Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

HDS Brochure

Caricato da

HBracing1Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

HDS Brochure

Caricato da

HBracing1Copyright:

Formati disponibili

Servo/Hydraulic Press Brake

HDS NT Series

HDS 5020NT, HDS 8025NT, HDS 1303NT,

HDS 1703NT & HDS 2204NT

The HDS NT Series Press Brake

An ultra-high precision, down-acting system featuring advanced

hydraulics that provide the ultimate in positioning accuracy.

Unique Hybrid Drive System

Independent AC-servo motors drive high

efficiency, bi-directional hydraulic pumps

Pressure Tank

Extremely fast approach, bending and return speeds provide faster

AC servo motor

cycle times and result in more parts per hour.

Unequalled ram positioning. Repeatability of 0.00004.

Two-way piston pump

Programmable ram tilting and 50% off-center bending capacity allows

for quick set-up of multiple stage part bending.

Cylinder

Low power consumption hydraulic pump motors are on only

when the ram is moving.

Stable hydraulic oil temperature ensures consistent angular accuracy.

Piston

Less hydraulic oil and fewer oil changes required.

Very low noise level.

Upper table

Rapid lowering

Bending process

Rapid rising

Multiple Axis Backgauge

5-axis backgauge speeds set-up for complex parts.

High-speed movement on all axes ensures that the gauge fingers

Z axis stroke:

250mm/9.84

L axis tilting:

500mm/19.68

are positioned as quickly as the operator positions the part.

Independent servo drives for L axis allow tapered bends.

Tool navigator software positions backgauge where each tool needs

to be installed, shortening the tool installation process.

Unprecedented positioning repeatability 0.0001.

Y axis speed:

60m/min

L axis stroke:

700mm/27.56

Extended gauging allows for up to a 27.5 flange dimension.

Low profile design enables part positioning over the top of

the backgauge.

Specifications vary depending on machine model

CNC Hydraulic Bed Crowning

Hybrid drive control of bed-crowning hydraulic cylinders.

(Number of crowning cylinders varies depending on machine model)

AMNC-PC control automatically calculates positioning of cylinders

based on program data such as bend length, material type, thickness,

tooling and part position along bed.

Eliminates the time-consuming process of shimming tools caused by

upper and lower bed deflection.

For automatic adjustment, the control allows entry of actual bend

angle (at ends and center of part). Adjustments are also possible by

control-mounted handwheel.

AMNC/PC PC Control with Network Capabilities

Amadas AMNC-PC control with touch screen offers multiple modes of

data entry (angle, depth, 2D and 3D) for maximum programming flexibility.

Graphic tool library and tool set-up graphics assist operator in quick

set-up of complicated parts.

3D graphics of machine, tooling and part, assist the operator in quick setup and part sequencing/handling (available when machine is programmed

offline with Amadas Dr. Abe Bend software).

When the control is networked, Amadas SDD database software

enables storage on the control or a server providing secure storage of

machine set-up and program data.

Bar code scanner provides easy and immediate retrieval of Dr. Abe Bend

programs from the network server.

Adjustment of all machine axes can be accomplished through use of

control mounted handwheel.

One Touch Punch Holders & Precision Ground Tooling

Innovative one touch punch holders ensure faster tool set-up.

Rotation of lever locks punch into place no need for wrench.

Precision ground, sectionalized tools are easy to handle and

eliminate shimming.

Quick change dies eliminate need to align punch and die when a

die is changed.

CS Clamp

Seat and secure punches with the turn of a single switch.

One switch activates all of the punch holders across the bed of

the machine.

Load and unload sectionalized punches from the front of the holder.

Increase safety with the drop-prevention mechanism.

Punches stay secure in the holder with the clamps in the open position.

Quick disconnect allows for easy removal of each punch holder.

Safety mechanism allows for continuous clamping in the event of a

power failure.

Modular Tooling System

Automatic Tool Alignment upper and lower holders are hydraulically activated

to align tools automatically (no bolts to tighten).

Drop Prevention System safety click buttons make tool changes safer and

faster and protects tools from damage caused by dropping.

Standardized Tool Heights allow for more accurate stage bending and

part repeatability.

Punch and Die Reversibility the ability to mount the punch in the lower

beam and the die in the upper beam, provides greater versatility when forming

complex parts.

Reduced Set-up Time the Amada Modular Tooling System is engineered to

reduce set-up time by 80%.

Easy Tool Selection and Positioning all sections of tools are marked for quick

identification. Tools are easily positioned by hand anywhere along the beam

of the machine.

Dr. ABE Bend Bending Simulation Software

Free up press brake capacity by moving

set-up offline.

Reduce cost-per-part.

Dr. ABE Bend selects tools,

automatically creates tool layouts

and bend sequences with a success

rate of up to 80%.

Manually program the remaining

Set-up instructions stored on network

are instantly available.

AMNC-PC control uses offline

programs to reduce remaining internal

set-up.

parts offline.

Improved Safety and Reduced Labor Costs

To enhance performance while improving operator safety, HDS Series press

brakes can be equipped with an automated Work Follower system.

HDS 2204NT

with WS-4000

HDS 2204NT

with WFN-150

Sensor technology provides simple operation without the need for

programming by the brake operator.

After bending starts, an automated table follows and supports the

material throughout the bending process eliminating part deformation.

Previously, processing large parts required two operators. The WF Series

eliminates the need for a second operator while providing faster and

safer transfer of material.

Provides easy handling and processing of various part geometries.

Dimensions

(Refer to the chart below for individual

machine measurements.)

Specifications

Model

HDS 5020NT

Tonnage (US)

HDS 8025NT

HDS1303NT

HDS1703NT

HDS 2204NT

55

88

143

187

243

Maximum Bend Length

81.5

102

127

127

168.5

Distance Between Frames (A)

66.9

87

106.3

106.3

148

Stroke Length

7.87

7.87

7.87

9.84

9.84

Open Height (with tool holders)

14.96

14.96

14.96

15.78

15.78

Open Height (without tool holders)

19.7

19.7

19.7

20.47

20.47

Throat Depth

16.3

16.3

17.7

17.7

17.7

Table Height

38.6

38.6

39.4

39.4

39.4

Approach Speed

7.87/second

7.87/second

7.87/second

7.87/second

7.87/second

Bending Speed

0.78/second

0.78/second

0.78/second

0.78/second

0.78/second

Return Speed

7.87/second

7.87/second

7.87/second

7.87/second

7.87/second

Oil Capacity

9.9gallons

9.9gallons

17.8gallons

33.4gallons

33.4gallons

Machine Length (B)

133.07

154.33

178.94

183.07

224.8

Machine Width (C)

89.57

89.57

89.57

97.05

97.05

Machine Height (D)

103.15

107.09

118.5

126.57

126.57

Approximate Weight

11,600 lbs.

14,800 lbs.

26,400 lbs.

44,000 lbs.

50,600 lbs.

Motor Power

7.2 HP

11.7 HP

15.8 HP

27.6 HP

27.6 HP

Backgauge Range

27.55

27.55

27.55

27.55

27.55

Backgauge Vertical Range

9.84

9.84

9.84

9.84

9.84

Amada AMNC-PC

Amada AMNC-PC

Amada AMNC-PC

Amada AMNC-PC

Amada AMNC-PC

Unlimited via network

Unlimited via network

Unlimited via network

Unlimited via network

Unlimited via network

D1 & D2

D1 & D2

D1 & D2

D1 & D2

D1 & D2

CC

CC

CC

CC

CC

Control Type

Program Capacity

Axis Under CNC Control

RAM

Hydraulic Crowning

Backgauge

L1 & L2

L1 & L2

L1 & L2

L1 & L2

L1 & L2

Backgauge Horizontal

Y1 & Y2

Y1 & Y2

Y1 & Y2

Y1 & Y2

Y1 & Y2

Backgauge Vertical

Ram Repeatability

0.00004

0.00004

0.00004

0.00004

0.00004

Backgauge Repeatability

0.0001

0.0001

0.0001

0.0001

0.0001

Backgauge Speed (L-axis)

1,180/min

1,180/min

1,180/min

1,180/min

1,180/min

Backgauge Speed (Y-axis)

2,362/min

2,362/min

2,362/min

2,362/min

2,362/min

Backgauge Speed (Z-axis)

393/min

393/min

393/min

393/min

393/min

Amada America, Inc.

7025 Firestone Boulevard Buena Park, CA 90621 (714) 739-2111 FAX (714) 670-8020 www.amada.com

Potrebbero piacerti anche

- 96ENSIS AJ 3kW - Fibre Laser Cutting MachineDocumento8 pagine96ENSIS AJ 3kW - Fibre Laser Cutting MachineXuan Phuong HuynhNessuna valutazione finora

- AMADA EM2510 With AMNC-F User Pre-Installation Guide ManualDocumento28 pagineAMADA EM2510 With AMNC-F User Pre-Installation Guide ManualParvezNessuna valutazione finora

- Quotation For Fiber Laser Cutting Machines 4 KW: NF - PRO 315 VentoDocumento25 pagineQuotation For Fiber Laser Cutting Machines 4 KW: NF - PRO 315 VentobeemasundarNessuna valutazione finora

- Basic Turret Press Set Up TrainingDocumento29 pagineBasic Turret Press Set Up TrainingBobfarabaughjr100% (2)

- FIBER LASER TechnologiesDocumento30 pagineFIBER LASER Technologieschathuranga chandrasekaraNessuna valutazione finora

- FOM2 NT Brochure-MainDocumento6 pagineFOM2 NT Brochure-MaindeepakNessuna valutazione finora

- Amada2510 PDFDocumento9 pagineAmada2510 PDFMedhat MerzekNessuna valutazione finora

- Laser SalesbookDocumento34 pagineLaser SalesbookManuel GonzalezNessuna valutazione finora

- 6 - Durma Laser User InterfaceDocumento30 pagine6 - Durma Laser User Interfacesciuc0% (1)

- Hartford Pro 1000 CNC Vertical MillDocumento14 pagineHartford Pro 1000 CNC Vertical MillChuck20620% (1)

- 367 PDFDocumento12 pagine367 PDFDang Anh DuyNessuna valutazione finora

- Dokumen - Tips Amada Astro II 100 NT Maschinen Press Brake Hds 1030 NT Press CapacityDocumento7 pagineDokumen - Tips Amada Astro II 100 NT Maschinen Press Brake Hds 1030 NT Press CapacityAnton WilliamsNessuna valutazione finora

- XPR 300 Manual HyperthermDocumento106 pagineXPR 300 Manual HyperthermDawitt BadilloNessuna valutazione finora

- Technical Data Press MaintenanceDocumento6 pagineTechnical Data Press MaintenanceKaran VirbhadreNessuna valutazione finora

- Warthog CNC Owner's ManualDocumento66 pagineWarthog CNC Owner's Manualursind100% (1)

- AS ING Rev0 PDFDocumento38 pagineAS ING Rev0 PDFNguyen Quyet ThangNessuna valutazione finora

- 05 01 Bytubework V01 enDocumento14 pagine05 01 Bytubework V01 enVojkan MilenovicNessuna valutazione finora

- Countersink Tool Downward - WZ19enDocumento10 pagineCountersink Tool Downward - WZ19enBebe Ionuț AnițaNessuna valutazione finora

- Multicam Plastics BrochureDocumento2 pagineMulticam Plastics BrochureMoe KimoNessuna valutazione finora

- TC600 e PDFDocumento12 pagineTC600 e PDFSalar SalahiNessuna valutazione finora

- TOGU BrochureDocumento4 pagineTOGU Brochureisaias_pm92Nessuna valutazione finora

- Vendaxo - Trumpf TrumaBend V50 CNC Press Brake Machine - 500 KNDocumento2 pagineVendaxo - Trumpf TrumaBend V50 CNC Press Brake Machine - 500 KNHalász Attila0% (1)

- 2361Documento103 pagine2361Alen AnušićNessuna valutazione finora

- 1120-Quick Ref PDFDocumento2 pagine1120-Quick Ref PDFRoman JambrekNessuna valutazione finora

- DIN EN 12622: April 2010Documento64 pagineDIN EN 12622: April 2010EvaldoGualbertoNessuna valutazione finora

- LIT00569 UltraThickTurret PN 2014 RevC Lo-ResDocumento96 pagineLIT00569 UltraThickTurret PN 2014 RevC Lo-ResAntonio AguilarNessuna valutazione finora

- Bystar Datasheet Eng OriginalDocumento2 pagineBystar Datasheet Eng OriginalAmer FatićNessuna valutazione finora

- HMC BasicDocumento14 pagineHMC BasicShashankNessuna valutazione finora

- Cnckad 9Documento1 paginaCnckad 9Thong ChanNessuna valutazione finora

- Davi-MCA - FOUR ROLLDocumento8 pagineDavi-MCA - FOUR ROLLبازرگانی راهیان کار و دانشNessuna valutazione finora

- Family eDocumento24 pagineFamily eisosicaNessuna valutazione finora

- Byspeed 3015 BA V010 enDocumento524 pagineByspeed 3015 BA V010 enΈλσαΟγκρένιNessuna valutazione finora

- Quotation Form: Camso LoadstarDocumento1 paginaQuotation Form: Camso Loadstarchathuranga chandrasekaraNessuna valutazione finora

- D800 BrochureDocumento4 pagineD800 BrochurefrankNessuna valutazione finora

- Learn Sheet Metal Design Terminology Including Bend DeductionDocumento4 pagineLearn Sheet Metal Design Terminology Including Bend DeductionSai Charan ChallapalliNessuna valutazione finora

- Operator'S Manual: Roller SolutionsDocumento14 pagineOperator'S Manual: Roller SolutionsnatshipNessuna valutazione finora

- TOX Sheet Metal Joining SystemDocumento24 pagineTOX Sheet Metal Joining SystemsachedalNessuna valutazione finora

- My CNC TurningDocumento7 pagineMy CNC Turningde_stanszaNessuna valutazione finora

- Durma Hydraulic 4 Roll PDFDocumento5 pagineDurma Hydraulic 4 Roll PDFthaivinhtuyNessuna valutazione finora

- Trumpf Parts Service Manual - January 2004Documento28 pagineTrumpf Parts Service Manual - January 2004Orlando Humberto Altamirano ArceNessuna valutazione finora

- New in CncKad V10Documento53 pagineNew in CncKad V10rzrasaNessuna valutazione finora

- Wilson Tool - Amada Thick Turret Catalogue 2011 - SM TECHDocumento37 pagineWilson Tool - Amada Thick Turret Catalogue 2011 - SM TECHSM TECH SRLNessuna valutazione finora

- 01.machine Fault Codes and SolutionsDocumento27 pagine01.machine Fault Codes and Solutionschathuranga chandrasekaraNessuna valutazione finora

- MARVEL 6000 Series High Power Fiber Laser Cutting Machine - Laser Cutting Farley Laserlab, CNC Laser Cutting Machine, Plasma Cutting Machine, Fiber Laser Cutting Machine, Cutting Machine PriceDocumento1 paginaMARVEL 6000 Series High Power Fiber Laser Cutting Machine - Laser Cutting Farley Laserlab, CNC Laser Cutting Machine, Plasma Cutting Machine, Fiber Laser Cutting Machine, Cutting Machine PriceTradiyo ForexNessuna valutazione finora

- Instruction SA DXBDocumento134 pagineInstruction SA DXBPhilip Cairns100% (2)

- TopsWorks CadDocumento6 pagineTopsWorks CadPeter DrummenNessuna valutazione finora

- The Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalDocumento1 paginaThe Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalSM TECH SRLNessuna valutazione finora

- CNC Kad User ManualDocumento50 pagineCNC Kad User Manualแผน กุลอัก100% (2)

- TRUMPF Bending Tools Catalog EN PDFDocumento261 pagineTRUMPF Bending Tools Catalog EN PDFjulio xNessuna valutazione finora

- Milling MachinesDocumento48 pagineMilling MachinesAliah IzzahNessuna valutazione finora

- ByStar Fiber Datasheet Eng OriginalDocumento2 pagineByStar Fiber Datasheet Eng OriginalDamir Merima MuslicNessuna valutazione finora

- TRUMPF TRUBEND 5230 Technical DataDocumento11 pagineTRUMPF TRUBEND 5230 Technical DatacoronaqcNessuna valutazione finora

- CNC Turning Programming Fundementalsls, Step by StepDocumento14 pagineCNC Turning Programming Fundementalsls, Step by Stepschriener50% (2)

- Altendorf F45Documento60 pagineAltendorf F45marianojoselarra2890Nessuna valutazione finora

- Promaster 7225Documento12 paginePromaster 7225AdragNessuna valutazione finora

- TP TP: Turret Punch Turret PunchDocumento20 pagineTP TP: Turret Punch Turret PunchMaly AliNessuna valutazione finora

- CamDocumento52 pagineCamGaurav DabhekarNessuna valutazione finora

- CNC Lathe Machines PDFDocumento7 pagineCNC Lathe Machines PDFMetwally Naser100% (1)

- Hindustan Hydraulics EHPsh25 PDFDocumento4 pagineHindustan Hydraulics EHPsh25 PDFshyam_ink50% (2)

- Delta CNC - C - ENDocumento44 pagineDelta CNC - C - ENErsin AkyüzNessuna valutazione finora

- Fans & Blowers-Calculation of PowerDocumento20 pagineFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- 10921EN BearingHeatersDocumento6 pagine10921EN BearingHeatersHBracing1Nessuna valutazione finora

- 9 AGR Gearboxes PDFDocumento10 pagine9 AGR Gearboxes PDFHBracing1Nessuna valutazione finora

- Hertz Ian ContactDocumento17 pagineHertz Ian ContactHaydar KilicNessuna valutazione finora

- Centrifugal FanDocumento52 pagineCentrifugal Fanabhishek_bhatia2k5Nessuna valutazione finora

- Die CutDocumento6 pagineDie CutHBracing1100% (1)

- Mts Sensors Faq MD 7815 v2Documento1 paginaMts Sensors Faq MD 7815 v2HBracing1Nessuna valutazione finora

- TR 05300001 eDocumento36 pagineTR 05300001 eJarolf Magpali CarrascoNessuna valutazione finora

- Troubleshooting1 PDFDocumento40 pagineTroubleshooting1 PDFDanielAlfaroNessuna valutazione finora

- Fans & Blowers-Calculation of PowerDocumento20 pagineFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- LubricationDocumento48 pagineLubricationHBracing1Nessuna valutazione finora

- 9 AGR GearboxesDocumento10 pagine9 AGR GearboxesHBracing1Nessuna valutazione finora

- LubricationDocumento104 pagineLubricationHBracing1Nessuna valutazione finora

- Ringfeder HeavyDutyCouplingsDocumento4 pagineRingfeder HeavyDutyCouplingsHBracing1Nessuna valutazione finora

- LubricationDocumento48 pagineLubricationHBracing1Nessuna valutazione finora

- Die CutDocumento6 pagineDie CutHBracing1100% (1)

- 6 MistakesDocumento6 pagine6 MistakesHBracing1100% (1)

- Tube BendingDocumento4 pagineTube BendingmainoNessuna valutazione finora

- Centrifugal FanDocumento52 pagineCentrifugal Fanabhishek_bhatia2k5Nessuna valutazione finora

- Fans & Blowers-Calculation of PowerDocumento20 pagineFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Mts Sensors Faq MD 7815 v2Documento1 paginaMts Sensors Faq MD 7815 v2HBracing1Nessuna valutazione finora

- Belt Theory06smDocumento18 pagineBelt Theory06smHBracing1Nessuna valutazione finora

- Tube BendingDocumento4 pagineTube BendingmainoNessuna valutazione finora

- Senzori PritiskaDocumento27 pagineSenzori PritiskaEdina Dizdarević100% (1)

- Duplomatic ValveDocumento4 pagineDuplomatic ValveHBracing1Nessuna valutazione finora

- Set23 RegReal V23 enDocumento28 pagineSet23 RegReal V23 enHBracing1Nessuna valutazione finora

- What You Should Know About Heat Straightening Repair of Damaged SteelDocumento23 pagineWhat You Should Know About Heat Straightening Repair of Damaged SteelAnonymous AlhzFE9EVNNessuna valutazione finora

- Jerehy's ReportDocumento65 pagineJerehy's Reportkupetroleum3Nessuna valutazione finora

- 11 My Immigration Story - Tan Le QuestionsDocumento3 pagine11 My Immigration Story - Tan Le QuestionsMallika Nand NairNessuna valutazione finora

- 1.4 BG00381946 - ADocumento1 pagina1.4 BG00381946 - AAnand KesarkarNessuna valutazione finora

- Thesis Final 2 Number c1-c5Documento167 pagineThesis Final 2 Number c1-c5Kimverly DomaganNessuna valutazione finora

- 02 Height and Distance - NIMCET Free Study MatrerialDocumento2 pagine02 Height and Distance - NIMCET Free Study MatrerialIshang VashishthaNessuna valutazione finora

- History of Nursing: Nursing in The Near EastDocumento7 pagineHistory of Nursing: Nursing in The Near EastCatherine PradoNessuna valutazione finora

- Scan 03-Jan-2020 PDFDocumento2 pagineScan 03-Jan-2020 PDFPavanSharmaNessuna valutazione finora

- Newsite KPI Check. - Ver2Documento4.183 pagineNewsite KPI Check. - Ver2nasircugaxNessuna valutazione finora

- Chapter 2 Fluid StaticsDocumento26 pagineChapter 2 Fluid StaticsSoban Malik100% (1)

- Sheiko 13week Beginner ProgramDocumento16 pagineSheiko 13week Beginner ProgramAnders DahlNessuna valutazione finora

- Metric Conversion WorksheetDocumento3 pagineMetric Conversion WorksheetKaiden HughesNessuna valutazione finora

- Reading The Bible From Feminist, Dalit, Tribal and Adivasi Perspectives (Course Code: BC 107)Documento8 pagineReading The Bible From Feminist, Dalit, Tribal and Adivasi Perspectives (Course Code: BC 107)Arun Stanley100% (2)

- ABS CBN CorporationDocumento16 pagineABS CBN CorporationAlyssa BeatriceNessuna valutazione finora

- Tuan Nor Akmal Imanina Binti Tuan MasorDocumento2 pagineTuan Nor Akmal Imanina Binti Tuan MasorIzza RosliNessuna valutazione finora

- PQM Quiz FinalDocumento11 paginePQM Quiz FinalSyeda Sadaf ZahraNessuna valutazione finora

- Healthy Body CompositionDocumento18 pagineHealthy Body CompositionSDasdaDsadsaNessuna valutazione finora

- Dry Docking QuotationDocumento4 pagineDry Docking Quotationboen jayme100% (1)

- Symantec Endpoint Protection 14.3 RU3 Release NotesDocumento28 pagineSymantec Endpoint Protection 14.3 RU3 Release NotesMilind KuleNessuna valutazione finora

- Technical EnglishDocumento7 pagineTechnical EnglishGul HaiderNessuna valutazione finora

- Hal Foster Vision and Visuality Discussions in Contemporary Culture PDFDocumento75 pagineHal Foster Vision and Visuality Discussions in Contemporary Culture PDFEd GomesNessuna valutazione finora

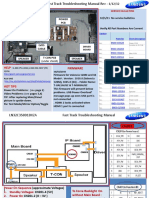

- Samsung LN55C610N1FXZA Fast Track Guide (SM)Documento4 pagineSamsung LN55C610N1FXZA Fast Track Guide (SM)Carlos OdilonNessuna valutazione finora

- Structure of An Atom Revision PaperDocumento5 pagineStructure of An Atom Revision PaperZoe Kim ChinguwaNessuna valutazione finora

- Glorious Mysteries 1Documento5 pagineGlorious Mysteries 1Vincent safariNessuna valutazione finora

- My TestDocumento18 pagineMy TestBlessmore Chitanha100% (1)

- How Do I Predict Event Timing Saturn Nakshatra PDFDocumento5 pagineHow Do I Predict Event Timing Saturn Nakshatra PDFpiyushNessuna valutazione finora

- 1422-Article Text-3684-1-10-20211104Documento57 pagine1422-Article Text-3684-1-10-20211104f.kpobi1473Nessuna valutazione finora

- Assessment 3 Comparative Analysis Primary Vs Secondary SourcesDocumento5 pagineAssessment 3 Comparative Analysis Primary Vs Secondary SourcesMATOZA, YLJOE V.Nessuna valutazione finora

- N Mon Visualizer OverviewDocumento27 pagineN Mon Visualizer OverviewClaudioQuinterosCarreñoNessuna valutazione finora

- Grief and BereavementDocumento4 pagineGrief and BereavementhaminpocketNessuna valutazione finora

- Chinese MedicineDocumento16 pagineChinese MedicineTrisNessuna valutazione finora