Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Selection PaP1 1

Caricato da

Rofocho0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

356 visualizzazioni32 pagineFormulas + Calculations for Optimum Selection of a Stepmotor 1.1. Determination of Load Torque MLoad the required drive torque of a Spindle Drive is determined by the sum of the load torques and the required acceleration torque.

Descrizione originale:

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoFormulas + Calculations for Optimum Selection of a Stepmotor 1.1. Determination of Load Torque MLoad the required drive torque of a Spindle Drive is determined by the sum of the load torques and the required acceleration torque.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

356 visualizzazioni32 pagineSelection PaP1 1

Caricato da

RofochoFormulas + Calculations for Optimum Selection of a Stepmotor 1.1. Determination of Load Torque MLoad the required drive torque of a Spindle Drive is determined by the sum of the load torques and the required acceleration torque.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 32

berger berger

motoren elecGronii

Formulas + Calculations

for Optimum Selection of a Stepmotor

yy es

peacen tare

BERGERLELE

1

1

4aa

o

(2)

12

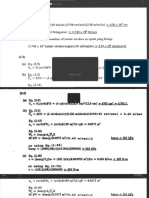

General Formulas

Vismire.

sme

Spindie Drive

Determination of Load Torque M, og

FE ra

Frapie + Fworingtoas * Ferestroce + FetovingForce

‘The required drive torque of a spindle drive is determined by the sum of the load torques and

the required acceleration torque.

Mucor = Miows + Mecsas (Nem

Moa =F (ata + ils [Nem]

Total force on nut IN]

Spindle pitch fom]

Spindle bearing mean radius [om]

Spindle bearing friction coefficient

Gear ratio = Motor! Meena

ee

tana |i i

1 = alee = Efficiency costficient of converting M into an axial force

Experience Values

1 = 0.9for bail bearing spindles (see figure}

= 0.3forsteel spindles with bronze nut

fp-Hp = 0.016 cmtor roller bearing

fq lg = 0.15 .om for steel/bronze friction bearings

Frrastroes

At10% Prestress andh= Smm: approx. 11to 15N

At 20% Prestressandh= 5mm: approx.22to 30N

At 10% Prestress andh= 10mm: approx. 40to 60N

At 20% Prestrass andh = 10 mm: approx. 80 to 120 N

@

Determination of Total Load F on Spindte Nut

a) Vertically Acting Forces:

Fay G+Fy+Fre

IN)

G = Weight of carriage and structure (kal

F, = Moving Force IN}

Fre = Prestress when using springloaded counter nut

" Friction coefficient

Gos 10m N

m = Mass [kg]

Values for u Dry Lubricated

Steel on steel 0,18 0,12

Steel oncastiron oi 040

Steal on bronze ont 0.10

Axial Guide

Rolling friction, Rollers - 0,005

4)

(4ay

(4b)

(4c)

b) ,,Non-vertical” Spindle

Fa Feet FutFe 2 ™

F, = Gina +4 cose) ifmoving up

F, = G(sing —p-cosa) ifmoving down

For upward mation

+Fy+G (sin@ +4 -cose) N)

NI

14

(5)

a)

©

m™

(Tay

8

(9)

Determination of Moments of Inertia

The total moment of inertia Jye. ig the sum of the moments of inertia of all masses in

rotatory and translatory motion.

at = Stor Stans tkgem?}

Jen = Totalexternal J referenced to motor shaft

Jit = Rotatory moment of inertia (full cylinder)

rans. = Translatory moment of inertia.

Jor 7 Soa + Sat Ikgom"}

2) Rotatory Moment of Inertia J,..~Full Cylinder

eon? Het TL Ikgom4]

r= Radiusofspindle cm

L = Length cm

¥ = Specificweight — kg/em?

Stee! 7 = 7,85: 10 kg/em?

Aluminum y = 2,7» 105kg/em?

Brass 7 = 8,4 - 10-3kg/om?

For Steel

[kgern?]

For Aluminum

Yor = 2.7 10 aL | kgoma

b) Translatory Moment of Inertia Jans

Janse (32)? tkgom}

m = Moved mass in kg

h = Spindte pitch inom

ta reduction gear is used, the external moment of inertia J,x is reduced by the square

of the gear ratio.

Yon = rar tSians? Ikgom?]

Ez

1.2

1.24

1254

09)

6)

(20)

4.242

(18)

(2)

(22)

Rack and Pinion Drive

Horizontally moved mass driven by rack and pinion.

=~+_ >, Rack

Pinion

Stepmot

Total Torques

‘The motor must provide the following total torques:

a) Acceleration of weight G, including rack

b) Acceleration of pinion

} Acceleration of rotor

d) Overcoming the friction

Moments of inertia

The following formula is used to calculate the rotatory moment of inertia equivalent to the weigt

Jeg = Gt? [kgom2]

Weight in kg

r= Radiysincm

Jy = Ferree Ley tkgem’] Soy

door log + Yap tq, kgem?]

Moy = Me M, [Nom]

Moos Guor [Nom]

10

1.3

134

1344

19)

©

134.2

(18)

(23)

(2y

Drum Drive

Lifting a Waight by Cabl

Total Torques

a} Acceleration of the weight

) Acceleration of the drum

¢} Lifting of the Weight G

Cable Drum Stepmotor

Moments of inertia

eq = Equivatent moment of inertia

‘The same formulas as used for the rack and pinion drive apply.

Jeg = Ger? ikgem?}

Youn = okey tego

Acceleration and Load Torques,

Mos (Nom)

M, = Torque required for accelerating the system.

Mo = Gr [Nom]

M, = Torque required for lifting the weight

Mor = Ma+M, [Nem]

Mg: = Total torque required tor lifting the weight

14 Additional Formulas

1.4.1 Start-Stop Operation

{10)

{102) foun ~ 199 « Ve E]

vi. = Total Moment of Inertia {kgom?]

consisting of Je, + Unter

f=

step frequency {Hz]

step angle (Degrees)

a

T,_ = Division angle of rotor teeth

(for S-phase motors: 7.2")

Ma = My Ger (Nem Drum drive

;

g

a

2

5

1.4.4 Advance, Speed and Power

Distance Increment

cr) as=zy | tom

h Spindle pitch in cm

Z_ = Number of steps per revolution

i = Gearratio

‘Advance Speed

(13) veds-tot¢ lem/s] (for spindle dives)

zi = te ene

{= Step frequency [s*]

wiZei = in

(ay ft = 22) sq for rotatory drives)

‘Advance ina defined time t

(14) sads-ft fem)

t = timeins

co) [min

1 ol

Powerfor rotation

(16) P =0,00105 M-n mM

Min Nem

in min

Pos 1g time for short distances

ea | aye S% | oy

Positioning frequency for short distances

Tay, 44, = Positioning time (s]

5) | at, - ae

{26) eh fea 43, = Positioning distance [or

41, = Max.positoning trea. [s

Suuon™ Acosleration distance [

= Senmme 48 | for

(28) || Sener 7 Sante (om) 8, = Acceleration distance ir

145

ay

Determination of the Moment of Inertia J for Arbitary Bodies by

Means of Measurement

Procedure,

‘The body is freely suspended by two strings attached to two fixes

paints. Then itis brought into rotational oscillation about the

‘skotched center ine, Tha moment of inertia is found using the

previously determined mass m of the body and the distances a,b

and hin the following formuta.

J=25-T2m loom}

J = Moment of inertia in gem?

T = Duration of period in sec.

Fixeaponts

Swings

b= Distances in om

14

1.4.6 Howto Find the Optimum Stepmotor

Aids: 1. “Formulasand Calculations for Optimum Selection of a Stepmotor” (this brochure)

2. BERGER Catalog “5-Phase Stepmotor System”

Determi

ion of motor

External moment of Inertia known?

ox fkgem?}

No

oo

Use formulas

5,6, 7, 8, 9,19, 20

Trial selection of motor from Catalog No. 250/...

"5-Phase Stepmotor System”

Max. allowable external moments of inertia,

/,. Terque [Nem] of the machine tobe driven known?

Myotr= Mood + Macon: Nom]

Use formulas

1,2,3, 4,10

M [em]

required values

Use formulas 10-16

Trial selection of motor

compatible with final

selection?

24

244

24.2

(2)

@

Calculation Examples

Calculation: Horizontal Spindle Drive

SS

LE LLLL LTT tae

ES

ez

Known and Required Values

Known Values Required Values

G=1000N Voue= 12 m/min =20 m/s.

F, =250N Positioning time for 10mm=0.58

B04 Resolution: 0.01 mm

9 =09

Spindle diameter 35 mm

Spindlelength =~ 800mm

Spindiepitchh = = Ss mm

Traveldistance 700 mm

Sought: the correct stepmotor

Required Torque

1

mer(ctoeen) } pen

Fo=WGth + Fre WN]

F 0,1: 1000N+250N=350N

95cm

2-314 08

M, = 36 Nem .

ma.=a50n( +0018 om) =96tlem

‘The calculation example doos not include gear ratio ( ) and Fora

213

©)

(6)

(8)

6)

244

1a)

245

6

Existing Moments of Inertia

Jen rot Jtrans [kgm

dot 0,5 t-18- Le 7 Ekgom?]

7,88 ka

Jrot = 05° 3,14 - (1,75 cm)" - 80cm

ag = 9,25 kgem?

10°

ne

smn (fs) em

2-314

oars = 0,83 kgem?

trans = 100 kg ( ) Ikgom?]

Yea = deot + dtrans

Jou — 9,25 kgom? + 0,63 kgom? = 9,88 kgcm? = 10 kgom?

ya = 10 kgom?

Required Operating Frequency

vie fomis}

te = _20cm/s-500Steps/Rev. fg

05 om

1 = 200008"

Values Determining the Motor Size

1M. = 36.Nem

2 Jen = 10 kgem?

3.1 = 20000Hz

24.6 Determination of Motor Size

5-Phase Stepmotor Data Overview

‘The motor data are contained

in our Catalog No. 2507...

»5-Phase Stepmotor System«

in the following arrangement.

“Size 110"

MOTOR MODEL > ROM 5117/50 ROM 5122/50

‘Step angle [Degrees] O72 O72

Maximum torque [Nem] 700 1000

Holding Torque, excited [Nem] 750 1100

Max. Power (W] ate HZ Fig ge

Moment of inertia of rotor [kgom?) 115

Motor Characteristics (Constant-Current Operation / Standard Winding)

Motor Model RDM 51117/50

Ry=030 ly=5A

ne ar’ T

Torque (Noa)

3

Constant Curent

5A/Phase

100

$iat-siop|

00 5001000)

a8

ff 1 (Stepar

1200 6000 12000

Irn“

2 oo 20

Maximum Permissible External Moments of Inertia

Motors of Series 511 ../50

,

‘ent ROM SHI7/50

T= 8AiPhase

eo

»

Fulstep0.72

©

cI

:

|

|

»

®

rn in

i

om ®

‘Motor size determined form curves: RDM 51117/50

Motor data see Catalog 250 "5-Phase Stepmotor Syster

7,5 kgom?

Myr (2t 20 kHz) —M,_INem]

150 Nem=36 Nem=114 Nem

zee

i

nud

247

(6a)

mn)

21.8

en

21.9

Determination of Acceleration Time.

Forlinear acceleration and deceleration, the acceleration and deceleration times are equal,

Jnct* Yana + Sot = 17.5 kgom?

Qr-asf

i. To 560° MM, Tor |S

4 -0,72° - 20000 Hz

‘360° - 4 Nem « 107

= 17.5 kgom?

t, 7 0986s ~ 0295

ty = Time for acceleration

tg ~ Time for constant speed

fp = Time for deceleration

ty > Total travel time

1 pal

20000 Fv = =~

Steps for acceleration

‘Steps for constant speed

Steps for deceleration

fear tel rat f

ree Ete

Sn

‘ (wed '

Distance Traveled in Total Travel Time

ft,

> Distance in steps)

8,= 20000 0,39 § _ 3900 Steps

a2

During acceleration phase = 9800 Steps =

During deceleration phase = 9900 Steps = sp

‘Sum for acceleration and deceleration = 7800 Steps

Total distance traveled s,..= 700 mm 70 000 Steps

Total Travel Time

fe = tet theth fs)

= Sia 7 (Sa + 8g)

t ' {s]

1. — 70000 = (3900 + 3800

. 20000

= atts -

htt +t, Is)

ty, = 0,99 + 3.11 + 0.99

tye = 3,808

24.10. Verification of Required Values

2.10.4 Positioning Time tps]

St, required0.5 8

Sot" 49 te

Sa toe

(24) At, {s)

4s, = 10mm = 10m

28) Sato = 5, [Steps] 48 = 54-4

Sate = 9800 Steps gpe'SOT-~ = 990m

bt, = O898-1oM _ org

pS "39 om

2110.2 Smallest Distance Increment per Step

48 required0.01 mm

12) As = > tem

4s = 08

BOGET = 0.001 cm = 0.01 mm

{|

\

2.2

224

2.2.2

(2)

(de)

Calculation: Vertical Spindle Drive (Lifting Force)

Known and Required Values.

32 Known Values

A G = 150kg

EXZZZZ722TRA DPIC 7 209

Ea .

EA w= O4

EA Spindle diameter 63mm

EA length 10m

A pitch 10mm

Ea

A

Gearratio i=20:1

Required Values.

Positioning time 10mmin 1 ¢

Resolution < 0.01 mm

Stepmotor

Required Torque

= 1

MOTE (atatnt) + Nem

F = G+(sing+u-cos@) IN]

90°

1

cose = 0

ata

sin «

22

22.3

@)

(6)

®

Fo = 1500N (1 + 01-0)

Fo = 1500N

tom 4

My s800N (72% + 9) 1 (Nom)

M. = 1500N (0,177 + 0,015) 3 = 14,4 Nom

Existing Moments of Inertia

sn + (4a *San)

Sot = O,5

Potrebbero piacerti anche

- Machine Design Elements and AssembliesDa EverandMachine Design Elements and AssembliesValutazione: 3.5 su 5 stelle3.5/5 (2)

- Oriental Motor Motor Sizing CalculationsDocumento10 pagineOriental Motor Motor Sizing CalculationsKha VeenNessuna valutazione finora

- Chapter 2 - Solution (Pulkrabek) PDFDocumento27 pagineChapter 2 - Solution (Pulkrabek) PDFAllen EspeletaNessuna valutazione finora

- Dynamometer: Theory and Application to Engine TestingDa EverandDynamometer: Theory and Application to Engine TestingNessuna valutazione finora

- Ball Screw Selection ExerciseDocumento7 pagineBall Screw Selection ExercisemaddyaugNessuna valutazione finora

- MINAS BLinfomationDocumento7 pagineMINAS BLinfomationmashudi_fikriNessuna valutazione finora

- Motor Selection, Inertia PDFDocumento6 pagineMotor Selection, Inertia PDFIswar Rauf Aboo 'AqilahNessuna valutazione finora

- Calculation of Torque For Selection of MotorDocumento6 pagineCalculation of Torque For Selection of Motoratanughosh125100% (6)

- Usa Tech Calculation PDFDocumento35 pagineUsa Tech Calculation PDFRizwan HameedNessuna valutazione finora

- Fan Starting TorqueDocumento4 pagineFan Starting Torquehardik033Nessuna valutazione finora

- Computer Aided Design of Feed Drives For CNC Machine ToolsDocumento6 pagineComputer Aided Design of Feed Drives For CNC Machine ToolsDĕĕpáķ ŚĥáŕmáNessuna valutazione finora

- Motor Torque Calculation: Lead Screw Drive LoadsDocumento5 pagineMotor Torque Calculation: Lead Screw Drive LoadsTruta IonutNessuna valutazione finora

- DOM ProblemsSolvedinClassDocumento129 pagineDOM ProblemsSolvedinClassrukmini_ramkiNessuna valutazione finora

- Process of Selection and Example of SelectionDocumento8 pagineProcess of Selection and Example of Selectionarvi_vinNessuna valutazione finora

- Servo Motor SelectionDocumento11 pagineServo Motor Selectionanandparasu100% (1)

- Main Spindle Motor Selection: 9/30/2018 Aruna Kumar.p 1Documento19 pagineMain Spindle Motor Selection: 9/30/2018 Aruna Kumar.p 1srinivas murthyNessuna valutazione finora

- Required Torque Calculations For CIT Power TruckDocumento5 pagineRequired Torque Calculations For CIT Power TruckMarco BalestriniNessuna valutazione finora

- A Design of The DC Motor Control CircuitDocumento9 pagineA Design of The DC Motor Control Circuitnyskyscraper051127Nessuna valutazione finora

- Engineering Reference: Sizing and Selection of Exlar Linear and Rotary ActuatorsDocumento8 pagineEngineering Reference: Sizing and Selection of Exlar Linear and Rotary ActuatorsJelena BauerNessuna valutazione finora

- CalculationDocumento10 pagineCalculationNur SurizzaNessuna valutazione finora

- Selecting A Belt Slide: Technical InformationDocumento3 pagineSelecting A Belt Slide: Technical InformationawemetalNessuna valutazione finora

- Do AnDocumento44 pagineDo AnNhat Vinh DoanNessuna valutazione finora

- Technical Reference OverviewDocumento17 pagineTechnical Reference OverviewHery Vázquez JiménezNessuna valutazione finora

- Department of Mechanical Engineering: Test No: 2Documento11 pagineDepartment of Mechanical Engineering: Test No: 2Ajith KumarNessuna valutazione finora

- 202-Fms Timing Belts Calc Methods enDocumento28 pagine202-Fms Timing Belts Calc Methods enYesenia AquilinaNessuna valutazione finora

- Estrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignDocumento12 pagineEstrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignHannahNessuna valutazione finora

- Rotordynamics TutorialDocumento59 pagineRotordynamics TutorialAmbrish SinghNessuna valutazione finora

- Fms200806 Timing Belts Calc Methods 202 enDocumento28 pagineFms200806 Timing Belts Calc Methods 202 enbrviraniNessuna valutazione finora

- Driving Torque: 8.1 Torque of Ball ScrewDocumento1 paginaDriving Torque: 8.1 Torque of Ball ScrewTurbosMixerNessuna valutazione finora

- Chapter11 Prob01Documento13 pagineChapter11 Prob01imranakhtarNessuna valutazione finora

- Bonfiglioli Reductoare C A F SDocumento582 pagineBonfiglioli Reductoare C A F SAgache ValentinNessuna valutazione finora

- Model Questions of Electric DrivesDocumento7 pagineModel Questions of Electric Drivesbiswajit_k25724100% (1)

- Torque Sensors: Common Sensing MethodsDocumento32 pagineTorque Sensors: Common Sensing MethodsvishiwizardNessuna valutazione finora

- Caculate Rotary LinearDocumento3 pagineCaculate Rotary LinearTrinh Luong MienNessuna valutazione finora

- FORMATO MATPR EES 8-PagDocumento8 pagineFORMATO MATPR EES 8-Pagarlette caizaNessuna valutazione finora

- Dinamica AutoDocumento73 pagineDinamica AutoMsale MsaleNessuna valutazione finora

- Note de Calcul Mécanique Convoyeur OCPDocumento11 pagineNote de Calcul Mécanique Convoyeur OCPAkram FerchichiNessuna valutazione finora

- 200-Foot Simple Span Bridge Girder Design Using NU2000 V1Documento50 pagine200-Foot Simple Span Bridge Girder Design Using NU2000 V1Anthony GravagneNessuna valutazione finora

- RtgergregDocumento13 pagineRtgergregabod saadehNessuna valutazione finora

- Motor SizingDocumento7 pagineMotor Sizingsaxadi4814Nessuna valutazione finora

- Topic 5 BearingDocumento4 pagineTopic 5 Bearingvuductoan07072003Nessuna valutazione finora

- Dom SolvedDocumento49 pagineDom SolvedRAJESH. RNessuna valutazione finora

- SolutionsofGears PDFDocumento4 pagineSolutionsofGears PDFGautam AdhikariNessuna valutazione finora

- FlywheelsDocumento33 pagineFlywheelsKaranSinghNessuna valutazione finora

- Do-An 2Documento46 pagineDo-An 2Nhat Vinh DoanNessuna valutazione finora

- Do AnDocumento46 pagineDo AnNhat Vinh DoanNessuna valutazione finora

- An Serv 002 PDFDocumento20 pagineAn Serv 002 PDFMario TapiaNessuna valutazione finora

- Speed Control OF WIND TURBINEDocumento4 pagineSpeed Control OF WIND TURBINESHADDOWWNessuna valutazione finora

- 2-Critical Speed of ShaftDocumento5 pagine2-Critical Speed of ShaftRidani Faulika Amma100% (3)

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkDa EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNessuna valutazione finora

- Modeling of Complex Systems: Application to Aeronautical DynamicsDa EverandModeling of Complex Systems: Application to Aeronautical DynamicsNessuna valutazione finora

- Design and Analysis of Centrifugal CompressorsDa EverandDesign and Analysis of Centrifugal CompressorsNessuna valutazione finora

- Shape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationDa EverandShape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationNessuna valutazione finora

- Variable Speed AC Drives with Inverter Output FiltersDa EverandVariable Speed AC Drives with Inverter Output FiltersNessuna valutazione finora

- Control of DC Motor Using Different Control StrategiesDa EverandControl of DC Motor Using Different Control StrategiesNessuna valutazione finora