Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Linen Policy 0310

Caricato da

Richard Allan SolivenDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Linen Policy 0310

Caricato da

Richard Allan SolivenCopyright:

Formati disponibili

IC/276/10 Linen Policy

BASINGSTOKE AND NORTH HAMPSHIRE NHS FOUNDATION TRUST

Linen Policy

IC/276/10

Owner

Final approval

committee

Authoriser

Name

Job Title

Name

Hazel Gray

Senior Infection Control Nurse

Infection Control Committee

Date of meeting

Name

Job Title

5 March 2010

Dr Nicki Hutchinson

Director Infection Prevention and

Control

Signature

Review date

Audience

Standards

Date of authorisation

(maximum 3 years from date

of authorisation)

(tick all that apply)

Standards for Better Health

NHSLA

05/03/2010

2013

Trust staff

NHS

General public

C4a

Reviewed in accordance with The Health and Social Care Act 2008:

Code of Practice for health and adult social care on the prevention and

control of infections and related guidance published 16 December 2009

Summary

This linen policy outlines how linen should be handled and transported around the

Trust and ensures Health and Safety and Infection Control Guideline are followed.

IC/276/10 Linen Policy

Implementation Plan

Summary of changes

New Policy

Action needed and owner of action

All staff that uses the linen service must adhere to the Trust policy.

All staff must ensure that all linen is segregated and sent back to trust linen supplier in the

correct linen bags depending on the condition of the linen, i.e. infected/fouled linen must be

placed in red alginate bag before being placed in red plastic bag.

IC/276/10 Linen Policy

Contents

1.0

2.0

3.0

3.1

3.2

4.0

5.0

6.0

6.1

6.2

6.3

6.4

6.5

6.6

7.0

7.1

7.2

8.0

9.0

10.0

10.1

10.2

10.3

10.4

11.0

12.0

12.1

12.2

12.3

12.4

13.0

13.1

13.2

14.0

14.1

14.2

15.0

15.1

15.2

Introduction

Aim of the Policy

Organisational Role and Responsibilities

All staff

Managers

Performance Management

Training

General Linen

Rental Items/Issues

Clean Linen Delivery

Linen Stocks/Issue Levels

Soiled Linen Collections

Infected/Foul Linen

Linen contaminated with chemotherapy waste

Curtains

Curtain Changes

Soiled Curtain Collection

Pillows

Mops

Garments/Workwear/Boiler suits

Chefs Wear

Scrub Suits

Theatre Drapes & Gowns

Rejects

Bags

Safe Management of Linen

Protection when handling used linen

When and how to dispose of used linen

Preparation and staff protection

Procedures

How to dispose of soiled/foul/infected linen

Preparation and staff protection

Procedures

Linen Transportation

Preparation and staff protection

Procedures

Advice for relatives on taking laundry home to launder

Preparation

Procedures

References

Appendix A: Linen Segregation Procedure

Appendix B: Laundry Service Procedures

Page

Number

3

3

3

3

3

3

3

4

4

4

4

4

4

4

5

5

5

5

5

6

6

6

6

6

6

7

7

7

7

7

7

7

7

8

8

8

8

8

8

8

9

10

IC/276/10 Linen Policy

1.0 Introduction

It has been shown that used linen, within healthcare settings, in particular, can harbour large

numbers of potentially pathogenic microorganisms. Therefore, it is important that the

appropriate precautions are taken to ensure contamination to/from linen does not occur as

this might then lead to transmission of microorganisms to people or to the environment

potentially causing infection. Such important precautions apply to all stages of linen

management: storage, handling, bagging, transporting, and laundering.

The provision and management of Linen Services is an important function to enable

sustainable delivery of patient care. By complying with this policy staff will facilitate the

continued delivery of these services, minimising risks to health & safety, complying with

infection control requirements and ensuring best value for the Trust.

2.0 Aim of the Policy

The Aim of the policy is to outline how linen should be handled to minimise the risk of cross

infection.

3.0 Organisational Role and Responsibilities

3.1 All staff

Have a responsibility to safely manage linen that they use whilst delivering care

Have the responsibility to report any exposure incidents that occur related to

contaminated linen and to take appropriate measures to avoid these in the first

instance

Have a responsibility to undertake training on relevant aspects of the

management of linen

Have a responsibility to display available posters clearly demonstrating the

actions to be taken to manage linen safely

3.2 Managers

Have the responsibility to ensure local risk assessments are carried out where

necessary, and ensure appropriate personal protective equipment (PPE) is

available to staff. They should also ensure immunisation programmes are offered

appropriately and any incidents that occur are reviewed and subsequent actions

taken where appropriate

Have the responsibility to ensure staff are aware of training sessions and facilitate

their attendance

Responsibility for the operational management of the linen services policy is that

of Estates and Facilities Domestic & linen Service and the Trusts chosen

provider Service Group

4.0 Performance Management

The General Manager Facilities and Domestic & linen Manager will ensure this

policy is implemented efficiently and that the ICT is informed of any infection

control non-compliance incidents

To monitor compliance to the policy spot checks will be undertaken by the ICT at

ward level on an ad hoc basis to ensure linen is segregated appropriately and any

discrepancies will be fed back to the ward managers

The ICT will provide advice and support on safe handling of infected linen

5.0 Training

Segregation of linen will be part of mandatory training for all staff who handle or

deal with linen throughout the Trust.

IC/276/10 Linen Policy

6.0 General Linen

6.1 Rental Items / Issues

All stock and Issue figures will be amended on a continuous basis responding to

changes in operational requirements e.g. outbreak situations

6.2 Clean Linen Delivery

Linen will be packed into linen roll cages the day prior to issue, identified and

stored in the A level linen room outer area.

Portering & designated linen staff will move the roll cages from the A level linen

room to a general area within each floor / departmental area each morning.

Linen services staff will top up each ward / departments linen store directly, with

the identified linen issue quantities in line with the identified delivery frequencies.

Linen services staff will return all empty linen cages to the linen room for use the

following day. (To comply with infection control requirements, linen cages

are to be used for clean linen only. They are not to be used for soiled linen,

rubbish or to move any other items)

6.3 Linen Stock/Issue Levels

Linen stock and issue levels will be constantly reviewed based on continuing

usage patterns within each ward I department, and amended by either increasing

or decreasing the quantities. Agreed ward/department quantity lists will be

maintained and serviced with variation to quantity being communicated as

instructed.

Ward / Departmental staff may request additional quantities I items of linen in

response to local ad hoc requirements, by speaking to linen services staff when

they are topping up the linen stocks or by contacting the linen room on ext 5043.

6.4 Soiled Linen Collections

Soiled linen is to be placed in the supplied white plastic linen bags for each

category of linen. The soiled linen bag colour scheme is attached as appendix A.

Portering or designated Linen Staff will collect soiled linen on a regular basis via

dedicated linen wheeled bins, from all ward / departmental areas.

All soiled linen collected should be taken to the soiled linen area, within the A

Level linen room and deposited in the trust linen supplier provided cages, in the

appropriate areas as identified. All soiled linen from all areas of the hospital

should be in the soiled linen area before 3am each morning to ensure that the

maximum linen is available for trust linen supplier to collect each day. (To

comply with infection control requirements all soiled linen is to be stored

within the A Level linen room soiled linen area only, no other areas of the

hospital are to be used as collection points for soiled linen)

Trust linen supplier will collect all soiled linen from the A Level linen room early

morning Monday to Friday. Additional arrangements will be made to allow for the

removal of soiled linen on Bank Holidays.

6.5 Infected/Fouled Linen

All Infected/fouled linen is to be placed in a red soluble bag (alginate), which

should then be placed within a red plastic bag (as per the soiled linen bag colour

scheme)

Collections of infected linen in red bags should follow the same procedure as for

soiled linen.

6.6 Linen contaminated with chemotherapy waste

If spillage has penetrated the bed linen place it in a yellow bag and dispose of as

cytotoxic waste. Hospital linen that is potentially contaminated with cytotoxic

drugs should never be returned to the hospital laundry. The mattress should then

be cleaned using warm soapy water. Once dried the bed may be remade with

4

IC/276/10 Linen Policy

clean linen. If the mattress is affected seek further guidance from health and

safety advisors.

7.0 Curtains and window Blinds

All curtains and window blinds supplied conform to all relevant regulations on fire

retardancy and fabric performance. The ICT should be informed of any change

and consulted on specifications

7.1 Curtain Changes

To ensure compliance with infection control procedures, curtains across all areas

with be changed by linen services staff on a rotating 3 month schedule.

To ensure that the above detailed scheduled changes take place, ad hoc

changes due to infection will be undertaken by the designated staff who

undertake deep cleaning of areas.

Standard curtain panels are available in the linen room for ad hoc changes.

These can be accessed by contacting the linen room on ext 5043 between 8am &

5pm Monday to Friday, outside of these hours curtains will be available in the

linen room for collection by EFM Portering staff via bleep 1201.

7.2 Soiled Curtain Collection

All soiled/infected curtains are to be placed within a red alginate bag and then a

red plastic bag

Paperwork is not required to accompany curtains sent for laundering.

Collections of curtains in red bags should follow the same procedure as for soiled

I fouled linen detailed above.

8.0 Pillows

All pillows used MUST have a protective cover on it that can be wiped down

Any pillow cover that becomes torn should be placed in a clear plastic bag (NOT

a trust linen supplier bag) and placed in the sluice area for collection by the linen

room staff.

Any pillow that becomes contaminated or stained and which cannot be wiped

clean must be double bagged at the ward area and the word condemned written

on the bag. This should then be placed in the sluice area for collection by the

linen room staff.

Pillows MUST NOT be disposed off at ward area by nursing staff.

9.0 Mops

Single undyed Kentucky string mops will be issued as standard rental items to

each area in quantities as required.

Mops will be issued to each area of the hospital on an exchange basis, replacing

each areas quantity of soiled mops with clean.

Linen Services staff will deliver the exchange quantity of mops to each agreed

area daily Mon to Fri with double quantities issued at weekends.

Soiled Mops should be individually bagged in the supplied clear plastic bags.

These bags should then be placed in the supplied mop container / bag identified

with the area name.

Portering staff on a daily basis should collect the identified container I bag

containing the soiled bagged mops and transport to the identified area within the

linen room.

Linen services staff will count each bagged mop for each area and reissue clean

mops to replace these in each area.

All soiled mops will then be collected by trust linen supplier for laundering to

thermal disinfection standards.

It is the responsibility of the cleaning staff in each area to ensure that all soiled

mops are returned to the linen room for laundering. (Under no circumstances

should soiled mops be placed in domestic or clinical waste bags)

5

IC/276/10 Linen Policy

10.0 Garments I Work wear/Boiler suits

Garments I work wear requiring industrial laundering with be issued as rental

items to each individual staff member on an exchange basis.

Staff should take their soiled garments I work wear to the A Level linen room

between 8AM and 5PM Mon to Fri, where linen services staff will exchange each

item for a clean replacement.

10.1 Chefs Wear

Chefs Wear requiring industrial laundering will be issued as rental items to each

individual staff member on an clean issue and dirty exchange basis.

Staff deposit their soiled Chefs wear into the designated linen bins located in the

Catering departments changing areas for cleaning by the designated service

provider.

10.2 Scrub Suits

Pool issue scrub suits will be issued to all areas requiring these items in the

range of sizes required as per the procedure for general linen detailed above.

Soiled scrub suits should only be placed in white (or red alginate followed by red

plastic bag if heavily soiled or if infected) bags as per the procedure for general

linen items detailed in above. (Under no circumstances should scrub suits be

placed in green bags)

10.3 Theatre Drapes & Gowns

Microfibre theatre drapes and gowns will be provided as rental items to theatres

as required.

All drapes and gowns will be supplied sterile direct from trust linen supplier.

Containers containing sterile drapes and gowns will be delivered by trust linen

supplier to the A level linen room. Linen service staff will sort each container into

the correct area.

Portering staff will distribute each container of sterile drapes to each area

identified.

Theatre staff are responsible for ordering replacement stock of theatre drapes

and gowns to their agreed stock levels direct from trust linen supplier. Contact

information is as issued to each department and is also available by contacting

the A Level linen room on ext 5043.

Soiled drapes and gowns should be placed in green bags only. These green bags

should be placed in the trust linen supplier cages used for delivery, and stored in

a suitable area to await collection. (Under no circumstances should theatre

drapes and gowns be placed in any other colour than green bags)

Portering staff will collect all cages of drapes and gowns, which are, bagged in

green bags, along with all delivery boxes. All cages and boxes are to be taken to

the A Level linen room soiled linen area and placed in the appropriate identified

location, to await collection.

10.4 Rejects

Reject Bags will be issued to all areas

Any items that are unsuitable for use (stained / holed etc.) should be placed in the

reject bag. (Under no circumstances should rejected items be placed in any

soiled linen bags)

11.0 Bags

Plastic soiled linen bags are supplied via trust linen supplier.

Additional supplies of all soiled linen bags can be obtained by contacting the linen

room on 5043.

To comply with manual handling requirements, and also to ensure undue strain is

not placed on the plastic bags, do not over fill the bags (as a guide fill to 2/3s full

to allow for tying the bag opening).

6

IC/276/10 Linen Policy

12.0 Safe Management of Linen

12.1 Protection when handling used linen

A disposable plastic apron should always be worn when handling used linen (and

disposable gloves where linen is soiled/foul), e.g. during bed making.

Hold used linen away from yourself to avoid contamination of clothing from linen

Hand hygiene should be performed following handling of used linen (see Hand

Hygiene Policy)

12.2 When and how to dispose of used linen

12.3 Preparation and staff protection:

Ensure appropriate and clean bags/receptacles, e.g. linen skips, are available as

close to the point of use as possible

Personal protective equipment (PPE) should be worn appropriately to ensure

contamination from used linen does not occur, e.g. disposable plastic apron and

gloves if handling used linen.

12.4 Procedures:

Place used linen immediately into a designated bag/receptacle

Separate used linen carefully. Place each item directly into the designated

bag/receptacle. (However, if linen is soiled/foul, it should be managed separately,

see - How to dispose of soiled/foul linen)

Never place/drop linen on the floor or on other surfaces, which may be touched

frequently as this could lead to contamination, especially during care delivery e.g.

a locker/table top

Staff should avoid shaking linen as this may result in the dispersal of potentially

pathogenic microorganisms and/or skin scales into the environment

Used linen bags/receptacles should never be overfilled

After handling linen, staff should ensure they dispose of any PPE appropriately

Hand hygiene should be performed following handling of linen

13.0 How to dispose of soiled/foul/infected linen:

13.1 Preparation and staff protection:

Ensure appropriate and clean bags/receptacles e.g. linen skips are available as

close to the point of use as possible

Personal protective equipment (PPE) should be worn appropriately to ensure

contamination from used linen does not occur, e.g. disposable plastic apron and

gloves if handling linen

13.2 Procedures:

Linen soiled or contaminated with blood or other body fluids or from infected

patients, should be placed directly into a water-soluble/alginate bag (these are

red in colour) to prevent any further handling and potential contamination,

particularly for those performing laundering procedures. This bag indicates that

linen is soiled/foul. The bag should be secured using a neck tie

Separate the linen carefully.

Staff should NOT shake the linen as this may result in the dispersal of potentially

pathogenic microorganisms and/or skin scales into the environment

The alginate bag once tied should be placed into a red plastic bag.

Soiled/foul linen should not be rinsed or sorted prior to it being laundered,

Never place/drop linen on the floor or on other surfaces which may be touched

frequently as this could then lead to contamination especially during care delivery

e.g. a locker/table top

Bags should never be over filled

After handling linen, staff should ensure they dispose of any PPE appropriately

Hand hygiene should be performed following handling of linen

IC/276/10 Linen Policy

14.0 Linen Transportation

14.1 Preparation and staff protection

PPE should be worn appropriately to protect those transporting linen, e.g. gloves

Measures should be in place to ensure that linen for use arrives clean e.g.

department or company agreements.

Inspections should be carried out on those transporting linen e.g. auditing of vans

or trolleys to ensure these are clean and that cages are used for storage of linen

in these settings with clear separation of clean and dirty linen

14.2 Procedures

Bags containing used linen that have not been properly secured should not be

lifted

Personnel transporting used linen should not open linen bags/receptacles/cages

nor should they handle linen

If a sharps injury is sustained from an item found during transport of linen, the

trusts standard procedure as per Sharps contamination injuries Policy,

should be followed.

Clean and used linen should never be transported in the same

bag/receptacle/storage cage. Instead, there should be designated

bags/receptacles/storage cages for each

Clean hands should only handle clean linen. The linen should be stored in a

designated, clean area with minimal handling until required for use

Hand hygiene should be performed after handling used linen

bags/receptacles/cages and prior to handling clean linen

15.0 Advice for relatives on taking laundry home to launder

15.1 Preparation

Staff should explain key elements of standard infection control precautions e.g.

PPE, hand hygiene, to relatives/friends prior to them taking linen home to launder

15.2 Procedures

These additional points should also be raised:

Dispose of plastic bag(s) used to carry items promptly

Launder items using as high a temperature as possible and as per machine

instructions

Use normal washing powder

Tumble dry where possible (following manufacturers guidance)

Iron according to manufacturers instructions. A hot iron is best if possible

Hand hygiene should be undertaken following handling of items

Where hand rinsing of heavily soiled items is absolutely necessary, this should be

carried out by fully submersing the items to avoid potential

aerosolisation/splashes while rinsing. Ensure splashing is minimised particularly

when throwing away used water

Generally, personal items do not need to be separated for washing unless soiled

References

1. National Health Service Executive. Hospital Laundry Arrangements for Used and

Infected Linen. HSG (95)18 Leeds: NHSE; 1995; 4.

2. Standard Principles for preventing hospital-acquired infections Journal of Hospital

Infection (2001) 47(Supplement): S21S37

3. Wilson J et al (1999), Infection Control in Clinical Practice. Bailliere Tindall London 1999.

4. Damani N.N. (2000), Manual of Infection Control Procedures: 2nd Edition, Greenwich

Medical Media Ltd. London.

IC/276/10 Linen Policy

Appendix A

Linen Segregation Procedure

LINEN SEGREGATION PROCEDURE

INFECTED &

USED

THEATRE

LINEN ONLY

HEAVILY SOILED

LINEN ONLY

Used/slightly soiled

linen from non-infected

patients must be

placed into a WHITE

plastic laundry bag

Used linen which has been in

contact with infected

patients OR is heavily

contaminated with body

fluids should be placed into a

RED SOLUBLE BAG (alginate)

and securely tied before being

placed into a RED PLASTIC BAG

Used linen must be placed

into a GREEN PLASTIC BAG

linen that has been heavily

contaminated with body

fluids must be placed into

a RED SOLUBLE BAG

(alginate) prior to going into a

GREEN PLASTIC BAG

ALL BAGS SHOULD BE NO MORE THEN 2/3 FULL

NO LINEN SHOULD BE PLACED INSIDE A YELLOW CLINICAL OR DOMESTIC WASTE BAG ENSURE

ALL SHARP ITEMS ARE REMOVED PRIOR TO PLACING LINEN INTO BAG

IC/276/10 Linen Policy

APPENDIX B

Basingstoke and North Hampshire NHS Foundation Trust

Laundry operational procedures for the BNHFT

1st April 2008

EFM Domestic and Laundry Service

Content

Heading

Section

Purpose

1.0

Overview of service

2.0

Arrangement for thermal infestation/infection control

3.0

Appendix

1. Sunlight service schedule HSG (95)18 and KPI

2. Service requirement

3. PASA cost schedule

4. Laundry returns procedure

5. Sunlight BCP and escalation data

IC/276/10 Linen Policy

1.0

Purpose

This procedure document details the Basingstoke and North Hampshire NHS Foundation

Trusts (BNHFT) Laundry and linen service arrangements. This includes the contracted

services provision for laundry and its respective governance and compliance with HSG(95)18.

2.0

Service overview

Healthcare linen provided by external laundry contract

External linen supplier delivers clean stock to site determined by volumes ordered or

agreed by Trust

Storage and distribution of linen is operated by the Trusts EFM Laundry team

supported by the Porter team for site distribution

Storage and distribution of linen stock at ward level is controlled by the ward team

along with collection and return of dirty and faulty stock to designated collection points

Dirty and faulty linen is collected and returned to the EFM laundry team for collation

and return to external linen supplier

External linen supplier collects dirty stock and launders as per schedule (HSG(95)18

The Trusts EFM laundry team manages

Contract performance management with external supplier

Stock control and distribution of stock

Safe delivery and return of clean and dirty stock

Support of linen service users in the Trust to ensure performance of service

Attendance at the Trusts Cleaner Hospital committee

Liaison with IC team and Health and Safety team on operational issues

Carry out annual duty of care visit to supplier/contract providers operation. Appendix

? Duty of care visit report.

This is led by the:

EFM domestic and Laundry manager

Laundry Supervisor

Linen room team

3.0

Arrangement for thermal infestation/infection control

The Trusts contracted service provider Sunlight Ltd operate to ensure compliance with

HSG(95)18 the below statement is provided as part of the operating protocols of the laundry

service contract at the BNHFT.

Sunlight Ltd operational governance of HSG (95)18

EFM/Laundrydoms/Proc/2008

IC/276/10 Linen Policy

3.1 Thermal disinfection of laundry

We comply with HSG(95)18, which gives guidance on infected linen and notifiable diseases.

We would conform to relevant guidance from the Trusts Control of Infection Officer where

appropriate.

The wash process will be designed to maintain at least two wash cycles. The first will attain a

temperature of 32 degrees centigrade. The second will attain a temperature of 71 degrees

centigrade or more which will be maintained for at least five minutes. Additional time at this

temperature will be added for heavily soiled work.

At least one sluice cycle will proceed the high temperature washes and controls will be so set

on the machine as to ensure the programme timer does not proceed until the set temperature

has been reached. The timer will stop each time the temperature falls below the set level.

Depending on the classification Peroxide or Chlorine bleach will be used.

The final load each day in every washing machine will be of a classification that will allow

Chlorine bleach to be used during the rinse cycle. No work will be left in washing machines

overnight. CBW's will be thermally disinfected before the start of work each day.

3.2 The prevention of subsequent re-infection

We comply with HSG(95)18, and refer to working practices, i.e. restricting movement of staff

from clean to dirty areas, gowning protocols and proper receptacles for storage of work in

process, trolley disinfection procedures, covering trolleys with polythene and vehicle cleaning

and disinfection routines.

3.3 The processing of fouled articles

We comply with HSG(95)18, and would advise additionally there are designated areas within

the sorting room, a designated processing washer extractor, sealed drains and vent to

atmosphere for the processing of infected articles. Work that is delivered in alginate bags with

surrounding red bag is processed unopened, which is then thermal disinfected in washer

extractor and then reprocessed again using the normal wash procedure.

EFM/Laundrydoms/Proc/2008

IC/276/10 Linen Policy

Appendix 1

NATIONAL FRAMEWORK AGREEMENT FOR THE PROVISION OF LAUNDRY

AND LINEN SERVICES TO THE BNHFT

Service Specification

Contents

Section

1

Overall service options

(a)

Wash and return

(b)

Linen Hire

(c)

Total Linen Management

(d)

Hire of CE marked, reusable barrier theatre textiles

Service standard

(a)

For service options 1a,1b and 1c

Collection and delivery for all service options

Storage for all service options

Packaging for all service options

Processing of articles of laundry

(a)

For service options 1a,1b and 1c

(b)

For service option 1d

Standard of finish for all service options

Quality assurance and control for all service options

Key Performance Indicators

10

Documentation-management information

11

Contingency planning

12

Emergency supplies (major incident)

Schedule 1

Schedule 2

Schedule 3

Schedule 4

Schedule 5

EFM/Laundrydoms/Proc/2008

HSG (95) 18

Performance standards

Menu of services

Key finish definitions

Standards of finish

IC/276/10 Linen Policy

Standard service requirements

1

Service options

The Contractor shall provide laundry and linen services based on all or some of the

following service options:

(a) Wash and return which consists of:

A laundering and finishing service

Collection and delivery to and from NHS clients

All linen owned by client trust

Product mix may include:

(a)

Flatwork

(b)

Uniforms

(c)

Theatre linen (traditional cotton based products)

(d)

Patient Clothing (personal & non personal)

(b) Linen hire which consists of:

A laundering and finishing service

Collection and delivery to and from NHS clients

All linen owned by contractor with the exception of wash and return

Contract may comprise an element of wash and return (see above)

Provision of linen articles that may include:

(a)

Flatwork

(b)

Uniforms

(c)

Patient Clothing (personal & non personal)

Curtain Hire

This service is to supply curtains with additional options to fit and take down as

required, in accordance with participating trusts requirements. All curtains to be flame

retardant in accordance with HTM87.

The unit costs for curtain hire to be shown in a two tier format that consists of a

separate charge, per metre, for hire of the curtain and an associated charge for

laundering as a wash and return item.

(c) Total linen management which consists of:

A laundry and finishing service

All linen owned by contractor with the exception of wash and return

Contract may comprise an element of wash and return (see above)

Collection of soiled linen from each ward and department

Delivery to each ward and department of clean linen

Sewing Room Service (optional)

Provision of linen articles that may include:

(a)

Flatwork

(b)

Uniforms

(c)

Theatre linen (traditional cotton based products)

(d)

Patient Clothing (personal & non personal)

(d) Hire of CE marked, reusable barrier theatre textiles, which consists of:

Provision of a laundry and finishing service for theatre textiles that meet the

requirements of the European Medical Devices Directive 93/42

Collection and delivery to and from NHS clients

EFM/Laundrydoms/Proc/2008

IC/276/10 Linen Policy

Provision of CE marked reusable barrier theatre textiles in compliance with EN

13795

Theatre top up service (optional)

In view of the wide range of drapes and gowns available, offerors are requested to list

a sample range of high usage product lines e.g. top 20 items, together with the

maximum price the NHS would pay for those product lines.

Under this framework agreement trusts will use this information as the basis of

identifying their bespoke requirements. Participating trusts will then use this to secure

more detailed information both in terms of products and prices that reflects local needs

2

(a)

Service standard for service options1a, 1b and 1c

The Contractor shall supply a service to HSG 95(18), as a minimum standard; to

ensure that service standards are reflective of the aims associated with relevant

Government best practice e.g. Peat standards. Organisations appointed to the

national framework agreement will be expected to comply with all future government

guidance, regulations and standards in the provision of this service. To assist

interpretation of these standards, a copy of HSG (95) is attached in Schedule 1.

Collection and delivery for all service options

The Contractor shall collect all used/infected linen from specified storage facilities, at

times agreed with NHS clients. All clean articles of laundry shall be delivered by the

Contractor to agreed delivery points within an agreed time frame.

Used/infected articles of laundry must be transported, stored and sorted in containers

and in accommodation separate from those used for clean linen and must not at any

time come into contact with clean linen.

Clean articles of laundry shall be transported in containers and vehicles that have been

appropriately cleaned by the Contractor before each occasion on which they are used.

Each stillage/roll cage will be appropriately covered.

Storage for all service options

The Contractor shall operate and maintain appropriate storage and handling systems

for all linen held within their facility. The storage areas must provide for the

segregation of clean and used/infected articles of laundry and prevent the damage or

soiling of clean articles of laundry from any source.

Packaging for all service options

Clean articles of laundry must be packed in such a manner as to prevent re-soiling.

6

(a)

Processing of articles of laundry

For service options 1a, 1b and 1c

All articles of laundry must be washed, thermally disinfected unless the fabric or

product does not allow for this, in which case chemical disinfection is allowed.

Laundering must be undertaken in accordance with HSG (95)18, relevant statutory

requirements and reflect good industrial practice.

(b)

For service option 1d

C.E marked barrier theatre drapes and gowns (medical devices) are to be laundered

from the soiled side via a barrier washing machine into a clean room certified and

EFM/Laundrydoms/Proc/2008

IC/276/10 Linen Policy

validated to ISO 14644 Class 8 Clean Room. There they are to be dried, inspected,

folded and packed for sterilisation. Entry and exit to be controlled via an airlock

system, with staff changing and washing facilities.

7

Standard of finish for all service options

All clean articles of laundry, including CE marked barrier theatre drapes and gowns, on

each occasion they are supplied shall be thoroughly clean and fresh, free from

infection, in good usable condition and a good state of repair and in every respect fit for

immediate use.

Quality assurance and control for all service options

The Contractor will provide evidence of its own quality assurance and control

procedures including any accreditations to ISO standards or equivalents. A quality

assurance plan is required to ensure that systems and procedures are in place to

guarantee that services are provided according to the standards laid down within the

Contract, on each and every occasion throughout the Contract Period.

Key Performance Indicators

The service provided will be in accordance with the standards specified and will meet

those key performance indicators detailed in Schedule 2

10

Documentation- management information

Documentation must be adequate to identify and control all articles of laundry being

held or processed by the Contractor and to substantiate invoices. Additionally

documentation must be sufficiently detailed and capable of manipulation to enable

computer modeling and management forecasting to be undertaken by NHS clients.

11

Contingency planning

The Contractor must put in place appropriate contingency plans, prior to the

commencement of Contract. The Contingency Plan is to detail how the Contractor

proposes to allow for the continuance or earliest resumption of services in the event of

an emergency or breakdown of normal services. This contingency response is to

cover all areas of service and must be 100%operational within 24hours of each service

failure.

12

Emergency supplies (major incident)

The Contractor must maintain sufficient supplies of linen to cover unforeseen increases

in demand. Such emergency supplies must be accessible within 1 hour, 24 hours a

day, 7 days a week.

Schedule 1

HSG (95) 18

Hospital Laundry Arrangements for Used and Infected Linen

EFM/Laundrydoms/Proc/2008

IC/276/10 Linen Policy

Health Service

Guidelines

Hospital Laundry Arrangements for Used and

Infected Linen

Executive Summary

The provision of adequate laundry services is a fundamental

requirement of direct patient care and a major feature among a

hospitals man activities which contribute to its commitment to

meet Patients Charter standards of quality services. Hospital

Laundry Arrangements for Used and Infected Linen sets out the

recommended procedures to help meet this commitment. In

particular it covers the handling and laundering of linen; the

importance of securing the disinfection of used and infected linen;

and the basic principles of infection control.

Background

The NHS has an obligation under the Health and Safety at Work

Act to take steps to prevent the risk of infection to staff handling

and laundering linen. There is also a need to deal with the

potential for harm to staff and damage to linen by a failure to

separate sharps from dirty linen before it is placed in laundry

bags.

Action

NHS managers are asked to draw the accompanying guidance to

the attention of all staff, including contract staff, which may need

to apply it.

Managers should ensure that relevant legislation, including the

requirements of the Registered Homes Act in respect of laundry

from small units, is complied with.

Management should adopt procedures to ensure that patients

and staff are not put at risk of infection from used and infected

linen.

Management should ensure that all staff, and laundry contractors,

responsible for handling or laundering linen are appropriately

trained.

The advice contained in the HSG should be incorporated into

contracts where laundry services are not provided in-house.

The help of the Society of Hospital Linen Services and Laundry

Managers, in conjunction with the industry technical association,

FCRA in drawing up this guidance is acknowledged.

EFM/Laundrydoms/Proc/2008

HSG(95)18

Hospital

Laundry

Arrangements for Used and

Infected Linen

This replaces HC(87)30

which

expired

on

1

December 1992

21 April 1995

IC/276/10 Linen Policy

LAUNDERING PROCEDURES TO SECURE DISINFECTION OF USED AND INFECTED

LINEN

1.

1.1

INTRODUCTION

This guidance, which should be applied to all laundry facilities including launderettes

and on-premise laundries associated with small units, is issued to promote practices

which will reduce the possible risk of infection to laundry staff during the laundry

process and to secure the disinfection of used and infected linen. These practices will

also help to eliminate possible damage to linen and laundry equipment from the failure

of staff to separate potentially dangerous items (sharps in particular) from dirty linen

before it is placed in laundry bags.

1.2

It is essential for a laundry and its associated operations to ensure that it provides

health care units with adequate and timely supplies of the necessary requirement of

clean items. This is a major feature in the many aspects of a hospitals activities which

also helps them to meet their Patients Charter commitment of providing quality

services. Even minor variations in the levels of service provided can have serious

consequences.

1.3

The main problems demonstrating the need for revised advice involve the sorting and

categorising of linen. Although handling of foul linen is undesirable there is a need to

separate articles requiring different treatment and to detect sharp objects that may

damage the whole load. This is a particular problem when dealing with linen from

some units e.g. geriatric and psychiatric where up to 80% of its linen is in the foul or

infected category. The separation of soiled and foul linen is often not carried out in the

wards and items likely to damage linen, or machines, are commonly found in pockets

of garments or accidentally placed in the laundry bag. Positive efforts should be made

to encourage ward and theatre staff to use the bagging procedures as in Appendix A

and to avoid putting extraneous items into laundry bags. Linen from patients with

diseases likely to be transmissible to staff should be transferred to a washing machine

without handling by the laundry operative.

1.4

The local control infection committee should use this advice when determining local

policy procedures. It should also take into account HC(91)33 Decontamination of

contaminated equipment, linen or other surfaces contaminated with hepatitis B and/or

Human Immunodeficiency Virus (HIV). The committee could also usefully urge staff

not to send sharp items with linen to the laundry.

1.5

All staff handling linen should receive appropriate training to carry out their duties

efficiently and safely.

2.

2.1

CATEGORIES OF LINEN

It is recommended that linen (in this document linen refers to all articles for

laundering) should be divided by staff in wards and departments into three categories.

2.1.1

Used (Soiled and Foul) all used linen, irrespective of state, but on occasion

contaminated by body fluids or blood, apart from linen from infectious patients, those

suspected as being infectious and linen covered by 2.1.2 and 2.1.3. Handling policy

for used (soiled and foul) linen will be determined at local level with advice from the

local infection control committee whether the foul linen is to be categorised with the

used or infected linen.

2.1.2

Infected linen from patients with or suspected of suffering from enteric fever, and

other salmonella infections, dysentery (Shigella spp), hepatitis A, hepatitis B,

hepatitis C and carriers, open pulmonary tuberculosis, HIV infection, notifiable

EFM/Laundrydoms/Proc/2008

IC/276/10 Linen Policy

diseases and other infections in hazard group 3 COSHH 1994 Approved List of

Biological Agents (see Advisory Committee on Dangerous Pathogens) and other

infections specified by the infection control officer as hazardous to staff. Linen from

patients infected with hazard group 4 organisms (haemorraghic fever viruses such

as Lassa Fever) must be steam-sterilised by autoclaving within the group 4

containment unit before laundering see Memorandum On The Control of Viral

Haemorraghic Fevers, HMSO 1986. It is most important that linen likely to infect

staff should be put immediately into a water-soluble bag or bag with a water-soluble

stitched seam or membrane which will release its load in the wash process and

which is sealed with an appropriate soluble tie and labeled as to its origin. The

containers should be correctly coloured in accordance with the amended SIB(10)20.

(See Appendix A.)

2.1.3

Heat-Labile fabrics damaged by the normal heat disinfection process and likely to

be damaged at thermal disinfection temperatures.

3.

3.1

DISINFECTION OF USED (SOILED AND FOUL) LINEN

This category accounts for the vast majority of used linen from hospitals. For

transportation, such linen should be placed into polythene or nylon/polyester laundry

bags, colour coded in accordance with Appendix A. Bags must be securely fastened

before being sent to the laundry. Care should be taken to prevent linen or foul

seepage (body fluids or blood) escaping from laundry bags and contaminating other

items or staff. Use of a water-soluble bag as a liner is recommended.

3.2

The washing process should have a disinfection cycle in which the temperature in the

load is maintained at 65C (150F) for not less than 10 minutes or preferably at 71C

(160F) for not less than 3 minutes. With both options, mixing time must be added to

ensure heat penetration and assured disinfection. For machines of conventional

design and a low degree of loading (for example, below 0.056 kg/litre) 4 minutes

should be added to these times to allow for mixing time. For machines with a heavy

degree of loading (for example, above 0.056 kg/litre) it is necessary to add up to 8

minutes. A sluice cycle should be included as necessary when dealing with foul linen.

3.3

All washing machines should be checked prior to purchase to ensure that they have

the specified programming ability to meet the above disinfection standards, and on

commissioning to ensure compliance with disinfection standards. The special

requirements for continuous batch washing machines are set out in paragraph 8.

3.4

All washing machines should be fitted with accurate heat sensors. The sensing

elements must be correctly placed to register the true wash temperature, i.e. the

temperature of the wash water in contact with the load. Wash temperatures should be

subject to a monitoring system and heat sensing systems should be tested at six

weekly intervals and calibrated accordingly. Records should be kept of the six weekly

testing and the necessary calibration.

3.5

Categorisation of linen should be done at local level with the appropriate coloured

coded containers. However, water soluble bags or bags with a water-soluble stitched

seam or membrane are recommended for heavily fouled linen.

DISINFECTION OF INFECTED LINEN

4.1

Linen in this category should not be sorted, but should be sealed in a water-soluble

bag or bag with a water-soluble stitched seam or membrane immediately on removal

from the bed or before leaving a clinical department. This primary container should

then be placed in a nylon or polyester bag with the appropriate colour code in

accordance with Appendix A and labelled if considered necessary locally. The inner

EFM/Laundrydoms/Proc/2008

IC/276/10 Linen Policy

bag should be transferred to the designated washer extractor without opening,

followed by the outer bag which should be washed in a similar fashion. Due to the

potential for blockages and a need for staff to enter the machine in this even, under no

circumstances should infected linen be processed in a batch continuous washing

machine.

4.2

The provision of a designated storage area should not be necessary but infected linen

should be stored under secure conditions prior to treatment.

4.3

The recommendations on the washing process for used linen regarding the thermal

disinfection stage, set out in paragraph 3.2, also apply to the process for infected

linen.

4.4

The temperatures recommended in paragraph 3.2 should inactivate HIV but there is

some uncertainty as to minimal temperatures required to inactivate hepatitis B virus.

However, the heat inactivation at these temperatures, combined with the considerable

dilution factor stage, should render the linen safe to handle on completion of the wash

cycle.

4.5

Where central disinfection areas exist it is not expected that the arrangements will

automatically be dispensed with but, if necessary, they will continue because of the

financial and practical implications of making the alteration. However, where laundries

are also producing linen and laundry for other than hospital purposes i.e. commercial

contracts which may include food industry or related work, it may be a contractual

requirement that a barrier operation is provided to effectively separate unprocessed

work from clean work. In this situation, a central disinfection area or barrier room for

infected work may be desirable.

4.6

Where a known infection occurs in a small unit all used and patients personal clothing

must be disinfected in accordance with the preceding guidance and advice from the

control of infection officer.

5.

5.1

DISINFECTION OF HEAT-LABILE LINEN

The purchase of fabrics which will not withstand the temperatures set out in paragraph

3.2 should be avoided where possible.

5.2

Heat-labile materials, for example, patients clothing articles manufactured from

knitted polyester, need to be washed at low temperatures (40C - 104F) to avoid

damage. The temperature in tumble driers, if used, must be limited to 60C and

calendars should be avoided wherever possible.

5.3

Disinfection with chemicals at low temperatures is possible with hypochlorite but the

performance of hypochlorite is often restricted by the presence of soiling, detergents

and alkalis in the wash. However, in clean conditions hypochlorite is active at a

temperature below 60C (140F) in low concentrations and will not damage fabrics

outside acceptable limits.

5.4

Disinfection of heat-labile materials, only if suitable, may be achieved by the addition

of sodium hypochlorite to the penultimate rinse. This should be a medium or high dip

rinse of at least five minutes duration and sufficient sodium hypochlorite must be

added to achieve a concentration of 150 ppm available chlorine. Overriding of

washing programmes must be avoided. Hypochlorite must not be used on fabrics

treated for fire retardance. Other chemical processes may be used if approved by the

Control of Infection Committee.

EFM/Laundrydoms/Proc/2008

IC/276/10 Linen Policy

6.

6.1

DESIGN FEATURES TO REDUCE CROSS-CONTAMINATION

The provision of a barrier between the section which receives the used or infected

linen and the rest of the laundry is not considered necessary. It is recommended that

infected linen should be washed in designated water extractors as set out in

paragraph 4.1. Any vent pipe associated with such machines should be routed

outside.

6.2

Effluent from the drains of such machines must be sealed (closed piped) from the

machine to the manhole (preferable situated outside the laundry) to prevent crossinfection. If machines drain into an open sump or pit immediately below the machine

drain valve, the sump or pit should be covered to reduce the risk of bacteria being

spread by the aerosol effect when the water is pumped from the machine.

6.3

When laundering infected linen at launderettes or in on-premise laundries associated

with small units the machine requirements set out in the preceding paragraphs are

necessary.

6.4

There must be a physical barrier between clean and used or infected linen when

carried on a vehicle at the same time. No bag of linen that is not securely fastened

should be placed in a vehicle.

6.5

Trolleys for clean linen in transit should be covered with washable or disposable

cover. Fully enclosed and sealed containers with a lockable door may be used in

preference, in which case these covers are not required.

7.

7.1

PROTECTION OF LAUNDRY WORKERS

Staff in the sorting areas handling used unwashed linen should wear protective

clothing e.g. waterproof aprons and gloves. Any exposed lesion should always be

covered with a waterproof dressing. Although care needs to be given to proper

protection at all times, the use of surgical face masks is not considered necessary.

Hand washing and changing facilities must be provided in accordance with current

legislation and clean overalls should be available to staff at each new shift or work

period change.

7.2

Staff should be fully trained in all laundry operations. Guidelines setting out cleaning

and operational procedures for plant, equipment and laundry buildings should be

made available.

7.3

Detailed policy on the occupational health supervision of laundry staff should be

determined locally in the light of guidance given in such documents as HN(82)33,

HC(78)3 and on vaccination for NHS staff.

8.

8.1

BATCH CONTINUOUS WASHING MACHINES

All batch continuous washing machines must be fitted with the necessary controls and

interlocks to ensure work being processed is not recontaminated during the rinsing

stages of the wash process. To satisfy this requirement, rinse sections must be

thermally disinfected before production commences each working day.

8.2

The apparatus used to thermally disinfect rinse sections of the batch continuous

washing machine must be interlocked with the normal running control of the machine

in order to prevent the machine being set to work before the thermal disinfection of the

cool stages of the machine have been satisfactorily completed. The requirements are

as follows:-

EFM/Laundrydoms/Proc/2008

IC/276/10 Linen Policy

i.

All sections of the machines, following the high temperature sections, which do not

reach a minimum temperature of 65C (150F), shall receive a thermal disinfection

cycle. The disinfection cycle shall be considered satisfactory when the water

temperature has been raised to 65C (150F) and held at this temperature for a

period of not less than 10 minutes or at a temperature of 71C (160F) for a period

of not less than 3 minutes. During the period of thermal disinfection of the rinse

stages, it is essential that the machine cage/drum rotates to ensure that all

surfaces are in contact with high temperature liquids. The disinfection process

should be controlled by a timer.

ii. A timer shall be incorporated into the control system to override the necessity to

proceed through the thermal disinfection of the cool stages of the machine if the

machine is stopped for short periods during the day. This timer however shall be

so interconnected that if the machine is shut down for a period of 3 hours or more

the cool stage thermal disinfection cycle will proceed, and at the same time lock

out the washing controls. The lock out shall include any mechanical devices,

interlocked with the washing cycle or not, for feeding work into the machine.

iii. It is expected that the cool stage disinfection cycle will be initiated by a single

button operation and that the cycling of any steam and/or water control valves

necessary to raise the temperature of these stages to that required for thermal

disinfection shall be automatic in operation. The incorporation of hand operated

valves in this system is not acceptable.

8.3

Due to the growth of bacteria which may take place overnight, it will be necessary to

run out all linen for the batch continuous washing machine at the end of the day to

avoid reinfection. The adequacy of disinfection procedures must also be considered in

the following ancillary areas:i.

Tanks which are used to collect water for reuse within the batch continuous

washer, from the extraction device or the conveyor leading from the washer to the

extractor to the shuttle, shuttle platform and tumblers.

ii. If the installation of a heat exchanger in the recovered water system is envisaged,

special consideration to thermal disinfection needs must be given.

iii. Machinery should be kept clean and free from algae.

iv. Attention to the cleaning and regular disinfection of all conveyor belting and

surfaces used to transfer clean, processed work from the press/extraction device

to tumblers is essential to avoid recontamination of the work.

v. Under no circumstances should infected linen be processed in batch continuous

washing machines. These may suffer blockage at any stage, though the pre-wash

section is the most likely. The pre-wash sections cannot be thermally disinfected

as a routine. In the event of a blockage neither the pre-wash sections nor the wash

sections would be safe to enter without exposing staff to an unacceptable level of

risk. Until such blockages could be removed the machine could not be operated or

any thermal disinfection routine undertaken. Washer extractor systems should be

used for infected linen or foul linen where this has been categorised with infected

linen following advice at local level from the local infection control committee.

EFM/Laundrydoms/Proc/2008

IC/276/10 Linen Policy

Circulars mentioned in this document

HC(87)30

HC(91)33

HN(82)33

HC(78)3

Hospital Laundry Arrangements for Used and Infected Linen

Decontamination of Equipment, Linen or Other Surfaces Contaminated

With Hepatitis B and/Or Human Immunodeficiency Viruses

Memorandum on the Control of Viral Haemorraghic Fevers, HMSO 1986

Occupational Health Services for NHS Staff

Control Of Tuberculosis in NHS Employees: Limitation of X-Ray

Examinations

EFM/Laundrydoms/Proc/2008

IC/276/10 Linen Policy

APPENDIX A

COLOUR CODING

1.

All DMUs and Trusts are asked to work towards implementing the National Colour

Standard.

2.

The following procedures should be adopted by ward and theatre staff:a. Used (Soiled and Foul) linen (Category 2.1.1) containers should be coloured

white or off-white.

b. Infected linen (Category 2.1.2) containers should be coloured red or, at least,

include red a prominent feature on a white or off-white background. Additionally

the container should carry a bold legend on a prominent yellow label such as

INFECTED LINEN. It should be noted that some red bags used for this purpose

may not be colour-fast.

c.

Heat-labile linen (Category 2.1.3) containers should be coloured white with a

prominent orange stripe.

The use of red for infected material should be regarded as mandatory and the

use of blue or yellow for this type of laundry should be avoided

d.

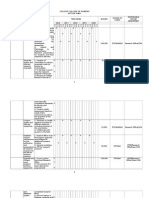

Schedule 2

Performance Standards - Key Performance Indicators

Description

Tolerance

Financial

Penalty

SSG Proposed Escalation Procedure

Factory

to

monitor

daily. No

more

than 3%

shorts of

each

specificat

ion

volume

supplied

per

invoice

period.

0.1% credit of

total invoice for

every 1%

above 3%

tolerance

If at the end of the month Sunlight

has failed to provide the service

within the tolerance stated the

General Manager will be notified.

They will work with the Trust

authorised officer to resolve the

issue by the end of the following

month. If Sunlight fail to rectify this

by the end of the second month the

Sunlight Regional / Business

Development Director will be

notified who will work with a Senior

Trust Representative to resolve the

issue. If the failure is not resolved

by the end of the 3rd month the

Commercial Director of Sunlight will

be notified. At this point the Trust

can issue a "PERFORMANCE

NOTICE" in line with the PaSA

Terms and conditions of the

contract. If the failure is still not

resolved by the end of the fourth

month the Trust may issue a

"REMEDY NOTICE" in line with the

PaSA Terms and Conditions of the

contract, giving Sunlight 30 days to

Actions to be undertaken

by Contractor

1. Each delivery meets ordered

requirements with no shortages,

provided ordered requirements

are no more than 120% of

average daily order. If a

shortage does occur, the

customer must be informed by

10.00am on the day of delivery

and remedial actions agreed to

rectify the stock shortage within

24 hours. If the shortage is not

rectified with 24 hours the first

stage of the escalation

procedure will be implemented. If

it is not rectified within the next

24 hours the second stage of the

escalation procedure will be

apply with a performance notice

being issued if a further 24 hours

passes without resolution.

EFM/Laundrydoms/Proc/2008

IC/276/10 Linen Policy

remedy the failure to the Trust's

reasonable satisfaction. If at the

end of the 30 days the failure is still

not remedied, the Trust may serve

written notice of "TERMINATION

OF CONTRACT" in line with the

PaSA Terms and Conditions of the

contract.

2. Clean linen is delivered to

designated location(s) during 2

hour delivery window which has

been agreed with the NHS client.

If the delivery will be outside of

the delivery window, the

customer must be informed prior

to the earliest time within the

agreed delivery window.

EFM/Laundrydoms/Proc/2008

Factory

to

monitor

daily. No

more

than 2

late

deliveries

per

invoice

period.

As long

as delays

are within

Sunlight

control.

0.1% credit of

total invoice for

every delivery

outside the 2

times delivery

tolerance

If at the end of the month Sunlight

has failed to provide the service

within the tolerance stated the

General Manager will be notified.

They will work with the Trust

authorised officer to resolve the

issue by the end of the following

month. If Sunlight fail to rectify this

by the end of the second month the

Sunlight Regional / Business

Development Director will be

notified who will work with a Senior

Trust Representative to resolve the

issue. If the failure is not resolved

by the end of the 3rd month the

Commercial Director of Sunlight will

be notified. At this point the Trust

can issue a "PERFORMANCE

NOTICE" in line with the PaSA

Terms and conditions of the

contract. If the failure is still not

resolved by the end of the fourth

month the Trust may issue a

"REMEDY NOTICE" in line with the

PaSA Terms and Conditions of the

contract, giving Sunlight 30 days to

remedy the failure to the Trust's

reasonable satisfaction. If at the

end of the 30 days the failure is still

not remedied, the Trust may serve

written notice of "TERMINATION

OF CONTRACT" in line with the

PaSA Terms and Conditions of the

contract.

IC/276/10 Linen Policy

3. Soiled linen is collected from

designated location(s) during the

2 hour delivery window which

has been agreed with the

participating NHS client. If any

on site logistics prevent this from

being achieved this must be

immediately communicated to

the NHS client and remedial

action taken within a 24 hour

period.

Factory

to

monitor

daily. No

more

than 2

late

collection

s per

invoice

period.

0.1% credit of

total invoice for

every collection

outside of the 2

times collection

tolerance

4. Provide evidence of the wash

processes utilised within the

factory. Including:-(i)

Water usage

(ii)

Water retention

(iii)

Detergent dosing

(iv)

Acidity/alkalinity

(v)

PH

(vi)

Temperature at

least 72oC for 3 mins or 65 oC

for 10 mins.

(vii)

Reflectance tests

average of 20 items

Tests to

be

complete

d on a 4

weekly

basis

minimum

and

results

supplied

to

customer

.

Variations from

standards to

trigger full

investigation

and start the

escalation

process

EFM/Laundrydoms/Proc/2008

If at the end of the month Sunlight

has failed to provide the service

within the tolerance stated the

General Manager will be notified.

They will work with the Trust

authorised officer to resolve the

issue by the end of the following

month. If Sunlight fail to rectify this

by the end of the second month the

Sunlight Regional / Business

Development Director will be

notified who will work with a Senior

Trust Representative to resolve the

issue. If the failure is not resolved

by the end of the 3rd month the

Commercial Director of Sunlight will

be notified. At this point the Trust

can issue a "PERFORMANCE

NOTICE" in line with the PaSA

Terms and conditions of the

contract. If the failure is still not

resolved by the end of the fourth

month the Trust may issue a

"REMEDY NOTICE" in line with the

PaSA Terms and Conditions of the

contract, giving Sunlight 30 days to

remedy the failure to the Trust's

reasonable satisfaction. If at the

end of the 30 days the failure is still

not remedied, the Trust may serve

written notice of "TERMINATION

OF CONTRACT" in line with the

PaSA Terms and Conditions of the

contract.

If any part of the laundering process

that is key to ensuring UHL is not

put at risk fails an alarm system

sounds immediately in the factory.

The machine will cease operating

automatically and reparative action

can be taken before the machine is

put back into service again. At this

point, Sunlight must notify the Trust

immediately and in writing if a

system/ operational failure will

affect delivery to the Trust or if linen

has already been delivered that has

been compromised or affected

before the detection of the

system/production failure. If at the

end of the 4 week period any issues

have arisen Christeyns (External

Company who complete Testing on

all Parts of the Laundry operations)

will rectify these immediately (where

applicable) and will issue the

General Manager with a written

report on the results and any

actions that need to be undertaken

before the next set of tests are

IC/276/10 Linen Policy

5. EMPA test pieces to be

passed through the wash system

every 6 months. Reflectance

values protein 40% (manual

washer), vegetable dye 48%,

vegetable oil 50% and mineral oil

50%.

EFM/Laundrydoms/Proc/2008

Tests to

be

carried

out every

6

months.

Variations from

standards to

trigger full

investigation

and start the

escalation

process

carried out. If the failure is not

resolved by the end of the 4 week

period the Commercial Director of

Sunlight will be notified. At this point

the Trust can issue a

"PERFORMANCE NOTICE" in line

with the PaSA Terms and

conditions of the contract. If the

failure is still not resolved by the

end of the fourth month the Trust

may issue a "REMEDY NOTICE" in

line with the PaSA Terms and

Conditions of the contract, giving

Sunlight 30 days to remedy the

failure to the Trust's reasonable

satisfaction. If at the end of the 30

days the failure is still not remedied,

the Trust may serve written notice

of "TERMINATION OF

CONTRACT" in line with the PaSA

Terms and Conditions of the

contract.

If at the end of the 6 months

Sunlight has failed to provide the

information within 4 weeks of the

due date the General Manager will

be notified. They will work with the

Trust authorised officer to resolve

the issue by the end of the following

month. If Sunlight fail to rectify this

by the end of the second month the

Sunlight Regional / Business

Development Director will be

notified who will work with a Senior

Trust Representative to resolve the

issue. If the failure is not resolved

by the end of the 3rd month the

Commercial Director of Sunlight will

be notified. At this point the Trust

can issue a "PERFORMANCE

NOTICE" in line with the PaSA

Terms and conditions of the

contract. If the failure is still not

resolved by the end of the fourth

month the Trust may issue a

"REMEDY NOTICE" in line with the

PaSA Terms and Conditions of the

contract, giving Sunlight 30 days to

remedy the failure to the Trust's

reasonable satisfaction. If at the

end of the 30 days the failure is still

not remedied, the Trust may serve

written notice of "TERMINATION

OF CONTRACT" in line with the

PaSA Terms and Conditions of the

contract.

IC/276/10 Linen Policy

6. Demonstrate a system that

ensures:(i)

stained or

contaminated items are diverted

to rewash or special wash

processes

(ii)

damaged items are

diverted to repair or rag

(iii)

any Trust owned

items that are not fit for purpose

should be bagged separately

and returned to the NHS client

Factory

produce

weekly

record

that

details

pieces

processe

d and

rewash

percenta

ge.

Defective items

supplied to

customer to be

replaced free of

charge within

48 hours

7. Linen is finished in

accordance with the agreed

specifications. The tolerance

level of 5% rejects will be applied

to the amount of linen inspected.

Monthly

check to

take

place to

ensure

specificat

ions are

being

met.

Factory

to

complete

internal

quality

check of

100

items on

a weekly

basis and

record

results.

Sunlight

Represe

ntative to

be in

attendan

0.1% credit of

total invoice for

every 1% of

rejects above

the 5%

tolerance

identified by the

customer.

EFM/Laundrydoms/Proc/2008

If at the Trusts request Sunlight fail

to provide proof of the weekly

records in relation to the tolerance

stated the General Manager will be

notified. They will work with the

Trust authorised officer to resolve

the issue by the end of the following

month. If Sunlight fail to rectify this

by the end of the second month the

Sunlight Regional / Business

Development Director will be

notified who will work with a Senior

Trust Representative to resolve the

issue. If the failure is not resolved

by the end of the 3rd month the

Commercial Director of Sunlight will

be notified. At this point the Trust

can issue a "PERFORMANCE

NOTICE" in line with the PaSA

Terms and conditions of the

contract. If the failure is still not

resolved by the end of the fourth

month the Trust may issue a

"REMEDY NOTICE" in line with the

PaSA Terms and Conditions of the

contract, giving Sunlight 30 days to

remedy the failure to the Trust's

reasonable satisfaction. If at the

end of the 30 days the failure is still

not remedied, the Trust may serve

written notice of "TERMINATION

OF CONTRACT" in line with the

PaSA Terms and Conditions of the

contract.

If at the end of the month Sunlight

has failed to provide the service

within the tolerance stated the

General Manager will be notified.

They will work with the Trust

authorised officer to resolve the

issue by the end of the following

month. If Sunlight fail to rectify this

by the end of the second month the

Sunlight Regional / Business

Development Director will be

notified who will work with a Senior

Trust Representative to resolve the

issue. If the failure is not resolved

by the end of the 3rd month the

Commercial Director of Sunlight will

be notified. At this point the Trust

can issue a "PERFORMANCE

NOTICE" in line with the PaSA

Terms and conditions of the

contract. If the failure is still not

resolved by the end of the fourth

month the Trust may issue a

"REMEDY NOTICE" in line with the

PaSA Terms and Conditions of the

contract, giving Sunlight 30 days to

IC/276/10 Linen Policy

8. Operate best practice to the

security of NHS client owned

items.

EFM/Laundrydoms/Proc/2008

ce when

audits

take

place (if

available)

remedy the failure to the Trust's

reasonable satisfaction. If at the

end of the 30 days the failure is still

not remedied, the Trust may serve

written notice of "TERMINATION

OF CONTRACT" in line with the

PaSA Terms and Conditions of the

contract.

Factory

will

polymark

all NHS

clients

goods

that are

not

labelled.

Full audit

trail

utilising

duplicate

paperwor

k.

If at the end of the month Sunlight

has failed to provide the service

within the tolerance stated the

General Manager will be notified.

They will work with the Trust

authorised officer to resolve the

issue by the end of the following

month. If Sunlight fail to rectify this

by the end of the second month the

Sunlight Regional / Business

Development Director will be

notified who will work with a Senior

Trust Representative to resolve the

issue. If the failure is not resolved

by the end of the 3rd month the

Commercial Director of Sunlight will

be notified. At this point the Trust

can issue a "PERFORMANCE

NOTICE" in line with the PaSA

Terms and conditions of the

contract. If the failure is still not

resolved by the end of the fourth

month the Trust may issue a

"REMEDY NOTICE" in line with the

PaSA Terms and Conditions of the

contract, giving Sunlight 30 days to

remedy the failure to the Trust's

reasonable satisfaction. If at the

end of the 30 days the failure is still

not remedied, the Trust may serve

written notice of "TERMINATION

OF CONTRACT" in line with the

PaSA Terms and Conditions of the

contract.

IC/276/10 Linen Policy