetweendifferentfeaturescan

berelatedtoacommondatum.

Thechoiceofsystemdependsonnumberoffactorslikeinitialcost,dimensional

tolerancesofthefeaturestobemeasured,complexityofthecomponent,complexityofthe

featurestobemeasured,numberoffeaturestobemeasured,speedofmeasurementrequired,

skillorotherwiseoftheuser.

Thereasonsaffectingthechoiceofdisplaysaregivenbelow:

(i)Pointerdisplaysbestwherearapidcheckofrunoutorconcentricityisrequired.

(ii)Columnsnaturalchoicewhereaconsiderablenumberofdimensionsareinvolved.

Thesearefastestandmostconvenientformofdisplayingthereadingsforevery

dimension.

(iii)Digitalprovideshighaccuracyoveralongermeasuringrangeandbestforsitua

tionswhereitisrequiredtoworkindrawingdimensions.Canbeviewedwithoutstrainover

longerdistances.

(iv)GraphiconVDUthemostsophisticateddisplayessentialwhenstatisticalprocess

controlsystemsareemployed.

Systemscapableofdealingwithverylargenumberofinterrelateddimensionscanbe

developed.

Automaticinspectionmachinesincorporatebothautomatedloadinghopper,magazine,

pickandplacerobotandautomatedsegregationofinspectedcomponents.Automaticinspec

tionisessentialwherethecomplexityofthecomponentissuchthatmanualmethodscannot

achievethedesiredlevelsofaccuracy.

Theresultsofinspectioncouldbefedtoelectroniccomputerbasedsystemwhichmay

alsocontrolthemachineoperation.Theuseofsuchcomputerbasedprocessingalsoallowsthe

resultsobtainedtoprovideawiderangeofcontrolfacilitiesincludingfeedbackforcontrolof

themanufacturingprocess.

Coordinatemeasuringmachinesaccommodatemultidimensionalinspectionbyusinga

singlepointcontacttotakesuccessivemeasurementsoverthecomponentprofile.Thecontact

movementandprocessingofthedimensionalinformationisundercomputercontrol,which

canalsoprovidesimilarfacilitiestothoseofferedbymultipointgauging.

Nextpost:FluidDisplacementComparators[Fig.5.53](Metrology)

Previouspost:ElectricalandElectronicComparators(Metrology)

RelatedLinks

Metrology

WhatisMetrology

PhysicalMeasurement(Metrology)

NeedofInspection(Metrology)

MeasuringInstruments(Metrology)

SelectionofInstruments(Metrology)

::SearchWWH::

Search

CustomSearch

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

16/17

3/12/2016

PneumaticComparators(Metrology)

HelpUnprivilegedChildrenCareersPrivacyStatementCopyrightInformation

http://whatwhenhow.com/metrology/pneumaticcomparatorsmetrology/

17/17

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Fluid Mechanics and Machinery (May2013)Documento3 pagineFluid Mechanics and Machinery (May2013)Dmj Anbu RajNessuna valutazione finora

- Fluid Mechanics and Machinery LabDocumento43 pagineFluid Mechanics and Machinery LabLarry SmithNessuna valutazione finora

- Fluid Mechanics and MachineryDocumento2 pagineFluid Mechanics and MachineryNellai VprNessuna valutazione finora

- Fluid Mechanics and MachineryDocumento10 pagineFluid Mechanics and Machinerysrajapraty50% (2)

- Fluid Mechanics and Machinery (May2012)Documento4 pagineFluid Mechanics and Machinery (May2012)Dmj Anbu RajNessuna valutazione finora

- Fluid Mechanics and Machinery Laboratory ManualDocumento54 pagineFluid Mechanics and Machinery Laboratory ManualLarry SmithNessuna valutazione finora

- Me 2204 - Fluid Mechanics and MachineryDocumento3 pagineMe 2204 - Fluid Mechanics and MachineryKarthik SubramaniNessuna valutazione finora

- NR-222101-Fluid Mechanics and MachineryDocumento8 pagineNR-222101-Fluid Mechanics and MachinerySrinivasa Rao G100% (1)

- 20041709Documento62 pagine20041709Larry SmithNessuna valutazione finora

- NE May2013Documento2 pagineNE May2013Larry SmithNessuna valutazione finora

- NE May2013Documento2 pagineNE May2013Larry SmithNessuna valutazione finora

- Me 1004 Nuclear ENGINEERING Questions Bank 2014: SubscribeDocumento14 pagineMe 1004 Nuclear ENGINEERING Questions Bank 2014: SubscribeLarry SmithNessuna valutazione finora

- Me2034 QB PDFDocumento2 pagineMe2034 QB PDFekanthamoorthyNessuna valutazione finora

- Gtbylathu 101231003739 Phpapp01Documento25 pagineGtbylathu 101231003739 Phpapp01Larry SmithNessuna valutazione finora

- Grouptechnology 140412022931 Phpapp01Documento22 pagineGrouptechnology 140412022931 Phpapp01Larry SmithNessuna valutazione finora

- ME 1004 NUCLEAR ENGINEERING Questions Bank 2014 Vidyarthiplus (V+) Blog - A Blog For StudentsDocumento14 pagineME 1004 NUCLEAR ENGINEERING Questions Bank 2014 Vidyarthiplus (V+) Blog - A Blog For StudentsLarry SmithNessuna valutazione finora

- Group Technology PPT at Bec DomsDocumento34 pagineGroup Technology PPT at Bec DomsBabasab Patil (Karrisatte)Nessuna valutazione finora

- Ansys PDFDocumento2 pagineAnsys PDFLarry SmithNessuna valutazione finora

- Group Technology (GT)Documento15 pagineGroup Technology (GT)Larry SmithNessuna valutazione finora

- Group Technology: Job Shop Production System Batch Production System Mass Production SystemDocumento11 pagineGroup Technology: Job Shop Production System Batch Production System Mass Production SystemLarry SmithNessuna valutazione finora

- Group Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Documento30 pagineGroup Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Larry SmithNessuna valutazione finora

- Grouptechnology1 131203094018 Phpapp01Documento9 pagineGrouptechnology1 131203094018 Phpapp01Larry SmithNessuna valutazione finora

- Grouptechnology1 131203094018 Phpapp01Documento9 pagineGrouptechnology1 131203094018 Phpapp01Larry SmithNessuna valutazione finora

- Group Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Documento30 pagineGroup Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Larry SmithNessuna valutazione finora

- Gtbylathu 101231003739 Phpapp01Documento25 pagineGtbylathu 101231003739 Phpapp01Larry SmithNessuna valutazione finora

- Group Technology: Job Shop Production System Batch Production System Mass Production SystemDocumento11 pagineGroup Technology: Job Shop Production System Batch Production System Mass Production SystemLarry SmithNessuna valutazione finora

- Cellular Manufacturing & Group TechnologyDocumento24 pagineCellular Manufacturing & Group TechnologyLarry SmithNessuna valutazione finora

- Grouptechnology1 131203094018 Phpapp01Documento9 pagineGrouptechnology1 131203094018 Phpapp01Larry SmithNessuna valutazione finora

- Group Technology PPT at Bec DomsDocumento34 pagineGroup Technology PPT at Bec DomsBabasab Patil (Karrisatte)Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Xtype Power Train DTC SummariesDocumento53 pagineXtype Power Train DTC Summariescardude45750Nessuna valutazione finora

- Table of Specification 1st QDocumento5 pagineTable of Specification 1st QVIRGILIO JR FABINessuna valutazione finora

- Final MS Access Project Class-10Documento17 pagineFinal MS Access Project Class-10aaas44% (9)

- Directorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratDocumento2 pagineDirectorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratgamailkabaaaapNessuna valutazione finora

- Lab Manual Switchgear and Protection SapDocumento46 pagineLab Manual Switchgear and Protection SapYash MaheshwariNessuna valutazione finora

- Natural Cataclysms and Global ProblemsDocumento622 pagineNatural Cataclysms and Global ProblemsphphdNessuna valutazione finora

- Case 3 SectionC Group 1 (Repaired)Documento3 pagineCase 3 SectionC Group 1 (Repaired)SANDEEP AGRAWALNessuna valutazione finora

- Clint Freeman ResumeDocumento2 pagineClint Freeman ResumeClint Tiberius FreemanNessuna valutazione finora

- Adaptive Leadership: Leadership: Theory and PracticeDocumento14 pagineAdaptive Leadership: Leadership: Theory and PracticeJose Daniel Quintero100% (1)

- Ismb ItpDocumento3 pagineIsmb ItpKumar AbhishekNessuna valutazione finora

- Cambridge IGCSE: CHEMISTRY 0620/42Documento12 pagineCambridge IGCSE: CHEMISTRY 0620/42Khairun nissaNessuna valutazione finora

- An Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyDocumento10 pagineAn Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyTimothy ZelinskiNessuna valutazione finora

- MolnarDocumento8 pagineMolnarMaDzik MaDzikowskaNessuna valutazione finora

- CCDocumento5 pagineCCnazmulNessuna valutazione finora

- X - WORMWOOD EVENT IMMEDIATE - Paranormal - 4chanDocumento7 pagineX - WORMWOOD EVENT IMMEDIATE - Paranormal - 4chanAnonymous dIjB7XD8ZNessuna valutazione finora

- Refutation EssayDocumento6 pagineRefutation Essayapi-314826327Nessuna valutazione finora

- Veritas™ High Availability Agent For WebSphere MQ Installation and Configuration Guide / WebSphere MQ InstallationDocumento64 pagineVeritas™ High Availability Agent For WebSphere MQ Installation and Configuration Guide / WebSphere MQ InstallationkarthickmsitNessuna valutazione finora

- Benefits and Limitations of BEPDocumento2 pagineBenefits and Limitations of BEPAnishaAppuNessuna valutazione finora

- CLA Brochure - 2022-3Documento10 pagineCLA Brochure - 2022-3Streamer AccountNessuna valutazione finora

- Description and Operating Instructions: Multicharger 750 12V/40A 24V/20A 36V/15ADocumento34 pagineDescription and Operating Instructions: Multicharger 750 12V/40A 24V/20A 36V/15APablo Barboza0% (1)

- CRISTIAN COLCERIU - PERSONALITATI CLUJENE Prof - Dr.ing - POMPILIU MANEADocumento21 pagineCRISTIAN COLCERIU - PERSONALITATI CLUJENE Prof - Dr.ing - POMPILIU MANEAcristian colceriu100% (2)

- John Wren-Lewis - NDEDocumento7 pagineJohn Wren-Lewis - NDEpointandspaceNessuna valutazione finora

- Nescom Test For AM (Electrical) ImpDocumento5 pagineNescom Test For AM (Electrical) Impشاہد یونسNessuna valutazione finora

- Artificial Intelligence Practical 1Documento5 pagineArtificial Intelligence Practical 1sadani1989Nessuna valutazione finora

- 2022 Tony Elumelu EntrepreneursDocumento10 pagine2022 Tony Elumelu EntrepreneursOladosu EmmanuelNessuna valutazione finora

- Reaserch On Effect of Social Media On Academic Performance: Study On The Students of University of DhakaDocumento27 pagineReaserch On Effect of Social Media On Academic Performance: Study On The Students of University of DhakaFatema Tuz Johoora88% (114)

- Reflection On The PoorDocumento5 pagineReflection On The Poorapi-347831792Nessuna valutazione finora

- Positive Psychology in The WorkplaceDocumento12 paginePositive Psychology in The Workplacemlenita264Nessuna valutazione finora

- Current Trends and Issues in Nursing ManagementDocumento8 pagineCurrent Trends and Issues in Nursing ManagementMadhu Bala81% (21)

- Second Conditional Conversation QuestionsDocumento2 pagineSecond Conditional Conversation QuestionsEdith Salomé PinosNessuna valutazione finora