Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Airflex® Air Cooled Disc Clutches and Brakes: Section E

Caricato da

rony adonay sandovalTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Airflex® Air Cooled Disc Clutches and Brakes: Section E

Caricato da

rony adonay sandovalCopyright:

Formati disponibili

Airflex Air Cooled Disc Clutches and Brakes

Section E

DBA Description ....................................................................................................................................................................... 181

DBA Brake Elements .................................................................................................................................................................. 183

DBA Technical information ......................................................................................................................................................... 184

DBB and DBBS Description ..................................................................................................................................................... 185

DBB Brake Elements .................................................................................................................................................................. 187

DBB Technical Information ......................................................................................................................................................... 188

DBBS Brake Elements ................................................................................................................................................................ 189

DBBS Technical Information ....................................................................................................................................................... 191

Type DC Description ................................................................................................................................................................. 192

DC Technical and Dimensional Data ........................................................................................................................................... 194

Type FHB Description................................................................................................................................................................ 196

Floating Housing Brake Technical and Dimensional Data............................................................................................................ 197

Selection Procedure ................................................................................................................................................................. 200

180

EATON Airflex Clutches & Brakes 10M1297GP November 2012

Airflex DBA Description

Section E

Model DBA brakes are spring applied, pressure released, disc

style brakes. They develop equal torque in either direction of

rotation. Their torque and thermal capacities allow them to be

used in the most demanding applications.

Brake construction and operation is shown in the figure.

Pressurizing the brake compresses the brake springs and

withdraws the clamping plates from the brake discs. Standard

brakes are furnished with either one or two discs, which are

free to move axially.

Model DBA uses a rubber diaphragm to form the releasing

pressure chamber and to serve as the releasing piston. Brake

friction material is attached to stationary components. Brake

discs are either solid or ventilated. The disc type is indicated

by an S for solid, or V, for ventilated, in the brake model designation. Solid discs are used in applications requiring a heat

sink and/or where engagement is infrequent. Ventilated discs

are recommended for cyclic applications.

Torque ratings listed are for brakes with a standard compliment of springs. The quantity of springs can be varied to

customize the torque of the brake to suit a particular application. Consult the factory for brake torque of units with nonstandard spring configurations.

Brake sizes are indicated by the number of brake discs and

the disc diameter in inches. For instance, size 229DBA has

two discs 29 inches in diameter.

Features

Large friction area.

Allows brakes to absorb and dissipate high energy loads associated with high cyclic and high inertia stops.

Where used:

Can making machines

Draglines

Power shovels

Conveyors

Power presses

Minimal adjustment required for lining wear.

Single disc units require no wear adjustment and dual disc

units require only one wear adjustment during the long life of

the friction material.

EATON Airflex Clutches & Brakes 10M1297GP November 2012

181

Airflex DBA Component parts

Section E

23

29

15, 21

19, 20

26, 27, 28

6

18

33

30, 31

16, 17

13

22

14, 15

12

11

32

34

25

10

24

35

Dual disc element shown

37

36

182

EATON Airflex Clutches & Brakes 10M1297GP November 2012

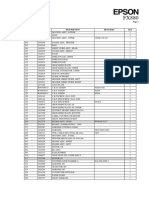

Item Number

Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

Mounting Flange

Stud

Clamp Tube

Disc

Friction Disc

Flat Head Screw

Pressure Plate

Spring Housing

Locknut

Outer Clamp Ring

Diaphragm

End Plate

Inner Clamp Ring

Hex Head Screw

Lockwasher

Hex Head Screw

Lockwasher

Spring Retainer Plate

Inner Spring

Outer Spring

Hex Head Screw

Gear

Reaction Plate

Release Spring

Wear Spacer

Name Plate

Self Tapping Screw

Warning Decal

Washer

Air Tube

Air Tube

90 Deg. Street Elbow

90 Deg. Male Elbow

Cross

Hose Assembly

Flow Control Valve

Bushing

Airflex DBA Brake Elements

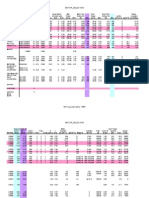

Form DBA808 Dimensional and Technical Data

Section E

D1

O2

G

D29

H13

D7

H13

H16

D29

D7

H16

H11

H11

D25

D25

Special Mounting Flanges

are available which permit

direct mounting to 800

Series frame motors.

6 Equally spaced

mounting holes on a

H bolt circle.

See Note

Single Disc Brake

Dual Disc Brake

English

Dimensions in inches

17DBA

21DBA

29DBA

2.00

2.00 2

2.75

21.000

3.000

31.000

17.25

21.00

28.00

10.00

12.12

14.75

5.38

7.62

10.25

24.998

26.498

33.998

0.78

1.06

1.06

1/2-14

1-11 1/2

1-11 1/2

Basic Size

D25

H11

H13

H16

02

17DBA

21DBA

29DBA

51

51

70

533

584

787

438

533

711

254

308

375

137

194

260

634,9

673,0

863,5

20

27

27

1/2-14

1-11 1/2

1-11 1/2

SI

Dimensions in millimeters

English

Dimensions in inches

117DBA

217DBA

121DBA

221DBA

129DBA

229DBA

329DBA

2.50

3.25

2.88

3.88

3.94

4.88

5.63

Size

Bore Range

Ventilated Disc Types

Solid Disc Types

117DBA

217DBA

121DBA

221DBA

129DBA

229DBA

329DBA

Min.

64

79

73

98

105

124

143

D

D1

319

284

401

366

335

287

418

371

394

349

486

441

582

D

272

341

288

361

383

459

SI

Dimensions in millimeters

4.25

4.25

5.75

5.88

7.38

7.19

6.88

Max.

108

108

146

149

187

182

175

12.55

11.19

15.77

14.41

13.19

11.33

16.47

14.61

15.51

13.75

19.13

17.38

22.93

4.88

6.50

2.50

5.63

3.50

7.12

10.63

D7

124

165

64

143

89

181

270

1.00

1.88

2.12

2.12

2.25

2.25

2.34

D29

25

48

54

54

57

59

59

10.69

13.41

11.33

14.23

15.06

18.06

Notes:

Tolerance +0.000/-0.003 in (+0,00/-0,08 mm)

All ventilated disc brakes are furnished with an approximate 15.5 inch

(394 mm) length of flexible hose and a flow control valve having a 1-11

1/2 American National Pipe Thread port.

American National Pipe Thread

4.88

6.50

5.62

5.62

5.88

7.00

1.88

1.88

2.00

2.25

2.38

3.12

D7

124

165

143

143

149

178

D29

48

48

51

57

60

79

EATON Airflex Clutches & Brakes 10M1297GP November 2012

183

Airflex DBA Elements

Dimensional and Technical Data

Section E

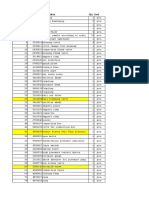

English

lbin

psi

in3

in2

lbft2

lb

rpm

117DBAS

217DBAS

121DBAS

221DBAS

129DBAS

229DBAS

146148

146152

146145

146151

146162

146163

413113

413248

413534

413535

413801

414126

29300

52600

69800

129300

176700

336200

85

85

85

85

100

100

100

100

160

160

310

310

270

540

406

812

890

1780

18

35

42

80

152

292

95

160

130

270

325

520

2300

2300

1900

1900

1500

1500

Size

Part

Number

Gear Mr

Part

Torque

Number

Rating

Disc Disc

&

&

Gear

Gear

Housing

Maximum

Speed

117DBAS

146148

413113

3310

5,9

1,64

1742

217DBAS

146152

413248

5940

5,9

1,64

3483

121DBAS

146145

413534

7890

5,9

2,62

2619

221DBAS

146151

413536

14600

5,9

2,62

5237

129DBAS

146162

413801

20000

6,9

5,08

5741

229DBAS

146163

414126

38000

6,9

5,08

11481

Wk2 Weight

J

Mass

0,76

43

1,47

72

1,76

59

3,36

122

6,38

147

12,26

236

2300

2300

1900

1900

1500

1500

SI

kgm2

Nm

Minimum

Releasing Releasing Friction

Pressure

Volume

Area

410

455

610

565

950

1150

bar

dm3

cm2

186

206

276

256

430

521

kg

rpm

English lbin

in3

in2

lbft2

lb

rpm

117DBAV

217DBAV

121DBAV

221DBAV

129DBAV

229DBAV

329DBAV

146148

146152

146145

146151

146162

146163

146210

100

100

160

160

310

310

310

270

540

406

812

890

1780

2670

10

20

30

60

97

191

285

70

112

105

210

185

340

495

1300

1300

1000

1000

900

900

900

Size

Gear Mr

Part Part Torque Releasing

Friction

Number

Number

Rating

Volume

Area

413113

413248

413534

413535

413683

413585

415080

20500

38000

52500

96000

113000

216000

339000

320

363

480

565

970

1150

1549

Disc Disc

&

&

Gear

Gear

Housing

Maximum

Speed

Wk2 Weight

J

Mass

117DBAV

146148

413113

2320

1,64

1742

0,42

32

145

217DBAV

146152

413248

4290

1,64

3483

0,84

51

164

121DBAV

146145

413534

5930

2,62

2619

1,26

48

217

221DBAV

146151

413535

10800

2,62

5237

2,52

95

256

1300

1300

1000

1000

129DBAV

229DBAV

329DBAV

900

900

900

146162

146163

146210

413683

413585

415080

12800

24400

38400

SI Nm

5,08

5,08

5,08

5741

11481

17223

4,07

8,02

11,97

84

154

224

dm3

cm2

kgm2

kg

Notes:

Basic part number only. Does not include gear. Gear must be ordered

separately with the bore and keyway requirements.

Dynamic torque shown. Static torque approximately 1.15 greater. Torque

values are for new linings. Torque decreases with lining wear. At the

worn out condition, torque is approximately 0.66 of values shown.

184

EATON Airflex Clutches & Brakes 10M1297GP November 2012

439

521

708

rpm

Torque ratings are for units with a standard complement of springs.

Consult factory for torque ratings of units with non-standard spring

configurations.

Maximum allowable cylinder pressure is 120 psi (8,3 bar).

Absolute volume of releasing cavity.

Minimum releasing pressure 60 psi (4,1 bar).

Airflex DBB Description

Section E

Model DBB brakes are spring applied, pressure released, disc

style brakes. They develop equal torque in either direction of

rotation. Their torque and thermal capacities allow them to be

used in the most demanding applications.

Brake construction and operation is shown in the figure.

Pressurizing the brake compresses the brake springs and

withdraws the clamping plates from the brake discs. Standard

brakes are furnished with either one or two discs, which are

free to move axially.

Model DBB uses a conventional piston design to release the

brake discs. The rotating component of the DBB style brake

is a very low inertia friction disc core with riveted on friction

discs. The low inertia of the rotating components coupled

with the high heat sink capacity of the stationary members allow these units to provide superior performance in high cyclic

applications. In applications requiring higher speed operation or where precise balance of the rotating components is

required, the DBBS style is offered, which utilizes a solid rotor

and stationary friction material. Similar to the DBAS design,

the DBBS should only be used for applications where brake

engagement is non-cyclic.

Torque ratings listed are for brakes with a standard compliment of springs. The quantity of springs can be varied to

customize the torque of the brake to suit a particular application. Consult the factory for brake torque of units with nonstandard spring configurations.

Brake sizes are indicated by the number of brake discs and

the disc diameter in inches. For instance, size 225DBB has

two discs 25 inches in diameter.

Where used:

Bottling equipment

Power Shovels

Conveyors

Shears

Power Presses

Features

Low inertia friction disc assembly.

Reduces the overall inertia that must be stopped.

Optional split friction discs.

Allows removal of friction discs without disturbing other components of drive system in mid-shaft brake arrangement.

Long wearing, self lubricating PolyPak* seals.

Eliminates premature twisting failure and requires no external

lubrication.

EATON Airflex Clutches & Brakes 10M1297GP November 2012

185

Airflex DBB Description

Section E

4

22

18

14

15

6, 7

10

13

23, 24

17

27

19

29

16

30

25

35

28, 32, 33

26

20

11

12

34

21

Dual disc element shown

31

Item Number

Description

Item Number

Description

Item Number

Description

1

2

3

4

5

6

7

8

9

10

11

12

Mounting Flange

Stud

Friction Disc Sub-Assembly

Friction Disc

Friction Disc Core

Rivet

Washer

Clamp Tube

Pressure Plate

Spring Housing

Flat Washer

Locknut

13

14

15

16

17

18

19

20

21

22

23

24

Cylinder

Hex Head Screw

Outer Seal

Spring

Inner Seal

Spacer Tube

Gear

Wear Spacer

Reaction Plate

Release Spring

Flat Washer

Hex Head Screw

25

26

27

28

29

30

31

32

33

34

35

Ring Gear

Pipe Nipple

Elbow

Pipe Cross

Hose Assembly

Pipe Nipple

Flow Control Valve

45 Deg. Street Elbow

Pipe Reducer

Hose Assembly

Spring Retainer

186

EATON Airflex Clutches & Brakes 10M1297GP November 2012

Airflex DBB Brake Elements

Dimensional and Technical Data Section E

English

Dimensions in inches

109DBB

209DBB

309DBB

115DBB

215DBB

120DBB

220DBB

320DBB

420DBB

125DBB

225DBB

325DBB

425DBB

138DBB

238DBB

338DBB

438DBB

1.68

1.94

2.13

2.13

3.06

3.00

3.75

4.25

4.50

3.88

3.88

5.38

5.88

6.00

7.38

8.38

9.06

2.50

2.56

2.63

2.50

4.25

5.88

6.00

5.88

5.88

7.50

7.56

7.50

7.50

11.00

11.00

10.88

10.88

Size

Bore Range

Min.

SI

Dimensions in millimeters

7.26

8.70

9.06

4.38

11.16

10.87

13.04

15.21

17.38

12.07

14.38

16.69

19.00

16.25

19.05

21.85

24.65

1.75

4.00

5.25

2.88

4.38

3.00

6.27

8.25

10.31

3.50

7.00

9.31

12.00

5.00

9.00

12.00

5.00

6.06

7.53

9.06

7.52

9.23

9.37

11.54

13.68

15.84

10.57

12.88

15.19

17.50

14.25

17.05

19.73

22.52

109DBB

209DBB

309DBB

115DBB

215DBB

120DBB

220DBB

320DBB

420DBB

125DBB

225DBB

325DBB

425DBB

138DBB

238DBB

338DBB

438DBB

43

49

54

54

78

76

95

108

114

99

99

137

149

152

187

213

230

D1

W4

Size

Bore Range

Min.

Max.

64

65

67

64

108

149

152

149

149

191

192

191

191

279

279

276

276

184

221

202

242

283

276

331

386

441

307

365

424

483

413

484

555

626

44

102

133

73

111

76

159

210

262

89

178

236

305

127

229

305

381

154

191

230

191

235

238

292

347

402

268

327

386

445

362

433

501

572

D1

W4

Max.

English

Dimensions in inches

9DBB

1.00

0.25

3.12

12.125

8.375

12.37

3/8-18

15DBB

1.47

0.38

0.38

6.00

18.375

14.375

18.94

1/2-14

20DBB

1.50

0.38

1.00

8.50

23.250

18.250

23.82

1/2-14

25DBB

1.75

0.25

0.75

11.50

30.630

24.375

30.89

1/2-14

38DBB

2.45

0.25

1.25

16.50

44.750

36.375

45.01

3/4-14

Size

D31

D44

D45

H16

J1 J2 O2

9DBB

15DBB

20DBB

25DBB

38DBB

25

37

38

44

62

6

10

10

6

6

10

25

19

32

79

152

216

292

419

308.0

466.7

590.6

778.0

1136.7

212.7

365.1

463.5

619.1

923.9

SI

Dimensions in millimeters

30

Mounting

60

314

481

605

785

1143

Bolt Circles

9DBB

(6) 0.531 (13,5) Mounting

holes equally spaced as

shown on 11.125 (282,5) Bolt

15DBB

(6) 0.656 (16,7) Mounting

holes based on 8 equally

spaced holes on

20DBB

(12) 0.656 (16,7) Mounting

holes equally spaced as

shown on 22.000 (558,8) Bolt

Notes:

0.50 in (13mm) for 109 DB

0.25 in (6mm) for 209 DBB

0.00 in (0mm) for 309 DBB

Tolerance +0.000/-0.003 in (+0,00/-0,08 mm)

25DBB

(12) 0.656 (16,7) Mounting

holes equally spaced as shown

on 28.750 (730,3) Bolt Circle

3/8-18

1/2-14

1/2-14

1/2-14

3/4-14

* Sizes 325 & 425 have 0.781"

(19.8 mm) Mounting Hole

38DBB

(16) 1.062 (27,0) Mounting

holes equally spaced as

shown on 42.000 (1066,8)

Basic part number only. Does not include gear. Gear must be ordered

separately with the bore and keyway requirements.

Dynamic torque shown. Static torque approximately 15% greater.

Torque values are for new linings. Torque decreases with lining wear. At

the worn out condition, torque is approximately 0.66 of values shown.

American National Pipe Thread.

Torque ratings are for units with a standard complement of springs.

Consult factory for torque ratings of units with non-standard spring

configurations.

Brake in disengaged position.

Maximum allowable cylinder pressure is 120 psi (8,3 bar).

All DBB brakes can be supplied plumbed as shown with a flow control

valve having American National Pipe thread ports of 1/2-14 for size

9DBB, 3/4-14 for sizes 15DBB, 20 DBB, 25DBB and 1-11 1/2 for size

38DBB

Tolerance +/- 0.12

Absolute volume of releasing cavity.

Tolerance +0.003/-0.000 in (+0,08/-0,00 mm)

Maximum diameter of as castsurfaces.

Some high torque applications of three and four disc elements require

additional support on the cylinder side of the unit. Contact your local

Airflex representative for more details.

EATON Airflex Clutches & Brakes 10M1297GP November 2012

187

Airflex DBB Brake Elements

Dimensional and Technical Data

Section E

D

W4

O2

D44

D45

J2 J J1

D1

D31

Single Disc Brake

H16

Dual Disc Brake

See Note on

pg. E-7

See Note

English

lb in

psi

in3

in2

lbft2

lb

rpm

109DBB

209DBB

309DBB

115DBB

215DBB

120DBB

220DBB

320DBB

420DBB

125DBB

225DBB

325DBB

425DBB

138DBB

238DBB

338DBB

438DBB

146333

146334

146380

146222

146337

146299

146300

146378

146379

146315

146327

146370

146381

146295

146296

146386

146387

415313

415314

416481

415454

415302

415900

416059

416304

416471

416073

416074

416223

416477

416068

416069

416241

416464

7500

14000

19400

30000

57000

53500

101500

149500

180000

115300

219000

303000

392000

420000

800000

1153000

1470000

60

60

60

60

60

60

60

60

60

60

60

60

60

60

60

60

60

30

30

30

75

75

133

133

133

133

259

259

259

259

612

612

612

612

96

192

238

238

476

334

668

1002

1336

600

1201

1802

2403

1322

2644

3966

5288

0.5

1

1.83

5

10

17

33

49

65

47

93

139

185

287

562

837

1112

9

18

27

35

64

40

67

213

102

78

148

403

280

203

340

1087

1424

3000

3000

3000

2400

2400

1850

1850

1850

1850

1400

1400

1400

1400

950

950

950

950

Size

Part

Number

Gear Mr

Part

Torque

Number

rating

Minimum

releasing

pressure

Disc

Releasing Friction &

Volume

Area

Gear

Housing

Wk2

Weight

J

Mass

109DBB

146333

415313

847

4,1

0,49

619

0,02

4

209DBB

146334

415314

1581

4,1

0,49

1238

0,04

8

309DBB

146380

416481

2192

4,1

0,49

1857

0,07

12

115DBB

146222

415454

3387

4,1

1,23

1535

0,21

16

215DBB

146337

415302

6435

4,1

1,23

3070

0,42

29

120DBB

146299

415900

6040

4,1

2,18

2154

0,71

18

220DBB

146300

416059

11459

4,1

2,18

4309

1,39

30

320DBB

146378

416304

16879

4,1

2,18

6463

2,06

97

420DBB

146379

416471

20338

4,1

2,18

8617

2,73

46

125DBB

146315

416073

13017

4,1

4,25

3870

1,97

35

225DBB

146327

416074

24725

4,1

4,25

7746

3,91

67

325DBB

146370

416223

34237

4,1

4,25

11623

5,84

183

425DBB

146381

416477

44067

4,1

4,25

15499

7,77

127

138DBB

146295

416068

47418

4,1

10,03

8527

12,05

92

238DBB

146296

416069

90320

4,1

10,03

17054

23,60

154

338DBB

146386

416241

130282

4,1

10,03

25581

35,15

493

438DBB

146387

416464

166101

4,1

10,03

34108

46,70

646

SI

188

nm

bar

EATON Airflex Clutches & Brakes 10M1297GP November 2012

dm3

cm

kgm

115

145

135

225

275

385

487

590

695

705

935

1120

1250

1955

2325

3280

3850

52

66

36

102

125

175

221

277

315

320

424

508

567

887

1055

1488

848

kg

Maximum

speed

3000

3000

3000

2400

2400

1850

1850

1850

1850

1400

1400

1400

1400

950

950

950

950

rpm

Airflex DBBS Component Parts

Section E

18

17

10

14

Dual disc element shown

13

11

15

12

20

19

2

16

21

Item Number

Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Mounting Flange

Stud

Friction Disc

Clamp Tube

Pressure Plate

Spring Housing

Flat Washer

Lock Nut

Cylinder

Hex Head Screw

Inner Seal

Spring

Outer Seal

Spacer Tube

Gear

Wear Spacer

Reaction Plate

Release Spring

Spring Retainer

Flat Head Screw

Disc

EATON Airflex Clutches & Brakes 10M1297GP November 2012

189

Airflex DBBS Brake Elements

Dimensional and Technical Data

Section E

English

Dimensions in inches

120DBBS

220DBBS

320DBBS

420DBBS

125DBBS

225DBBS

325DBBS

425DBBS

138DBBS

238DBBS

338DBBS

438DBBS

150DBBS

250DBBS

350DBBS

450DBBS

3.50

5.63

10.30

4.25

5.69

13.48

4.88

5.75

16.63

5.13

5.81

19.81

4.50

7.00

11.49

5.50

7.13

14.73

6.13

7.38

17.96

6.63

7.31

21.19

8.50

10.06

15.20

8.50

10.06

18.97

9.63

10.06

22.60

10.38

10.38

26.34

10.24 15.51 20.43

12.36 15.51 24.84

13.90 15.51 29.29

14.88 15.51 35.24

3.00

6.27

10.31

12.50

3.50

7.00

12.00

15.00

5.00

9.00

13.00

18.00

5.75

10.00

14.49

20.00

Size

Bore Range

D1

262

342

422

503

292

374

456

538

386

482

574

669

519

631

744

895

76

159

262

318

89

178

381

381

127

229

330

457

146

254

368

508

Min.

120DBBS

89

220DBBS

103

320DBBS

124

420DBBS

130

125DBBS

114

225DBBS

140

325DBBS

156

425DBBS

168

138DBBS

216

238DBBS

216

338DBBS

245

438DBBS

264

150DBBS 260

250DBBS 314

350DBBS 353

450DBBS 378

SI

Max.

143

145

146

148

177

181

187

186

256

256

256

264

394

394

394

394

J1

J2 J

Single Disc element

J2 J

D44

D31

Single Disc element

D45

J2

H16

D44

D1

O2

D45

Dimensions in millimeters

J2

English

Dimensions in inches

20DBBS

25DBBS

38DBBS

50DBBS

1.50 0.38 1.00

1.75 0.25 1.00

2.45 0.25 1.00

3.50 0.25 2.00

8.50 23.25z 18.250

11.50 30.63z 24.375

16.50 44.498 36.375

23.00 46.25z 57.64

Size

D31

D44

D45

H16

J J1 J2 O2

20DBBS 38

25DBBS 44

38DBBS 62

10

6

6

25

25

25

216

292

419

590.6 463.5

778.0 5619.1

1135.7 923.9

SI

J1

D31

23.82

30.89

45.00

1-11

1/2-14

1/2-14

3/4-14

1/2

605

1/2-14

6

785

1/2-14

1143 3/4-14

Dimensions in millimeters

H16

D1

O2

Dual Disc element

Mounting Bolt Circles

Dual Disc element

5

5

Mounting Bolt Circles4

Notes:

Brake in disengaged position.

Tolerance +0.000/-0.005 in (+0,00/-0,08 mm)

Tolerance +0.003/-0.000 in (+0,08/-0,00 mm)

Maximum diameter of as castsurfaces.

American National Pipe Thread.

z Tolerance +.120/-.120 in (+3.00/-3.00 mm)

* Sizes 325 and 425 have 0.781 (19.8) mounting holes

190

20DBBS

(12) 0.656 (16.7)

Mounting holes equally

spaced as shown on

22.000 (558.0) Bolt

EATON Airflex Clutches & Brakes 10M1297GP November 2012

25DBBS

25DBBS 20DBBS

38 DBBS

*

(12) 0.656

0.656

(16.7)

(16)(12)

1.062

(27.0)

(12) 0.656 (16.7)

(16.7)

Mounting holes equally

Mounting holes equally

Mounting holes

equally

holes

equally

spaced

as shown on Mounting

spaced

as shown

on

22.000 (558.0)

28.750

Bolt

spaced as shown

on Bolt

spaced

as (730,0)

shown

on

28.750 (730,0) Bolt

42.000 (1066.8) bolt circle

38 DBBS

50 DBBS

50 DBBS

(16) (16)

1.062 1.438

(27.0) (36.5)

(16) 1.438 (36.5)

Mounting holes equally

Mounting holes equally

Mounting

holes

spaced

as shown

on equally spaced as shown on

as circle

shown on 54.000 (1371.6) bolt circle

42.000spaced

(1066.8) bolt

54.000 (1371.6) bolt circle

Airflex DBBS Brake Elements

Dimensional and Technical Data

Section E

English lbin

Worn

Torque

Multiplier

psi

in3

in2

lbft2

lb

rpm

120DBBS

146323

415900

80,000

90

133

346

33

125

400

2200

220DBBS

146322

416059

150,000

90

133

692

65

232

550

2200

320DBBS

146373

416471

224,000

90

133

1,038

120

357

720

2200

420DBBS

146374

416472

220,000

90

133

1,384

159

464

914

2200

125DBBS

146320

416073

173,000

90

259

628

89

212

880

1700

225DBBS

146330

416074

325,000

90

259

1,255

178

416

1,318

1700

325DBBS

146382

416477

455,000

90

259

1,883

309

682

1,585

1700

425DBBS

146383

416470

585,000

90

259

2,510

411

854

1,882

1700

138DBBS

146328

416068

630,000

.81

90

612

1,357

553

583

2,125

950

238DBBS

146329

416069

1,200,000

.80

90

612

2,714

1,094

1,100

3,125

950

338DBBS

146384

416414

1,730,000

.80

90

612

4,071

1,709

1,680

4,085

950

438DBBS

146385

416461

2,200,000

.79

90

612

54,28

2,285

2,264

4,975

950

150DBBS 146524 417277 1 ,798,000

.81

120

1,115 2,111 1,682 1,071 5,872 600

250DBBS 146525 417278 3 ,284,000

.79

120

1,115 4,222 3,330 1,929 7,196 600

350DBBS 146526 417279 4 ,555,000

.77

120

1,115 6,333 4,895 2,738 8,685 600

450DBBS 146527 417280 5 ,578,000

.75

120

1,115 8,444 6,506 3,515 10,092 600

Size

Gear Mr

Worn

Minimum

Disc

Part Part Torque Torque

Releasing

Releasing

Friction

&

Number

Number

Rating

Multiplier

Pressure

volume

Area

Gear

Housing

Maximum

Speed

Wk2

Weight

J

Mass

120DBBS 146323

415900

9.032

6,2

2,18

2.232

1,39

56

181

2200

220DBBS

146322

416059

16.935

6,2

2,18

4.465

2,74

105

249

2200

320DBBS

146373

416471

25.290

6,2

2,18

6,697

5,06

162

327

2200

420DBBS

146374

416472

24.839

6,2

2,18

8.930

6,70

211

415

2200

125DBBS

146320

416073

19.532

6,2

4,24

4.052

3,75

96

398

1700

225DBBS

146330

416074

36.693

6,2

4,24

8.097

7,50

188

596

1700

325DBBS

146382

416477

51.372

6,2

4,24

12.149

13,03

310

720

1700

425DBBS

146383

416470

66.049

6,2

4,24

16.194

17,34

388

855

1700

138DBBS

146328

416068

71.127

.81

6,2

10,02

8.755

23,30

264

962

950

238DBBS

146329

416069

135.480

.80

6,2

10,02

17.510

46,10

498

1.414

950

338DBBS

146384

416414

195.325

.80

6,2

10,02

26.265

72,10

736

1.856

950

438DBBS

146385

416461

248.391

.79

6,2

10,02

35.020

96,41

1.029

2.261

950

150DBBS 146524 417277 203,164 .81

8.3

18.3

13,619 70.88 486 2,663 600

250DBBS 146525 417278 371,073 .79

8.3

18.3

27,239 140.33 875 3,264 600

350DBBS 146526 417279 514,689 .77

8.3

18.3

40,858 206.28 1,242 3,939 600

450DBBS 146527 417280 630,282 .75

8.3

18.3

54,477 274.16 1,594 4,578 600

SI Nm

bar

dm3

cm2

kgm2

kg

Notes:

configurations.

Basic part number only. Does not include gear. Gear must be ordered

separately with bore and keyway requirements.

Maximum allowable cylinder pressure is 120 psi (8,31 bar).

Dynamic torque shown. Static torque approximately 15% greater.

Torque values are for new linings. Torque decreases with lining wear. At

worn out condition, torque is approximately 0.66 of values shown,

unless otherwise noted.

rpm

Absolute volume of releasing cavity.

Torque ratings are for units with a standard complement of springs.

Consult factory for torque ratings of units with non-standard spring

EATON Airflex Clutches & Brakes 10M1297GP November 2012

191

Airflex Type DC Element Description

Section E

Type DC elements can be used as either pressure actuated

clutches or brakes. They are available in single and multiple

disc designs.

Element construction and operation is illustrated in the figure.

Pressurizing the cylinder causes the piston to clamp the

friction disc assemblies between clamping plates. External

springs ensure positive disengagement.

Type DC elements are available in five basic disc sizes with

static torque ratings to 2,061,000 lb.in (233.000 N.m). Element sizes are indicated by the number of friction discs and

by the disc diameter in inches. For instance, size 225DC has

two friction discs 25 inches in diameter.

Features

Favorable torque to size ratio.

DC type elements are physically smaller than most other type

clutches and brakes with the same torque capacity.

Low inertia friction disc assembly.

Reduces the overall inertia that must be started or stopped.

Optional split friction discs.

Allows removal of friction discs without disturbing other components of drive system in mid-shaft element arrangement.

Where used:

Long wearing, self lubricating PolyPak* seals.

Eliminates premature twisting failure and requires no external

lubrication.

Tension Brakes

192

EATON Airflex Clutches & Brakes 10M1297GP November 2012

Power Presses

Emergency Stop Brakes on Unwind Stands

Airflex DC Component Parts

Section E

19

17

Dual disc element shown

6, 7

14

18

20, 21

13

15

12

22

2

16

10

11

Item Number

Description

Item Number

Description

1

2

3

4

5

6

7

8

9

10

11

Mounting Flange

Stud

Friction Disc Sub-Assembly

Friction Disc

Friction Disc Core

Rivet

Washer

Clamp Tube

Pressure Plate

Flat Washer

Locknut

12

13

14

15

16

17

18

19

20

21

22

Cylinder

Inner Seal

Outer Seal

Gear

Wear Spacer

Reaction Plate

Piston

Release Spring

Flat Washer

Hex Head Screw

Ring Gear

EATON Airflex Clutches & Brakes 10M1297GP November 2012

193

Airflex Type DC Elements

Technical Data

Section E

lbin

English

@ 75 psi

rpm

in3

in2

lbft2

lb

109DC

209DC

115DC

215DC

120DC

220DC

320DC

420DC

125DC

225DC

325DC

425DC

138DC

238DC

338DC

438DC

3000

3000

2400

2400

1850

1850

1850

1850

1400

1400

1400

1400

950

950

950

950

4

7

9

17

27

53

79

105

43

86

129

172

102

203

304

405

96

192

238

476

334

668

1002

1336

600

1201

1801

2400

1322

2644

3966

5288

8

9.5

55

65

82

104

126

148

339

420

501

582

2031

2139

2247

2355

60

70

170

190

235

297

359

421

557

689

821

953

1568

1651

1734

1817

10500

21000

41000

82000

77000

154000

231000

308000

160000

320000

480000

640000

560000

1120000

1680000

2240000

1600

1600

1050

1050

850

850

850

850

650

650

650

650

450

450

450

450

24

30

60

70

133

160

187

214

216

259

302

345

510

612

714

816

0.5

1

5

10

17

33

49

66

47

93

140

186

287

562

837

1112

9

18

35

64

77

145

213

281

143

273

403

533

413

750

1087

1424

Mr

Disc Disc

Torque

Maximum Engaging

Friction & &

Size

Rating

Speed

Volume

Area

Housing Gear Housing Gear

Disc

Element New

Worn

Wk2

Weight

J

Mass

109DC

1190

3000

1600

0,07

0,39

619

0,34

0,02

27

209DC

2370

3000

1600

0,11

0,49

1238

0,40

0,04

32

115DC

4630

2400

1050

0,15

0,99

1535

2,32

0,21

77

215DC

9260

2400

1050

0,28

1,15

3069

2,74

0,42

86

120DC

8690

1850

850

0,44

2,18

2154

3,46

0,72

107

220DC

17390

1850

850

0,87

2,63

4307

4,38

1,39

135

320DC

26080

1850

850

1,30

3,07

6461

5,31

2,06

163

420DC

34770

1850

850

1,72

3,52

8614

6,24

2,76

191

125DC

18060

1400

650

0,71

3,55

3869

14,29

1,98

253

225DC

36130

1400

650

1,41

4,25

7744

17,70

3,92

312

325DC

54190

1400

650

2,12

4,96

11619

21,11

5,90

372

425DC

72260

1400

650

2,83

5,67

15488

24,53

7,84

432

138DC

63220

950

450

1,68

8,38

8524

85,59

12,09 711

238DC

126450 950

450

3,33

10,05 17048

90,14

23,68 749

338DC

189670 950

450

4,99

11,73 25572

94,69

35,27 786

438DC

252900 950

450

6,65

13,41 34097

99,24

46,86 824

Nm

SI

@ 5,2 bar

rpm

dm3

cm

kgm

4

8

16

29

35

66

97

127

65

124

183

242

187

340

493

646

Mounting Bolt

Circles

45

9DC

(6) 0.531 (13.5) Mounting

Holes Equally Spaced as

Shown on 11.125 (282.5) Bolt

Circle

13

15DC

(6) 0.656 (16.7) Mounting

Holes Based on 8 Equally

Spaced as Shown on 17.500

(444.5) Bolt Circle

25

20DC

(12) 0.656 (16.7) Mounting

Holes Equally Spaced as

Shown on 22.000 (558.8) Bolt

25

25DC

(12) 0.656 (16.7) Mounting

Holes Equally Spaced as

Shown on 28.750 (730.3) Bolt

kg

18.75

Notes:

Tolerance +0.003/-0.000 in (+0,08/-0,00 mm)

Dynamic torque shown. Static torque 15% greater. Maximum allowable

pressure 120 psi (8,3 bar).

Maximum diameter of as cast surfaces.

Absolute cylinder volume with new or worn friction linings.

Some high torque applications of three and

four disc elements require additional sup

port on the cylinder side of the unit.

Contact your local Airflex representative for

more details.

Based upon minimum bore.

Basic part number only. Gear not included.

Tolerance +0.000/-0.003 in (+0,00/-0,08 mm)

194

EATON Airflex Clutches & Brakes 10M1297GP November 2012

American National Pipe Thread

38DBC

(16) 1.062 (27.0) Mounting

Holes Equally Spaced as

Shown on 42.000 (1066.8) Bolt

Circle

Airflex Type DC Elements

Dimensional Data

Section E

W4

H

O2

D44

J2

D46

J

H16

J1

D1

See Note on

pg. E-14

D31

English Dimensions in inches

109DC

209DC

115DC

215DC

120DC

220DC

320DC

420DC

125DC

225DC

325DC

425DC

138DC

238DC

338DC

438DC

146239

146240

146225

146226

146301

146317

146366

146390

146316

146355

146354

146389

146307

146336

146360

416388

415313

415510

415454

415454

415900

415959

416304

416472

416073

416074

416623

416477

416068

416069

416241

416461

Gear

Part Part

Size

Number Number

1.75

1.88

2.75

3.44

3.31

4.25

4.88

5.38

4.38

5.50

6.25

6.25

6.75

8.50

9.25

8.50

2.38

2.38

3.98

3.94

5.63

5.69

5.56

5.69

7.13

7.13

6.88

6.88

10.50

10.25

9.75

10.25

Min.

Max.

Bore

Range

1.75

3.25

2.88

4.38

3.00

5.63

8.25

12.50

3.50

7.00

9.31

12.00

5.00

9.00

13.00

18.00

5.63

7.63

7.00

9.00

8.00

11.50

14.63

16.25

9.50

12.00

14.50

18.00

13.50

16.50

19.50

25.00

0.25

0.25

0.38

0.38

0.75

0.00

0.00

0.00

0.75

0.38

0.00

0.00

1.25

0.00

0.00

0.00

SI

Dimensions in millimeters

109DC

209DC

115DC

215DC

120DC

220DC

320DC

420DC

125DC

225DC

325DC

425DC

138DC

238DC

338DC

438DC

146239

146240

146225

146226

146301

146317

146366

146390

146316

146355

146354

146389

146307

146336

146360

146388

415313

415510

415454

415454

415900

415901

416304

416374

416073

416074

416623

416477

416068

416069

416241

416461

D1

W4

D46

Gear

Part Part

Size

Number Number

44

48

70

87

97

108

124

137

111

140

159

159

171

216

235

216

60

60

98

100

143

143

141

145

181

181

175

175

267

260

248

260

Min.

Max.

Bore

Range

44

83

73

111

76

143

210

277

89

178

236

305

127

229

330

457

143

194

178

229

203

292

372

413

241

305

368

457

343

419

495

635

6

6

10

10

19

0

0

0

19

10

0

0

32

0

0

0

D1

W4

D46

English

Dimensions in inches

9DC

15DC

20DC

25DC

38DC

1.00

1.47

1.50

1.75

2.45

0.25

0.38

0.38

0.25

0.25

3.25

6.00

8.50

11.50

16.50

3

3

3

4

4

Size

D31

D44

H16

J J1 J2 O2

No.

3

3

3

4

4

308,0

466,7

590,6

778,0

1136,7

9DC

25

6

83

15DC

37

10

152

20DC

38

10

216

25DC

44

6

292

38DC

62

6

419

SI

1/4-20NC-2

3/8-16NC-2

3/8-16NC-2

3/8-16NC-2

1/2-13NC-2

Size

1/4-20NC-2

3/8-16NC-2

3/8-16NC-2

3/8-16NC-2

1/2-13NC-2

3.50

6.50

9.13

12.25

17.50

Bolt Circle

89

165

232

311

445

12.125

18.375

23.250

30.630

44.750

8.375

14.375

18.250

24.375

36.375

212,7

365,1

463,5

619,1

923,9

12.37

18.94

23.82

30.58

44.86

314

481

605

777

1139

3/8-14

1/2-14

1/2-14

1/2-14

3/4-14

3/8-14

1/2-14

1/2-14

1/2-14

3/4-14

Dimensions in millimeters

Notes are on page E - 14

EATON Airflex Clutches & Brakes 10M1297GP November 2012

195

Airflex FHB Brake Elements

Section E

Overview

Eaton Airflex has introduced a revolutionary new design in

disc brake technology called the Floating Housing Brake

(FHB). The spring applied (power off), air-cooled disc brake

is well suited for applications in Surface Mining, Oilfield and

other heavy-duty industrial machinery designs.

The FHB is an air cooled spring applied brake with exceptional

friction life and rapid friction replacement capability. It is supplied with long wearing, organic friction material and a rugged

solid cast, rotating disc that provides lower inertia than typical

caliper brakes.

Features

Rated for over 430,000 lb-in of torque

Patented braking concept uses a floating housing instead of

a floating rotor

Multiple brake installation designs exist for industry leading

motors

Fixed hub and rotor design

Benefits

Ability to quickly change the friction pads reduces down

time on dragline from 3 hours to 1 hour

Reduced maintenance cost with elimination of spline tooth

or gear wear

Longer friction pad wear life due to a full 360 annular disc

Faster and safer installation with exclusive shaft lock

assembly for ease of mounting and removal

Virtually no wear during free wheeling, allows high product

life

196

EATON Airflex Clutches & Brakes 10M1297GP November 2012

Airflex FHB Brake Elements

Section E

Technical Introduction

The FHB brake is offered for applications with non-cyclic

brake engagement that require higher speed operation or precise balance of the rotating components is required. It uses

a solid rotor and stationary friction material to develop equal

torque in either direction of rotation. The disc is mounted on

the shaft which is to be stopped while the brake assembly

is attached to the machine frame. Pressurizing the brake

compresses the brake springs and withdraws the clamping

force from the brake disc so the shaft can rotate freely. As

air pressure is exhausted, the springs force the pressure plate

towards the mounting flange and the spring housing which in

turn forces the floating plate away from the mounting flange,

clamping the disc and the friction pad assembly.

Typical Applications

Draglines

Electric Shovels

Winches

Hoist Hoist

Drag Crowd

Swing Swing

Propel (Walk)

Propel

No. of

Length

Dynamic Torque* Max Length Engaged

Spring

Released

Size

RPM

Sets

lb-in

N-m

in.

mm.

in.

mm.

138FHB

36

432,900 48,918

950

18.24 463.3 18.48 469.39

*Dynamic torque calculated based on 36 sets of springs, static torque is approximately

15% more. Torque in each application is dependent on number of spring sets.

EATON Airflex Clutches & Brakes 10M1297GP November 2012

197

Airflex FHB Brake Elements

Section E

Typical Applications

Item

Qty.

*2

1

3

1

*4 1

5

1

6

1

7

1

*8

1

9

16

10

16

11

16

12

8

13

8

14

8

15

8

16

8

Typical Applications

Description

Part Number

Item

Qty.

Description

Part Number

Mounting Flang

Floating Plate

Disc

Pressure Plate

Spring Housing

Cylinder

B-Loc

Friction Linning S/A

Flanged Bolt

Metric Shoulder Screw

Main Stud

Clamp Tube

Support Stud

Spacer

Plain Washer

515532

515503

515536

515505

515507

515509

417385-02

308589

308602

308593

308601-01

308586-01

308592-01

308590-01

000067X0063

17

18

19

20

21

22

**23

**24

25

26

27

28

29

30

31

8

4

8

8

2

2

36

36

12

8

8

8

8

8

8

Nut

Return Spring

Plain Washer

Nut

Lip Seal

Lip Seal

Inner Apply Spring

Outer Apply Spring

Spring Retainer

FP Bush

PP Bush

SH Bush

Power Head Spacer

Plain Washer

Screw

000414X0013

416751-04

000067X0065

000414X0004

000402X0005

000402X0006

416751-08

416751-07

415635

204214-01

204214-02

204214-03

308599-01

000067X0064

000391X3602

*Part number may vary - depending on application

**Quantity may vary - depending on application requirements

198

EATON Airflex Clutches & Brakes 10M1297GP November 2012

Airflex FHB Brake Elements

138FHB Specifications and Dimensions Illustrated

Section E

21

52.5

* Consult factory for alternate mounting options.

EATON Airflex Clutches & Brakes 10M1297GP November 2012

199

Airflex Brake Selection Procedure

Section E

Torque and Thermal Capacities

No. of

Friction Discs

Pressure pp

General

1

2

3

4

psi

3

4

5

6

Technical Section Y of the catalog contains useful information

pertaining to the selection, mounting, alignment and control

of clutches and brakes in general. Formulas, symbols and

units are also identified. It is recommended that Section Y be

reviewed before attempting to size a specific product for an

application.

DBA and DBB Brakes

The torque ratings are dependent upon spring force and

quantity, not a pressurizing medium. However, a pressurizing

medium is required to compress the springs to release the

brake. Minimum releasing pressures, as well as the maximum pressures which the piston and cylinder can withstand,

are given on the catalog pages.

Type DBA and DBB brakes are disc type and develop equal

torque in both directions of rotation. Several springs are used

in their design. If brake size is determined by thermal requirements rather than torque requirements, brake torque can be

reduced by spring removal.

For spring applied brakes, torque will decrease with lining

wear, due to the longer piston travel required for engagement. Single disc DBA and DBB brakes have no provision for

adjustment. Multiple disc brakes have a provision for adjustment after a given amount of lining wear. Therefore, DBA and

DBB brake torque with worn linings must be considered in

the selection process.

DC Elements

DC element dynamic torque ratings Mr, are based on an

effective pressure pr of 75 psi (5,2 bar). Maximum allowable

operating pressure is 120 psi (8,3 bar). Torque ratings must

be adjusted for operating pressure po and parasitic loss pp.

The elements have an inherent parasitic pressure pp, required

to cause friction disc engagement, which represents the

pressure to overcome internal sliding friction and to compress

disc releasing springs.

200

Element torque is calculated from:

Me =

Torque

EATON Airflex Clutches & Brakes 10M1297GP November 2012

bar

0,21

0,28

0,34

0,41

p o pp

pr

Mr

Cyclic and Non-Cyclic Thermal Capacity

Brake types DBAV and DBB were designed for cyclic stopping applications. They are capable of a maximum thermal

capacity Pc of 0.012 HP/in2.

Non-cyclic thermal capacity is determined by the element's

friction area, drum or disc mass, material heat capacity and

thermal conductivity. The properties of our standard elements

result in the limits indicated in the Non-Cyclic Energy Capacity

Graph. An explanation on the use of this graph follows.

The thermal energy calculated for the load is adjusted to

include the energy associated with accelerating or decelerating the components of the tentative clutch and/or brake

selection. The adjusted thermal energy Wt is divided by the

element's friction area A. Next, the average power loading

Pave is calculated from:

Pave =

Pt

A

The point (Wt/A, Pave) is plotted on the graph. If the point falls

below the appropriate product limit line, the selection will

handle the load. If it does not, an element having a greater

friction area is required.

Airflex Selection Procedure

W1/A (joule/cm2)

W1/A (ftlb/in 2)

Section E

Pave (HP/in2)

Non-Cylic Energy Capacity

Pave (kW/cm2)

Example

Reverse brake torque required =

A cyclic stopping brake is required for use on a power press

operating under the following conditions. Determine the

brake size and allowable cyclic rate.

0.5strokeweight/reduction

Brake shaft speed: 300 rpm

Stopping angle at crankshaft: 15

Inertia referred to brake shaft: 750 lbft2

Press stroke: 10 in

Ram and die weight: 2500 lb

Reduction between brake shaft and crankshaft: 10:1

Stopping angle at brake shaft 0d = 1510 = 150

0

0 d 150

=

= 0.17sec.

3 n 3 300

Wk 2 n

750 300

Mb =

=

25.58 t d 25.58 0.17

td

= 51,700 lbin

= 0.5102500/10

= 1250 lbin

From required torques, select 215DBB

Lining area = 476 in2

Disc and gear WK2 = 10 lbft2

Total WK2 = 750 + 10 = 760 lbft2

W k 2 n2 760 3002

W=

=

5873

5873

= 11650 ftlb

W cpm

33000

P 33000

cpm = c

W

0.012 476 33000

=

11650

= 16

Pc =

EATON Airflex Clutches & Brakes 10M1297GP November 2012

201

Potrebbero piacerti anche

- CTP Water PumpsDocumento2 pagineCTP Water PumpsSERGIOEDWARDONessuna valutazione finora

- PZH (PZ-8) Pump Parts List AF 19002011Documento25 paginePZH (PZ-8) Pump Parts List AF 19002011mantilla7Nessuna valutazione finora

- Fuel Supply Pump Inner Parts PDFDocumento2 pagineFuel Supply Pump Inner Parts PDFMilorad ZelenovicNessuna valutazione finora

- Injector Adjust - PDFDocumento2 pagineInjector Adjust - PDFMusaferNessuna valutazione finora

- C15 Acert: Industrial Caterpillar Engine SpecificationsDocumento4 pagineC15 Acert: Industrial Caterpillar Engine Specificationsyash singhNessuna valutazione finora

- Marine SiteContent en Binary Asset Attachments Products CCEC N855 CCEC Performance Curves FR11169 NT855 325 1800 IMOIIDocumento3 pagineMarine SiteContent en Binary Asset Attachments Products CCEC N855 CCEC Performance Curves FR11169 NT855 325 1800 IMOIIOscar Eduardo Parra GuerreroNessuna valutazione finora

- 008-014 Coolant Thermostat HousingDocumento3 pagine008-014 Coolant Thermostat HousingYè WințNessuna valutazione finora

- TF-450 Power EndDocumento2 pagineTF-450 Power EndppglNessuna valutazione finora

- 420 Mobile Piston Pump Design Code CDocumento41 pagine420 Mobile Piston Pump Design Code CFernando Sabino100% (1)

- Cylinder Head - InstallDocumento7 pagineCylinder Head - InstallJose PichinteNessuna valutazione finora

- Omega 600S ManualDocumento36 pagineOmega 600S ManualLeandroNessuna valutazione finora

- 200h-917121-Chapter Eight-Engine Timing Part 1 PDFDocumento3 pagine200h-917121-Chapter Eight-Engine Timing Part 1 PDFFauan SNessuna valutazione finora

- QuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERDocumento14 pagineQuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERKrisman SimanjuntakNessuna valutazione finora

- Sjiii 4632Documento209 pagineSjiii 4632Victor FriasNessuna valutazione finora

- Specifications KTA38 G DRIVEDocumento2 pagineSpecifications KTA38 G DRIVEMehdi ChakrouneNessuna valutazione finora

- Datasheet Deutz 1015 SeriesDocumento2 pagineDatasheet Deutz 1015 SeriesRizki Heru HermawanNessuna valutazione finora

- R065E2Documento7 pagineR065E2Mk MakyNessuna valutazione finora

- Duplo MaticDocumento8 pagineDuplo MaticHENRYGALLEGOSNessuna valutazione finora

- Cat 3400Documento8 pagineCat 3400cesaraugustom100% (1)

- Eaton Clutch Selector Chart Technical Data Sheet enDocumento2 pagineEaton Clutch Selector Chart Technical Data Sheet enGustavo MosqueraNessuna valutazione finora

- Manual Services Performance Winch Services PD12C-41039-02Documento40 pagineManual Services Performance Winch Services PD12C-41039-02Bram StrausNessuna valutazione finora

- Catálogo de Productos MurphyDocumento28 pagineCatálogo de Productos MurphyRené GPNessuna valutazione finora

- QSK 50 Fan Pully & Fan Idler EX2500-6 & EX5500-6Documento5 pagineQSK 50 Fan Pully & Fan Idler EX2500-6 & EX5500-6Bambang DwiantoNessuna valutazione finora

- DurstDocumento6 pagineDurstAryoSatrioNessuna valutazione finora

- Volvo Penta 200 KW TAD753GE EPA Tier 3 Emissions Engine Spec SheetDocumento13 pagineVolvo Penta 200 KW TAD753GE EPA Tier 3 Emissions Engine Spec SheetJoanne CordesNessuna valutazione finora

- Engine Brakes PDFDocumento18 pagineEngine Brakes PDFMitchelle GonouyaNessuna valutazione finora

- Caterpillar C15 FTH000001Documento3 pagineCaterpillar C15 FTH000001Hendra MechanicNessuna valutazione finora

- Eight Position Cylinders Service Information: Warnings-Installation and MountingDocumento10 pagineEight Position Cylinders Service Information: Warnings-Installation and MountingyelmustafaaliNessuna valutazione finora

- Qsx15 BrochureDocumento8 pagineQsx15 BrochureferminNessuna valutazione finora

- Perkins 400 Series: Workshop ManualDocumento6 paginePerkins 400 Series: Workshop ManualDella AstariNessuna valutazione finora

- C15 Acert Spec SheetDocumento4 pagineC15 Acert Spec SheetMalasquez Leon XavierNessuna valutazione finora

- Cat c15 Cylinder Head RemovalDocumento6 pagineCat c15 Cylinder Head RemovalMUHSIN MTNessuna valutazione finora

- 006 026 InjectorDocumento9 pagine006 026 InjectorYè WințNessuna valutazione finora

- 6015 Crane 3203HDocumento74 pagine6015 Crane 3203HfelixvosNessuna valutazione finora

- Adjustment of The Compression BrakeDocumento2 pagineAdjustment of The Compression BrakeCarlos Juarez ChungaNessuna valutazione finora

- PC-K-Series-01-A MBH 4 CYLINDERDocumento92 paginePC-K-Series-01-A MBH 4 CYLINDERibrahim salemNessuna valutazione finora

- Rubia S10 20 LT 20 LT 80 LT Castrol CRB Monograde 10W Rubia S 10W 208 LT 208 LT 4368 LTDocumento6 pagineRubia S10 20 LT 20 LT 80 LT Castrol CRB Monograde 10W Rubia S 10W 208 LT 208 LT 4368 LTRovshan GasimovNessuna valutazione finora

- DTM-4 Install Instr Rev B-1Documento30 pagineDTM-4 Install Instr Rev B-1Jorge AriasNessuna valutazione finora

- Cummins n855 Engine Specs PDF FreeDocumento6 pagineCummins n855 Engine Specs PDF Freema.powersourceNessuna valutazione finora

- D2876 Medium DutyDocumento4 pagineD2876 Medium Dutyfajar saputra100% (1)

- Perkins M215C and M185C 1006 SeriesDocumento2 paginePerkins M215C and M185C 1006 SeriesDamian Cid Morales100% (1)

- C11 Troubleshooting High Coolant Temperature PDFDocumento3 pagineC11 Troubleshooting High Coolant Temperature PDFmanu luvungaNessuna valutazione finora

- Caterpillar C15 Engine SpecsDocumento5 pagineCaterpillar C15 Engine SpecsDesta 77Nessuna valutazione finora

- 04 Turbo PDFDocumento26 pagine04 Turbo PDFFabioMacielNessuna valutazione finora

- Detroit Engine Service Manual DD S in Line71Documento17 pagineDetroit Engine Service Manual DD S in Line71reynaldo galvisNessuna valutazione finora

- DynasetDocumento64 pagineDynasetAlexis Peña0% (1)

- 1 Mbe4000 06aDocumento38 pagine1 Mbe4000 06azahar222Nessuna valutazione finora

- Cylinder Liner ProjectionDocumento4 pagineCylinder Liner ProjectionFernando Daniel Saez VillarrealNessuna valutazione finora

- Parts Catalog - Option Detail: Content For Engine Serial Number (ESN) : 37211299Documento3 pagineParts Catalog - Option Detail: Content For Engine Serial Number (ESN) : 37211299nurdinzaiNessuna valutazione finora

- Vtrack - ENGINESDocumento64 pagineVtrack - ENGINESanderson cesconettoNessuna valutazione finora

- Ipd Parts For Detroit Diesel 60 Series Quick RefDocumento2 pagineIpd Parts For Detroit Diesel 60 Series Quick RefÑengo Flow Full RecordNessuna valutazione finora

- Jacobs Brake 310 312 Parts Book On Caterpillar C10 C12 022040BDocumento4 pagineJacobs Brake 310 312 Parts Book On Caterpillar C10 C12 022040Bvasanth kumar100% (1)

- Caterpillar Engine Service Manual CT S Eng d353Documento7 pagineCaterpillar Engine Service Manual CT S Eng d353CarlosNessuna valutazione finora

- Meritor Preventative Maintenance and Lubrication Mm1Documento242 pagineMeritor Preventative Maintenance and Lubrication Mm1David PomaNessuna valutazione finora

- 2013 Us Shop Tech BrochureDocumento16 pagine2013 Us Shop Tech Brochurefollowjesus100% (1)

- Generac Mobile Products Manual Parts Light Towers MLT3000Documento64 pagineGenerac Mobile Products Manual Parts Light Towers MLT3000ider100% (1)

- Manual F 1300 1600Documento71 pagineManual F 1300 1600Camilo Sanchez VanegasNessuna valutazione finora

- Briggs & Stratton Model 091200 Illustrated Parts ListDocumento20 pagineBriggs & Stratton Model 091200 Illustrated Parts Listb0beiiiNessuna valutazione finora

- ZoomDocumento26 pagineZoomelseservNessuna valutazione finora

- Drilco PDFDocumento48 pagineDrilco PDFrony adonay sandoval100% (2)

- Catalogo Bombas de LodoDocumento170 pagineCatalogo Bombas de Lodorony adonay sandoval100% (3)

- MCM CentrifugalDocumento8 pagineMCM CentrifugalalexmaldonadohdzNessuna valutazione finora

- IndustrialDocumento204 pagineIndustrialrony adonay sandovalNessuna valutazione finora

- Increse Valve de PeriaDocumento18 pagineIncrese Valve de Periarony adonay sandovalNessuna valutazione finora

- Airflex Constricting Type Clutches and BrakesDocumento100 pagineAirflex Constricting Type Clutches and Brakesrony adonay sandovalNessuna valutazione finora

- Service Training DM Valves EN Compatibility Mode PDFDocumento170 pagineService Training DM Valves EN Compatibility Mode PDFAob AprilNessuna valutazione finora

- Bell Crank Lever Lab ManualDocumento3 pagineBell Crank Lever Lab Manualbluewingstechnologies25Nessuna valutazione finora

- Model TA Belt Alignment ControlDocumento4 pagineModel TA Belt Alignment ControlRobertoNessuna valutazione finora

- OpenDocumento9 pagineOpenchristian1777Nessuna valutazione finora

- Air Intake Manifold and After CDocumento1 paginaAir Intake Manifold and After Cmuhammad nurhidayatNessuna valutazione finora

- FX 880Documento5 pagineFX 880Nma ColonelnmaNessuna valutazione finora

- Motor Selection NewerDocumento2 pagineMotor Selection Newerdan paluskaNessuna valutazione finora

- Pittman GM9236S027Documento0 paginePittman GM9236S027Nicola's SacNessuna valutazione finora

- Hyundai 200 HPDocumento2 pagineHyundai 200 HPMaurizio BernasconiNessuna valutazione finora

- Cummins Fault CodeDocumento8 pagineCummins Fault Codetrs100100% (2)

- Experiment No.: 1: Engine & Working PrinciplesDocumento10 pagineExperiment No.: 1: Engine & Working PrinciplesJatin prasad TandanNessuna valutazione finora

- E90 Dynamic Driving SystDocumento55 pagineE90 Dynamic Driving SystArturo Martinez SerranoNessuna valutazione finora

- L30-L75 Fixed Speed Rotary Screw Compressor BrochureDocumento2 pagineL30-L75 Fixed Speed Rotary Screw Compressor BrochureSpark ElectricNessuna valutazione finora

- Códigos de Falha Escavadeira HyundaiDocumento8 pagineCódigos de Falha Escavadeira HyundaiGuemep Guemep100% (3)

- Ford Focus PCMDocumento58 pagineFord Focus PCMEl OhmimetroNessuna valutazione finora

- CHAP 3 Gas - Power CyclesDocumento88 pagineCHAP 3 Gas - Power CyclesMuez GhideyNessuna valutazione finora

- KR - Single Package - R410A - 50Hz - CO - MEA - MFL67452913 - 5CUK0-02H (Nov.2020) PDFDocumento72 pagineKR - Single Package - R410A - 50Hz - CO - MEA - MFL67452913 - 5CUK0-02H (Nov.2020) PDFVan Flyheight100% (1)

- Full AssemblyDocumento1 paginaFull AssemblybenNessuna valutazione finora

- Knots 2 UGear WarningDocumento7 pagineKnots 2 UGear Warningrocketbob8704100% (1)

- BT WRX 30Documento198 pagineBT WRX 30Socma ReachstackersNessuna valutazione finora

- Pneumatic Actuator Eb-Syd, Double Acting Pneumatic Actuator Eb-Syd, Double ActingDocumento4 paginePneumatic Actuator Eb-Syd, Double Acting Pneumatic Actuator Eb-Syd, Double ActingBaehaqiNessuna valutazione finora

- Steering Systems Exam P-22 2022MYDocumento3 pagineSteering Systems Exam P-22 2022MYNeo ZaoNessuna valutazione finora

- Transmission Valve Body Assy (A245E/A246E) : OverhaulDocumento2 pagineTransmission Valve Body Assy (A245E/A246E) : OverhaulGearauto Power100% (2)

- Chapter 2 (Operating Characteristics)Documento45 pagineChapter 2 (Operating Characteristics)zoro3samaNessuna valutazione finora

- 793D Electrico PDFDocumento4 pagine793D Electrico PDFminh le huuNessuna valutazione finora

- Improving Dehumidification in HVAC SystemsDocumento48 pagineImproving Dehumidification in HVAC Systems2360459Nessuna valutazione finora

- Features:: 1250kVA, Open Type, 4012-46TWG2A, PI734A, 3phase, AMFDocumento7 pagineFeatures:: 1250kVA, Open Type, 4012-46TWG2A, PI734A, 3phase, AMFhelmy muktiNessuna valutazione finora

- Honda CBR250R Engine CutoutDocumento7 pagineHonda CBR250R Engine CutoutOmkar SheteNessuna valutazione finora

- Listado Repuestos BollfilterDocumento9 pagineListado Repuestos BollfilterJ. Salvador Calderon B.Nessuna valutazione finora

- Cooling Tower Bypass LineDocumento1 paginaCooling Tower Bypass LinekapsarcNessuna valutazione finora

- Eat & Run: My Unlikely Journey to Ultramarathon GreatnessDa EverandEat & Run: My Unlikely Journey to Ultramarathon GreatnessNessuna valutazione finora

- Merle's Door: Lessons from a Freethinking DogDa EverandMerle's Door: Lessons from a Freethinking DogValutazione: 4 su 5 stelle4/5 (326)

- Becky Lynch: The Man: Not Your Average Average GirlDa EverandBecky Lynch: The Man: Not Your Average Average GirlValutazione: 4.5 su 5 stelle4.5/5 (15)

- The Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsDa EverandThe Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsValutazione: 4 su 5 stelle4/5 (49)

- Elevate and Dominate: 21 Ways to Win On and Off the FieldDa EverandElevate and Dominate: 21 Ways to Win On and Off the FieldValutazione: 5 su 5 stelle5/5 (7)

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthDa EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthValutazione: 4 su 5 stelle4/5 (59)

- Bloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyDa EverandBloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyValutazione: 4 su 5 stelle4/5 (8)

- Crazy for the Storm: A Memoir of SurvivalDa EverandCrazy for the Storm: A Memoir of SurvivalValutazione: 3.5 su 5 stelle3.5/5 (217)